Boiler Name

Applicability

All boilers

Definition

A unique descriptor for each boiler, heat pump, central heating heat-exchanger or heat recovery device.

Units

None

Input Restrictions

User entry. Where applicable, this should match the tags that are used on the plans for the proposed design.

Standard Design

Boilers are only designated in the baseline model if the Baseline System type uses hot water for space heating.

Boiler Fuel Source

Applicability

All boilers

Definition

The fuel source for the central heating equipment. The choices are:

•Gas

•Oil

•Electricity

Units

List (see above)

Input Restrictions

As designed

This input is restricted, based on the choice of Boiler Type, according to the following rules:

|

|

Electricity |

Gas |

Steam |

|

Steam Boiler |

|

|

Allowed |

|

Hot Water Boiler |

|

Allowed |

|

Standard Design

Gas

Boiler Type

Applicability

All boilers

Definition

The boiler type. Choices include:

•Steam Boiler

•Hot Water Boiler

•Heat-Pump Water Heater

Units

List (see above)

Input Restrictions

As designed

Standard Design

Hot water boiler

Boiler Draft Type

Applicability

All boilers

Definition

How combustion airflow is drawn through the boiler. Choices are:

•Natural (sometimes called atmospheric)

•Mechanical

Natural draft boilers use natural convection to draw air for combustion through the boiler. Natural draft boilers are subject to outside air conditions and the temperature of the flue gases.

Mechanical draft boilers enhance the air flow in one of three ways: 1) Induced draft, which uses ambient air, a steam jet, or a fan to induce a negative pressure which pulls flow through the exhaust stack; 2) Forced draft, which uses a fan and ductwork to create a positive pressure that forces air into the furnace, and 3) Balanced draft, which uses both induced draft and forced draft methods to bring air through the furnace, usually keeping the pressure slightly below atmospheric.

Units

List (see above)

Input Restrictions

As designed.

Standard Design

Mechanical (forced).

Number of Identical Boiler Units

Applicability

All boilers

Definition

The number of identical units for staging

Units

Numeric: integer

Input Restrictions

As designed. Default is 1.

Standard Design

The baseline building shall have one boiler for a when the baseline plant serves a conditioned floor area of 15,000 ft2 or less, and have two equally size boilers for plants serving more than 15,000 ft2.

Boiler Design Capacity

Applicability

All boilers

Definition

The heating capacity at design conditions

Units

Btu/h

Input Restrictions

As designed. If unmet load hours shall not exceed 150, see Section 2.6.1.for how the software handles undersized systems.

Standard Design

The boiler is sized to be 25% larger than the peak loads of the baseline building. Baseline boilers shall be sized using weather files containing 99.6% heating design temperatures and 0.5% dry-bulb and 1% wet-bulb cooling design temperatures.

Boiler Efficiency Type

Applicability

All boilers

Definition

The full load efficiency of a boiler is expressed as one of the following:

•Annual Fuel Utilization Efficiency (AFUE) is a measure of the boiler’s efficiency over a predefined heating season.

•Thermal Efficiency (Et) is the ratio of the heat transferred to the water divided by the heat input of the fuel.

•Combustion Efficiency (Ec) is the measure of how much energy is extracted from the fuel and is the ratio of heat transferred to the combustion air divided by the heat input of the fuel.

Units

List (see above)

Input Restrictions

None

Standard Design

Same as proposed design

Boiler Efficiency

Applicability

All boilers

Definition

The full load efficiency of a boiler at rated conditions (see efficiency type above) expressed as a dimensionless ratio of output over input. The software must accommodate input in either Thermal Efficiency (Et), Combustion Efficiency (Ec) or Annual Fuel Utilization Efficiency (AFUE). The software shall make appropriate conversions to thermal efficiency if either AFUE or combustion efficiency is entered as the rated efficiency.

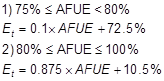

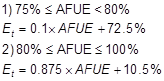

Where AFUE is provided, Et shall be calculated as follows:

(45)

All electric boilers will have an efficiency of 100%.

If combustion efficiency is entered, the compliance software shall convert the efficiency to thermal efficiency by the relation:

Et = Ec – 0.015

Units

Ratio

Input Restrictions

As designed

Standard Design

Boilers for the baseline design are assumed to have the minimum efficiency as 'listed in Table E-4 of the 2009 CEC Appliance Efficiency Standards.

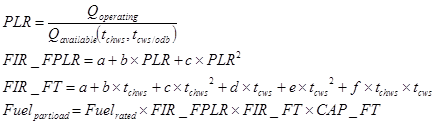

Boiler Part-Load Performance Curve

Applicability

All boilers

Definition

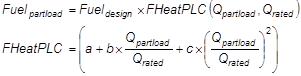

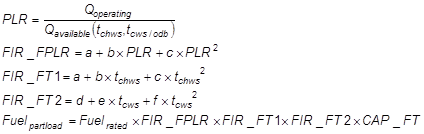

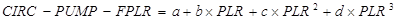

An adjustment factor that represents the percentage full load fuel consumption as a function of the percentage full load capacity. This curve shall take the form of a quadratic equation as follows:

(46)

where

FHeatPLC The Fuel Heating Part Load Efficiency Curve

Fuelpartload The fuel consumption at part load conditions (Btu/h)

Fuel design The fuel consumption at design conditions (Btu/h)

Qpartload The boiler capacity at part load conditions (Btu/h)

Qrated The boiler capacity at design conditions (Btu/h)

a Constant

b Constant

c Constant

Units

Ratio

Input Restrictions

Prescribed to the part-load performance curve in ACM Appendix 5.7, based on the Boiler Draft Type.

Standard Design

The baseline building uses the mechanical draft fan curve in Appendix 5.7.

Boiler Forced Draft Fan Power

Applicability

All mechanical draft boilers

Definition

The fan power of the mechanical draft fan at design conditions.

Units

Nameplate Horsepower

Input Restrictions

As designed.

The software shall convert the user entry of motor HP to fan power in Watts by the following equation:

Fan Power = Motor HP x 746 x 0.5

Standard Design

Sized for an energy input ratio of 0.001018.(0.2984 W per kBtu/h heat input).

Boiler Minimum Unloading Ratio

Applicability

All boilers

Definition

The minimum unloading capacity of a boiler expressed as a percentage of the rated capacity. Below this level the boiler must cycle to meet the load.

