Only materials approved by the Commission may be used in defining constructions. Additional materials may be added to the Compliance Manager. Table 2-4 shows the materials currently available for construction assemblies.

|

Material Name |

Thickness (in.) |

Conductivity (Btu/h-°F-ft) |

Coefficient for Temperature Adjustment of Conductivity (°F(-1)) |

Specific Heat (Btu/ |

Density (lb/ft3) |

per Inch (°F-ft2-h/ |

|

Gypsum Board |

0.5 |

0.09167 |

0.27 |

40 |

0.9091 | |

|

Wood layer |

0.5 |

0.06127 |

0.45 |

41 |

1.36 | |

|

R4 Synth Stucco |

1 |

0.02083 |

0.00418 |

0.35 |

1.5 |

4 |

|

3 Coat Stucco |

0.875 |

0.4167 |

0.2 |

116 |

0.2 | |

|

Carpet |

0.5 |

0.02 |

0.34 |

12.3 |

4.1667 | |

|

Light Roof |

0.2 |

1 |

0.2 |

120 |

0.0833 | |

|

5 PSF Roof |

0.5 |

1 |

0.2 |

120 |

0.0833 | |

|

10 PSF Roof |

1 |

1 |

0.2 |

120 |

0.0833 | |

|

15 PSF Roof |

1.5 |

1 |

0.2 |

120 |

0.0833 | |

|

25 PSF Roof |

2.5 |

1 |

0.2 |

120 |

0.0833 | |

|

TileGap |

0.75 |

0.07353 |

0.24 |

0.075 |

1.1333 | |

|

SlabOnGrade |

3.5 |

1 |

0.2 |

144 |

0.0833 | |

|

Earth |

1 |

0.2 |

115 |

0.0833 | ||

|

Crawl |

12 |

0.16667 |

0.24 |

0.075 |

0.5 | |

|

SoftWood |

0.08167 |

0.39 |

35 |

1.0204 | ||

|

Concrete |

1 |

0.2 |

144 |

0.0833 | ||

|

R1 Sheathing |

1 |

0.08333 |

0.00418 |

0.35 |

1.5 |

1 |

|

R2 Sheathing |

1 |

0.04167 |

0.00418 |

0.35 |

1.5 |

2 |

|

R3 Sheathing |

1 |

0.02778 |

0.00418 |

0.35 |

1.5 |

3 |

|

R4 Sheathing |

1 |

0.02083 |

0.00418 |

0.35 |

1.5 |

4 |

|

R5 Sheathing |

1 |

0.01667 |

0.00418 |

0.35 |

1.5 |

5 |

|

R6 Sheathing |

1 |

0.01389 |

0.00418 |

0.35 |

1.5 |

6 |

|

R7 Sheathing |

1 |

0.0119 |

0.00418 |

0.35 |

1.5 |

7 |

|

R8 Sheathing |

1 |

0.01042 |

0.00418 |

0.35 |

1.5 |

8 |

Material Name

The material name is used to select the material for a construction.

Thickness

Some materials, such as 3-coat stucco, are defined with a specific thickness (not editable by the compliance user). The thickness of other materials, such as softwood used for framing, is selected by the compliance user based on the constructions in the building.

Conductivity

The conductivity of the material is the steady state heat flow per square foot, per foot of thickness, per degree Fahrenheit temperature difference. It is used in simulating the heat flow in the construction.

Coefficient for Temperature Adjustment of Conductivity

The conductivity of insulation materials varies hourly with their temperature according to the coefficient listed. Other materials have a coefficient of 0 and their conductivity does not vary with temperature.

Specific Heat

The specific heat is the amount of heat in Btu it takes to raise the temperature of one pound of the material one degree Fahrenheit.

Density

The density of the material is its weight in pounds per cubic foot.

R-value per inch

The R-value is the resistance to heat flow for a 1-inch thick layer.

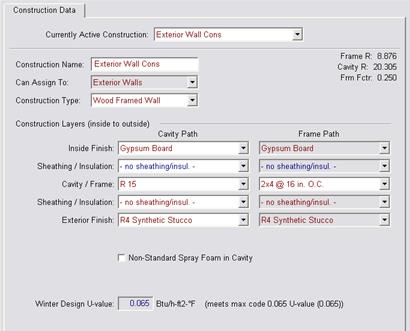

Constructions are defined by the compliance user for use in defining the building. The user assembles a construction from one or more layers of materials as shown in Figure 2-3. For framed constructions there is a framing layer that has parallel paths for the framing and the cavity between the framing members. The layers that are allowed depend on the surface type. The Compliance Manager calculates a winter design U-factor which is compared to a construction that meets the prescriptive standard. The U-factor is displayed as an aid to the user. The calculations used in the energy simulation are based on each individual layer and framing rather than the U-factor.

