References: 150.0(m)15, 150.1(c)13, JA1:Glossary: ZONAL CONTROL, RA 3.1.4.6

Zonally controlled systems are usually installed primarily for improved comfort, not improved energy consumption. Recent studies have shown that zonally controlled cooling systems that utilize bypass ducts or that substantially reduce the airflow across the coil when zone dampers close can actually use more energy. Because of this, HERS raters are required to evaluate these systems to ensure that it is consistent with what was modeled and what appears on the CF1R form.

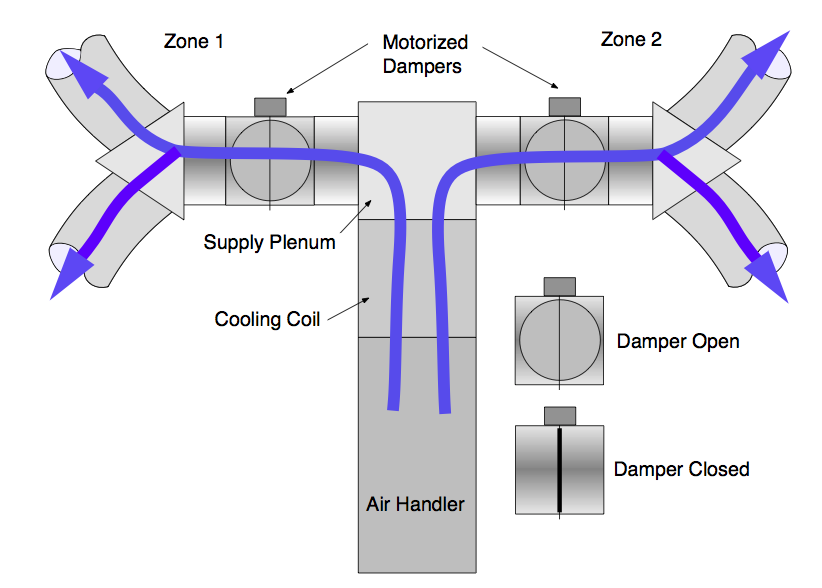

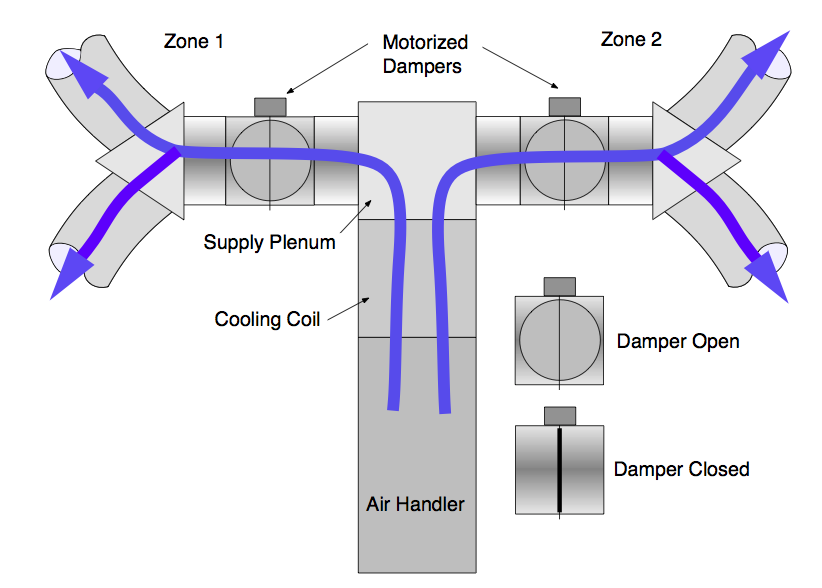

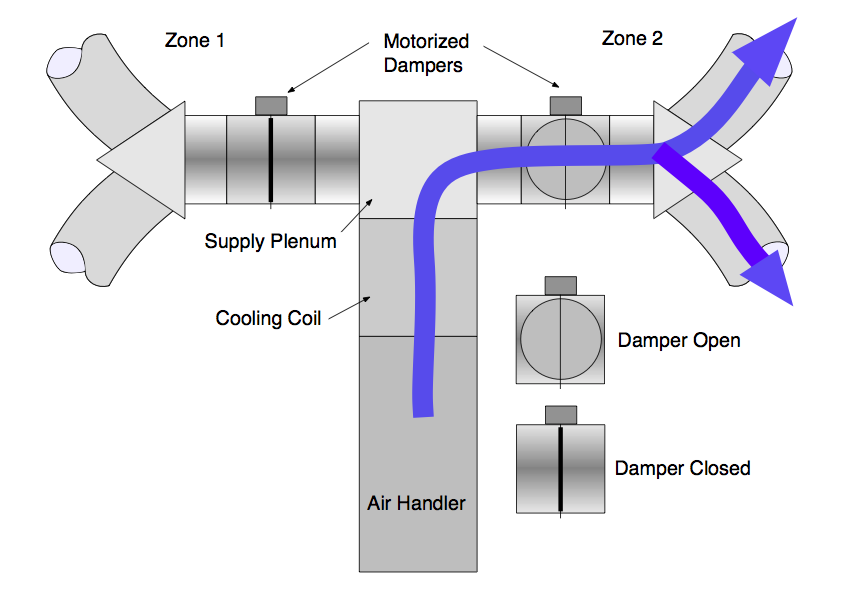

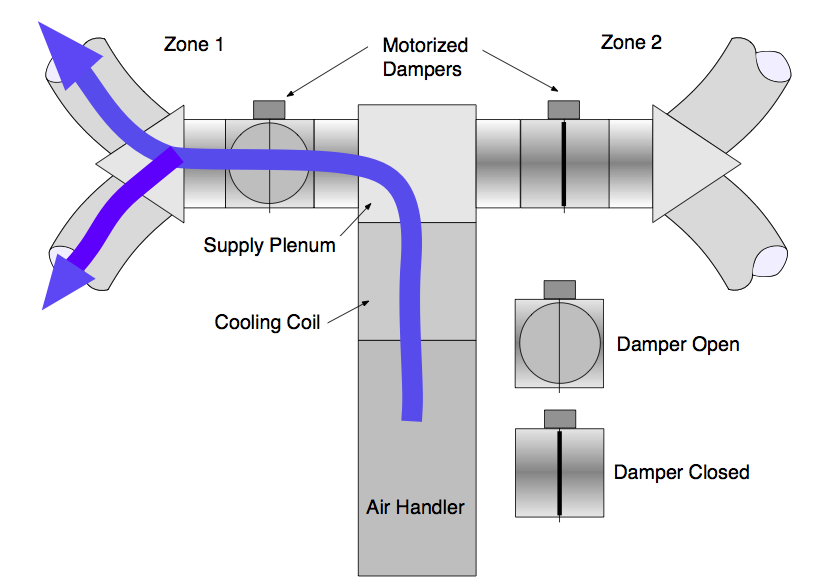

One type of zonally controlled forced air system utilizes motorized zone dampers in the supply ducts to send supply air from a single air handler to different zones, as needed, rather than sending air to the entire are served by that system. These require multiple thermostats or temperature sensors in each of the zones. The number of zones can be two or more. Two-zone systems are by far the most common. The most common application of this type of system is in two story homes served by a single forced air system. The tendency for air to stratify, along with substandard duct design, causes comfort issues that can often be overcome by zonal control.

Note that dampers may also be installed on the return ducts, but are not required for the system to be considered a zonally controlled system.

