Section 120.6(e) applies to all new compressed air systems and all additions or alterations to a compressed air system with a total installed compressor capacity ≥ 25 hp. For alterations, an exception is given for systems containing one or more centrifugal compressors. An exception is also given for systems serving healthcare facilities.

Key terms and definitions:

A. Online compressors: all compressors available to serve peak load. Online compressors do not include backup compressors whose only purpose is to be available when a compressor fails. Online compressors are all compressors that are physically connected to compressed air piping excluding backup compressors.

B. Backup compressors: compressors not used to meet peak compressed air flow loads. Backup compressors can be physically connected to the compressed air piping system and can be automatically controlled to turn on if one of the other compressors on the system fails. Backup compressors do not normally operate.

C. Online capacity: total combined capacity in actual cubic feet per minute (acfm) of compressed air at a given pressure during times of peak compressed air load.

D. Trim compressor: a compressor that is designated for part-load operation, handling the short-term variable trim load of end uses, in addition to the fully loaded base compressor. In general, the trim compressor will be controlled by a VSD but it also can be a compressor with good part-load efficiency. If the trim compressor does not have good part load efficiency broadly across the operating range, then it will take more compressors to meet the Energy Standards requirements.

E. Base compressor: the opposite of a trim compressor, a base compressor is expected to be mostly loaded. If the compressed air system has only one compressor, the requirements of the Energy Standards require that the single compressor be treated as a trim compressor.

F. Specific power: the ratio of power to compressed air flow rate at a given pressure typically given in units of kW/100 acfm. The lower the specific power, the more efficient the compressor is at a given compressed air load.

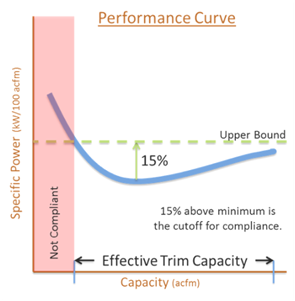

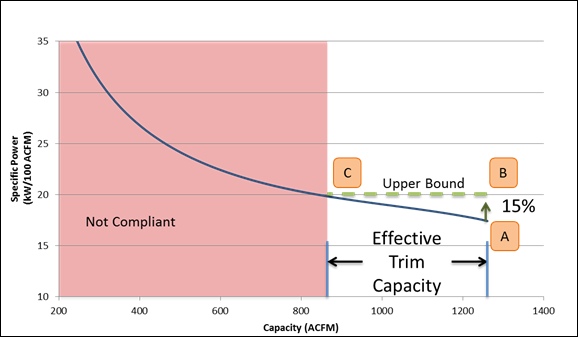

G. Total effective trim capacity: the combined effective trim capacity of all trim compressors where effective trim capacity for each compressor is the range of capacities in acfm, which are within 15 percent of the specific power at the most efficient operating point. This is displayed in Figure 10-42.

H. Largest net capacity increment: the largest increase in capacity when switching between combinations of base compressors that is expected to occur under the compressed air system control scheme. See Example 10-54.

I. Primary Storage: tanks or other devices that store compressed air. Also known as an air receiver, they reduce peak air demand on the compressor system and reduce the rate of pressure change in a system. As primary storage, these devices are near the air compressors and are differentiated from remote storage that might be near an end-use device.

As described in the following paragraphs, there are three main requirements in this section:

•Trim Compressor and Storage - §120.6(e)1.

•Controls - §120.6(e)2.

•Acceptance - §120.6(e)3.

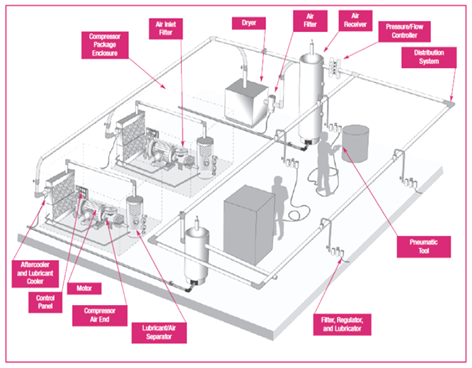

Figure 10-40: Zone Components for a VAV Lab

Source: Improving Compressed Air System Performance: A Sourcebook for Industry, USDOE 2003

10.8.2.1 Trim Compressor and Storage

This requirement targets the performance of a compressed air system across the full range of the system.

There are two paths to comply with this requirement:

1. Using a variable-speed drive (VSD) controlled compressor(s) as the trim compressor (§120.6(e)1A):

•The VSD trim compressor(s) must have a capacity (acfm) of at least 1.25 times the largest net capacity increment (see Example 10-54).

