Hydronic heating is the use of hot water to distribute heat. Hydronic heating is discussed in this compliance manual as an “alternative system” because it is much less common in California than in other parts of the United States.

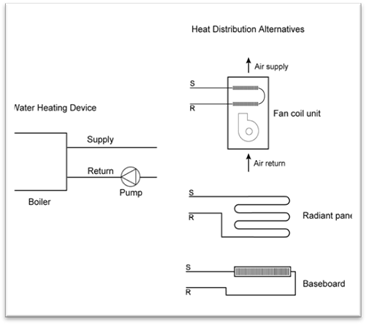

A hydronic heating system consists of a heat source, which may be a boiler, water heater, or heat pump, and a distribution system. There are three main types of hydronic distribution systems, and they may be used individually or in combination: baseboard convectors or radiators, air handlers, and radiant panel systems. Radiant panel surfaces can include floors, walls, and/or ceilings. Air handlers and radiant panels may be used for heating and cooling. Hot water air handlers may also be equipped with DX coils for cooling. The three distribution options are illustrated in Figure 4-32. Ducting is used only with air handlers.

4.7.1.1 Mandatory Requirements

For hydronic heating systems without ducts, the mandatory measures cover pipe insulation, tank insulation, and boiler efficiency. For fan coils with ducted air distribution, the mandatory air distribution measures also apply. For combined hydronic systems, as described below, mandatory water heating requirements also apply to the water heating portion of the system.

A. Pipe and Tank Insulation

The typical residential hydronic heating system operating between 105° and 140° F must have at least 1 inch (25 mm) of insulation on pipes less than 1 inch in diameter and 1.5 inch (38 mm) of insulation on pipes 1 inch or more in diameter. Systems operating between 141° and 200° F must have at least 1.5 inches of insulation on pipes less than 1.5 inches in diameter. For other temperatures and pipe insulation characteristics, see Table 4-5

There are a few exceptions where insulation is not required:

1. Sections of pipes where they penetrate framing members

2. Pipes that provide the heat exchange surface for radiant heating and/or cooling

3. Piping in the attic that is covered by at least 4 inches (100 mm) of blown insulation on top

4. Piping installed within walls if all the requirements for Insulation Installation Quality are met (see Chapter 3 Building Envelope Requirements).

If the system includes an unfired hot water storage tank, then the tank must be either wrapped with R-12 insulation or insulated internally to at least R-16.

Piping used to deliver chilled water to panels or air handlers should be continuously insulated with closed-cell foam to prevent condensation damage.

Figure 4-33: Hydronic Heating System Components

Source: Richard Heath & Associates/Pacific Gas and Electric Company

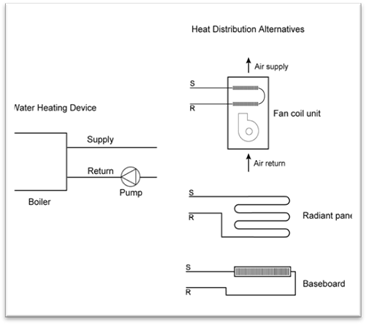

Figure 4-34: Combined Hydronic System With Water Heater as Heat Source

Source: Richard Heath & Associates/Pacific Gas and Electric Company

For pipes in hydronic heating systems that operate at pressure greater than 15 psi, the requirements of §120.3 apply. These are the same requirements that apply to nonresidential piping systems.

B. Equipment Efficiency

Gas or oil boilers used for residential space heating (typically less than 300,000 Btu/hr capacity) must be rated with an AFUE of 80 percent or greater. (See Appliance Efficiency Regulations, Title 20 for minimum efficiencies of other heating equipment.) A gas or oil water heater may also be used as a dedicated source for space heating. Other hot water sources, including heat pumps or electric resistance water heaters, are not allowed for use in dedicated space-heating systems. Therefore, some water heaters may be used for space heating only if used as part of a combined hydronic system, as described below. In that case, the mandatory water heater requirements apply.

There are no minimum efficiency requirements for heat pumps that produce hot or chilled water, but compliance calculations must use ratings listed in the Energy Commission’s Title 20 appliance database under the category “Central Heat Pumps” and Appliance Type “Heat Pump Water Heating Packages.”

https:/cacertappliances.energy.ca.gov/Pages/ApplianceSearch.aspx

Thermostat requirements also apply to hydronic systems, as described in Section 4.5.1.

