Choosing the proper windows, glazed doors, and skylights is one of the most important decisions for any high-performance project. The use of high-performance fenestration can actually reduce energy consumption by decreasing the lighting and heating and cooling loads in nonresidential and high-rise residential buildings. The size, orientation, and types of fenestration products can dramatically affect overall energy performance.

This section will specify the mandatory and prescriptive features of fenestration products, the performance of fenestration, ratings and labeling by the National Fenestration Rating Council (NFRC), and details on daylighting through skylights.

The mandatory measures for windows, glazed doors, and skylights address the air-tightness of the units (air leakage), how the U-factor and solar heat gain coefficient (SHGC) are determined, as well as the visible transmittance (VT).

Any fenestration product or glazed door, other than field-fabricated fenestration products and field-fabricated glazed doors, may be installed if the manufacturer has certified to the Energy Commission by using a default label, or if an independent certifying organization approved by the Energy Commission has certified that the product complies.

3.3.1.1 Determining Fenestration Performance

A. U-Factor

The U-factor describes the rate of heat flow through the entire unit, not just the glass or plastic glazing material. The U-factor includes the heat flow effects of the glass, the frame, and the edge-of-glass conditions. (There also may be spacers, sealants and other elements that affect heat conduction.) The lower the U-factor, the lower the amount of heat loss.

Reference Appendix JA1 lists many of the terms and product characteristics that relate to fenestration U-factors. In particular, see the definitions for window, skylight, window area, skylight area, site-built fenestration, and field-fabricated fenestration.

The preferred methods for determining fenestration U-factor are those in NFRC 100 for manufactured windows and for site-built fenestration. The default U-factors in Table 110.6-A of the Energy Standards (reproduced in Table 3-14 below) must be used when a NFRC label for the U-factor is not available. The U-factors in Table 110.6-A represent the most inefficient possible values, thereby encouraging designers to obtain ratings through NFRC test procedures, when they are available.

|

SHGC Determination Method |

Manufactured Windows |

Manufactured Skylights |

Site-Built Fenestration (Vertical & Skylight) |

Field-Fabricated Fenestration |

Glass Block |

|

NFRC’s Component Modeling Approach (CMA) |

ü |

ü |

ü |

N/A |

N/A |

|

NFRC-100 |

ü |

ü |

ü |

N/A |

N/A |

|

Default Table 110.6-A of the Energy Standards |

ü |

ü |

ü |

ü |

ü |

|

NA61 |

N/A |

N/A |

ü |

N/A |

N/A |

|

The Alternative Default U-factors from Nonresidential Reference Nonresidential Appendix NA6 may only be used for site-built vertical and skylights having less than 1,000ft2. | |||||