Units

Percent (%)

Input Restrictions

As designed. If the user does not use the default value the software must indicate that supporting documentation is required on the output forms. Fixed at 1% (this accounts for jacket losses and start/stop losses).

Standard Design

1%

Boiler Minimum Flow Rate

Applicability

All boilers

Definition

The minimum flow rate recommended by the boiler manufacturer for stable and reliable operation of the boiler.

Units

gpm

Input Restrictions

As designed.

If the boiler(s) is piped in a primary only configuration in a variable flow system then the software shall assume there is a minimum flow bypass valve that allows the HW pump to bypass water from the boiler outlet back to the boiler inlet to maintain the minimum flow rate when boiler is enabled. Note that the boiler entering water temperature must accurately reflect the mixed temperature (colder water returning from the coil(s) and hotter bypass water) in order to accurately model boiler efficiency as a function of boiler entering water temperature.

Standard Design

0 gpm

Hot Water Supply Temperature

Applicability

All boilers

Definition

The temperature of the water produced by the boiler and supplied to the hot water loop

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed

Standard Design

Use 180°F for baseline boiler

Hot Water Return Temperature

Applicability

All boilers

Definition

The temperature of the water returning to the boiler from the hot water loop

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed

Standard Design

Use 140°F for baseline boiler design.

Hot Water Supply Temperature Reset

Applicability

All boilers

Definition

Variation of the hot water supply temperature with outdoor air temperature.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed (Not allowed for non-condensing boilers)

Standard Design

The hot water supply temperature should vary according to the following:

180°F when outside air is < 20°F

ramp linearly between 180°F & 150°F when outdoor air is between 20°F and 50°F

150°F when outdoor air is > 50°F

Not applicable

Chiller Name

Applicability

All chillers

Definition

A unique descriptor for each chiller

Units

Text, unique

Input Restrictions

User entry. Where applicable, this should match the tags that are used on the plans.

Standard Design

Chillers are only designated when the baseline system uses chilled water

Chiller Type

Applicability

All chillers

Definition

The type of chiller, either a vapor-compression chiller or an absorption chiller.

Vapor compression chillers operate on the reverse-Rankine cycle, using mechanical energy to compress the refrigerant, and include:

•Reciprocating*

•Scroll*

•Screw*

•Centrifugal – uses rotating impeller blades to compress the air and impart velocity

•Direct Fired Single Effect Absorption – use a single generator & condenser

•Direct Fired Double Effect Absorption – use two generators/concentrators and condensers, one at a lower temperature and the other at a higher temperature. It is more efficient than the single effect, but it must use a higher temperature heat source.

•Indirect Fired Double Effect Absorption

•Gas Engine Driven

* Positive displacement – includes reciprocating (piston-style), scroll and screw compressors

Units

List (see above) The software shall support all chiller types 'listed above

Input Restrictions

As designed

Standard Design

The baseline building chiller is based on the design capacity of the standard design (baseline) as follows:

|

Building Peak Cooling Load |

Number and Type of Chiller(s) |

|

|

|

|

<= 300 tons |

1 water-cooled screw chiller |

|

>300 tons, < 600 tons |

2 water-cooled screw chillers, sized equally |

|

>= 600 tons |

A minimum of two (2) water-cooled centrifugal chillers, sized to keep the unit size below 800 tons |

Number of Identical Chiller Units

Applicability

All chillers

Definition

The number of identical units for staging.

Units

None

Input Restrictions

As designed. Default is 1.

Standard Design

From Table 47 above.

Chiller Fuel Source

Applicability

All chillers

Definition

The fuel source for the chiller. The choices are:

•Electricity (for all vapor-compression chillers)

•Gas (Absorption units only, designated as direct-fired units)

•Hot Water (Absorption units only, designated as indirect-fired units)

•Steam (Absorption units only, designated as indirect-fired units)

Units

List (see above)

Input Restrictions

As designed.

This input is restricted, based on the choice of Chiller Type, according to the following rules:

|

|

Electricity |

Gas |

Hot Water |

Steam |

|

Reciprocating |

allowed |

|

|

|

|

Scroll |

Allowed |

|

|

|

|

Screw |

Allowed |

|

|

|

|

Centrifugal |

Allowed |

|

|

|

|

Single Effect Absorption |

|

Allowed |

Allowed |

Allowed |

|

Direct Fired Double Effect Absorption |

|

Allowed |

Allowed |

Allowed |

|

Indirect Fired Absorption |

|

Allowed |

Allowed |

Allowed |

Standard Design

Electricity

Chiller Rated Capacity

Applicability

All chillers

Definition

The cooling capacity of a piece of heating equipment at rated conditions.

Units

Btu/h or tons

Input Restrictions

As designed. If unmet load hours are greater than 150 for any zone served by the chiller, the user must follow procedures outlined in Section 2.6.1|topic=2.6.1 Specifying HVAC Capacities for the Proposed Design to address undersized systems.

Standard Design

Determine loads for baseline building and oversize by 15%.

Chiller Rated Efficiency

Applicability

All chillers

Definition

The Efficiency of the chiller (Energy Efficiency Ratio (EER) for air-cooled chillers, kW/ton for water-cooled electric chillers and COP for fuel-fired and heat-driven chillers) at AHRI 550/590 rated full-load conditions.

Units

Ratio (kW/ton, COP, EER, depending on Chiller Type and Condenser Type)

Water-cooled electric chiller: kW/ton

Air-cooled or evaporatively cooled electric chiller: EER

All non-electric chillers: COP

Input Restrictions

As designed. Must meet the minimum requirements of Table 110.2-D.

Standard Design

Use the minimum efficiency requirements from Tables 110.2-D Path B.

If Chiller Type is Reciprocating, Scroll or Screw, use the efficiency for Positive Displacement chillers from Table 110.2-D.

Integrated Part-Load Value

Applicability

All chillers

Definition

The part-load efficiency of a chiller developed from a weighted average of four rating conditions, according to AHRI Standard 550.

Units

Ratio (kW/ton, COP, EER, depending on Chiller Type and Condenser Type)

Water-cooled electric chiller: kW/ton

Air-cooled or evaporatively cooled electric chiller: EER

All non-electric chillers: COP

Input Restrictions

As designed. Must meet the minimum requirements of Table 110.2-D.

Standard Design

Not used. When the standard design system has a chiller, the standard design will always use Path B performance curves.

