Construction Inspection

Reference supporting documentation as needed. It will be necessary to reference NRCC-MCH-03-E or the mechanical equipment schedules to determine the total required outdoor airflow for the system.

Indicate method and equipment used to measure airflow during the functional test (e.g. hot-wire anemometer) on the Acceptance Form. Note calibration date; calibration date must be within one year.

Check the system type (VAV or CAV) on the Acceptance Form. The following instructions apply to VAV systems.

Check that the sensors used to control outside air (OSA) flow is either factory or field calibrated. Attach the calibration certificate or field calibration results to the acceptance test form NRCA-MCH-02-A.

Check that a fixed minimum damper setpoint is not being used to control OSA. The Field Technician should review the sequences of operation to ensure that the system has been designed for dynamic control of minimum outdoor air and review the installation to make sure that all of the devices that are part of that sequence are indeed installed.

Indicate the dynamic control method being used to control OSA in the system. There are a number of means to dynamically control minimum OSA for VAV systems, and many ways for the designer to specify an active ventilation air control “system” intended to maintain a constant outdoor air flow rate as supply fan flow rate decreases. For example, a flow station may be installed to measure outdoor air flow rate and modulate the outdoor air dampers accordingly. Or perhaps dampers are modulated to maintain a constant differential pressure across a dedicated outdoor air damper assembly. Regardless of how the outdoor air flow is to be controlled, the sensors, equipment, and control strategy necessary to achieve the desired control must be calibrated as a “system”.

Indicate the method being used to deliver outside air to the unit (e.g. duct, return air plenum). For systems where return air plenum is used to distribute outside air to a zonal heating or cooling unit, confirm that outside air supply is connected either:

•Within five ft. of the unit

•Within 15 ft. of the unit, with the air directed substantially toward the unit, and with a discharge velocity of at least 500 ft. per minute.

Confirm that pre-occupancy purge has been programmed into the system for the 1-hour period immediately before the building is normally occupied per the Standards Section 120.1(c)2|topic=(c) Operation and Control Requirements for Minimum Quantities of Outdoor Air.. This is most easily accomplished by scheduling the unit to start one hour prior to actual occupancy. The purge amount must be the lesser of the minimum outdoor air rate or three complete building air changes (ACH).

Functional Testing

Air handling systems that have a dedicated fan providing ventilation air to the unit would be exempt from measuring ventilation airflow at minimum and maximum supply airflow conditions. An independent ventilation air fan will deliver a constant minimum outdoor air volume to the air handling unit regardless of the speed of the supply fan. Therefore, the only verification needed for this system type would be to measure the actual CFM delivered by the dedicated ventilation air fan.

Follow the best practice guidelines below in order to increase accuracy of outdoor air flow measurements:

•Traverse measurements taken in supply, return or outdoor air ducts should be located in an area of steady, laminar flow. If possible, take measurements at least six to eight duct diameters away from turbulence, air intakes, bends, or restrictions.

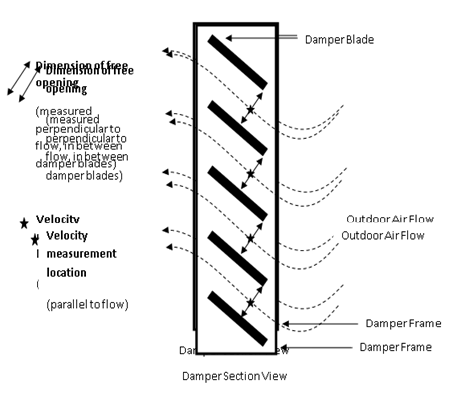

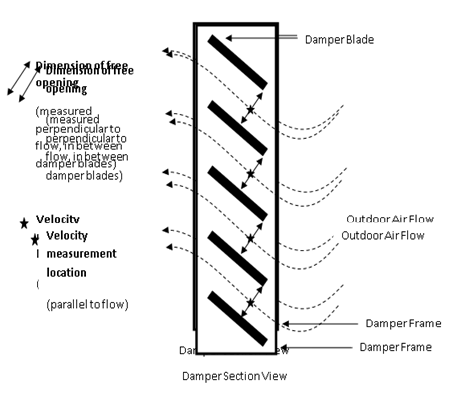

•If using face velocity measurements to calculate outdoor air flow, care should be taken to accurately measure free area dimensions of intake.

•

|

•Hot wire anemometers are more appropriate than velocity pressure probes for measuring low speed flows (i.e. less than 250 feet per minute). When measuring flow with a hot wire anemometer, make sure to position the measurement device such that it is perpendicular to direction of flow.

•Take multiple measurements and average results in order to minimize effects of fluctuations in system operation and environmental conditions (i.e. wind).

Your body can serve as an obstruction to air flow and affect measurements. To increase measurement accuracy, position your body away from the intake and flow of air.