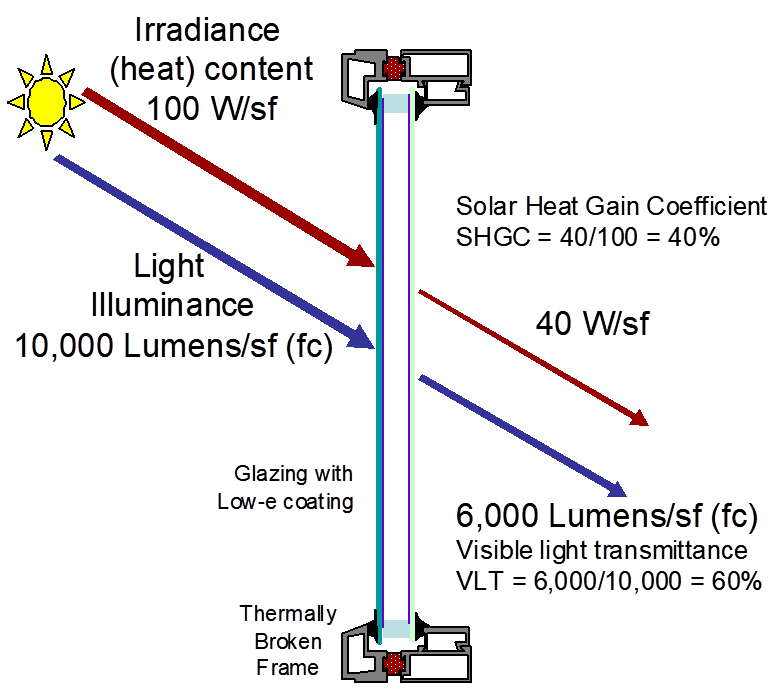

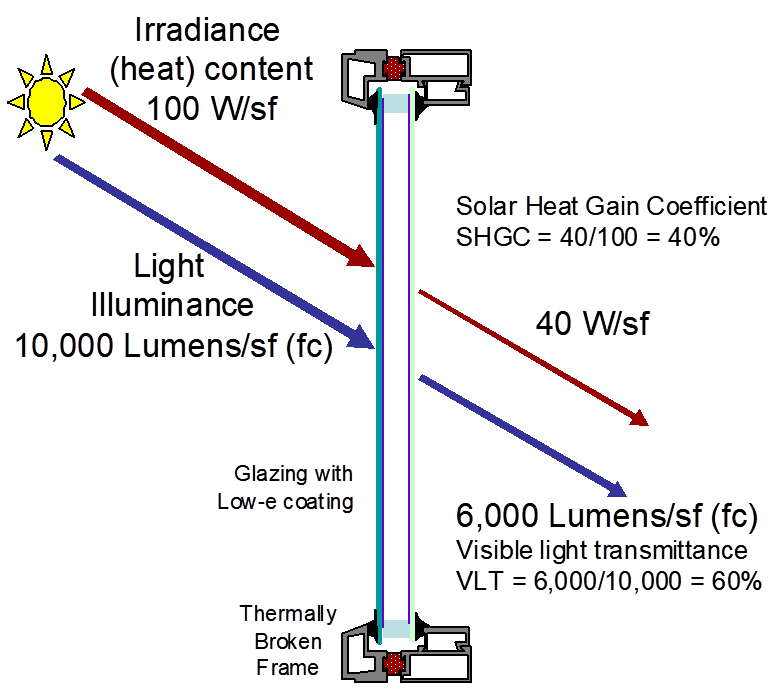

B. Solar Heat Gain Coefficient (SHGC)

The SHGC measures the rate of heat gain from solar energy passing through a product. The lower the SHGC, the lower the amount of heat gain. SHGC is measured for the whole window, including the effects of the frame. For the SHGC, the methods determining the preferred values are in NFRC 200. If they are not available, Table 110.6-B of the Energy Standards (Table 3-15 below) must be used for default values.

|

Fenestration Category | |||||

|

SHGC Determination Method |

Manufactured Windows |

Manufactured Skylights |

Site-Built Fenestration

(Vertical& |

Field-Fabricated Fenestration |

Glass Block |

|

NFRC’s Component Modeling Approach (CMA)1 |

ü |

ü |

ü |

N/A |

N/A |

|

NFRC-200 |

ü |

ü |

ü |

N/A |

N/A |

|

Standards Default Table 110.6-B |

ü |

ü |

ü |

ü |

ü |

|

NA62 |

N/A |

N/A |

ü |

N/A |

N/A |

|

The NFRC Residential CMA method is an option that may be available in the Energy Standards. The Alternative Default U-factors from Nonresidential Reference Nonresidential Appendix NA6 may only be used for site-built vertical and skylights having less than 1,000ft2. | |||||

C. Visible Transmittance (VT)

VT is the ratio of light that passes through the glazing material to the light that is incident outside the glazing. VT affects the amount of daylight that enters the space and how well views through windows are rendered. Glazing materials with a very low VT have little daylighting benefit and views appear dark, even on bright days.

The VT of the fenestration shall be rated in accordance with NFRC 200 or ASTM E972. More specifically, the NFRC 200 test method is appropriate only for flat, clear glazing and does not cover curved glazing or diffusing glazing. NFRC 202 is the approved test method for rating the visible transmittance of planar diffusing glazing such as is used in fiberglass insulating fenestration. NFRC 203 is the approved test method for rating the visible transmittance of tubular skylights, also known as tubular daylighting devices (TDDs). For other types of fenestration, including dome skylights, use ASTM E972 to rate the visible transmittance.

Visible transmittance (VT) is a property of glazing materials that has a varying relationship to SHGC (Figure 3-9). The ideal glazing material for most of California’s summer climates would have a high VT and a low SHGC. Such a glazing material allows solar radiation in the visible spectrum to pass while blocking radiation in the infrared and ultraviolet spectrums. Materials that have this quality are labeled “spectrally selective” and have a VT that is up to 2.2 times the SHGC.

