RA3.3 contains procedures for:

(a) Verification of improved system airflow rate (cfm) in ducted split system and packaged space conditioning systems serving low-rise residential buildings.

(b) Verification of reduced fan power (Watt) draw achieved through improved air distribution system design, including more efficient motors and ducts that have less resistance to airflow.

(c) Determination of fan efficacy (Watt/cfm) utilizing simultaneous measurement of system Watt draw and airflow rate.

The instrumentation for the diagnostic measurements shall conform to the following specifications:

RA3.3.1.1 Pressure Measurements

All pressure measurements shall be performed with measurement systems (i.e., sensor plus data acquisition system) having an accuracy of ± 1% of pressure reading or ± 0.2 Pa (.0008 inches water) (whichever is greater). All pressure measurements within the duct system shall be made with static pressure probes such as Dwyer A303 or equivalent.

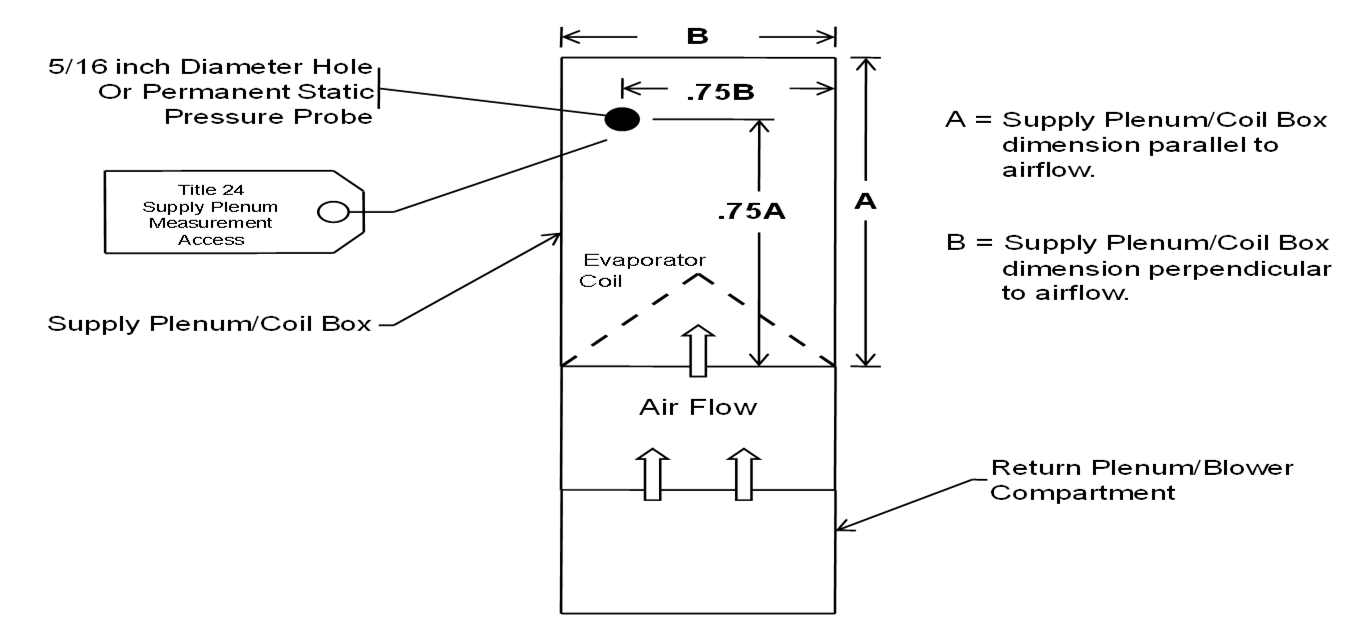

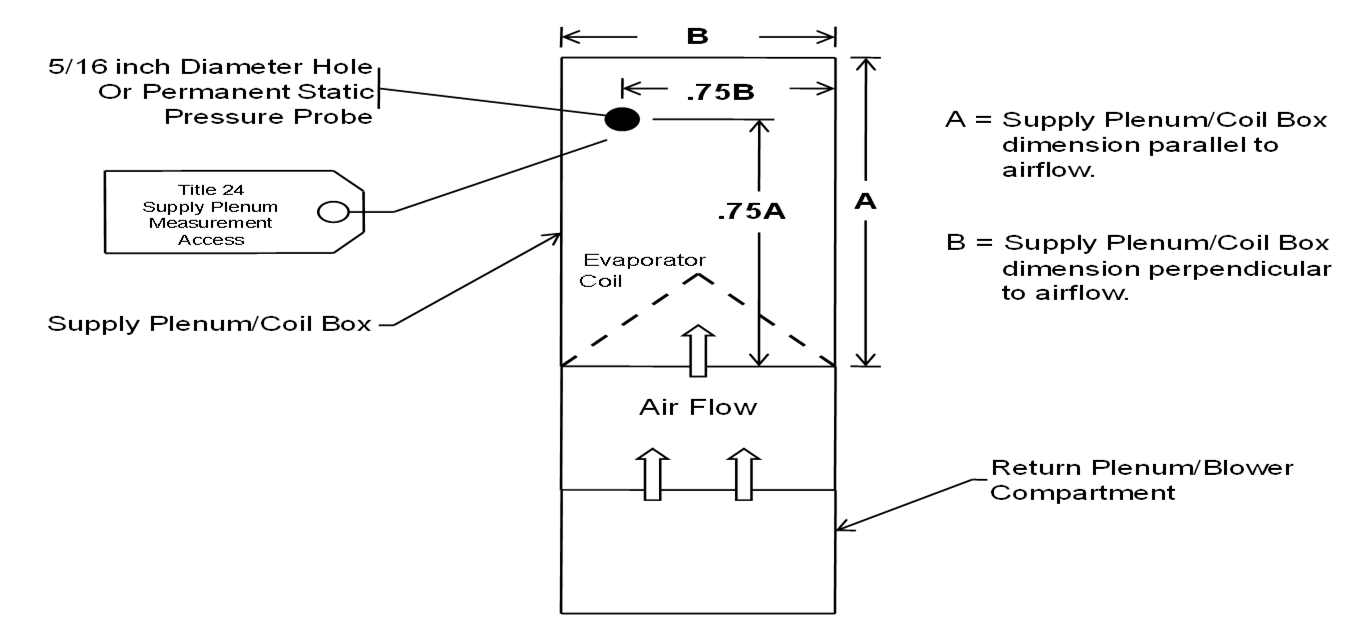

When required for compliance with Standards Section 150.0(m)13A, or when supply plenum pressure measurements are used for plenum pressure matching or flow grid measurements, a 5/16 inch (8 mm) diameter hole for a static pressure probe (HSPP) or a permanently affixed static pressure probe (PSPP) shall be provided as shown in Figure RA3.3-1.

When supply plenum pressure measurements are used for plenum pressure matching or flow grid measurements, the supply plenum pressure measurement shall be taken at the supply plenum measurement access location as shown in Figure RA3.3-1.

The hole location shown in Figure RA3.3-1 can be applied to any one of the four sides of the coil box or supply plenum. The hole location shall be labeled "Title 24 – Supply Plenum Measurement Access" in at least 12-point type.

Systems that cannot conform to the specifications for the hole location shown in Figure RA3.3-1 shall not be required to have holes as described in Figure RA3.3-1; however if supply plenum pressure measurements are required for compliance, an alternate location that provides access for making an accurate supply plenum pressure measurement shall be used.

RA3.3.1.2 Airflow Rate Measurements

All measurements of system airflow rates shall be made with an airflow rate measurement apparatus (i.e., sensor plus data acquisition system) having an accuracy of ± 7% of reading or ± 5 cfm whichever is greater.

RA3.3.1.3 Fan Watt Draw Measurements

All measurements of air handler Watt draws shall be made with true power measurement systems (i.e., sensor plus data acquisition system) having an accuracy of ± 2% of reading or ± 10 watts whichever is greater.