4.7.1.2 Prescriptive Requirements

There are no specific prescriptive requirements that apply to hydronic systems. However, if the system has a fan coil with ducted air distribution, the relevant prescriptive requirements apply, including duct insulation and duct sealing.

4.7.1.3 Performance Compliance Options

Credit for choosing a hydronic heating system is possible using the performance compliance method. The standard design is assumed to have a furnace and ducted air distribution system. Therefore, hydronic systems without ducts can take credit for avoiding duct leakage penalties. In addition, minimizing the amount of pipe outside conditioned space will provide some savings. Hydronic heating and cooling compliance calculations are described in the Residential ACM Manual.

If the proposed hydronic system includes ducted air distribution, then the associated compliance options described earlier in this chapter may apply, such as improved airflow (if there is air conditioning) and supply duct location.

A “combined hydronic” system is another compliance option that is possible when using the performance method. Combined hydronic heating refers to the use of a single water heating device as the heat source for space and domestic hot water heating.

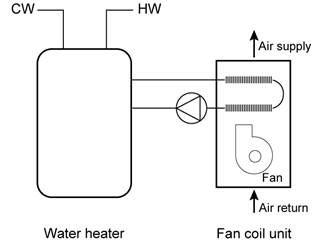

Combined hydronic systems may use either a boiler (as in the figure below) or a water heater as a heat source. The boiler heats domestic water by circulating hot water through a heat exchanger in an indirect-fired water heater. The water heater provides domestic hot water as usual.

Figure 4-35: Combined Hydronic System With Boiler and Indirect Fired Water Heater

Source: Richard Heath & Associates/Pacific Gas and Electric Company

Space heating is accomplished by circulating water from the boiler or water heater through the space heating delivery system. Sometimes a heat exchanger is used to isolate potable water from the water circulated through the delivery system. Some water heaters have built-in heat exchangers for this purpose.

For compliance calculations, the water-heating function of a combined hydronic system is analyzed for water-heating performance as if the space-heating function were separate. For the space-heating function, an “effective” AFUE or HSPF rating is calculated. These calculations are performed automatically by the compliance software.

§110.8(g) and

Table

118.0-A

Radiant floor systems, using either hydronic tubing or electric cable, must meet mandatory insulation measures. (See below.) Radiant floors may take one of several forms. Tubing or electric elements for radiant floor systems may be:

1. Embedded in a concrete floor slab.

2. Installed over the top of a wood subfloor and covered with a concrete topping.

3. Installed over the top of a wood subfloor in between wood furring strips.

4. Installed on the underside surface of a wood subfloor

In the latter two types of installations, aluminum fins are typically installed to spread the heat evenly over the floor surface and to reduce the temperature of the water as required. All hydronic systems use one or more pumps to circulate hot water. Pumps are controlled directly or indirectly by thermostats or by special outdoor reset controls. When concrete slabs are heated by radiant tubing or cables, one of the insulation methods listed below must be complied with to prevent excessive heat loss from the slab edge.

|

Location of Insulation |

Orientation of Insulation |

Installation Criteria |

Climate Zone |

Insulation R-Value |

|

Outside edge of heated slab, either inside or outside the foundation wall |

Vertical |

From the level of the top of the slab, down 16

inches or to the frost line, whichever is greater. Insulation may stop at

the top of the footing where this is less than the required depth. |

1-15 |

5 |

|

16 |

10 | |||

|

1-15 |

5 | |||

|

Between heated slab and outside foundation wall |

Vertical and Horizontal |

Vertical insulation from the top of the slab at the inside edge of the outside wall down to the top of the horizontal insulation. Horizontal insulation from the outside edge of the vertical insulation extending 4 feet toward the center of the slab in a direction normal to the outside of the building in the plan view. |

16 |

10 vertical and 7 horizontal |

Source: 2019 Energy Standards Table 110.8-A

The required insulation value for each of these insulating methods is shown in Table 4-7.

Slab edge insulation applied to basement or retaining walls (with heated slab below grade) must be installed so that insulation starts at or above ground level and extends down to the bottom of the foundation or to the frost line, whichever is greater.

When using the performance compliance method with slab-on-grade construction, the standard design includes slab edge insulation as described above using the F-factors in Reference Joint Appendix JA4, Table 4.4.8.

When tubing or heating cables are set into a lightweight concrete topping slab laid over a raised floor, the edges of the radiant panel must not extend beyond the inside surface of insulated walls, and underside insulation must meet the mandatory minimum R-value for wood floor assemblies.