Chiller Minimum Unloading Ratio

Applicability

All chillers

Definition

The minimum unloading capacity of a chiller expressed as a fraction of the rated capacity. Below this level the chiller must either cycle to meet the load or false-load the compressor (such as with hot gas bypass).

|

Chiller Type |

Default Unloading Ratio |

|

Reciprocating |

25% |

|

Screw |

15% |

|

Centrifugal |

10% |

|

Scroll |

25% |

|

Single Effect Absorption |

10% |

|

Double Effect Absorption |

10% |

Units

Percent (%)

Input Restrictions

As designed, but constrained to a minimum value of 10%.. If the user does not employ the default values, supporting documentation is required.

Standard Design

Use defaults 'listed above.

Chiller Minimum Part Load Ratio

Applicability

All chillers

Definition

The minimum unloading capacity of a chiller expressed as a fraction of the rated capacity. Below this level the chiller must cycle to meet the load. If the chiller minimum part-load ratio (PLR) is less than the chiller minimum unloading ratio, then the compliance software shall assume hot gas bypass operation between the minimum PLR and the minimum unloading ratio.

Units

Percent (%)

Input Restrictions

As designed, but constrained to a minimum value of 10%.. If the user does not employ the default values, supporting documentation is required.

Standard Design

When the standard design has a screw chiller, the minimum part load ratio is 15%. When the standard design has a centrifugal chiller, the minimum part load ratio is 10%.

Chiller Cooling Capacity Adjustment Curve

Applicability

All chillers

Definition

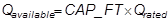

A curve or group of curves or other functions that represent the available total cooling capacity as a function of evaporator and condenser conditions and perhaps other operating conditions. The default curves are given as follows:

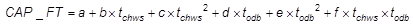

(47)

For air-cooled chillers:

(48)

For water-cooled chillers:

(49)

where

Qavailable Available cooling capacity at present evaporator and condenser conditions (MBH)

tchws The chilled water supply temperature (°F)

tcws The condenser water supply temperature (°F)

todb The outside air dry-bulb temperature (°F)

Qrated Rated capacity at AHRI conditions (MBH)

Note: If an air-cooled unit employs an evaporative condenser, todb is the effective dry-bulb temperature of the air leaving the evaporative cooling unit.

Separate curves are provided for Path A and Path B chillers in Appendix 5.7.

Units

Data structure

Input Restrictions

Prescribed curves are provided in Appendix 5.7 for the proposed design chiller type and the compliance path (Path A or Path B).. If the default curves are overridden, supporting documentation is required.

Standard Design

Use prescribed curve for Path B chiller as applicable to the standard design chiller type.

Electric Chiller Cooling Efficiency Adjustment Curves

Applicability

All chillers

Definition

A curve or group of curves that varies the cooling efficiency of an electric chiller as a function of evaporator conditions, condenser conditions and part-load ratio. Note that for variable-speed chillers, the part-load cooling efficiency curve is a function of both part-load ratio and leaving condenser water temperature. The default curves are given as follows:

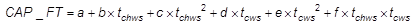

(50)

where

PLR Part load ratio based on available capacity (not rated capacity)

Qoperating Present load on chiller (Btu/h)

Qavailable Chiller available capacity at present evaporator and condenser conditions (Btu/h)

tchws The chilled water supply temperature (°F)

tcws The condenser water supply temperature (°F)

todb The outside air dry-bulb temperature (°F)

Prated Rated power draw at AHRI conditions (kW)

Poperating Power draw at specified operating conditions (kW)

Note: If an air-cooled chiller employs an evaporative condenser, todb is the effective dry-bulb temperature of the air leaving the evaporative cooling unit.

Units

Data structure

Input Restrictions

Curves are prescribed in Appendix 5.7 given the chiller capacity and type. A separate set of curves is be provided for Path A chillers and Path B chillers. The Path is determined by comparing software inputs of full-load efficiency and integrated part-load value with the requirements of Standards Table 110.2-D.

Standard Design

Use Path B curves specified in Appendix 5.7.

Fuel and Steam Chiller Cooling Efficiency Adjustment Curves

Applicability

All chillers

Definition

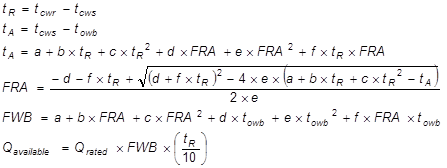

A curve or group of curves that varies the cooling efficiency of a fuel-fired or steam chiller as a function of evaporator conditions, condenser conditions, and part-load ratio. The default curves are given as follows:

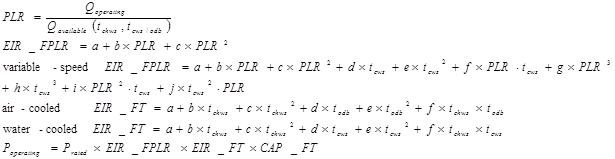

Default Curves for Steam-Driven Single and Double Effect Absorption Chillers

(51)

Default Curves for Direct-Fired Double Effect Absorption Chillers

(52)

The default curves for engine driven chillers are the same format as those for the Steam-Driven Single and Double Effect Absorption Chillers but there are three sets of curves for different ranges of operation based on the engine speed.

where

PLR Part load ratio based on available capacity (not rated capacity)

FIR-FPLR A multiplier on the fuel input ratio (FIR) to account for part load conditions

FIR-FT A multiplier on the fuel input ratio (FIR) to account for the chiller water supply temperature and the condenser water temperature

FIR-FT1 A multiplier on the fuel input ratio (FIR) to account for chilled water supply temperature

FIR-FT2 A multiplier on the fuel input ratio (FIR) to account for condenser water supply temperature

CAP-FT A multiplier on the capacity of the chiller (see Equation (48))

Qoperating Present load on chiller (in Btu/h)

Qavailable Chiller available capacity at present evaporator and condenser conditions (in Btu/h)

tchws The chilled water supply temperature (in °F)

tcws The condenser water supply temperature (in °F)

todb The outside air dry-bulb temperature (°F)

Fuelrated Rated fuel consumption at AHRI conditions (in Btu/h)

Fuelpartload Fuel consumption at specified operating conditions (in Btu/h)

Units

Data structure

Input Restrictions

Restricted to curves specified in Appendix 5.7.