•Primary storage of at least one gallon per acfm (1 gal/acfm) of the largest trim compressor.

2. Using a compressor or set of compressors as the trim compressor (§120.6(e)1B) without requiring a VSD-controlled compressor:

•The trim compressor(s) must have a total effective trim capacity no less than the largest net capacity increment.

•Primary storage of at least two gallons per acfm (2 gal/acfm) of the largest trim compressor.

•Effective trim capacity is the range of compressed air flow rates where the specific power (W/acfm) is no greater than 115% of the minimum specific power (Figure 10-42).

Both paths aim to reduce the amount of cycling of fixed-speed compressors by using a better-suited compressor that operates well in part-load.

A. Compliance Option 1: VSD-controlled Trim Compressor

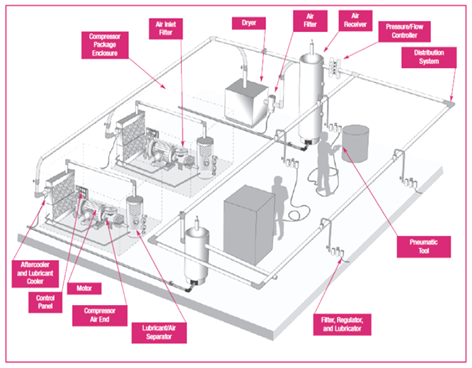

Many base-load compressors are designed to provide peak efficiency near the rated capacity with a significant drop off in efficiency at lower flow rates (in acfm). Compressed air systems often avoid the losses in efficiency associated with part-load compressed air flows by staging multiple compressors so that in most cases base compressors operate near full load. A trim compressor is designed to have close to peak efficiency over a broad range of compressed air flow rates. To make sure the compressed air system is operating efficiently over the entire range, it is important to have a trim compressor sized to handle the gaps between base compressors. The minimum size of the trim compressor(s) is determined calculating the Largest Net Capacity Increment - the biggest step increase between combinations of base compressors.

With equally sized compressors, this is fairly intuitive: in a system with a two-100 hp (434 acfm) rotary screw compressor system, the largest step increase would be the size of one of the compressors (434 acfm). For systems with uneven compressor sizes, it requires going through the following steps:

1. Determine all combinations of base compressors (including all compressors off).

2. Order these combinations in increasing capacity.

3. Calculate the difference between every adjacent combination.

4. Choose the largest difference.

This largest difference is what must be covered by the trim compressor(s) to avoid a control gap.

Once the largest net capacity increment is calculated, this value can be used to satisfy the first compliance option. Option 1 mandates that the rated capacity of the VSD compressor(s) be at least 1.25 times the largest net increment.

For Compliance Option 1, the system must include primary storage that has a minimum capacity of 1 gallon for every acfm of capacity of the largest trim compressor.

Example 10-60

Question

Given a system with three base compressors with capacities of 200 acfm (Compressor A), 400 acfm (Compressor B), and 1,000 acfm (Compressor C), what is the Largest Net Capacity Increment?

Answer

As shown in the image below, there are eight possible stages of capacity ranging from 0 acfm with no compressors to 1,600 acfm with all three compressors operating. The largest net increment is between Stage 4 with Compressors A and B operating (200+400=600 acfm) to stage 5 with compressor C operating (1,000 acfm)

For this system the Largest Net Capacity Increment is 1,000 acfm-600 acfm = 400 acfm

Example 10-61

Question

Using the system from the previous example, what is the minimum rated capacity of VSD compressor(s) that are needed to comply with Option 1?

Answer

As previously shown, the Largest Net Capacity Increment is 1,000 acfm-600 acfm = 400 acfm. The minimum rated capacity for VSD compressor(s) is 400 acfm X 1.25 = 500 acfm.

Example 10-62

Question

What is the required minimum primary storage capacity for the trim compressor from the previous example to comply with Option 1?

Answer

Assuming there is a VSD compressor with a rated capacity of 500 acfm, per §120.6(e)1A, it must have 1 gallon of storage per acfm of rated capacity or 500*1 = 500 gallons of storage.

B. Compliance Option 2: Other Compressors as Trim Compressor

The second compliance option offers more flexibility but requires looking at both the largest net capacity increment of the system, as well as the effective trim capacity of the trim compressor(s).