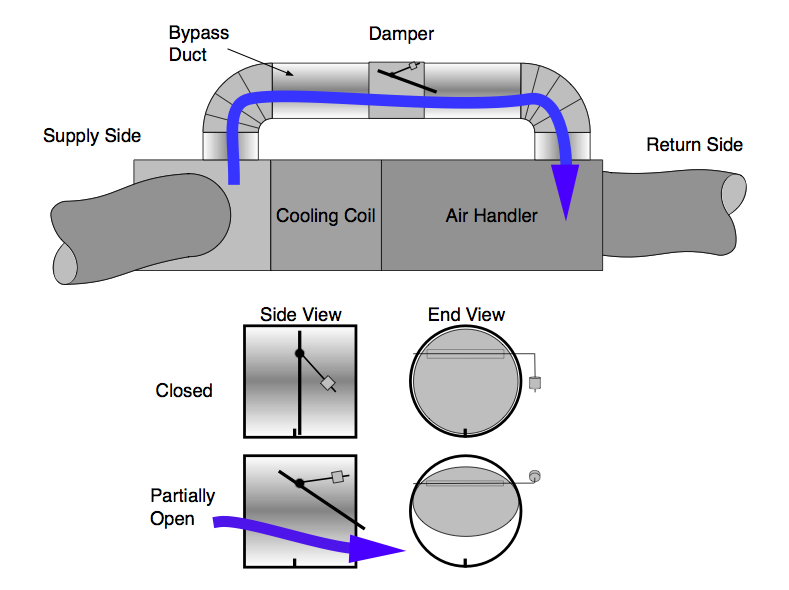

Problems with this type of zonally controlled systems arise from the excess air pressure that occurs at the air handler fan when one or more of the zone dampers close and restrict airflow to just a portion of the supply duct system. One strategy is to simply let the pressure increase, which substantially reduces airflow across the cooling coil or heat exchanger. Another is to install a bypass duct that allows the excess air to “short circuit” from the supply side back to the return side. This causes problems by sending excessively hot air (heating mode) or excessively cold air (cooling mode) back into the system.

An alternative approach is to send the “excess air” back into conditioned space rather than directly back into the return air. These are not considered bypass ducts if the air has a chance to mix with house air in a way that does not substantially change the return air temperatures. The area in the home where the excess air is sent to is referred to as a “dump zone”. These dump zones will generally be over conditioned by this excess air and are usually unoccupied portions of the home, such as hallways or vaulted ceiling areas above the occupied zones. This design may lose some of the comfort benefits of a zonally controlled system.

Note that zonal control can be also achieved by using two separate systems, sized appropriately for each zone. These act independently and do not need zone dampers. These also do not require bypass dampers or other strategies to handle the excess air. For example, zonal control can be achieved in a two story home by installing a single system with zone dampers that separately control air to the upstairs and downstairs; or it can be achieved by installing two small systems, one dedicated to the first floor and one to the second floor. Assuming that the house can be adequately served by a single large system, the first approach generally costs less.

If it is discovered that a zonally controlled forced air system is installed but not claimed for credit, it needs to be reported to the HERS provider (registry). Because zonally controlled systems can be an energy penalty, they need to be correctly modeled when installed.

Prescriptive compliance approach –

1. Zonally controlled systems are not required, but if installed must meet mandatory AF/FE requirements (slightly different test methods for single speed and variable speed compressors)

2. Bypass ducts/dampers are NOT allowed.

Performance compliance approach –

1. Zonally controlled systems must be modeled if installed.

2. Bypass dampers allowed only if modeled.

3. Dual speed/multi speed condensers may also qualify for a credit (reduced penalty) and if modeled, must be installed.

Note: when a feature is “modeled” using the performance compliance approach it will appear on the certificate of compliance.

The following are characteristics of most zonally controlled systems that utilize dampers. Not all of these items need to be apparent for the system to be considered zonally controlled. Final determination may require consulting with the installer, designer and system manufacturer.