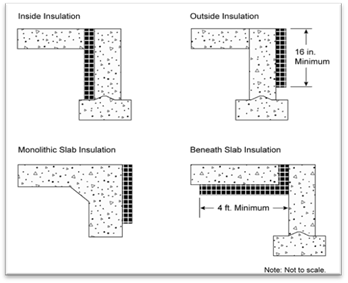

Figure 4-36: Heated Slab-On-Grade Floor Insulation Options

Source: California Energy Commission

Local conditions (such as a high water table) may require special insulation treatment to achieve satisfactory system performance and efficiency. To determine the need for additional insulation, follow the recommendations of the manufacturer of the hydronic tubing or heating element being installed. Where there is any danger of termite infestation, install termite barriers to prevent hidden access for insects from the ground to the building framing. Termite barrier flashing should be embedded into the concrete.

In addition to the insulation R-value requirements, §110.8(g)1 also sets mandatory measures related to moisture absorption properties of the insulation and protection of the insulation from physical damage or pest intrusion.

Example 4-36

Question:

My client wants a dedicated hydronic-heating system (space heating only), but a few things are unclear: (1) What piping insulation is required? (2) Can I use any compliance approach? (3) Do I have to insulate the slab with slab edge insulation? (4) What special documentation must be submitted for this system type?

Answer:

(1) The supply lines not installed within a concrete radiant floor must be insulated in accordance with §150.0(j)2— Systems operating between 105° and 140° F must have at least 1 inch of insulation on pipes less than 1 inch in diameter, and 1.5 inches of insulation on pipes between 1 inch and less than 1.5 inches in diameter. Systems operating between 141° and 200° F must have at least 1.5 inches of insulation on pipes less than 1.5 inches in diameter.

(2) You can use any compliance approach, but the boiler must meet the mandatory efficiency 80 percent AFUE.

(3) The slab edge insulation shown in Table 4-16 is required only when the distribution system is a slab-on-grade radiant floor system (pipes in the slab). When this is the case, the insulation values shown are mandatory measures (no modeling or credit).

(4) No special documentation is required.

Question:

What are the slab edge insulation requirements for a hydronic-heating system with the hot water pipes in the slab?

Answer:

The requirements for slab edge insulation can be found in §110.8 and §150.0(l).

Material and installation specifications are as follows:

1. Insulation values as shown in Table 4-16

2. Protected from physical damage and ultraviolet light deterioration

3. Water absorption rate no greater than 0.3 percent (ASTM-C272)

4. Water vapor permeance no greater than 2.0 per inch (ASTM-E96-14).

Evaporative coolers cool a building by passing outdoor air through a wetted evaporative medium (direct evaporative cooler), by indirect cooling through a nonporous heat exchanger separating evaporatively cooled secondary air from outdoor air, or by a combination indirect-direct system that combines an indirect heat exchanger with a downstream direct evaporative process. Although direct coolers are most common, the more advanced indirect and indirect-direct systems offer generally lower supply air temperatures with less moisture introduced to the indoor space. For the Energy Standards, performance credit is allowed only for indirect and indirect-direct evaporative cooling systems. All coolers receiving credits within the ACM Manual must be listed in the Energy Commission’s Title 20 Evaporative Cooler appliance database (https:/cacertappliances.energy.ca.gov/Pages/ApplianceSearch.aspx).

Evaporative coolers may be used with any compliance approach. In the prescriptive compliance approach, all evaporative coolers are treated as a minimum efficiency 13.0 SEER air conditioner.

In the performance approach, the compliance software uses an hourly model based on unit effectiveness, supply airflow, and power to determine the magnitude of the credit based on climate conditions and unit sizing relative to the loads. Typical cooling budget credits are 20-30 percent, depending upon these factors.

The evaporative cooling system must meet the following requirements to receive credit based on the hourly performance method described above. Direct coolers, as well as indirect and indirect-direct coolers not meeting these criteria, shall be modeled as a minimum efficiency (13.0 SEER) central air conditioner.

1. The equipment manufacturer shall certify to the Energy Commission that water use does not exceed 7.5 gallons per ton hour based on the Title 20 Appliance Efficiency Regulations testing criteria.

2. Equipment shall be permanently installed (no window or portable units).

3. Installation shall provide for automatic relief of supply air from the house with maximum air velocity through the relief dampers not exceeding 800 feet per minute (at the Title 20 rated airflow). Pressure relief dampers and ductwork shall be distributed to provide adequate airflow through all habitable rooms. For installations with an attic, ceiling dampers shall be installed to relieve air into the attic and then outside through attic vents. For installations without an attic, sidewall relief dampers are acceptable.