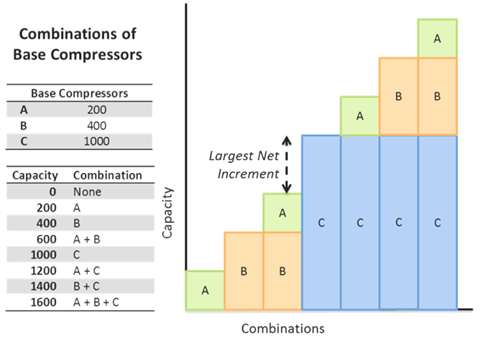

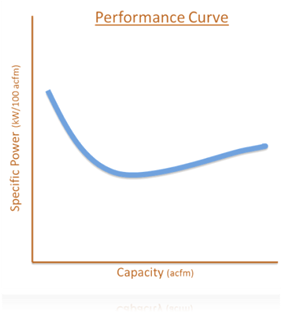

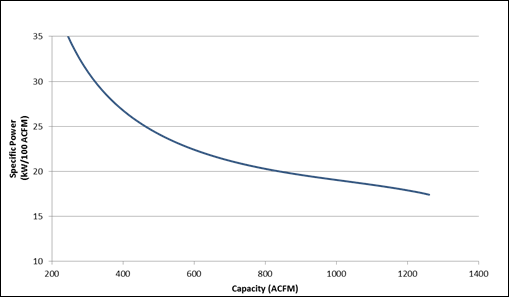

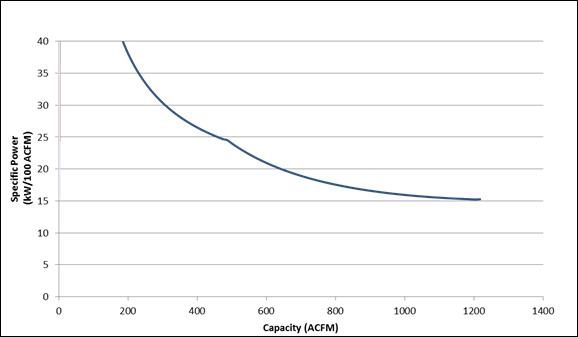

The effective trim capacity is the range across which a trim compressor has adequate part-load performance. Performance is measured in power input over air volume output or specific power (kW/100 acfm). Many VSD compressors come with a compressor performance graph in a CAGI data sheet that looks similar to the graph in Figure 10-41.

Figure 10-41: Example Compressor Power vs. Capacity Curve

The capacity of the compressor is along the x-axis, while the power is on the y-axis. The curve in Figure 10-41 is a typical shape of a performance curve for a VSD compressor. The lower the specific power, the more energy-efficient the compressor is at that condition.

The effective trim capacity uses the minimum of the compressor power vs. capacity curve to determine the range of adequate part-load performance. This can be done in the following steps and is illustrated in the graph below.

1. Find the minimum specific power across the range.

2. Find the upper bound by calculating 1.15 times the minimum specific power.

3. Determine the endpoints of the capacity (acfm) where the specific power is less than or equal to the upper bound.

4. The capacity difference in units of acfm between these two endpoints is the effective trim capacity.

Figure 10-42: Determination of Effective Trim Capacity From a Compressor Curve

This definition of effective trim capacity, along with the largest net capacity increment of the system, is used to size the trim compressor appropriately in the next section.

For Compliance Option 2, the system must include primary storage that has a minimum capacity of 2 gallons for every acfm of capacity of the largest trim compressor.

Example 10-63

Question

Continuing with the system from the previous examples, what is the required minimum effective trim capacity of the trim compressor(s) to comply with Option 2?

Answer

As previously shown, the largest net capacity increment is (1,000 acfm) – (600 acfm) = 400 acfm. Per §120.6(e)1 the minimum effective trim capacity is equal to the largest Net Capacity Increment or 400 acfm.

Example 10-64

Question

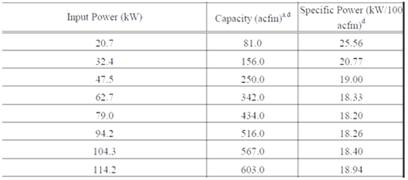

A manufacturer provided the following data for its compressor; would this provide the minimum effective trim capacity for

this system to comply with Option 2?

Answer

From the manufacturer’s data, the minimum specific power is 18.2 kW/100 acfm. The upper limit would be 18.2 * 1.15 = 20.9 kW/100 acfm. Interpolating from the manufacturer’s data, this appears to go from 155 acfm to 605 acfm for an effective trim capacity of 605-155= 450 acfm. This is larger than the largest net capacity increment of 400 acfm, so this compressor would comply as a trim compressor for this system.