RA3.3.2.1 System Airflow Rate Measurement Apparatus

Forced air system airflow rate shall be measured using one of the apparatuses 'listed in Section RA3.3.2. The apparatus shall produce airflow rate measurements that conform to the accuracy requirements specified in Section RA3.3.1.2 for measurements of residential forced air system airflow at system return grilles of single and multiple return duct systems.

The airflow rate measurement apparatus manufacturers shall publish in their product documentation, specifications for how their airflow measurement apparatuses are to be used for accurately measuring residential system airflow at system return grilles of single and multiple return duct systems.

The airflow measurement apparatus manufacturers shall certify to the Energy Commission that use of the apparatus in accordance with the specifications given in the manufacturer's product documentation will produce measurement results that are within the accuracy required by Section RA3.3.1.2.

For the airflow measurement apparatuses that are certified to the Commission as meeting the accuracy required by Section RA3.3.1.2, the following information will be posted on the Energy Commission website, making the information available to all people involved in the airflow verification compliance process:

(a) The product manufacturers' model numbers for the airflow measurement apparatuses.

(b) The product manufacturers' product documentation that gives the specifications for use of the airflow measurement apparatuses to accurately measure residential system airflow at system return grilles of single and multiple return duct systems.

A manufacturer's certification to the Commission of the accuracy of the airflow measurement apparatus, and submittal to the Commission of the product documentation that specifies the proper use of the airflow measurement apparatus to produce accurate airflow rate measurements shall be prerequisites for allowing the manufacturer's airflow measurement apparatus to be used for conducting the system airflow verification procedures in Section RA3.3 for demonstrating compliance with Part 6.

The apparatus for measuring the system airflow rate shall consist of a duct pressurization and airflow measurement device (subsequently referred to as a fan flowmeter) that meets all applicable instrumentation specifications in Section RA3.3.1, and a static pressure measurement device that meets the specifications in Section RA3.3.1.1. The fan flowmeter shall be attached at the inlet to a return duct from the conditioned space. If the system is not a multi-zoned automatic dampered system, the fan flowmeter may be attached at the air handler blower compartment door as an alternative to placement at the inlet to a return duct from conditioned space. The fan flowmeter shall be attached at a point where all the airflow through the system will flow through it. When the air handler blower compartment door attachment alternative is used, an air barrier must be placed between the return duct system and the air handler inlet(s). All registers shall be in their normal operating condition. The static pressure probe shall be fixed to the supply plenum at the location specified in Section RA3.3.1.1 so that it is not moved during this test.

The apparatus for measuring the system airflow rate shall consist of a flow measurement device (subsequently referred to as a flow grid) that meets all applicable instrumentation specifications in RA3.3.1 and a digital pressure measurement device that meets the specifications in Section RA3.3.1.1. The flow grid shall be attached at a point where all the fan airflow will flow through the flow grid. All registers shall be in their normal operating condition. The static pressure probe shall be fixed to the supply plenum at the location specified in Section RA3.3.1.1 so that it is not moved during this test.

A powered and pressure balanced flow capture hood (subsequently referred to as a Powered Flow Hood) that has the capability to balance the flow capture static pressure difference between the room and the flow capture hood enclosure to 0.0 ± 0.2 Pa (.0008 inches water) and meets the applicable instrumentation specifications in Section RA3.3.1 may be used to verify the system airflow rate at the return grille(s) if the powered flow hood has a flow capture area at least as large as the return grille in all dimensions. The fan adjustment needed to balance the flow capture static pressure difference between the room and the flow capture hood enclosure to 0.0 ± 0.2 Pa (.0008 inches water) shall be provided by either an automatic control or a manual control operated in accordance with the apparatus manufacturer's instructions specified in the manufacturer's product documentation. All supply registers shall be in their normal operating position. Measurement(s) shall be taken at the return grille(s).