4. To minimize water consumption, bleed systems are not allowed.

5. A water quality management system (either “pump down” or conductivity sensor) is required. “Pump down” systems can either be integral to the evaporative cooler or they can be accessories that operate on a timed interval. The time interval between pumps shall be set to a minimum of 6 hours of cooler operation. Longer intervals are encouraged if local water quality allows. Automatic systems that use conductivity sensors provide the best water efficiency compared to a timed pump down system. These sensors monitor the water quality and don’t unnecessarily drain the water based on elapsed time.

6. Automatic thermostats are required. Manual on/off controls are not allowed.

7. If the evaporative cooler duct system is shared with a heating and/or cooling system, the installed duct system shall employ backdraft dampers at the evaporative cooler supply.

8. The installing contractor must provide a winter closure device that substantially blocks outdoor air from entering the indoor space.

9. The size of the water inlet connection at the evaporative cooler shall not exceed 3/8 inch.

10. Unless prohibited by local code, the sump overflow line shall not be directly connected to a drain and shall terminate in a location that is normally visible to the building occupants.

Example 4-38

Question:

How are applications with vapor compression cooling systems and evaporative cooling systems handled?

Answer:

In situations where evaporative cooling system(s) and vapor compression system(s) are installed in a house, the size of the evaporative cooler will dictate the magnitude of the credit. The performance approach will ensure that an evaporative cooler sized to meet most of the cooling loads will generate a higher credit than one sized to meet a fraction of the design cooling load.

Example 4-40

Question:

How do you model multiple evaporative coolers on one house?

Answer:

In situations with multiple evaporative coolers, effectiveness inputs should be averaged, and airflow and power inputs should be totaled. Performance characteristics of each piece of equipment should be listed on the compliance forms.

|

Appliance |

Rating Condition |

Minimum Standard |

|

Ground water-source heat pumps (cooling) |

59º F entering water temperature |

16.2 EER |

|

Ground water-source heat pumps (heating) |

50º F entering water temperature |

3.6 COP |

|

Ground-source heat pumps (cooling) |

77º F entering brine temperature |

13.4 EER |

|

Ground-source heat pumps (heating) |

32º F entering brine temperature |

3.1 COP |

Section 1605.3 Table C-7 of the 2015 California Appliance Efficiency Regulations

A geothermal or ground-source heat pump uses the earth as a source of energy for heating and as a heat sink for energy when cooling. Some systems pump water from an aquifer in the ground and return the water to the ground after exchanging heat with the water. A few systems use refrigerant directly in a loop of piping buried in the ground. Those heat pumps that either use a water loop or pump water from an aquifer have efficiency test methods that are accepted by the Energy Commission.

The mandatory minimum efficiencies for ground water-source heat pumps shown in Table 4-17 are certified to the Energy Commission by the manufacturer and are expressed in terms of coefficient of performance (COP) for heating and EER for cooling.

Verify that the system will meet local code conditions before choosing this type of system to meet the Energy Standards.

Solar space-heating systems are not recognized within either the prescriptive packages or the performance compliance method.

The Energy Commission’s exceptional method for wood heaters with any type of backup heating is available in areas where natural gas is not available. If the required eligibility criteria are met, a building with one or more wood heaters may be shown to comply with the Energy Standards using either the prescriptive or performance approaches as described below.

4.7.6.1 Prescriptive Approach

The building envelope conservation measures of the component package must be installed. The overall heating system efficiency (wood stove plus backup system) must comply with the prescriptive requirements.

4.7.6.2 Performance Approach

A computer compliance method may be used by modeling wood heat, which simulates an 80 percent AFUE central furnace with ducts that meet prescriptive requirements.

4.7.6.3 Wood Heater Qualification Criteria

The Energy Standards establish exceptional method guidelines for the use of wood heaters. If all the criteria for the wood heat exceptional method are not met, a backup heating system must be included in the compliance calculations as the primary heat source.

The building department having jurisdiction must determine that natural gas is not available.

Note: Liquefied petroleum gas, or propane, is not considered natural gas.

The following eligibility criteria apply:

1. The local or regional air quality authority must determine that its authorization of this exceptional method is consistent with state and regional ambient air quality requirements according to Sections 39000 to 42708 of the California Health and Safety Code.