3.3.1.2 Field-Fabricated Fenestration Product or Exterior Door

Field-fabricated fenestration is fenestration assembled on site that does not qualify as site-built fenestration. It includes windows where wood frames are constructed from raw materials at the building site, salvaged windows that do not have an NFRC label or rating, and other similar fenestration items.

For field-fabricated fenestration, the U-factor and SHGC are default values that can be found in Table 3-14, respectively, below. Values are determined by frame type, fenestration type, and glazing composition.

Exterior doors are doors through an exterior partition. They may be opaque or have a glazed area that is less than or equal to one-half of the door area. U-factors for opaque exterior doors are listed in Reference Appendix JA4, Table 4.5.1. Doors with glazing for more than one-half of the door area are treated as fenestration products and must meet all requirements and ratings associated with fenestration.

When a door has glazing of less than one-half the door area, the portion of the door with fenestration must be treated as part of the envelope and fenestration independent of the remainder of the door area.

A field-fabricated product may become a site-built product if all the requirements for receiving a label certificate required of site-built products are met.

|

FRAME |

PRODUCT TYPE |

SINGLE PANE3, 4 |

DOUBLE PANE1, 3, 4 |

GLASS BLOCK2,3 |

|

Metal |

Operable |

1.28 |

0.79 |

0.87 |

|

Fixed |

1.19 |

0.71 |

0.72 | |

|

Greenhouse/garden window |

2.26 |

1.40 |

N.A. | |

|

Doors |

1.25 |

0.77 |

N.A. | |

|

Skylight |

1.98 |

1.30 |

N.A. | |

|

Metal, Thermal Break |

Operable |

N.A. |

0.66 |

N.A. |

|

Fixed |

N.A. |

0.55 |

N.A. | |

|

Greenhouse/garden window |

N.A. |

1.12 |

N.A. | |

|

Doors |

N.A. |

0.59 |

N.A. | |

|

Skylight |

N.A. |

1.11 |

N.A. | |

|

Nonmetal |

Operable |

0.99 |

0.58 |

0.60 |

|

Fixed |

1.04 |

0.55 |

0.57 | |

|

Doors |

0.99 |

0.53 |

N.A. | |

|

Greenhouse/garden windows |

1.94 |

1.06 |

N.A. | |

|

Skylight |

1.47 |

0.84 |

N.A. | |

|

1. For all dual-glazed fenestration products, adjust the listed U-factors as follows: a. Add 0.05 for products with dividers between panes if spacer is less than 7/16 inch wide. b. Add 0.05 to any product with true divided lite (dividers through the panes). 2. Translucent or transparent panels shall use glass block values when not rated by NFRC 100. 3. Visible transmittance (VT) shall be calculated by using Reference Nonresidential Appendix NA6. 4. Windows with window film applied that is not rated by NFRC 100 shall use the default values from this table. | ||||

Table 110.6-A of the Energy Standards

|

FRAME TYPE |

PRODUCT |

GLAZING |

FENESTRATION PRODUCT SHGC | ||

|

Single Pane2,3 |

Double Pane2,3 |

Glass Block1,2 | |||

|

Metal |

Operable |

Clear |

0.80 |

0.70 |

0.70 |

|

Fixed |

Clear |

0.83 |

0.73 |

0.73 | |

|

Operable |

Tinted |

0.67 |

0.59 |

N.A. | |

|

Fixed |

Tinted |

0.68 |

0.60 |

N.A. | |

|

Metal, Thermal Break |

Operable |

Clear |

N.A. |

0.63 |

N.A. |

|

Fixed |

Clear |

N.A. |

0.69 |

N.A. | |

|

Operable |

Tinted |

N.A. |

0.53 |

N.A. | |

|

Fixed |

Tinted |

N.A. |

0.57 |

N.A. | |

|

Nonmetal |

Operable |

Clear |

0.74 |

0.65 |

0.70 |

|

Fixed |

Clear |

0.76 |

0.67 |

0.67 | |

|

Operable |

Tinted |

0.60 |

0.53 |

N.A. | |

|

Fixed |

Tinted |

0.63 |

0.55 |

N.A. | |

|

Translucent or transparent panels shall use glass block values when not rated by NFRC 200. Visible transmittance (VT) shall be calculated by using Reference Nonresidential Appendix NA6. Windows with window film applied that is not rated by NFRC 200 shall use this table’s default values | |||||

Table 110.6-B of the Energy Standards

3.3.1.3 Certification and Labeling

§10-111

and §110.6

Reference Nonresidential Appendices

NA6

The Administrative Regulations §10-111 and §110.6 require that fenestration products have labels that list the U-factor, SHGC, VT and the method used to determine those values. The label must also certify that the fenestration product meets the requirements for air leakage from §110.6(a)1.