Standard Design

Use prescribed curves specified in Appendix 5.7

Chilled Water Supply Temperature

Applicability

All chillers

Definition

The chilled water supply temperature of the chiller at design conditions

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed

Standard Design

The baseline chilled water supply temperature is set to 44°F.

Chilled Water Return Temperature

Applicability

All chillers

Definition

The chilled water return temperature setpoint at design conditions

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed

Standard Design

The standard design chilled water return temperature is set to 64°F.

Chilled Water Supply Temperature Control Type

Applicability

All chillers

Definition

The method by which the chilled water setpoint temperature is reset. The chilled water setpoint may be reset based on demand or outdoor air temperature.

Units

List

None

Outside air-based reset

Demand-based reset

Input Restrictions

As designed.

Standard Design

Outside-air based reset

Chilled Water Supply Temperature Reset

Applicability

All chillers

Definition

The reset schedule for the chilled water supply temperature. The chilled water setpoint may be reset based on demand or outdoor air temperature.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed.

Standard Design

10°F from design chilled water supply temperature

The chilled water supply temperature reset follows an outside-air reset scheme, where the setpoint is 44F at outside air conditions of 80F dry-bulb and above, the setpoint is 54F at outside air conditions of 60F dry-bulb and below, and ramps linearly from 44F to 54F as the outside air dry-bulb temperature varies between 80F and 60F.

Condenser Type

Applicability

All chillers

Definition

The type of condenser for a chiller. The choices are:

•Air-Cooled

•Water-Cooled

•Evaporatively-Cooled

Air-cooled chillers use air to cool the condenser coils. Water-cooled chillers use cold water to cool the condenser and additionally need either a cooling tower or a local source of cold water. Evaporatively-cooled chillers are similar to air-cooled chillers, except they use a water mist to cool the condenser coil which makes them more efficient.

Units

List (see above)

Input Restrictions

As designed

Standard Design

The baseline chiller is always assumed to have a water-cooled condenser, although the chiller type will change depending on the design capacity.

Standard Design Summary. Standard Design system 6 has one or more cooling towers. One tower is assumed to be matched to each standard design chiller. Each standard design chiller has its own condenser water pump that operates when the chiller is brought into service. The range between the condenser water return (CWR) and condenser water supply (CWS) is 10 F. The baseline building condenser pumping energy is assumed to be 12 W/gpm. The cooling tower is assumed to have a variable-speed fan that is controlled to provide a CWS equal to the design wet-bulb temperature when weather permits. The design approach shall be 10°F.

Cooling Tower Name

Applicability

All cooling towers

Definition

A unique descriptor for each cooling tower

Units

Text, unique

Input Restrictions

User entry. Where applicable, this should match the tags that are used on the plans.

Standard Design

Descriptive name that keys the baseline building plant

Cooling Tower Type

Applicability

All cooling towers

Definition

The type of cooling tower employed. The choices are:

•Open tower, centrifugal fan

•Open tower, axial fan

Open cooling towers collect the cooled water from the tower and pump it directly back to the cooling system. Closed towers circulate the evaporated water over a heat exchanger to indirectly cool the system fluid.

Units

List (see above)

Input Restrictions

As designed

Standard Design

The baseline cooling tower is an open tower axial fan device

Cooling Tower Capacity

Applicability

All cooling towers

Definition

The tower thermal capacity per cell adjusted to CTI (Cooling Technology Institute) rated conditions of 95 °F condenser water return, 85 °F condenser water supply, and 78 °F wet-bulb with a 3 gpm/nominal ton water flow. The default cooling tower curves below are at unity at these conditions.

Units

Btu/h

Input Restrictions

As designed

Standard Design

The baseline building chiller is autosized and increased by 15%. The tower is sized to supply 85 °F condenser water at design conditions for the oversized chiller.

Cooling Tower Number of Cells

Applicability

All cooling towers

Definition

The number of cells in the cooling tower. Each cell will be modeled as equal size. Cells are subdivisions in cooling towers into individual cells, each with their own fan and water flow, and allow the cooling system to respond more efficiently to lower load conditions.

Units

Numeric: integer

Input Restrictions

As designed

Standard Design

One cell per tower and one tower per chiller.

Cooling Tower Total Fan Horse Power

Applicability

All cooling towers

Definition

The sum of the nameplate rated horsepower (hp) of all fan motors on the cooling tower. Pony motors should not be included.

Units

Gpm/hp or unitless if energy input ratio (EIR) is specified (If the nominal tons but not the condenser water flow is specified, the condenser design water flow shall be 3.0 gpm per nominal cooling ton.)

Input Restrictions

As designed, but the cooling towers shall meet minimum performance requirements in Table 110.2-G.

Standard Design

The cooling tower fan horsepower is 60 gpm/hp.

Cooling Tower Design Wet-Bulb

Applicability

All cooling towers

Definition

The design wet-bulb temperature that was used for selection and sizing of the cooling tower.

Units

Degrees Fahrenheit (°F)

Input Restrictions

Specified from design wet-bulb conditions from Reference Appendix JA2 for the city where the building is located, or the city closest to where the building is located.

Standard Design

Specified from design wet-bulb conditions from Reference Appendix JA2 for the city where the building is located, or from the city closest to where the building is located.

Cooling Tower Design Entering Water Temperature

Applicability

All cooling towers

Definition

The design condenser water supply temperature (leaving tower) that was used for selection and sizing of the cooling tower.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed. Default to 85°F.

Standard Design

85°F or 10°F above the design wet-bulb temperature, whichever is lower

Cooling Tower Design Return Water Temperature

Applicability

All cooling towers

Definition

The design condenser water return temperature (entering tower) that was used for selection and sizing of the cooling tower.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed. Default to 95°F.

Standard Design

Set to a range of 10 F (10°F above the cooling tower design entering water temperature.

Cooling Tower Capacity Adjustment Curve(s)

Applicability

All cooling towers

Definition

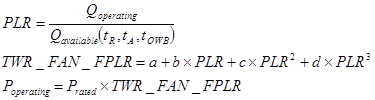

A curve or group of curves that represent the available total cooling capacity as a function of outdoor air wet-bulb, condenser water supply and condenser water return temperatures. The default curves are given as follows:

Option 1 (DOE-2 based performance curves)

(53)

Where

Qavailable Available cooling capacity at present outside air and condenser water conditions (MBH)

Qrated Rated cooling capacity at CTI test conditions (MBH)

tcws The condenser water supply temperature (in °F)

tcwr The condenser water return temperature (in °F)

towb The outside air wet-bulb temperature (°F)

tR The tower range (in °F)

tA The tower approach (in °F)

FRA An intermediate capacity curve based on range and approach

FWB The ratio of available capacity to rated capacity (gpm/gpm).