2. The wood heater must be installed in a manner that meets the requirements of all applicable health and safety codes, including, but not limited to, applicable requirements for maintaining indoor air quality.

3. The wood heater must meet the EPA definition of a wood heater as defined in Title 40, Part 60, Subpart AAA of the Code of Federal Regulations (40CFR60 Subpart AAA) (See below.)

4. The performance of the wood heater must be certified by a nationally recognized agency and approved by the building department having jurisdiction to meet the performance standards of the EPA.

5. The rated output of the wood heater must be at least 60 percent of the design heating load, using calculation methods and design conditions as specified in §150(h).

6. At the discretion of the local enforcement agency, a backup heating system may be required and designed to provide all or part of the design heating load, using calculation methods and design conditions as specified in §150(h).

7. The wood heater must be located such that transfer of heat from the wood heater is effectively distributed throughout the entire residential dwelling unit, or it must be used in conjunction with a mechanical means of providing heat distribution throughout the dwelling.

8. Habitable rooms separated from the wood heater by one free opening of less than 15 ft² or two or more doors must be provided with a positive heat distribution system, such as a thermostatically controlled fan system. Habitable rooms do not include closets or bathrooms.

9. Wood heaters on a lower level are considered to heat rooms on the next level up, provided they are not separated by two or more doors.

10. The wood heater must be installed according to manufacturer and local enforcement agency specifications and must include instructions for homeowners that describe safe operation.

11. The local enforcement agency may require documentation that demonstrates that a particular wood heater meets all these requirements.

Federal regulation 40CFR60 Subpart AAA includes minimum criteria for wood heaters established by the U.S. EPA. These criteria define a wood heater as an enclosed, wood-burning appliance capable of and intended for space heating or domestic water heating that meets all the following criteria:

1. An air-to-fuel ratio averaging less than 35 to 1

2. A firebox volume less than 20 ft3.

3. A minimum burn rate less than 5 kilogram/hour (11.0 lbs/hr)

4. A maximum weight of less than 800 kilograms (1,760 lbs)

5. The federal rules explicitly exclude furnaces, boilers, cook stoves, and open masonry fireplaces constructed on site, but include wood-heater inserts.

Example 4-41

Question:

Are pellet stoves treated the same as wood stoves for compliance with the Energy Standards?

Answer:

Yes.

Example 4-42

Question: If a wood stove is installed in a wall, does it have to meet the fireplace requirements of §150(e)?

Answer:

No. A wood stove that meets EPA certification requirements does not have to meet any requirements applicable to fireplaces.

Pilot lights are prohibited in fan-type central furnaces, pool heaters, spa heaters, and natural gas indoor and outdoor fireplaces.

Household cooking appliances are also prohibited from having a pilot light unless there is no electrical supply voltage connection and each pilot consumes less than 150 Btu/hr.

For requirements related to installation of fireplaces, decorative gas appliances, and gas logs, see Chapter 3 of this manual.

Evaporatively cooled condenser air conditioners are a type of air-conditioning system that can provide significant space-cooling savings, especially in hot, dry climates. The equipment minimal efficiencies are determined according to federal test procedures. The efficiencies of these air conditioners are reported in terms of energy efficiency rating (EER).

If credit is taken for a high EER, field verification by a HERS Rater is required. Other HERS-verified measures are also required, including duct sealing, airflow, fan efficacy, and refrigerant charge or fault indicator display.

Besides the HERS verification, there are additional special requirements for evaporatively cooled condensing air conditioners. These include that the manufacturer provide certification that water use is limited to no more than 0.15 gallon per minute per ton of capacity and that the supply line be no larger than ¼-inch in diameter. For a listing of all the requirements for evaporatively cooled condensing air conditioners, see the CF2R compliance form.

Several manufacturers offer equipment that does not use air distribution ducts to heat or cool spaces. These systems use either refrigerant or water that is heated and/or cooled to condition the space. These systems may provide advanced controls and multispeed compressors for optimizing performance through a wide range of conditioning loads without losing efficiency.

These systems are required to be modeled as minimally efficient systems because a compliance option that specifies appropriate modeling rules and installation criteria has not been developed or approved. All applicable HERS verifications are required to be conducted for these systems, if possible.

