Water heating energy use is an important end use in low-rise residential buildings. Roughly 90 percent of California households use natural gas fueled water heaters, typically atmospheric gas storage units with tank volumes of 40 to 50 gallons. Roughly 6% of households use electricity to heat water and a few percent use propane (liquefied petroleum gas, or LPG). Standby loss associated with the center flue design represents about 25-35% of a typical gas storage water heater system's annual energy use.

The electricity generation system is comprised of a variety of generation plants including fossil fueled (natural gas and coal), nuclear, hydroelectric, solar, and wind. Approximately two-thirds of the source energy used to produce the electricity is lost in the generation, transmission, and distribution processes. Historically this has played into Title 24’s decision to base the water heating budget on the more “source energy” efficient gas water heating system. The Standards require water heating systems to account for hourly usage impacts of the overall efficiency of each fuel type in the form of Time Dependent Valuation (TDV). Natural gas fired system are used as the reference TDV for water heating, except where natural gas is not available which in those cases, in which cases propane is the reference case. Since electric TDV is much higher (per unit of energy content) than gas, electric resistance water heating is essentially precluded unless it is used in conjunction with an adequately sized solar water heating system. One electrical option which can comply with the standards is heat pump water heaters.

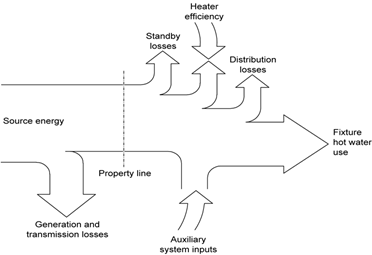

Figure 5-1 below shows the energy flows that constitute water heating energy usage. On the right hand side, hot water draws at the end use points represents the useful energy consumed. Hot water that is actually used typically represents the largest fraction of water heating energy use, although in situations with very small draws, standby losses from the typical gas storage water heater can exceed the end use. Distribution system associated energy impacts vary widely based on the type of system, quality of installation, house design, and hot water use patterns. Typical single family water heating system distribution losses may amount to up to 30 percent of energy consumed, while compact single family distribution systems may be less than 10 percent. Multifamily water heating system distribution losses can exceed 30 percent. The heating device must meet this recovery load (end use plus distribution losses) minus any contribution from auxiliary heat inputs, such as a solar thermal system. Total building water heating energy use is comprised of the end use, heater inefficiencies, standby loss, and distribution system inefficiencies.

The key changes in water heating code from 2013 are 'listed below and are distinguished between two cases: one or more water heaters serving a single dwelling unit, and a central multi-family design where one or more water heaters serves many dwelling units:

One or more water heating systems serving a single dwelling unit (includes single family homes and dedicated water heating systems serving a single dwelling unit in multi-family and hotel/motel buildings).

1. New Mandatory Requirements:

a. A 120 V electrical receptacle that is within three feet of the water heater and accessible to the water heater with no obstructions; and,

b. A Category III or IV vent, or a Type B vent with straight pipe between the outside termination and the space where the water heater is installed; and,

c. A condensate drain that is no more than 2 inches higher than the base of the installed water heater, and allows natural draining without pump assistance, and,

d. A gas supply line with a capacity of to provide at least 200,000 Btu/hr to the water heater.

2. New Prescriptive Requirements:

a. Increased solar water heating requirement for electric resistance water heating systems. Under the 2013 standards, the minimum solar thermal water heating system size has increased from a solar savings fraction (SSF) of 25% to at least 50%.

3. New Performance Compliance Options:

a. The Point of Use Distribution multiplier now applies to systems with water heaters no more than (5 feet of ¾ inch), (10 feet of ½ inch), or (15 feet of 3/8 inch) of pipe from any point of use are acceptable alternatives. Distances are measured in plan view, allowing for water heaters on either the first or second floor to serve points located on the floor above or below, hence ignoring the direct vertical length of pipe from the water heater. This measure requires HERS verification.

b. HERS verified Compact Distribution System credit has been added as a new compliance option credit. The furthest hot water use point from the water heater must be field-measured and shown to be within a prescribed distance from the water heater. This measure requires HERS verification

c. Additional optional HERS verification elements have been added to offer credits for verified quality pipe insulation installation on both recirculating and non-recirculating distribution systems. This measure requires HERS verification.

d. Central home run manifold systems located within 5 feet of the water heater will receive a small compliance credit. This measure requires HERS verification.

Multi-family central distribution systems (One or more central water heaters serving multiple dwelling units):

1. New Mandatory Requirements:

a. Dwelling unit pipe insulation is now required on all hot water distribution piping greater than ¾ inch diameter, as well as all piping from the water heater to the kitchen. For central multi-family systems, all piping in the recirculation loop must be insulated. This requirement applies to the distribution to each dwelling unit.

2. New Prescriptive Requirements:

a. Demand recirculation controls are the default basis of the performance energy budget for buildings with central recirculation systems.

b. Solar water heating is required for all climate zones. The required solar savings fractions are either 20% or 35%, depending on the climate zone.

c. Water heating recirculation systems are required to be designed with two recirculation loops. This measure must be HERS verified to ensure that two sets of recirculation loops are put in place from either the same or separate water heating equipment. Buildings with 8 units or less are not required to meet this requirement

3. New Performance Compliance Options:

While demand recirculation controls are the basis of the performance energy budget, both temperature modulation controls and time clock controls can be used for performance compliance. Using temperature modulation controls will require additional energy efficiency measures to offset higher energy consumption due to higher recirculation loop pipe heat loss than those for demand controls. Using time clock controls will require even more efficiency measures to offset relatively high heat losses from recirculation loops using this control strategy.

More detailed recirculation piping system design information, including number of recirculation loops, pipe lengths, diameters, and locations, is required to properly calculate energy consumption due to recirculation pipe heat loss. The prescriptive requirement is to install two recirculation loops, connected to the same or separate water heating equipment. These installation requirements are not applicable to central system serving 8 or fewer units. If just one recirculation loop is used, pipes need to be sized according to hot water demand of all dwelling units. As a result, larger pipes than those in dual loop systems have to be installed, which lead to larger pipe surface area and higher heat loss. Dual recirculation loop designs have to be verified by a HERS rater in order to receive the compliance credit. Systems with more than two recirculation loops will NOT be given additional compliance credit.

In 'addition to the dual recirculation loop requirement, the Standard also incorporates a performance calculation method to verify user input of recirculation designs. Energy budget of the recirculation system is determined based on an optimized recirculation system design with two recirculation loops and optimized pipe routing. The performance calculation method also generates a default design based on best practices, which is not as good as the optimized design. Both the optimized design and the default design are generated according to building characteristics such as floor area, number of dwelling units, and number of storied. The default design can be used for compliance to avoid providing detailed recirculation system design information. However, note that the default design uses more energy than what is established by the energy budget and, therefore, requires other efficiency measures to make up the difference. A dual loop design with HERS verification is the only possible compliance option to match the performance of the optimized design, For all other user-input designs, the total pipe surface area will be adjusted to match that of the default (best practice) design, if it is smaller.