Option 2: CoolTools performance curve (EnergyPlus)

Approach = Coeff(1) + Coeff(2)•FRair + Coeff(3)•(FRair)2 +Coeff(4)•(FRair)3 + Coeff(5)•FRwater + Coeff(6)•FRair•FRwater + Coeff(7)•(FRair)2•FRwater + Coeff(8)•(FRwater)2 + Coeff(9)•FRair•(FRwater)2 +

Coeff(10)•(FRwater)3 + Coeff(11)•Twb + Coeff(12)•FRair•Twb + Coeff(13)•(FRair)2•Twb + Coeff(14)•FRwater•Twb + Coeff(15)•FRair•FRwater•Twb + Coeff(16)•(FRwater)2•Twb +

Coeff(17)•(Twb)2 + Coeff(18)•FRair•(Twb)2 + Coeff(19)•FRwater•(Twb)2 + Coeff(20)•(Twb)3 + Coeff(21)•Tr + Coeff(22)•FRair•Tr + Coeff(23)•FRair•FRair•Tr + Coeff(24)•FRwater•Tr + Coeff(25)•FRair•FRwater•Tr +

Coeff(26)•(FRwater)2•Tr + Coeff(27)•Twb•Tr + Coeff(28)•FRair•Twb•Tr + Coeff(29)•FRwater•Twb•Tr +

Coeff(30)•(Twb)2•Tr + Coeff(31)•(Tr)2 + Coeff(32)•FRair•(Tr)2 + Coeff(33)•FRwater•(Tr)2 + Coeff(34)•Twb•(Tr)2 + Coeff(35)•(Tr)3

Where

FRair – ratio of airflow to airflow at design conditions

FRwater – ratio of water flow to water flow at design conditions

Tr – tower range (deg F)

Twb – wet-bulb temperature

Coefficients for this performance curve are provided in Appendix 5.7.

Data structure

Input Restrictions

User may only use one of the two curves specified in Appendix 5.7.

Standard Design

Use one of the prescribed curves defined in Appendix 5.7.

Cooling Tower Set Point Control

Applicability

All cooling towers

Definition

The type of control for the condenser water supply. The choices are:

•Fixed

•Wet-bulb reset

A fixed control will modulate the tower fans to provide the design condenser water supply temperature at all times when possible. A wet-bulb reset control will reset the condenser water setpoint to a fixed approach to outside air wet-bulb temperature. The approach defaults to 10°F. A lower approach may be used with appropriate documentation.

Units

List (see above)

Input Restrictions

As designed.

Standard Design

Fixed at the 0.4% design wet-bulb temperature, which is prescribed and specified for each of the 86 weather data files

Cooling Tower Capacity Control

Applicability

All cooling towers

Definition

Describes the modulation control employed in the cooling tower. Choices include:

•Fluid Bypass provides a parallel path to divert some of the condenser water around the cooling tower at part-load conditions

•Fan Cycling is a simple method of capacity control where the tower fan is cycled on and off. This is and is often used on multiple-cell installations.

•Two-Speed Fan/Pony Motor. From an energy perspective, these are the same. A lower horsepower pony motor is an alternative to a two-speed motor; the pony motor runs at part-load conditions (instead of the full sized motor) and saves fan energy when the tower load is reduced. Additional building descriptors are triggered when this method of capacity control is selected.

•Variable Speed Fan. A variable frequency drive is installed for the tower fan so that the speed can be modulated.

Units

List (see above)

Input Restrictions

As designed.

Standard Design

Variable-speed fan

Cooling Tower Low-Speed Airflow Ratio

Applicability

All cooling towers with two-speed or pony motors

Definition

The percentage full load airflow that the tower has at low speed or with the pony motor operating. This is equivalent to the percentage full load capacity when operating at low speed.

Units

Ratio

Input Restrictions

As designed.

Standard Design

Not applicable

Cooling Tower Low-Speed kW Ratio

Applicability

All cooling towers with two-speed or pony motors

Definition

The percentage full load power that the tower fans draw at low speed or with the pony motor operating

Units

Ratio

Input Restrictions

Calculated, using the as-designed flow ratio and the cooling tower power adjustment curve below

Standard Design

Not applicable

Cooling Tower Power Adjustment Curve

Applicability

All cooling towers with VSD control

Definition

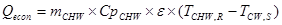

A curve that varies the cooling tower fan energy usage as a function of part-load ratio for cooling towers with variable speed fan control. The default curve is given as follows:

(54)

where

PLR Part load ratio based on available capacity (not rated capacity)

Qoperating Present load on tower (in Btu/h)

Qavailable Tower available capacity at present range, approach, and outside wet-bulb conditions (in Btu/h).

towb The outside air wet-bulb temperature (°F)

tR The tower range (°F)

tA The tower approach (°F)

Prated Rated power draw at CTI conditions (kW)

Poperating Power draw at specified operating conditions (kW)

|

Coefficient |

TWR-FAN-FPLR |

|

A |

0.33162901 |

|

B |

-0.88567609 |

|

C |

0.60556507 |

|

D |

0.9484823 |

Units

Data structure

Input Restrictions

User shall use only default curves.

Standard Design

Use default curves given above.

Cooling Tower Minimum Speed

Applicability

All cooling towers with a VSD control

Definition

The minimum fan speed setting of a VSD controlling a cooling tower fan expressed as a ratio of full load speed.

Units

Ratio

Input Restrictions

As designed. The default is 0.50.

Standard Design

0.5

Baseline Building Summary. None of the baseline building systems use a water-side economizer.

Water-Side Economizer Name

Applicability

All water-side economizers

Definition

The name of a water-side economizer for a cooling system

Units

Text, unique

Input Restrictions

Descriptive reference to the construction documents. The default is no water-side economizer.

Standard Design

Water Economizer Type

Applicability

All water-side economizers

Definition

The type of water-side economizer. Choices include:

•None

•Heat exchanger in parallel with chillers. This would be used with an open cooling tower is often referred to as a non-integrated economizer, because the chillers are locked out when the plant is in economizer mode.