Ventilation cooling is differentiated from the mechanical ventilation provided to maintain adequate indoor air quality, in that the primary focus is to bring in higher volumes of cool outdoor air (if available) to cool the dwelling unit to reduce the use of conventional vapor compression air conditioning. Ventilation cooling systems generally operate during summer evenings and nights when cooler outdoor air is available. The cooler outdoor air ventilation reduces indoor air temperatures during the evening and nighttime hours, and in the process cools the building interior thermal mass, which may offset or eliminate the next-day cooling loads of the dwelling. Ventilation cooling systems may cool the dwelling to temperatures that are below the normal air conditioner set point, which may improve the effectiveness of the next-day cooling load offset. The effectiveness of ventilation cooling depends upon the climate conditions, thermal envelope, and how much indoor temperature variation the occupant will tolerate.

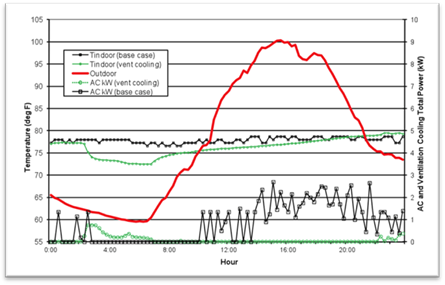

Figure 4-37 compares cooling energy use over a day for two identical houses, one with and one without ventilation cooling, and illustrates how ventilation cooling can offset most of the air-conditioning energy by use of a relatively small amount of off-peak ventilation fan operation.

Figure 4-37: Diurnal Temperature Variation and Ventilation Cooling

Source: California Energy Commission

4.7.10.1 Whole-House Fans

The simplest form of ventilation cooling is a whole-house fan (WHF), which draws cooler outdoor air through open windows, exhausts the warmer air into the attic, and then expels the air outside through attic vents.

Traditional whole-house fans have a simple barometric damper (Figure 4-38) and either a belt-driven or direct-drive motor driving a prop fan. Figure 4-39 shows the damper open with the fan immediately above.

Figure 4-40 shows a similar product that moves less air but provides an insulated damper with a better leakage seal between the attic and conditioned space. These units are generally designed to fit between standard rafter spacing, simplifying retrofit installations.

Finally, Figure 4-41 shows a remote whole-house fan design that removes the fan farther from indoor space, reducing noise during operation.

WHFs cool a dwelling space most effectively when all windows throughout the house are opened only enough to produce a fairly uniform airflow into all rooms throughout the dwelling while not restricting the WHF total airflow. This results in the greatest interaction of the cool air with the interior mass throughout the dwelling, providing the greatest amount of stored cooling. Running the fan all night long increases the effectiveness of the next-day cooling offset by more fully “charging” the thermal mass. Noise can be reduced through either use of a variable-speed control or installation of a multispeed fan, allowing low-speed nighttime operation.

Security concerns may arise if windows are left open at night, but most window products can be secured if they are only partially open, thus providing the minimum open area for air to enter the room but preventing unauthorized entry from outside the dwelling.

Homeowners who have sensitivities to particulate matter in the outdoor air should consider that dust and allergens present in the outdoor air will easily enter the dwelling through the open windows during operation of a WHF.

The WHFs used to comply with the Energy Standards must be listed in the Energy Commission’s Appliance Database which can be accessed at https://cacertappliances.energy.ca.gov/Pages/ApplianceSearch.aspx.

Figure 4-38: Whole-House Fan With Barometric Damper

Source: California Energy Commission

Figure 4-39: Open Barometric Damper With Fan Above

Source: California Energy Commission

Figure 4-40: Insulated Whole-House Fan With Damper Actuation

Source: California Energy Commission

Figure 4-41: Ducted Remote Whole-House Fan

Source: California Energy Commission

4.7.10.2 Central Fan Ventilation Cooling Systems

Another type of ventilation cooling system, the central fan ventilation cooling system (CFVCS) uses an automatically controlled outside air damper and the HVAC system fan or other fan to draw outside air through a large outdoor air vent and distributes the cool outdoor air through the HVAC system ductwork. Warm indoor air is then expelled into the attic through the same damper.

Primary advantages of this system include filtration of outside air, elimination of the need to open windows (improved security), and automatic sensing of the moment when the outdoor air temperature falls below the indoor temperature. A disadvantage of central fan systems is that they typically move less air and consume more energy per CFM as compared to a whole-house fan because of the more restrictive duct systems.