Assembly Types

The types of assemblies are:

Exterior wall

Interior

wall

Demising wall

Knee wall

Attic roof

Cathedral roof

Ceiling below attic

Interior

floor

Exterior floor (over unconditioned space or

exterior)

Floor over crawl space

Construction Type:

1. Ceiling below attic (the roof structure is not defined here, but is part of the attic), wood or metal framed. In a residence with a truss roof, the ceiling is where the insulation is located. The structure above that is encompassed by the term attic or roof deck. The roof or attic consists of (moving from inside to outside) the radiant barrier, below deck insulation, framing, above deck insulation, and the asphalt, tile roofing. See more in Section 2.4.5.

2. Cathedral ceiling (with the roof defined as part of the assembly), wood or metal framed. Since there is no attic, the roof structure is connected to the insulated assembly at this point.

3. Roof, structurally insulated panels (SIP).

4. Walls (interior, or exterior), wood or metal framed, or SIP.

5. Floors (over exterior, over crawl space, or interior).

Construction Layers:

All assemblies have a cavity path and a frame path.

Spray foam insulation may use either default values with no special inspection requirements, or higher values when supported by an ICC report (see details Section 2.3.3 and RA3.5) verified by a HERS rater.

As assemblies are completed, the screen displays whether the construction meets the prescriptive requirement for that component.

Proposed Design

The user defines a construction for each surface type included in the proposed design. Any variation in insulation R-value, framing size or spacing, interior or exterior sheathing or interior or exterior finish requires the user to define a different construction. Insulation R-values are based on manufacturer’s rated properties rounded to the nearest whole R. Layers such as sheetrock, wood sheathing, stucco and carpet whose properties are not compliance variables are included as generic layers with standard thickness and properties.

Walls separating the house from an attached unconditioned attic or garage are modeled as interior walls with unconditioned space as the adjacent zone, which the compliance manager recognizes as a demising wall. Floors over a garage are modeled as floor over exterior. The exterior walls, floor, ceiling/roof of the garage are modeled as part of the unconditioned garage zone.

Standard Design

The compliance software assembles a construction that meets the prescriptive standards for each user-defined construction or assembly.

Verification and Reporting

All proposed constructions, including insulation, frame type, frame size, and exterior finish or exterior condition are listed on the CF1R. Non-standard framing (e.g., 24” on center wall framing, advanced wall framing) is reported as a special feature.

The R-values for spray applied polyurethane foam insulation differs depending on whether the product is open cell or closed cell.

|

Required R-values for SPF insulation |

R-11 |

R-13 |

R-15 |

R-19 |

R-21 |

R-22 |

R-25 |

R-30 |

R-38 |

|

Required thickness closed cell @ R5.8/inch |

2.00 |

2.25 |

2.75 |

3.50 |

3.75 |

4.00 |

4.50 |

5.25 |

6.75 |

|

Required thickness open cell @ R3.6/inch |

3.0 |

3.5 |

4.2 |

5.3 |

5.8 |

6.1 |

6.9 |

8.3 |

10.6

|

Additional documentation and verification requirements for a value other than default values shown in Table 2-5 is required (see RA3.5.6).

2.3.3.1 Medium Density Closed-Cell SPF Insulation

The default R-value for spray foam insulation with a closed cellular structure is R-5.8 per inch, based on the installed nominal thickness of insulation. Closed cell insulation has an installed nominal density of 1.5 to less than 2.5 pcf.

2.3.3.2 Low Density Open-Cell SPF Insulation

The default R-value for spray foam insulation with an open cellular structure is calculated as an R-3.6 per inch, calculated based on the nominal required thickness of insulation. Open cell insulation has an installed nominal density of 0.4 to 1.5 pounds per cubic foot (pcf).

Proposed Design

The user will select either typical values for open cell or closed cell spray foam insulation or higher than typical values, and enter the total R-value (rounded to the nearest whole value).

Standard Design

The compliance software assembles a construction that meets the prescriptive standards for each assembly type (ceiling/roof, wall, and floor).

Verification and Reporting

When the user elects to use higher than typical R-values for open cell or closed cell spray foam insulation, a special features note is included on the CF1R requiring documentation requirements specified in RA4.1.7. Additionally, a HERS verification requirement for the installation of spray foam insulation using higher than default values is included on the CF1R.