Step 1: Disable demand control ventilation, if applicable.

Step 2: Verify unit is not in economizer mode. Disable the air economizer, if applicable.

For systems with an air economizer, disabling the economizer will prevent the outdoor air damper from modulating during the test due to atmospheric conditions rather than supply airflow variations. Disabling the economizer is necessary only if the system is in cooling mode and outdoor air temperature is below the economizer high limit setpoint. The economizer can be disabled in a number of ways depending on the control strategy used to modulate the outdoor air dampers:

•Use the high limit switch by reducing the setpoint (return air value or outdoor air value if a comparative or changeover strategy, respectively, is used) below the current OSA dry-bulb or enthalpy measurement

•Disable the economizer damper control loop through software if it is a DDC system.

Step 3: Modify VAV boxes to achieve full design airflow.

The intent is to measure outdoor air flow when the system is operating at or near the design airflow condition, or maximum airflow at full cooling. This point is provided along with the minimum operating point to test the minimum OSA control at either end of its control range. There are a number of ways to achieve design airflow including:

•Override all space temperature cooling setpoints to a low temperature (e.g. 60°F cooling) that will force the VAV boxes into full cooling (may be accomplished by a global command or it may have to be done per individual box).

•Command all VAV boxes to design flow position (may be accomplished by a global command or it may have to be done per individual box).

•Set the VAV box minimum flow setpoint to be the same as maximum flow setpoint (may be accomplished by a global command or it may have to be done per individual box).

Verify and Document

Document supply airflow at full cooling on the Acceptance Form.

Document VFD speed; VFDs should be at or near 60Hz.

Document the measured outdoor air reading. Document the required outdoor airflow as found on Mechanical Plan Check document NRCC-MCH-03-E Column M, or mechanical equipment schedules. In “Testing Calculation and Results” section of the Acceptance Form, confirm that measured outdoor air flow is within 10 percent of design outdoor air flow rate.

Outdoor air flow can be measured directly, or indirectly, in a variety of ways. Acceptable methods for measuring outdoor air flow include, but are not limited to the following techniques:

•Read the outdoor air flow value measured by an air flow monitoring station if one is installed.

•Traverse across the outdoor air duct to measure duct velocity, measure duct size, and calculate flow.

•Measure face velocity at various points across outdoor air intake, measure intake damper size, and calculate flow.

•Traverse across the supply and return ducts to calculate flow (outdoor airflow can be estimated as the difference between the supply and return airflow rates).

Document time for OSA damper to stabilize after the VAV boxes open on the Acceptance Form. Confirm that dampers stabilize within 5 minutes. The intent is to ensure the PID control loops are tuned properly so that the system does not hunt.

Step 4: Drive all VAV boxes to either the minimum airflow, full heating airflow, or 30 percent of total design airflow.

The intent is to measure outdoor air flow when the system is operating at or near a minimum flow condition (e.g. full heating). This point is provided along with the design point to test the minimum OSA control at either end of its control range. If the system has an airflow monitoring station (AFMS) it will test the accuracy of that AFMS at the lowest velocity, its least accurate point.

There are a variety of ways to force the VAV boxes to a minimum position depending on the building automation system capabilities and control strategies used, for example:

•Override all space temperature setpoints to a wide range (e.g. 60°F heating and 90°F cooling) that will force the VAV boxes into the deadband (may be accomplished by a global command or it may have to be done per individual box).

•Command all VAV boxes to minimum flow position (may be accomplished by a global command or it may have to be done per individual box).

•Set maximum flow setpoint to be the same as minimum flow setpoint (may be accomplished by a global command or it may have to be done per individual box).

An alternative method is to manually adjust the VFD until the system airflow is at the desired condition. If the VAV boxes are in control they will open up as you are doing this, so you need to provide some time (about 5 minutes) to allow the system to settle. Be warned that although this is acceptable for testing OSA, this would not meet the requirements of test NA7.5.6 Supply Fan Variable Flow Controls for testing the stability of the pressure control loop. These two tests should be done concurrently to minimize cost.

Verify and Document

Document supply airflow on the Acceptance Form.

Document VFD speed.

Document the measured outdoor air reading. In “Testing Calculation and Results” section of the Acceptance Form, confirm that measured outdoor air flow is within 10 percent of design outdoor air flow rate found on Mechanical Plan Check document NRCC-MCH-03-E Column M, or mechanical equipment schedules. The methodologies provided earlier for conducting field airflow measurements also apply here.

Document time for OSA damper to stabilize after the VAV boxes open on the Acceptance Form. Confirm that dampers stabilize within 5 minutes. The intent is to ensure the PID control loops are tuned properly so that the system does not hunt.

Step 5: Return system back to normal operating condition.

Ensure all schedules, setpoints, operating conditions, and control parameters are placed back at their initial conditions. Release any overrides on the economizer or demand ventilation controls.