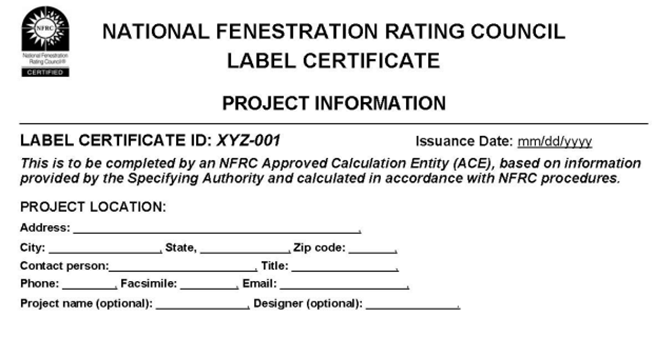

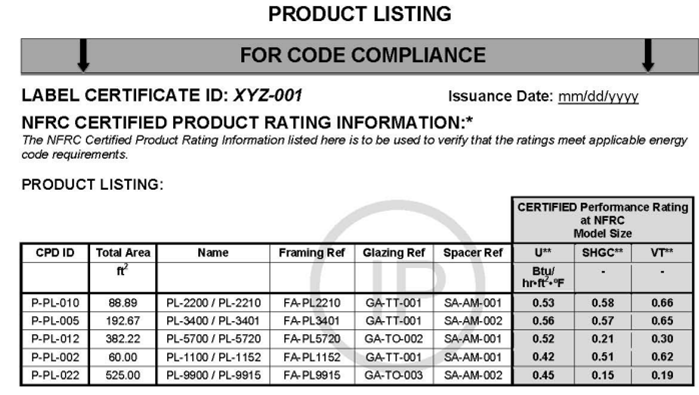

A. Manufactured (Factory-Assembled) Fenestration Label Certificates

Each manufactured (factory-assembled) fenestration product must have a clearly visible temporary label attached to it, which is not to be removed before inspection by the enforcement agency. For rating and labeling manufactured fenestration products, the manufacturer rates its products for U-factor, SHGC and VT.

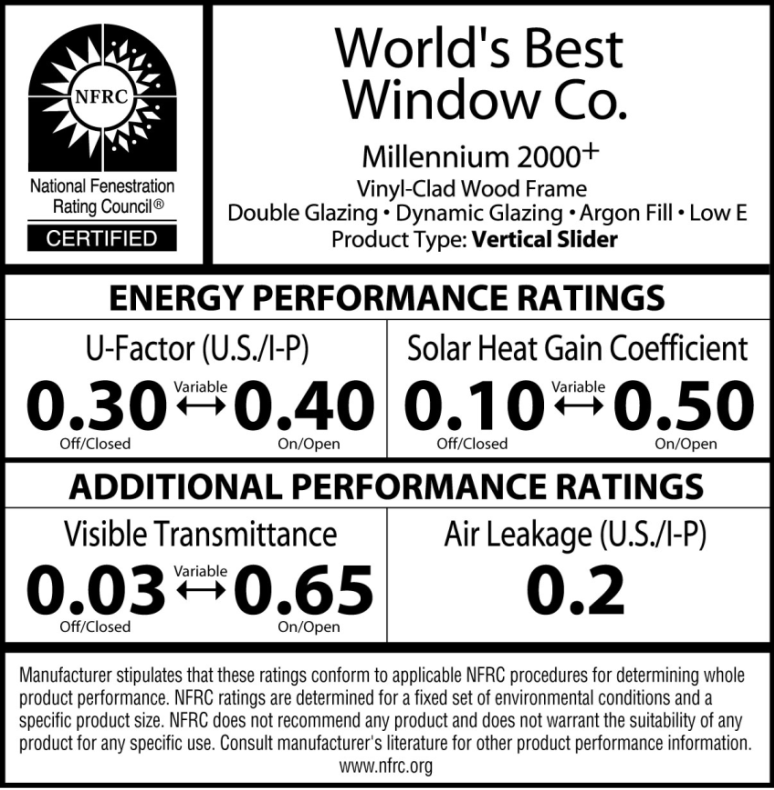

The manufacturer can choose to have the fenestration product rated and labeled in accordance with the NFRC Rating Procedure (NFRC 100 for U-factors and NFRC 200 for SHGC and VT) shown in Figure 3-10. If the manufactured fenestration product is rated using the NFRC rating procedure, it must also be permanently labeled in accordance with NFRC procedures.