Example 10-64

Question

What is the required minimum primary storage capacity for the trim compressor from the previous example to comply with Option 2?

Answer

This compressor has a rated capacity of 603 acfm. Per §120.6(e)1B, it must have 2 gallons of storage per acfm of rated capacity or 603*2 = 1,206 gallons of storage.

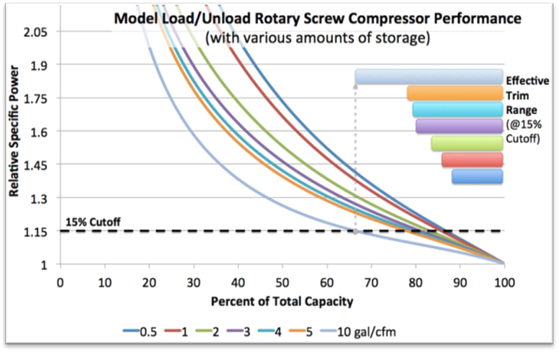

The last example used a VSD compressor, but other technologies can be used for compliance option 2 such as a compressor with unloaders and sufficient compressed air storage to achieve relatively high part-load efficiencies over a broad range of compressed airflow rates. Generally, higher levels of storage improve part-load performance. The following data, in Figure 10-43 and for this example, were generated from theoretical curves used in AirMaster+, a tool created by the U.S. Department of Energy.

Figure 10-43: Normalized Efficiency Curves for a Screw Compressor With Load/Unload Controls for Various Amounts of Storage

Source: Derived from Fact Sheet 6 – Compressed Air Storage, Improving Compressed Air Storage: a Sourcebook for Industry, U.S. Department of Energy, 2003

The next example examines a 250-hp load-unload, single-stage, rotary-screw compressor coupled with 10 gallons/cfm of storage. This combination of compressor and storage was chosen to meet the part-load performance mandated by code.

Example 10-65

Question

Part-load data were approximated below for a 250-hp load-unload, single-stage, rotary-screw compressor (with a capacity of 1,261 acfm) coupled with 10 gallons/cfm of storage. Would this provide the minimum effective trim capacity for this system to comply with Option 2 using the previous examples?

Answer

Using

the previous examples, a compressor with an effective trim capacity of at least

400 acfm is necessary.

Looking at the graph, the minimum specific power (labeled as A below) occurs at full load - a capacity of 1,261 acfm, with a specific power of 17.4 kW/100 acfm. Using this minimum specific power, the upper bound is 17.4 * 1.15 = 20.01 kW/100acfm or 15% higher than the minimum specific power. This puts the ends of the effective trim capacity at 1261 acfm (labeled as B) and 845 acfm (labeled as C), resulting in an effective trim capacity of 1261 – 845 = 416 acfm. This is larger than the largest net capacity increment of 400 acfm, so this compressor would comply as a trim compressor for this system.

Example 10-66

Question

What is the required minimum primary storage capacity for the trim compressor from the previous example to comply with Option 2?

Answer

This compressor has a rated capacity of 1,261 acfm, and per §120.6(e)1B it must have 2 gallons of storage per acfm of rated capacity or 1261 * 2 = 2,522 gallons of storage.

However, a minimum of 10 gallons of storage per acfm was needed for the screw compressor with load/unload controls to have a large enough effective trim capacity. The minimum required primary storage to meet the effective trim capacity and storage requirements in §120.6(e)1B is 10 gal per acfm of rated trim compressor capacity; thus the minimum primary storage capacity required is 1,261 * 10 = 12,610 gallons.

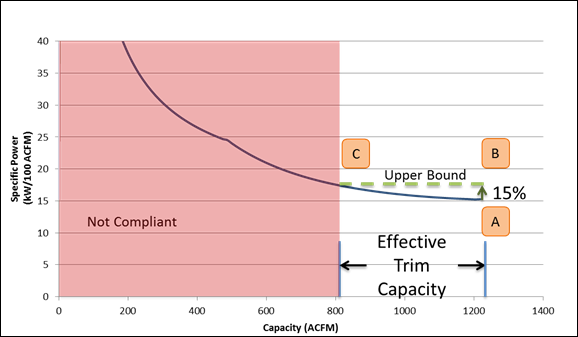

Example 10-67

Question

Part-load data were approximated below for a 250-hp variable-capacity compressor. Would this provide the minimum effective trim capacity for this system to comply with Option 2?