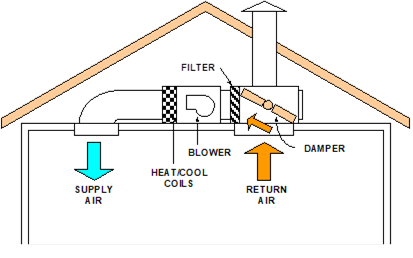

Figure 4-42 shows the airflow path through a CFVCS when the system is not operating to provide ventilation cooling (return air mode). In this mode, the system performs the same as a conventional central space-conditioning system, drawing the return air from the conditioned space, through the heating/cooling coils, then back to the conditioned space.

Figure 4-42: Central Fan Ventilation Cooling System (Return Air Mode)

Source: California Energy Commission

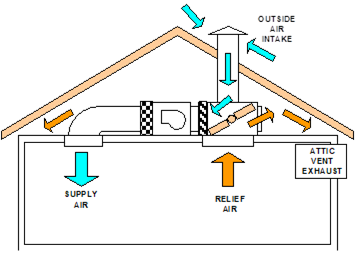

Figure 4-43 shows the airflow paths when the system is operating to provide ventilation cooling (outdoor air mode). In this mode, the damper changes position and draws outdoor air through the outdoor air intake vent, through the air handler, and then to the conditioned space. During outdoor air mode, the cooling/heating coils are not operated, and the damper allows indoor air to pass into the attic, then back to outdoors through the attic vents.

Figure 4-43: Central Fan Ventilation Cooling System (Outdoor Air Mode)

Source: California Energy Commission

Figure 4-44: Sample Rooftop Air Intake

Source: California Energy Commission

Figure 4-45: Sample Gable End Air Intake (Lower Set of Vents)

Source: California Energy Commission

CFVCSs may use a variable-speed motor with a fan-speed control that responds to outdoor temperature conditions and indoor comfort settings, which may improve energy savings compared to fixed-speed CFVCSs.

4.7.10.3 Prescriptive Requirements

Component packages specify a WHF as a prescriptive requirement for single-family newly constructed buildings in Climate Zones 8 through 14. The WHF, or CFVCS, must meet the eligibility criteria specified below to meet the prescriptive requirement.

Additions of 1,000 ft2 or less are exempt from the whole-house fan prescriptive requirements.

1. Where atmospherically vented combustion appliances or solid-fuel burning appliances are located inside the pressure boundary, the operation of the whole-house fan must be considered in determining the adequacy of providing combustion air and prevention of back-drafting, which may cause toxic products of combustion to enter conditioned space of the the dwelling.

2. WHFs used to comply with the Energy Standards must be listed in the Energy Commission Appliance Database.

3. To meet the prescriptive requirement, the installed WHF(s) must have a listed airflow of at least 1.5 CFM/ft2 of conditioned floor area. The house must have a minimum attic net free vent area to outdoors of one square foot per 750 CFM of installed whole-house fan(s) rated airflow. See Table 4-18 and Table 4-19 for net free ventilation area requirements based on the square footage of the house.

4. Homeowners who have WHFs installed must be provided with a one-page “How to operate your whole house fan” informational sheet.

A. Eligibility Criteria for Central Fan Ventilation Cooling Systems

CFVCS may be approved for use for compliance credits as “fixed-speed” systems or as "variable speed" systems. The Energy Commission must review submittals from manufacturer applicants and determine whether the system meets the qualifying criteria:

When applying for approval for either fixed speed or variable speed systems, the manufacturer must provide documentation to demonstrate the system meets the criteria listed in paragraphs 1, 2, and 3 below

1. CFVCS must meet the applicable duct leakage requirements with the system operating in return air mode (Figure 4-42).

2. CFVCS must be HERS verified for airflow (CFM) and fan efficacy (w/CFM), demonstrating an efficacy of no more than 0.45 watts/CFM for furnaces, 0.58 W/CFM for heat pumps, and 0.62W/CFM for small duct, high velocity systems.

3. In addition to sensing temperature at the thermostat, the CFVCS must have an outdoor temperature sensor to initiate and terminate ventilation cooling operation and a means to detect damper failure.

When applying for approval as a variable speed system, the manufacturer must also provide the documentation described in paragraphs 4, 5, and 6 below.

4. The installed fan motor is a variable-speed motor.

5. The motor is controlled in ventilation cooling mode to vary in a continuous range between full air flow (100 percent) and a minimum airflow of no more than 25 percent of full airflow.

6. The manufacturer must provide written documentation that describes how its control strategy is implemented, how the ventilation cooling fan speed is controlled, and how ventilation cooling rates are determined. The ventilation cooling rate calculation must occur within a 24-hour interval or less to ensure that the system responds in a timely manner to changes in weather patterns.