Where possible, it is best to select a fenestration product that is NFRC-rated and to do so before completing compliance documents. This selection enables the use of NFRC-certified data for compliance.

B. Default Temporary Label

Fenestration product manufacturers can choose to use default performance values listed in Tables 110.6-A and Table 110.6-B in §110.6 for U-factors and SHGC in lieu of testing. For fenestration products requiring a VT value, assume a value of 1.0 as specified in the Reference Nonresidential Appendix NA6. If default values are used, the manufacturer must attach a temporary label to each window (See Figure 3-11 and manufacturer specification sheets or cut sheets must be included with compliance documentation. A NRCC-ENV-05-E will be required to document the thermal performance if no default temporary labels are attached to the window units.

Although there is no exact format for the default temporary label, it must be clearly visible and large enough to be clearly visible from 4 feet so the enforcement agency field inspectors are able to read easily, and it must include all information required by the regulations.

The minimum suggested label size is 4 in. x 4 in., and the label must have the words at the bottom of the label, as noted in the example in Figure 3-11.

“This product meets the air infiltration requirements of §110.6(a)1, U-factor criteria of §110.6(a)2, SHGC criteria of §110.6(a)3 and VT criteria of §110.6(a)4 of the 2016 California Building Energy Efficiency Standards for Residential and Nonresidential Buildings.”

If the product claims the default U-factor for a thermal-break product, the manufacturer must certify that the thermal-break criteria upon which the default value is based are met by placing a check in the check box:

1. Air space 7/16 in. or greater

2. For skylights, the label must indicate the product was rated with a built-in curb

3. Meets thermal-break default criteria

|

2013 California Energy Commission Default Label XYZ Manufacturing Co. | ||

|

Key Features: |

o Doors |

o Double-Pane |

|

o Skylight |

o Glass Block | |

|

|

|

|

|

Frame Type |

Product Type: |

Product Glazing Type: |

|

o Metal |

o Operable |

o Clear |

|

o Non-Metal |

o Fixed |

o Tinted |

|

o Metal, Thermal Break |

o Greenhouse/Garden Window |

o Single-Pane |

|

o Air space 7/16 in. or greater o With built-in curb o Meets Thermal-Break Default Criteria |

---------- |

To calculate VT see NA6 |

|

California Energy Commission Default U-factor = |

California Energy Commission Default SHGC = |

California Energy Commission Calculated VT = |

|

Product meets the air infiltration requirements of §110.6(a)1, U-factor criteria of §110.6(a)2, SHGC criteria of §110.6(a)3 and VT criteria of §110.6(a)4 of the 2016 Energy Standards for Residential and Nonresidential Buildings. | ||

The person taking responsibility for fenestration compliance may choose to attach default temporary labels to each fenestration product as described instead of providing a default label certificate for each product line.

For the visible transmittance (VT) of diffusing skylights that is not covered by NFRC 200 or NFRC 203, a test report should be included using the ASTM E972 method. Manufacturers, specifiers, or a responsible party should include the report with the energy documentation.

C. Field-Fabricated Fenestration

Field-fabricated fenestration is not the same as site-built fenestration. Field-fabricated fenestration is a very limited category of fenestration that is made at the construction site out of materials that were not previously formed or cut with the intention of being used to fabricate a fenestration product. No attached labeling is required for field-fabricated fenestration products; only a NRCC-ENV-05-E is needed. Field-fabricated fenestration and field-fabricated exterior doors may be installed only if the compliance performance documentation has demonstrated compliance. The field inspector is responsible for ensuring field-fabricated fenestration meets the specific U-factor, SHGC, and VT, as listed on the NRCC-ENV-05-E. Thermal break values do not apply to field-fabricated fenestration products.