•Heat exchanger in series with chillers. This would be used with an open cooling tower and is often referred to as an integrated, because the chillers can operate simultaneously with water economizer operation.

•Direct water economizer. This would be used with a closed cooling tower. In this case, a heat exchanger is not needed. This type works only as a non-integrated economizer. (also known as strainer-cycle)

•Thermo-cycle (also known as refrigerant migration). With thermo-cycle, bypass valves allow for the flow to vapor refrigerant to the condenser and allow gravity flow of liquid refrigerant to the evaporator without use of the compressor. Only some chillers have this capability and capacity may be limited under this mode. There is no additional piping; the cooler water from the tower is brought directly to the chiller(s) and the chiller(s) respond by shutting down the compressor and relying on thermal forces to drive the refrigerant. This method is also known as “thermosiphon” since thermal gradients passively move refrigerant between the evaporator and condenser.

Units

List (see above)

Input Restrictions

As designed

Standard Design

No water economizer

Water-Side Economizer HX Effectiveness

Applicability

Water-side economizers with an open cooling tower

Definition

The effectiveness of a water-side heat exchanger at design conditions. This is defined as:

(55)

Where

Qecon The maximum load that the economizer can handle

mCHW The chilled water flow rate

Cp The chilled water specific heat

TCHW,R The chilled water return temperature

TCW,S Condenser water supply temperature

WSEeff The effectiveness of the water-side economizer coil

tea The entering coil air dry-bulb temperature (°F)

tla The leaving coil air dry-bulb temperature (°F)

tea The entering coil water temperature (°F)

Units

Ratio

Input Restrictions

As designed. The default is 60%.

Standard Design

No water economizer

Water-Side Economizer Operating Range

Applicability

All water-side economizers

Definition

The minimum temperature difference between the chilled water inlet to the heat exchanger and the condenser water inlet to the heat exchanger that is required to enable the water-side economizer.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed. Defaults to 4°F.

Standard Design

No water economizer

Water-Side Economizer Maximum CWS

Applicability

All water-side economizers

Definition

The control temperature (condenser water supply temperature) above which the water-side economizer is disabled.

Units

Degrees Fahrenheit (°F)

Input Restrictions

As designed. Defaults to 50°F.

Standard Design

No water economizer

Water-Side Economizer Availability Schedule

Applicability

All water-side economizers

Definition

A schedule which represents the availability of the water-side economizer

Units

Data structure: schedule, on/off

Input Restrictions

As designed

Standard Design

No water economizer

Water-Side Economizer Auxiliary kW

Applicability

Water-side economizers with an open tower

Definition

The electrical input (pumps and auxiliaries) for a dedicated pump for the chilled water side of the heat exchanger. This power is in excess of the condenser water pumps and cooling tower fans for the system during water-side economizer operation.

Units

KW or kW/ton

Input Restrictions

As designed

Standard Design

No water economizer

Baseline Building Summary. Hot water pumping in the baseline building shall be modeled as a variable flow primary only system. Two-way valves are assumed at the heating coils.

Chilled water pumping in the baseline building (system 6) is a primary system. Each chiller has its own primary and condenser water pumps that operate when the chiller is activated. For plants less than or equal to 300 tons, the secondary pump “rides the curve” for larger plants, the pump has a variable speed drive. The chilled water pump shall be variable speed and the condenser water pump shall be fixed speed.

General Notes. The building descriptors in this section are repeated for each pumping system. See the Pump Service building descriptor for a list of common pump services.

Pump Name

Applicability

All pumps

Definition

A unique descriptor for each pump

Units

Text, unique

Input Restrictions

User entry. Where applicable, this should match the tags that are used on the plans.

Standard Design

Same as the proposed design. If there is no equivalent in the proposed design, assign a sequential tag to each piece of equipment. The sequential tags should indicate the pump service as part of the descriptor (e.g. CW for condenser water, CHW for chilled water, or HHW for heating hot water).

Pump Service

Applicability

All pumps

Definition

The service for each pump. Choices include:

•Chilled water

•Chilled water (primary)

•Chilled water (secondary)

•Heating water

•Heating water (primary)

•Heating water (secondary)

•Service hot water

•Condenser water

•Loop water (for hydronic heat pumps)

Units

List (see above)

Input Restrictions

As designed

Standard Design

As needed by the baseline building system

Number of Pumps

Applicability

All pumps

Definition

The number of identical pumps in service in a particular loop, e.g. the heating hot water loop, chilled water loop, or condenser water loop

Units

Numeric: integer

Input Restrictions

As designed

Standard Design

There will be one heating hot water pump for each boiler, one chilled water pump, and one condenser water pump for each chiller.

Water Loop Design

Applicability

All pumps

Definition

The heating and cooling delivery systems can consist of a simple primary loop system, or more complicated primary/secondary loops or primary/secondary/tertiary loops.

Units

List (see above)

Input Restrictions

As designed

Standard Design

Assume primary loops only for heating hot water. For chilled water loops, a primary loop design is assumed s.

Applicability

All pumps

Definition

Software commonly models fans in one of two ways: The simple method is for the user to enter the electric power per unit of flow (W/gpm). This method is commonly used for smaller systems. A more detailed method requires a specification of the pump head, design flow, impeller and motor efficiency.

Units

List: Power-Per-Unit-Flow or Detailed

Input Restrictions

Detailed

Standard Design

Detailed for Chilled Water and Condenser Water Pumps; Power-per-unit-flow for Heating hot water and Service hot water pumps

Pump Motor Power-Per-Unit-Flow

Applicability

All proposed design pumps that use the Power-Per-Unit-Flow method.

Definition

The electric power of the pump divided by the flow at design conditions.

Units

W/gpm

Input Restrictions

As designed

Standard Design

Not applicable for chilled water and condenser water pumps; 19 W/gpm for heating hot water and service hot water pumps

Pump Motor Horsepower

Applicability

All pumps

Definition

The nameplate motor horsepower

Units

horsepower

Input Restrictions

Constrained to be a value from the following list of standard motor sizes:

A Standard Motor Size table (hp) is defined as: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 125, 150, 200

Standard Design

Not applicable

Pump Design Head

Applicability

All baseline building pumps and proposed design pumps that use the Detailed method.

Definition

The head of the pump at design flow conditions.

Units

ft of w.g.