Table 4-18 shows example conversions for the calculated net free vent area (NFVA) for a range of whole-house fan airflow levels. Instead of using the table, one can calculate the NFVA by dividing the listed CFM by 750.

Source: California Energy Commission

Since attic vents present some level of airflow restriction, use the appropriate screen and louver reduction factor from Table 4-19.

|

Vent Type |

Reduction Factor |

|

¼” screen (hardware cloth) |

0.90 |

|

¼” screen with metal louvers |

0.75 |

|

¼” screen with wood louvers |

0.25 |

|

Insect screen (mesh under ¼”) |

0.50 |

|

Insect screen with metal louvers |

0.50 |

|

¼” screen with wood louvers |

0.25 |

Source: California Energy Commission

Example 4-43

Required vent area = Minimum Attic NFVA (Table 4-18) ÷ Reduction Factor

A 3,000 CFM fan is selected from the Energy Commission Appliance Database. The builder plans to use vents with ¼” screen with metal louvers.

Answer

The minimum required vent area is = 4.0 ÷ 0.90 = 4.4 ft2

Example 4-44 – Ventilation Cooling

Question:

I am building a 2,350 ft2 house in Climate Zone 8. Do I need to install a whole-house fan or central fan ventilation system?

Answer:

Yes, if you are complying prescriptively.

No, if you are complying using the performance method and no whole-house fan was modeled.

Whole-house fans are a prescriptive requirement in Climate Zones 8-14, meaning that they are not mandatory, although they define the prescriptive compliance level. If you decide to install a whole-house fan to meet the prescriptive requirement, you should select a fan from the Energy Commission Appliance Database. The prescriptive requirement specifies a minimum airflow of 1.5 CFM/ft2 (3,525 CFM for the proposed house) and 1 ft2 of attic net free ventilation area per 750 CFM of airflow (4.7 ft2 for a 3,525 CFM fan).

Example 4-45

Question:

Why do I need to provide attic ventilation area for a whole-house fan?

Answer:

Whole-house fans move a lot of air from inside the dwelling unit, all of which is exhausted to the attic. Without sufficient attic relief to the outdoors, the fan will move less air.

Example 4-46

Question:

What are the advantages and disadvantages of whole-house fans relative to central fan ventilation cooling systems?

Answer:

Whole-house fans are relatively inexpensive; both in first cost and operating cost, and are highly effective if used properly in the right climate. They move much more air than central fan systems, which must deliver air through the duct system. Whole-house fans may be noisy, require user operation to open windows, turn on and off, bring in dust and allergens from outside, and potentially reduce home security if windows are left open throughout the night. Central fan systems are more expensive and generally move less air, but provide totally automated operation, independent of whether the occupant is home. Windows can remain shut, and all outdoor air is filtered. Some central fan systems may also be configured to provide ventilation that complies with the whole-dwelling indoor air quality requirements in §150.0(o). Review product literature to determine if available products meet the Energy Commission’s fresh air ventilation requirements.

Example 4-47

Question:

A two-story home with 2,500 sf of conditioned space and an attic is located in Climate Zone 10. Is a whole-house fan required? Does this affect the number of vents in the attic?

Answer:

Yes, if complying prescriptively. Section 150.1(c)12 requires whole-house fans (WHF) in single-family houses that are in Climate Zones 8-14. These are climate zones that have summer cooling needs but where the home can be efficiently cooled on cool summer evenings by the use of a whole-house fan.

Section 150.1(c)12 also requires that these fans be sized so they provide at least 1.5 cubic feet per minute (CFM) of flow for each square foot of conditioned space in the house. The fans used must be listed in the Energy Commission’s Appliance Database (http://appliances.energy.ca.gov/QuickSearch.aspx) and the rated CFM listed on the CF2R-MCH-02 form. In addition, the attic must have at least 1 sf of attic vent free area for each 750 CFM of whole-house fan-rated flow.

Thus, for this house with 2,500 sf of conditioned floor area, the minimum total flow rate of whole-house fans installed in the house must be at least:

Min WHF flow rate = Conditioned Floor Area x 1.5 CFM/sf = 2,500 sf x 1.5 CFM/sf = 3,750 CFM.

In this case, the builder has selected two 2,000 CFM whole-house fans. The minimum amount of vent net-free area in the attic is calculated as follows:

Net Free Area = Total WHF CFM / (750 CFM/sf NFA) = (2,000 + 2,000) / 750 = 5.3 sf