The Standards now include many additional requirements for residential swimming pool filtration equipment which affect pump selection and flow rate, piping and fittings, and filter selection. These new Standards are designed to reduce the energy used to filter and maintain the clarity and sanitation of pool water.

Before any pool or spa heating system or equipment may be installed, the manufacturer must certify to the Energy Commission that the system or equipment complies with §110.4 and §110.5. The requirements include minimum heating efficiency according to Appliance Efficiency Regulations, an on-off switch outside the heater, permanent and weatherproof operating instructions, no continuous pilot light, and no electric resistance heating (see exceptions below).

Pool and spa heaters may not have continuously burning pilot lights.

Outdoor pools and spas with gas or electric heaters shall have a cover installed. The cover should be fitted and installed during the final inspection.

There are two exceptions for electric heaters, which may be installed for:

a. Listed package units with fully insulated enclosures (e.g., hot tubs), and with tight-fitting covers, insulated to at least R-6.

b. Pools or spas getting 60 percent or more of their annual heating from site solar energy or recovered energy.

1. Pool Pump Requirements

For maximum energy efficiency, pool filtration should be operated at the lowest possible flow rate for a time period that provides sufficient water turnover for clarity and sanitation. Auxiliary pool loads that require high flow rates such as spas, pool cleaners, and water features, should be operated separately from the filtration to allow the filtration flow rate to be kept to a minimum.

All pumps and pump motors shall comply with the specifications of the Appliance Efficiency Regulations.

The pool filtration flow rate may not be greater than the rate needed to turn over the pool water volume in 6 hours or 36 gpm, whichever is greater. This means that for pools of less than 13,000 gallons the pump must be sized to have a flow rate of less than 36 gpm and for pools of greater than 13,000 gallons, the pump must be sized using the following equation:

Max Flow Rate (gpm) = Pool

Volume (gallons)

360min.

These are maximum flow rates. Lower flow rates and longer filtration times are encouraged and will result in added energy savings.

Pools with auxiliary pool loads must use either a multi-speed pump or a separate pump for each auxiliary pool load. For example, if a spa shares the pool filtration system, either a multi-speed pump must be used or a separate pump must be provided to operate the spa. If the pool system can be served by one pump of less than 1 total-hp in capacity, the pump may be single speed.

Filtration pump motors with a capacity of 1 total-hp or more must be multi-speed.

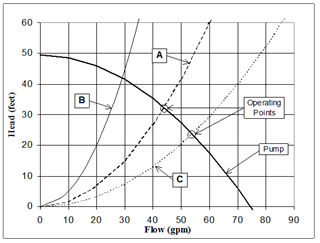

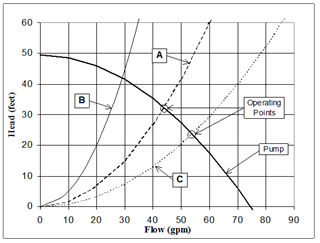

All pool pumps sold in California must be tested and listed with the Energy Commission according to the Appliance Efficiency Regulations. Pump manufacturers must list flow rate, power, and energy factor at each of three system curves (see Figure 5-14). For pools equal to or less than 17,000 gallons, a pump must be chosen such that the flow rate listed for Curve A is less than the 6-hour turnover rate. For pools greater than 17,000 gallons, a pump must be chosen such that the listed flow rate at Curve C is less than the 6-hour turnover rate.

2. Pool Pump Controls

Pool controls are a critical element of energy efficient pool design. Modern pool controls allow for auxiliary loads such as cleaning systems, solar heating, and temporary water features without compromising energy savings.

A time switch or similar control mechanism must be installed as part of the pool water circulation control system that will allow all pumps to be set or programmed to run only during the off-peak electric demand period and for the minimum time necessary to maintain the water in the condition required by applicable public health standards. Solar system that requires pumps to during peak hours must also have control mechanism installed

Multi-speed pumps must have controls that default to the filtration flow rate when no auxiliary pool loads are operating. The controls must also default to the filtration flow rate setting within 24 hours and must have a temporary override capability for servicing.

3. Pool Pipe, Filter, and Valve Requirements

System design for residential pools was introduced in 2008. Correct sizing of piping, filters, and valves reduces overall system head, reduces noise and wear, and increases energy efficiency. Other mandatory requirements include leading straight pipe into the pump, directional inlets for mixing, and piping to allow for future solar installations.