A traditional flow capture hood meeting the applicable instrumentation specifications in Section RA3.3.1 may be used to verify the system airflow rate at the return grille(s) if the device has a capture area at least as large as the return grille in all dimensions. All registers shall be in their normal operating position. Measurement(s) shall be taken at the return grille(s).

RA3.3.2.2 Air Handler Watt Draw Measurement Apparatus

The air handler watt draw shall be measured using one of the following apparatuses.

The apparatus for measuring the air handler watt draw shall consist of a wattmeter meeting the applicable instrumentation specifications in RA3.3.1. The measuring device shall be attached to measure the air handler fan watt draw. All registers and blower access panel(s) shall be in their normal operating condition.

When required to measure fan watt draw in packaged and heat pump units, it is recommended to use portable true power clamp-on meters to provide flexibility for isolating the correct fan wires serving in packaged or heat pump units. Note: Higher voltage clamp-on meters may be required for packaged and heat pump units

The apparatus for measuring the air handler watt draw shall consist of the utility revenue meter meeting the applicable instrumentation specifications in RA3.3.1 and a stopwatch that provides measurements in units of seconds. All registers and blower access panel(s) shall be in their normal operating condition.

The apparatus for measuring the air handler watt draw shall consist of the digital utility revenue meter meeting the applicable instrumentation specifications in RA3.3.1 that provides direct digital display of the Watt draw. All registers and blower access panel(s) shall be in their normal operating condition.

RA3.3.3.1 System Airflow Rate Measurement Procedures

When required for compliance, the installed system's airflow shall be diagnostically tested using one of the methods specified in this section.

For systems utilizing an intentional ducted ventilation airflow from outside the conditioned space into the return system, the outside airflow may be included in the system airflow if that flow occurs in all operating modes of the HVAC system.

Diagnostic system airflow rate measurement values shall be converted to fan cfm/ton by dividing the measured system airflow rate (Qah) by the nominal tons of condensing unit cooling capacity for the air conditioner.

The measured airflow rate shall be expressed in cubic feet per minute of standard air (standard air has a density of 0.075 lb/ft³). When the airflow measurement is made at altitudes significantly different from sea level or at temperatures significantly different from 70°F, the airflow indicated on the device gauge may differ from the standard CFM by as much as 15 percent. Corrections from indicated to standard CFM shall be made using the procedure specified by the airflow measurement device manufacturer.

This system airflow measurement shall be performed using the following procedures:

(a) If the fan flowmeter is to be connected to the air handler outside the conditioned space, then the door or access panel between the conditioned space and the air handler location shall be opened.

(b) With the system fan on at the maximum speed used in the installation (the cooling speed when air conditioning is present), measure the pressure difference (in Pa) between the supply plenum and the conditioned space (Psp). Psp is the target pressure to be maintained during the system airflow tests. Place the pressure probe in the Supply Pressure Measurement Location described in Section RA3.3.1.1. Adjust the probe to achieve the highest pressure and then firmly attach the probe to ensure that it does not move during the system airflow test.

(c) If the fan flowmeter is to be connected to the air handler at the access, block the return duct system from the plenum upstream of the air handler fan and the fan flowmeter. Filters are often located in an ideal location for this blockage.

(d) Attach the fan flowmeter to the duct system at the inlet to one return duct from the conditioned space with the grille and filter removed (if there is more than one system return grille, block off all return grilles other than the one used for this measurement. Alternatively the fan flowmeter may be placed at the air handler.

(e) Turn on the system fan and the fan flowmeter, adjust the fan flowmeter until the pressure between supply plenum and conditioned space matches Psp.

(f) Record the flow through the fan flowmeter (Qah, cfm) - this is the diagnostic system airflow. In some systems, system fan and fan flowmeter combinations may not be able to produce enough flow to reach Psp. In this case record the maximum flow (Qmax, cfm) and pressure (Pmax) between the supply plenum and the conditioned space. The following equation shall be used to correct measured system flow and pressure (Qmax and Pmax) to operating condition at operating pressure (Psp).