D. Site-Built Label Certificates

The designer should select a U-factor, SHGC, and VT for the fenestration system that meets the design objectives and occupancy needs for the building. Site-built fenestration is field-assembled using specific factory-cut or factory-formed framing and glazing units that are manufactured with the intention of being assembled at the construction site or glazing contractor’s shop. Site-built certificates should be filed at the contractor’s project office during construction or in the building manager’s office. (See the CMA sample on Figures 3-12 and 3-12A and discussion of CMA in subsection F below.)

Note: The highlighted circles in the figures indicate the field inspector’s area to inspect and compare to the energy compliance submittal and building plans.

1. For site-built fenestration totaling 1,000 ft2 or greater, the glazing contractor or specifier must generate a NFRC label certificate from either approach listed below:

a. A NFRC label certificate generated by the CMA computer program.

b. Default to the U-factor values from Table 110.6-A, the SHGC values from Table 110.6-B, and for VT values, use the method specified in NA6.

2. For site-built fenestration totaling less than 1,000 ft² or any area of replacement of site-built fenestration that includes vertical windows, glazed doors, and skylights, the glazing contractor or specifier must comply with one of the following:

a. A NFRC label certificate generated by the CMA computer program.

b. The center-of-glass values from the manufacturer’s product literature to determine the total U-factor, SHGC and VT. (See Reference Nonresidential Appendix NA6 - the Alternative Default Fenestration Procedure).

c. The U-factor values from Table 110.6-A and SHGC values from Table 110.6-B. For VT values, use the method specified in NA6.

NA6 calculations are based on center-of-glass (COG) values from the manufacturer. For example, when using a manufacturer’s SHGC center-of-glass specification of 0.27, the NA6 calculation results in an overall SGHC value of 0.312, which may be rounded to 0.31. Rounding to the nearest hundredth decimal place is acceptable to determine the overall fenestration efficiency value with either the prescriptive or performance approach.

E. Fenestration Certificate NRCC-ENV-05-E

For nonrated products where no default label certificates are placed on the fenestration product, use Fenestration Certificate NRCC-ENV-05-E to document thermal performances of each fenestration product that results in a different U-factor, SHGC, and VT. Alternatively, one certificate will suffice when all the windows are the same.

The NRCC-ENV-05-E should indicate the total amount of non-NFRC-rated fenestration products throughout the project. The locations and orientations where fenestration products are being installed should be indicated on the drawings and in a fenestration schedule that lists all fenestration products.

The NRCC-ENV-05-E should clearly identify the appropriate table or equation that is used to determine the default U-factor and SHGC and, if applicable, the center of glass, SHGCC, used in calculating the SHGCfen. Manufacturer’s documentation of these product characteristics that list the center-of-glass values must also be attached to the NRCC-ENV-05-E and located at the job site for verification.

F. Component Modeling Approach (CMA)

NFRC has developed a performance base calculation, the component modeling approach (CMA), to make the rating process quicker and simpler and serve as an energy ratings certification program for windows and other fenestration products used in nonresidential projects. This approach allows users to assemble fenestration products in a virtual environment. The approach draws data for NFRC-approved components from online libraries choosing from preapproved glazing, frame, and spacer components. CMA users are able to obtain preliminary ratings for various configurations of their designs. CMA is a fair, accurate, and credible method based on NFRC 100 and 200 program documents, which are verified by third-party rating procedures.

Architects and others can use this tool to:

1. Help design energy-efficient windows, curtain wall systems, and skylights for high-performance building projects.

2. Determine whether a product meets the specifications for a project and local/state building energy codes.

3. Model different fenestration designs to compare energy performance.

Once the user is satisfied with the product, he or she creates a bid report containing the data for all fenestration products to be reviewed. This report can serve as an indication that the products comply with the energy-related requirements of the project and building energy codes. The windows are then built, either on-site or in a factory. The final products are reviewed and are rated by an NFRC-approved calculation entity (ACE); then a license agreement is signed with NFRC.

At

this point, NFRC issues a CMA label certificate for the project. This label

certificate, unlike NFRC’s residential window label that is applied to

individual units, is a document that lists the certified fenestration ratings at

the NFRC standard testing size for the entire building project. Once approved,

the CMA label certificate is available online immediately. This certificate

serves as code compliance documentation for fenestration energy performance, and

the certified products may be applied to future projects without repeating the

certification process.