Input Restrictions

As designed, but subject to an input restriction. The user inputs of Pump Design Head, Impeller Efficiency and Cooling Tower Design Entering Water Temperature and Cooling Tower Design Return Water Temperature shall be used to calculate the proposed brake horsepower. This shall be compared to the Pump Motor Horsepower for the next smaller motor size (MHPi-1) than the one specified by the user (MHPi).

The Proposed Design Pump Design Head shall be constrained so that the resulting brake horsepower is no smaller than 95% of the next smaller motor size:

Proposed Design bhp = min(Proposed Design bhpuser_head, 0.95 x MHPi-1)

Where

Proposed Design bhp – is the brake horsepower used in the simulation

Proposed Design bhpuser_head = the brake horsepower resulting from the user input of design head

MHPi = the Pump Motor Horsepower specified by the user

i = the index into the Standard Motor Size table for the user motor horsepower

MHPi-1 = the motor horsepower for the next smaller motor size. For example, if the user-specified Pump Motor Horsepower is 25, the next smaller motor size in the table above is 20.

Since all other user inputs that affect the proposed design brake horsepower are not modified, the Proposed Design Pump Design Head is adjusted in the same proportion as the pump brake horsepower in the equation above. If the user-entered Pump Design Head results in a brake horsepower that is at least 95% of the horsepower of the next smaller motor size, no modification of the user input is required.

Standard Design

For chilled water pumps, 40 ft plus an additional allowance of 0.03 ft/ton, but not to exceed 100 ft

For condenser water pumps, 45 ft

Impeller Efficiency

Applicability

All pumps in proposed design that use the detailed modeling method

Definition

The full load efficiency of the impeller

Units

Ratio

Input Restrictions

As designed

Standard Design

70%

Motor Efficiency

Applicability

All pumps in proposed design that use the detailed modeling method

Definition

The full load efficiency of the pump motor

Units

Ratio

Input Restrictions

As designed

Standard Design

Not applicable T The motor efficiency is taken from Table 29, using the next larger motor size than the calculated Standard Design brake horsepower.

Pump Minimum Speed

Applicability

All two-speed or variable-speed pumps

Definition

The minimum pump speed for a two-speed for variable-speed pump. For two-speed pumps this is typically 0.67 or 0.5. Note that the pump minimum speed is not necessarily the same as the minimum flow ratio, since the system head may change.

Units

Ratio

Input Restrictions

As designed

Standard Design

0.10.

Pump Minimum Flow Ratio

Applicability

Primary Chilled water pumps

Definition

The minimum fraction of design flow when the pump is operating at its minimum speed. Note that the pump minimum speed is not necessarily the same as the minimum flow ratio, since the system head may change.

Units

Ratio

Input Restrictions

As designed

Standard Design

0.3

Pump Design Flow (GPM)

Applicability

All pumps

Definition

The flow rate of the pump at design conditions. This is derived from the load, and the design supply and return temperatures.

Units

gpm or gpm/ton for condenser and primary chilled water pumps

Input Restrictions

Not a user input

Standard Design

The temperature change on the evaporator side of the chillers is 20 F (64 F less 44 F) and this equates to a flow of 1.2 gpm/ton. The temperature change on the condenser side of the chillers is 12 F, which equates to a flow of 2.0 gpm/ cooling ton. A VSD is required for heating pumps when the service area is greater than or equal to 120,000 ft². For hot water pumps servicing boilers, the flow rate in gpm shall correspond to a loop temperature drop of 40°F.

Pump Control Type

Applicability

All pumps

Definition

The type of control for the pump. Choices are:

•Fixed speed, fixed flow

•Fixed speed, variable flow (the default, with flow control via a valve)

•Two-speed

•Variable speed, variable flow

Units

None

Input Restrictions

As designed. The default is “Fixed Speed, Variable Flow” which models the action of a constant speed pump riding the curve against 2-way control valves.

Standard Design

The chilled water pumping for systems 7 and 8 is primary/secondary with variable flow. When the chilled water system has a capacity of less than 300 tons, the secondary system pumps shall ride the pump curve. When the chilled water system has a capacity of more than 300 tons, the secondary chilled water pumps shall be variable speed. Chilled water pumps used in the primary loop shall be fixed speed, fixed flow. Condenser water pumps shall be modeled as fixed speed, fixed flow.

The chilled water pumps shall be modeled as variable-speed, variable flow, and the condenser water pumps shall be modeled as fixed speed. The hot water pumps shall be modeled as fixed-speed, variable flow, riding the curve.

Pump Operation

Applicability

All pumps

Definition

The type of pump operation can be either On-Demand, Standby or Scheduled. On-Demand operation means the pumps are only pumping when their associated equipment is cycling, so chiller and condenser pumps are on when the chiller is on and the heating hot water pump operates when its associated boiler is cycling. Standby operation allows hot or chilled water to circulate through the primary loop of a primary/secondary loop system or through a reduced portion of a primary-only system, assuming the system has appropriate 3-way valves. Scheduled operation means that the pumps and their associated equipment are turned completely off according to occupancy schedules, time of year, or outside conditions. Under scheduled operation, when the systems are on they are assumed to be in On-Demand mode.

Units

List (see above)

Input Restrictions

As designed

Standard Design

The baseline system pumps are assumed to operate in On-Demand mode. The chilled water and condenser pumps are tied to the chiller operation, cycling on and off with the chiller, and the heating hot water pumps are tied to the boiler operation.

Pump Part Load Curve

Applicability

All pumps

Definition

A part-load power curve for the pump

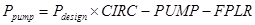

(56)

(57)

where

PLR Part load ratio (the ratio of operating flow rate in gpm to design flow rate in gpm)

Ppump Pump power draw at part-load conditions (W)

Pdesign Pump power draw at design conditions (W)

|

Default (No Reset) |

DP Reset | |

|

a |

0 |

0 |

|

b |

0.5726 |

0.0205 |

|

c |

-0.301 |

0.4101 |

|

d |

0.7347 |

0.5753 |

Source:

Units

Data structure

Input Restrictions

Default is Default (No Reset). The DP Reset curve may only be selected if the DDC Control Type building descriptor indicates that the building has DDC controls.

Standard Design

DP Reset curve for chilled water pumps. Heating Hot water pump power is assumed to be constant even though the pump is riding the curve.