Answer

Using the previous examples, a compressor with an effective trim capacity of at least 400 acfm is necessary.

Looking at the graph, the minimum specific power (labeled as A below) occurs at full load - a capacity of 1,218 acfm, with a specific power of 15.3 kW/100 acfm. Using this minimum specific power, the upper bound is 15.3 * 1.15 = 17.56 kW/100 acfm or 15% higher than the minimum specific power. This puts the ends of the effective trim capacity at 1,218 acfm (labeled as B) and 804 acfm (labeled as C), resulting in an effective trim capacity of 1218 – 804 = 414 acfm. This is larger than the largest net capacity increment of 400 acfm so this compressor would comply as a trim compressor for this system.

Example 10-68

Question

What is the required minimum primary storage capacity for the trim compressor from the previous example to comply with Option 2?

Answer

This compressor has a rated capacity of 1,218 acfm, and per §120.6(e)1B it must have 2 gallons of storage per acfm of rated capacity or 1,218 * 2 = 2,236 gallons of storage.

10.8.2.2 Controls

This section applies to compressed air systems with more than one on-line compressor and a combined power of ≥100 hp. This section requires an automated control system that will optimally stage the compressors to minimize energy for the given load. With new systems, this ideally means that at any given load, the only compressors running at part-load are the trim compressors. Because not all systems are required to upgrade the trim compressor, the installed controls must stage the compressors in the most efficient manner.

This requirement also mandates the measurement of air demand. The control system must be able to measure or calculate the current system demand (in terms of actual cubic feet per minute of airflow). There are two ways to accomplish this, including, but not limited, to the following sensors:

•A flow meter

•A combination of pressure transducers and power meters

10.8.2.3 Acceptance

New systems and altered systems that are subject to the trim compressor requirements of §120.6(e)1 or the staging control requirements of §120.6(e)2 must be tested per NA7.13.

There are no prescriptive measures for compressed air systems.

These requirements apply to existing systems that are being altered and that have a total compressor capacity ≥ 25 hp. These requirements will be triggered by replacing a compressor, adding a compressor, or removing a compressor.

These requirements do not apply to:

•Adding a VFD to a fixed-speed compressor.

•Repairing a compressor.

•Replacing a compressor drive motor.

•Adding compressed air controls.

•Adding air dryers.

•Adding oil separators.

•Adding compressed air storage capacity.

•Removing an air compressor without adding any air compressors.

For alterations or additions to an existing compressed air system, the requirements for trim compressor size and storage apply only when the combined capacity of compressor replacements and/or additions are 50 percent or more of the existing online capacity (not including backup compressor capacity) of the compressed air system. Because the capacity of a compressor is closely correlated to horsepower, for simplicity of compliance and enforcement, the combined horsepower of the alterations or additions or both can be used to determine the total combined capacity.

Example 10-69

Question

If a 50 hp compressor was added to a compressed air system with only one existing 100 hp compressor, would the requirements of §120.6(e) apply?

Answer

Yes, because 50 hp is equal to or greater than 50 percent of the existing 100 hp capacity.

Example 10-70

In some cases, after a compressed air assessment, it is recognized that the on-line compressor capacity can be downsized. As an example, a plant has a system with a 100 hp on-line compressor and a 100 hp backup compressor. After the assessment, it is identified that the maximum horsepower needed to meet the air demand is only 50 hp. The project scope calls for the installation of one 50 hp compressor and leaving both existing 100 hp compressors as backup compressors.

Question

What requirements of §120.6(e) apply?

Answer

After the retrofit, the on-line compressor horsepower is 50 hp. Because the total on-line compressor horsepower is greater than 25 hp, the requirements of §120.6(e) 1, 2, and 3 must be considered.

The new 50 hp compressor is 50 percent of the existing on-line capacity; therefore, the requirements of §120.6(e)1 apply.

Because this system only has one on-line compressor, the requirements for a load controller that optimizes compressor selection as described in §120.6(e)2 is not required.

Since this system was required to install a trim compressor, the acceptance test requirement of §120.6(e)3 would apply.

The requirements for staging control apply only if after the alterations/additions, there are more than one online compressor and the total combined horsepower is greater than 100 hp.

The acceptance testing mentioned in §120.6(e)3 tests for system blow-off and short cycling. These issues are affected by sizing and specification of the trim compressor or the selection and programming of an optimal staging control. Thus, the acceptance tests are required only for alterations/additions where a trim compressor and/or staging controls are required.