Benefits of CMA

CMA provides facility managers, specifiers, building owners, and design teams with a simple method for designing and certifying the energy performance of fenestration systems for their buildings without having to test every possible permutation of glazing and framing. This is significantly less expensive than building sample wall sections and testing them in a large test enclosure. However, there are several additional advantages gained by using the CMA:

1. CMA’s online tool has the ability to output a file with values for use in building energy analysis software programs.

2. The program can export detailed information for angular-dependent SHGC and VT values, seamlessly transferring the data to the analytical software.

3. A 2010 study1 conducted in California demonstrated that fenestration modeled with the CMA program can provide an increase in compliance margins by as much as 11.7 percent over the Energy Commission’s default calculation methods.

4. CMA can help demonstrate above-code performance, which is useful for environmental rating programs such as Leadership in Energy and Environmental Design (LEED™) or local green building programs.

Use of the CMA can help lead to a more efficient building and enable cost savings due to more accurate fenestration performances and potential energy benefits from above-code utility incentives. Details are available at www.NFRC.org/.

3.3.1.4 Air Leakage

Manufactured and site-built fenestration such as doors and windows must be tested and shown to have infiltration rates not exceeding the values shown in Table 3-16. For field-fabricated products or an exterior door, the Energy Standards require that the unit be caulked, gasketed, weatherstripped, or otherwise sealed. Unframed glass doors and fire doors are the two exceptions to these air leakage requirements. Field-fabricated fenestration and field-fabricated exterior doors are not required to comply with Table 3-16.

|

Class |

Type |

Rate |

|

Windows (cfm/ft²) of window area |

All |

0.3 |

|

Residential Doors (cfm/ft²) of door area |

Swinging, Sliding |

0.3 |

|

All Other Doors (cfm/ft²) of door area |

Sliding, Swinging (single door) |

0.3 |

|

Swinging (double door) |

1.0 |

Example 3-11

Question:

A 150,000 ft² “big box” retail store has 800 ft² of site-built vertical fenestration at the entrance. An operable double-pane aluminum storefront framing system is used without a thermal break. What are the acceptable methods for determining the fenestration U-factor and SHGC? What are the labeling requirements assuming a center of glass U-factor of 0.50 and SHGC of 0.70 and a center glass visible transmittance of 0.75?

Answer:

For

site-built fenestration less than 1,000 ft2 then one of the following

three methods may be used:

1. The easiest method for site-built fenestration

is to rate the fenestration using the component modeling approach (CMA), which

will yield the most efficient values possible.

2. In this case, use the

default U-factor and SHGC values from equations in Reference Nonresidential Appendix

NA6 as described in the following bullets:

l The Alternate U-factor may be calculated

from the Reference Nonresidential Appendix NA6, Equation NA6-1, UT =

C1 + C2 X UC. From Table NA-1 for metal–framed,

site-built fenestration, C1= 0.311 and C2 = 0.872,

therefore the overall U-factor is calculated to be 0.311 + 0.872 x 0.50 =

0.47.

l Likewise, the SHGC is determined from the

Reference Nonresidential Appendix, NA6, Equation NA6-2, SHGCT =

0.08 + 0.86 x SHGCC. Therefore, the SHGC is calculated to be 0.08 +

0.86 x 0.70 = 0.68.

l For VT, from Appendix NA6, the visible

transmittance of the frame is 0.88 for a curtain wall, so the VTT =

VTF X VTC = 0.88 X 0.75 = 0.66.

3. The third option

for determining U-factor and SHGC may be to select from Default Table 110.6-A

and 110.6-B of the Energy Standards. From these tables, the U-factor is 0.79 and

the SHGC is 0.70. An Energy Commission Default Label Certificate, NRCC-ENV-05-E,

should be completed for each fenestration product unless the responsible party

chooses to attach a default temporary label to each fenestration unit throughout

the building.

Example 3-12

Question:

What

constitutes a “double-pane” window?

Answer:

Double-pane

(or dual-pane) glazing is made of two panes of glass (or other glazing material)

separated by a space [generally ¼ inch (6 mm) to ¾ inch (18 mm)] filled with air

or other inert gases. Two panes of glazing laminated together do not constitute

double-pane glazing, but are treated as single pane.