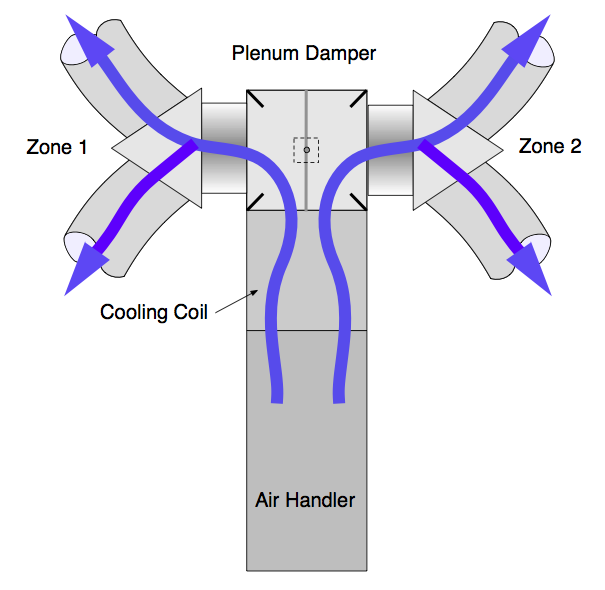

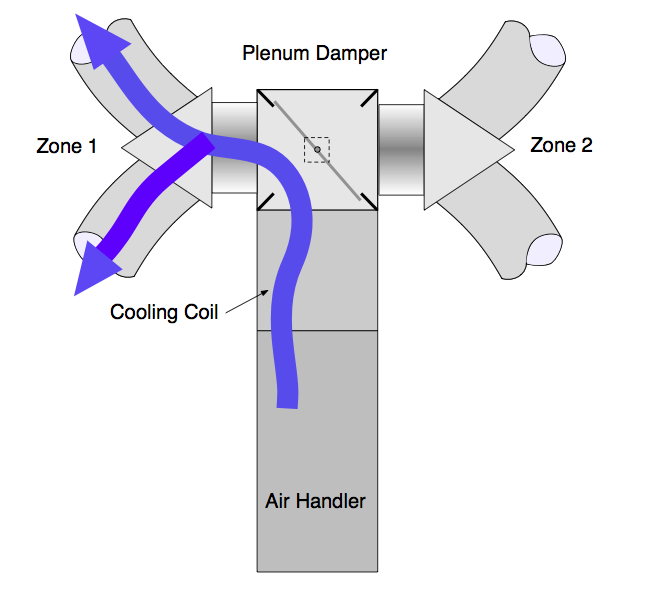

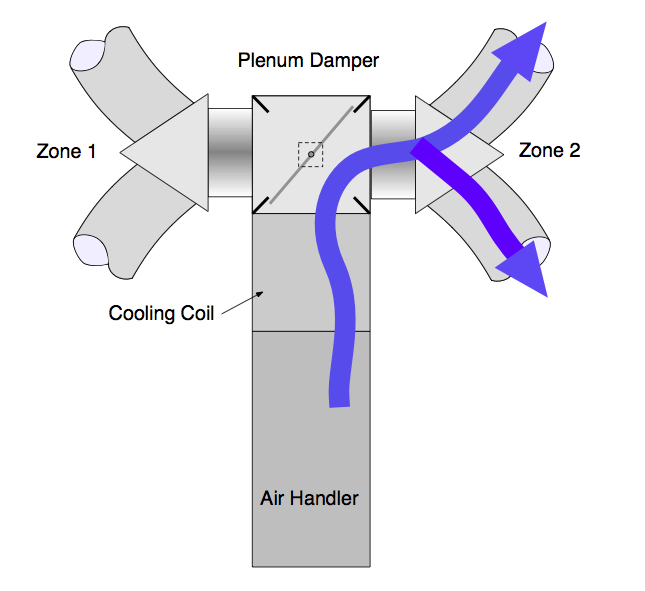

1. Motorized or actuated zone dampers on the supply ducts. These can be one or more large dampers in or near the supply plenum or they can be one damper for each supply outlet (register). See diagrams below.

2. Multiple thermostats or temperature sensors in area served by a single system. The most common two zone systems utilize ordinary thermostats for each zone. Some systems have a single master thermostat with small temperature sensors in each zone.

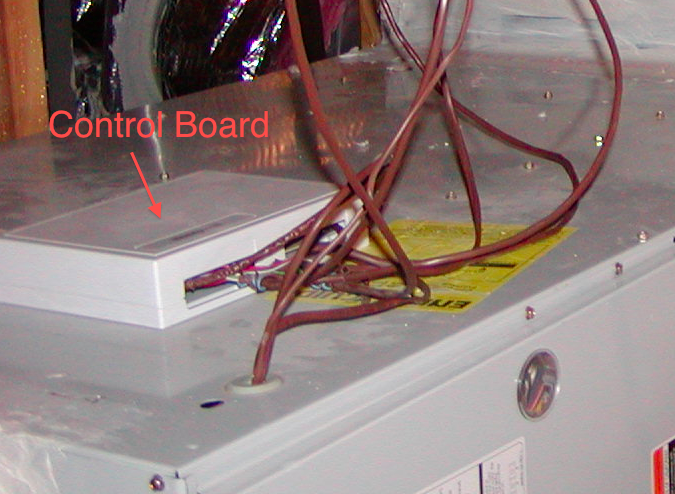

3. A control board on or near the air handler with low voltage wires going to the thermostats/temperature sensors and to each damper. Low voltage wires will also connect the control board and the main air handler control board. See photos below.

4. Bypass duct and damper. This will be a duct connecting the supply end directly to the return end. On the supply side it will connect after the coil and before the zone damper(s), usually off of the supply plenum. On the return side, it can either connect directly to the side of the return end of the furnace, near the return end of the furnace in a return plenum, or as far away as a return grill boot. Some sort of automatic damper will control airflow through this duct. When all zones are calling for cooling (all zone dampers open), the bypass damper should be fully closed. When one or more zone dampers close, the damper should open partially or fully as needed to reduce the supply plenum pressure. This is commonly achieved by a barometric bypass damper. Barometric dampers are held closed by an adjustable weight. When enough pressure builds up on one side of the damper, it overpowers the weight and opens the damper. See diagram below. Another strategy is to use a motorized damper.