There are multiple ways to model thermal storage in the proposed design. The baseline building does not have thermal storage. Stratified storage tanks with a chilled water storage medium are not supported by the ACM.

Storage Type

Applicability

All thermal storage systems

Definition

A type of thermal energy storage (TES) that indicates the storage medium.

Units

List

Input Restrictions

Ice, Chilled Water

Standard Design

No thermal storage systems

Configuration

Applicability

All thermal storage systems

Definition

Indication of how the TES is configured and operated in relation to the chilled water cooling

Units

List

Input Restrictions

Series, Chiller Upstream

Series, Chiller Downstream

Parallel

Standard Design

No thermal storage systems

Ice Storage Type

Applicability

All thermal storage systems with Storage Type=Ice

Definition

Indication of the storage type for ice storage

Units

List

Input Restrictions

IceOnCoilExternal

IceOnCoilInternal

Standard Design

No thermal storage systems

Storage Capacity

Applicability

All thermal storage systems using ice storage

Definition

Nominal Storage Capacity of the tank

Units

GJ

Input Restrictions

None

Standard Design

No thermal storage systems

Tank Volume

Applicability

All thermal storage systems using ice storage

Definition

Nominal Storage Capacity of the tank

Units

m3

Input Restrictions

None

Standard Design

No thermal storage systems

CHW Setpoint Schedule

Applicability

All thermal storage systems using ice storage

Definition

Nominal Storage Capacity of the tank

Units

Series, deg F

Input Restrictions

None

Standard Design

No thermal storage systems

Deadband Temperature Difference

Applicability

All thermal storage systems using chilled water

Definition

The deadband temperature difference between enabling and disabling use of the TES system for cooling

Units

Degrees F

Input Restrictions

None

Standard Design

No thermal storage systems

Minimum Temperature Limit

Applicability

All thermal storage systems using chilled water

Definition

The minimum allowed temperature of the tank, below which charging of the tank cannot occur

Units

Deg F

Input Restrictions

None

Standard Design

No thermal storage systems

Storage Tank Location Indicator

Applicability

All thermal storage systems using ice storage

Definition

Nominal Storage Capacity of the tank

Units

List

Input Restrictions

Schedule, Zone, or Exterior.

If Schedule, the ambient temperature schedule must be specified. If Zone, the Zone name must be specified.

Standard Design

No thermal storage systems

Storage Tank Heat Gain Coefficient

Applicability

All thermal storage systems using chilled water

Definition

The heat transfer coefficient between the tank and the ambient surroundings

Units

W/K

Input Restrictions

None

Standard Design

No thermal storage systems

Use Side Heat Transfer Effectiveness

Applicability

All thermal storage systems using chilled water

Definition

The heat transfer effectiveness between the use side water and the tank water

Units

none

Input Restrictions

Between 0 and 1

Standard Design

No thermal storage systems

Use Side Design Flow Rate

Applicability

All thermal storage systems using chilled water

Definition

Design flow rate through the use side of the storage tank

Units

gpm

Input Restrictions

None

Standard Design

No thermal storage systems

Source Side Heat Transfer Effectiveness

Applicability

All thermal storage systems using chilled water

Definition

The heat transfer effectiveness between the source side water and the tank water

Units

none

Input Restrictions

Between 0 and 1

Standard Design

No thermal storage systems

Source Side Design Flow Rate

Applicability

All thermal storage systems using chilled water

Definition

Design flow rate through the source side of the storage tank

Units

gpm

Input Restrictions

None

Standard Design

No thermal storage systems

Tank Recovery Time

Applicability

All thermal storage systems using ice storage

Definition

This is the time in hours for the tank to cool from 14.4°C to 9°C. This input is only used if the source side design flow rate is not specified.

Units

hours

Input Restrictions

None

Standard Design

No thermal storage systems

Heat Recovery Name

Applicability

All heat recovery systems

Definition

A name assigned to a heat recovery system. This would provide a link to the construction documents.

Units

Text, unique

Input Restrictions

As designed

Standard Design

No heat recovery systems

Heat Recovery Device Type

Applicability

All heat recovery systems

Definition

The type of heat recovery equipment. Choices include:

•Double-Bundled Chiller

•Generator

•Engine-Driven Chiller

•Air Conditioning Unit

•Refrigerated Casework

Units

List (see above)

Input Restrictions

As designed

Standard Design

Heat recovery systems are not included in the baseline system.

Heat Recovery Loads

Applicability

All heat recovery systems

Definition

The loads met by the heat recovery system. Choices include:

•Space heating

•Process heating

More than one load may be selected.

Units

List (see above)

Input Restrictions

As designed

Standard Design

Not required in the baseline system.

Plant management is a method of sequencing equipment. Separate plant management schemes may be entered for chilled water systems, hot water systems, etc. The following building descriptors are specified for each load range, e.g. when the cooling load is below 300 tons, between 300 tons and 800 tons, and greater than 800 tons.

Equipment Type Managed

Applicability

All plant systems

Definition

The type of equipment under a plant management control scheme. Choices include:

•Chilled water cooling

•Hot water space heating

•Condenser water heat rejection

•Electrical generation

Units

None

Input Restrictions

As designed

Standard Design

Same as the proposed design

Equipment Schedule

Applicability

All plant equipment

Definition

A schedule which identifies when the equipment is in service.

Units

Data structure

Input Restrictions

As designed

Standard Design

Where multiple equipment is used, they shall be staged in operation.

Equipment Operation

Applicability

All plant equipment

Definition

Equipment operation can be either On-Demand or Always-On. On-Demand operation means the equipment cycles on when it is scheduled to be in service and when it is needed to meet building loads, otherwise it is off. Always-On means that equipment runs continuously when it scheduled to be in service.

Units

None

Input Restrictions

As designed; the default is On-Demand.

Standard Design

Assume On-Demand operation

Equipment Staging Sequence

Applicability

All plant equipment

Definition

The staging sequence for plant equipment (chillers and boilers) indicates how multiple equipment will be staged on and off when a single piece of equipment is unable to meet the load.

Units

Structure – this should include (a) the percent of capacity above which additional equipment is staged on; (b) the percent of capacity below which one plant equipment is staged off

Input Restrictions

As designed.

Standard Design

Compliance software shall bring up each boiler to 90 percent capacity prior to the staging of the next boiler.

Compliance software shall bring up each chiller to 90 percent capacity prior to the staging of the next chiller.