Pool piping must be sized according to the maximum flow rate needed for all auxiliary loads. The maximum velocity allowed is 8 fps in the return line and 6 fps in the suction line. Table 5-9 shows the minimum pipe sizes required by pool volume based on a 6-hour turnover filtration flow rate. These pipe sizes would need to be increased if there are auxiliary loads that operate at greater than the filtration flow rate. Conversely, they could be reduced if the pump is sized for greater than a 6-hour turnover filtration flow rate.

|

Pool Volume (gallons) |

Minimum Pipe Diameter (in) | ||

|

Min |

Max |

Return |

Suction |

|

- |

13,000 |

1.5 |

1.5 |

|

13,000 |

17,000 |

1.5 |

2.0 |

|

17,000 |

21,000 |

2.0 |

2.0 |

|

21,000 |

30,000 |

2.0 |

2.5 |

|

30,000 |

42,000 |

2.5 |

3.0 |

|

42,000 |

48,000 |

3.0 |

3.0 |

|

48,000 |

65,000 |

3.0 |

3.5 |

There must be a length of straight pipe that is greater than or equal to at least 4 inches pipe diameters installed before the pump. That is, for a 2 inch suction pump, there must be at least 8 inches of straight pipe before the pump’s strainer basket.

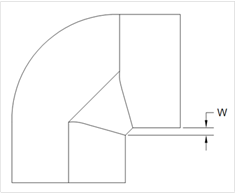

Traditional hard 90o elbows are not allowed. All elbows must be sweep elbows or a type of elbow that has a pressure drop less than the pressure drop of straight pipe with a length of 30 pipe diameters. For example, a 2 inch elbow must have a pressure drop less than a 5-foot length of 2 inch straight pipe.

Field verification of sweep elbows may be performed by checking that the distance “w” of the installed sweep elbow is greater than that for a hard 90 elbow (refer to Figure 5-15). The difference in measurement between the radial edge of one sleeve to the perpendicular side of the elbow is found to be distinct between sweep elbows and hard 90’s. There is sufficient difference in distance “w” such that all sweep elbows exceed the minimum values listed in Table 5-10.

Figure 5-15 below illustrates “w” the dimension between the elbow sleeves and Table 5-10 shows the minimum distances “w” for an acceptable sweep elbow.

|

Pipe Diameter |

Minimum W (inch) |

|

1.5 |

3/8 |

|

2 |

1/2 |

|

2.5 |

5/8 |

|

3 |

3/4 |

|

4 |

1 |

Filters shall be sized using NSF/ANSI 50 based on the maximum flow rate through the filter. The filter factors that must be used are (in ft²/gpm):

Cartridge 0.375

Sand 15

Diatomaceous Earth 2

Backwash valves must be sized to the diameter of the return pipe or two inches, whichever is greater. Multiport backwash valves have a high pressure drop and are discouraged. Low-loss slide and multiple 3-way valves can provide significant savings.

The pool must have directional inlets to adequately mix the pool water.

If a pool does not currently use solar water heating, piping must be installed to accommodate any future installation. Contractors can choose three options to allow for the future 'addition of solar heating equipment:

1. Provide at least 36 inches of pipe between the filter and the heater to allow for the future 'addition of solar heating equipment.

2. Plumb separate suction and return lines to the pool dedicated to future solar heating.

3. Install built-up or built-in connections for future piping to solar water heating. An example of this would be a capped off tee fitting.

Example 5-11 - Pool covers

Question

My pool has both a solar heater and a gas heater. Do I need to install a pool cover?

Answer

Yes. A cover is required for all pools with gas or electric heaters, regardless of whether they also have a solar heater.

Example 5-12 - Pool pump

Question

I have a 25,000 gallon pool and want to use a two-speed pump with a Curve C flow rate of 79 gpm on high-speed and 39 gpm on low-speed. Is this okay and what size piping must I installed?

Answer

The maximum filtration flow rate for a 25,000 gallon pool is 69 gpm by using equation [Max Flow Rate (gpm) =Pool Volume (gallons) / 360 minutes], so the pump is adequately sized, as long as a control is installed to operate the pump on low-speed for filtration. The maximum pipe size must be based on the maximum flow rate of 79 gpm. Referencing Table 5-9, you must use 2.5 inch suction and 2 inch return piping.