Most condensers operate at a single speed and capacity and either run for longer or shorter periods of time during hotter or cooler weather, respectively. Short run times (aka, short cycling) reduce efficiency. Multi-speed condensers typically have a high and low speed. This can be accomplished by two separate compressors inside a single condenser, or by a single dual-stage compressor. During cooler weather (aka, part load times) the condenser will run in low speed for longer run periods. When needed, the condenser can run in high speed.

Variable-speed condensers are not limited to just high and low speeds. They can gradually ramp from lowest to highest speeds as needed.

There are several features that can indicate that a condenser is multi-speed. These include:

1. Product tags, labels and marketing names that indicate two-stage, dual-stage, multi-stage, etc.

2. Two compressors observed by looking down through the condenser fan.

3. High and low capacities or nominal tonnages indicated on nameplate.

The only definitive way to determine if the condenser is multi-speed or variable speed is to record the make and model number and find the manufacturer’s specifications.

This diagram shows a common two-zone, two-damper system with both zones open (i.e., both zones are calling for cooling).

This diagram shows a common two-zone, two-damper system with zone 2 open (i.e., only zone 2 is calling for cooling).

This diagram shows a common two-zone, two-damper system with zone 1 open (i.e., only zone 1 is calling for cooling).

This diagram shows a common two-zone, single-damper system with both zones open (i.e., both zones are calling for cooling).

This diagram shows a common two-zone, single-damper system with zone 1 open (i.e., only zone 1 is calling for cooling).

This diagram shows a common two-zone, single-damper system with zone 2 open (i.e., only zone 2 is calling for cooling).

This diagram shows a common bypass duct/damper strategy. The bypass duct is sheet metal (which should always be insulated) and the damper is a barometric type. The details show how the damper opens when air pressure builds up against the adjustable weight. Sending heated or cooled air back into the space conditioning equipment can cause problems and reduce efficiency.

These photos show two examples of zonal control control-boards.

JA1:Glossary

ZONAL CONTROL is the practice of dividing a residence into separately controlled HVAC zones. This may be done by installing multiple HVAC systems that condition a specific part of the building, or by installing one HVAC system with a specially designed distribution system that permits zonal control. The Energy Commission has approved an alternative calculation method for analyzing the energy impact of zonally controlled space heating and cooling systems. To qualify for compliance credit for zonal control, specific eligibility criteria specified in the Residential ACM Manual must be met.

150.0(m)15. Zonally Controlled Central Forced Air Systems. Zonally controlled central forced air cooling systems shall be capable of simultaneously delivering, in every zonal control mode, an airflow from the dwelling, through the air handler fan and delivered to the dwelling, of greater than 350 CFM per ton of nominal cooling capacity, and operating at an air-handling unit fan efficacy of less than 0.58 W/CFM as confirmed by field verification and diagnostic testing in accordance with the procedures specified in Reference Residential Appendix RA3.3.

EXCEPTION to 150.0(m)15: Multi-speed compressor systems or variable speed compressor systems shall demonstrate compliance for airflow (cfm/ton) and fan efficacy (Watt/cfm) by operating the system at maximum compressor capacity and maximum system fan speed and with all zones calling for conditioning.

150.1(c)13. HVAC System Bypass Ducts. Unless otherwise specified on the Certificate of Compliance, bypass ducts that deliver conditioned supply air directly to the space conditioning system return duct airflow shall not be used. All zonally controlled forced air systems shall be verified by a HERS Rater utilizing the procedure in Reference Residential Appendix Section RA3.1.4.6 to confirm compliance with 150.1(c)13.

When a zonally controlled forced air system is installed, the following shall be verified to determine compliance as required by Standards Section 150.1(c)13:

1. A visual inspection shall confirm that bypass ducts that deliver conditioned supply air directly to the space conditioning system return duct airflow are not used; or

2. If the Certificate of Compliance indicates an allowance for use of a bypass duct, the bypass duct shall conform to the specifications given on the Certificate of Compliance.

If the zonally controlled system meets one of these criteria, the system complies. Otherwise the system does not comply.