Equation RA3.3-1 Air Handler Flow

Qah = Qmax x (Psp/Pmax) ^0.5

The system airflow measurement shall be performed using the following procedures:

(a) With the system fan on at the maximum speed used in the installation (the cooling speed when air conditioning is present), measure the pressure difference (in Pa) between the supply plenum and the conditioned space (Psp). Place the pressure probe in the Supply Pressure Measurement Location described in Section RA3.3.1.1. Adjust the probe to achieve the highest pressure and then firmly attach the probe to ensure that it does not move during the system airflow test.

(b) The flow grid shall be attached at a point where all the system air flows through the flow grid. If there are multiple return grilles in the duct system, flow grids may be used to measure airflow at the return grilles, but only by installing a flow grid in each return grill and making simultaneous measurements of all return grill airflows.

(c) Re-measure the system operating pressure with the flow grid in place.

(d) Measure the airflow through the flow grid (Qgrid) and the test pressure (Ptest). If multiple flow grids are used Qgrid is the sum of the flows through each of the flow grids.

(e) The following equation for air handler flow shall be used to correct flow through the flow grid and pressure (Qgrid and Ptest) to operating condition at operating pressure (Psp).

Equation RA3.3-2 Air Handler Flow

Qah = Qgrid x (Psp/Ptest) ^0.5

The system airflow measurement shall be performed using the following procedures; all registers shall be fully open, and the air filter shall be installed. Turn on the system fan at the cooling speed and measure the airflow at the return grille(s) with a calibrated powered flow hood to determine the total system return airflow. Operation of the powered flow hood shall conform to the specifications in the manufacturer's product documentation. For multiple return systems, the total system return airflow (Qah, cfm) shall be the sum of the airflow measurements at each of the system's return grilles.

The system airflow measurement shall be performed using the following procedures; all registers shall be fully open, and the air filter shall be installed. Turn on the system fan at the cooling speed and measure the airflow at the return grille(s) with a calibrated traditional flow capture hood to determine the total system return airflow. For multiple return systems, the total system return airflow (Qah, cfm) shall be the sum of the airflow measurements at each of the system's return grilles.

When an altered space conditioning system fails to demonstrate compliance with the required 300 cfm per nominal ton of RA3.3.3.3, the system shall perform the remedial actions listed, in Section RA3.3.3.4. If these remedial actions fail to bring the system into compliance with the 300 cfm per nominal condensing unit ton airflow requirement of RA3.3.3.3, the installer shall complete the refrigerant charge verification utilizing the best airflow rate attainable. The system shall be considered in compliance if the installer certifies that the following corrective measures have been performed:

The installer shall attempt to correct non-compliant system airflow by performing the following remedial actions:

a) Check to determine that the air filter media is clean. If the air filter media is dirty, then replace it with clean filter media.

b) Open all registers and dampers and remove any obstructions.

c) Replace crushed, blocked or restricted ducts if possible.

d) Check to determine that the evaporator coil is clean, or that there are no obstructions to airflow through the evaporator coil. If the evaporator coil is dirty or blocked with debris, if possible, clean the evaporator coil using a method approved by the manufacturer.

e) Set the air handler fan to high speed for cooling, and ensure that the blower wheel and motor are operating properly, within manufacturer’s specifications.

f) Check to determine whether the return duct system or return filter grille is sized too small for the installed system. If the return duct or return grille is sized too small, if possible, perform applicable alterations work on the return duct system or return grille in order to improve the system airflow rate.

When performing these remedial actions determines that there is a fault, a corrective action shall be performed if possible. In many cases, airflow can be improved by adding a return duct and filter grille, or enlarging the existing return duct or filter grille. Alteration of the return duct system is an alternative that shall be considered if applicable to the existing system, and if other remedial actions do not improve the airflow. Alteration of the return duct system to bring the system airflow rate into compliance is expected to be attainable for systems with ducts in an attic space with sufficient clearances for accommodating improvements to the return duct system.

For each of the listed remedial actions, the HVAC installer shall certify that the remedial action was performed, and indicate whether the action was completed successfully or was not completed successfully. When a remedial action was not completed successfully the installer shall indicate on the installation certificate the reason the action was not completed successfully.

The HERS Rater shall review the information submitted on the installation certificate and perform follow-up communications with the HVAC installer or the homeowner. The system complies if the HERS Rater determines the remedial actions have been performed, and the information reported on the installation certificate is valid.

RA3.3.3.2 Air Handler Fan Watt Draw Measurement Procedures

The diagnostic air handler watt draw shall be measured using one of the following methods:

The air handler watt draw measurement shall be performed using the following procedures; all registers shall be fully open, and the air filter shall be installed. Turn on the system fan at the maximum speed used in the installation (usually the cooling speed when air conditioning is present; usually the cooling speed with outdoor air introduction if ventilation is provided through the return duct system) and measure the fan watt draw (Wfan).

When required to measure fan watt draw in packaged and heat pump units, it is recommended to use portable true power clamp-on meters to provide flexibility for isolating the correct fan wires serving in packaged or heat pump units. Note: Higher voltage clamp-on meters may be required for packaged and heat pump units

The air handler watt draw measurement shall be performed using the following procedures; all registers shall be fully open, and the air filter shall be installed. Turn on the system fan at the maximum speed used in the installation (usually the cooling speed when air conditioning is present; usually the cooling speed with outdoor air introduction if ventilation is provided through the return duct system) and turn off every circuit breaker except the one exclusively serving the air handler. Record the Kh factor on the revenue meter, count the number of full revolutions of the meter wheel over a period exceeding 90 seconds. Record the number of revolutions (Nrev) and time period (trev, seconds). Compute the air handler watt draw (Wfan) using the following formula:

Equation RA3.3-3 Air Handler Fan Watt Draw

Wfan = (Kh x Nrev x 3600) / trev

Return all circuit breakers to their original positions.

The air handler watt draw measurement shall be performed using the following procedures; all registers shall be fully open, and the air filter shall be installed. Turn on the system fan at the maximum speed used in the installation (usually the cooling speed when air conditioning is present; usually the cooling speed with outdoor air introduction if ventilation is provided through the return duct system) and turn off every circuit breaker except the one exclusively serving the air handler. Read the Watt draw from the digital utility meter digital display. Return all circuit breakers to their original positions.

RA3.3.3.3 Determination of Forced Air System Fan Efficacy

Demonstrating compliance with fan efficacy requirements requires simultaneous measurement of the system airflow rate using Section RA3.3.4.1procedures and fan Watt draw using Section RA3.3.2 procedures. The results of the simultaneous airflow rate and fan Watt draw measurements are used for calculation of a value for the forced air system fan efficacy as follows:

(a) The measured value for fan Watt draw (Watt) shall be divided by the measured value for airflow rate (cfm) to determine the fan efficacy (Watt/cfm).

RA3.3.3.4 Determining Compliance with Fan Efficacy or System Airflow Requirements

Compliance with the requirements for improved airflow or for improved fan efficacy both require simultaneous measurement of airflow and fan Watts. The simultaneous measurements shall be used to calculate the following values used to determine compliance:

The measured value for airflow (cfm) shall be converted to cfm per ton by dividing the measured system airflow rate by the nominal tons of condensing unit cooling capacity for the air conditioner.

The measured value for fan Watt draw (Watt) shall be divided by the measured value for airflow rate (cfm) to determine the fan efficacy (Watt/cfm).

In order to comply with either the fan efficacy requirement, or the system airflow requirement, the following criteria shall be met:

(a) The system airflow (cfm/ton) shall meet or exceed the system airflow compliance criteria specified in the Standards or on the Certificate of Compliance as applicable.

(b) The calculated value for fan efficacy (Watt/cfm) shall be equal to or less than the fan efficacy compliance criterion specified in the Standards or on the Certificate of Compliance as applicable.