3.3.2.1 Site-Built Fenestration

Manufactured fenestration products are factory-assembled as a unit, and the manufacturer is able to assume the burden of testing and labeling. However, with site-built fenestration, multiple parties are responsible. The steps of producing site-built fenestration are as follows:

1. Architects and/or engineers design the basic glazing system by specifying the components, the geometry of the components, and, sometimes, the assembly method.

2. An extrusion manufacturer provides the mullions and frames that support the glazing and is responsible for thermal breaks.

3. A glazing manufacturer provides the glazing units, cut to size and fabricated as insulated glass (IG) units. The glazing manufacturer is responsible for tempering or heat strengthening, the tint of the glass, any special coatings, the spacers, and the sealants.

4. A glazing contractor (usually a subcontractor to the general contractor) puts the system together at the construction site, or the contractor’s shop and is responsible for many quality aspects. Predetermining the energy performance of site-built fenestration as a system is more challenging than for manufactured units.

5. One of the parties (architect, glazing contractor, extrusion manufacturer, IG fabricator, or glass manufacturer) must take responsibility for testing and labeling of the site-built fenestration system under the most recent NFRC 100 procedure. The responsible party must obtain a label certificate as described in §10-111.

6. The glazing contractor or other appropriate party assumes responsibility for acquiring the NFRC label certificate. Each label certificate has the same information as the NFRC temporary label for manufactured products but includes other information specific to the project, such as the name of the glazing manufacturer, the extrusion contractor, the places in the building where the product line is used, and other details.

It is typical for the glazing contractor to assume responsibility for the team and to coordinate the certification and labeling process. A common procedure is for the design team to include language in the contract with the general contractor that requires that the general contractor be responsible; the general contractor typically assigns this responsibility to the glazing contractor, once the responsible party has established a relationship with an NFRC.

It is not necessary to complete the NFRC testing and labeling prior to completing the compliance documentation and filing the building permit application. However, plans examiners should verify that the fenestration performance shown in the plans and specifications and used in the compliance calculations is “reasonable” and achievable. This requires some judgment and knowledge on the part of the plans examiner. Generally, designers will know the type of glass that they plan to use and whether the frame has a thermal break or is thermally improved. This information is adequate to consult the default values for U-factor and SHGC in Reference Nonresidential Appendix NA6.

The label certificate remains on file in the construction office for the building inspector to view. After construction is complete, the label certificate should be filed in the building office with the as-built drawings and other operations and maintenance data. This will give building managers the information needed for repairs or replacements.

3.3.2.2 Prescriptive Measures

There are four aspects of the envelope component approach for windows:

1. Maximum total area plus west-facing.

2. Maximum U-factor.

3. Maximum relative solar heat gain coefficient (RSHGC).

4. Minimum visible transmittance (VT).

A. Window Area

In the prescriptive approach, the total window area may not exceed 40 percent of the gross wall area (encompassing total conditioned space) for the building. Likewise, the west-facing window area may not exceed 40 percent of the west gross wall area (encompassing total conditioned space for the building). This maximum area requirement will affect those buildings with very large glass areas, such as high-rise offices, automobile showrooms, or airport terminals.

The maximum area may be determined by multiplying the length of the display perimeter (see definition below in this section) by 6 ft in height and use the larger of the product of that multiplication or 40 percent of gross exterior wall area.

Glazing in a demising wall does not count toward the total building allowance. There is no limit to the amount of glazing allowed in demising walls, but it must meet the prescriptive U-factor, relative solar heat gain coefficient (RSHGC), and visible light transmittance (VT) requirements for the climate zone.

As a practical matter, window area is generally taken from the rough opening dimensions. To the extent this opening is slightly larger than the frame, the rough opening area will be slightly larger than the formally defined window area.

For glazed doors, also use the rough opening area, except where the door glass area is less than 50 percent of the door, in which case the glazing area may be either the entire door area or the glass area plus 2 inches added to all four sides of the glass (to represent the “window frame”) for a window in a door. Calculate the window area from the rough opening dimensions and divide by the gross exterior wall area, which does not include demising walls.

Display perimeter is the length of an exterior wall in a Group B; Group F, Division 1; or Group M occupancy that immediately abuts a public sidewalk, measured at the sidewalk level for each story that abuts a public sidewalk. This generally refers to retail display windows, although other occupancies such as offices can also have a display perimeter. Public sidewalks are accessible to the public at large (no obstructions, limits to access, or intervening nonpublic spaces). Demising walls are not counted as part of the display perimeter.

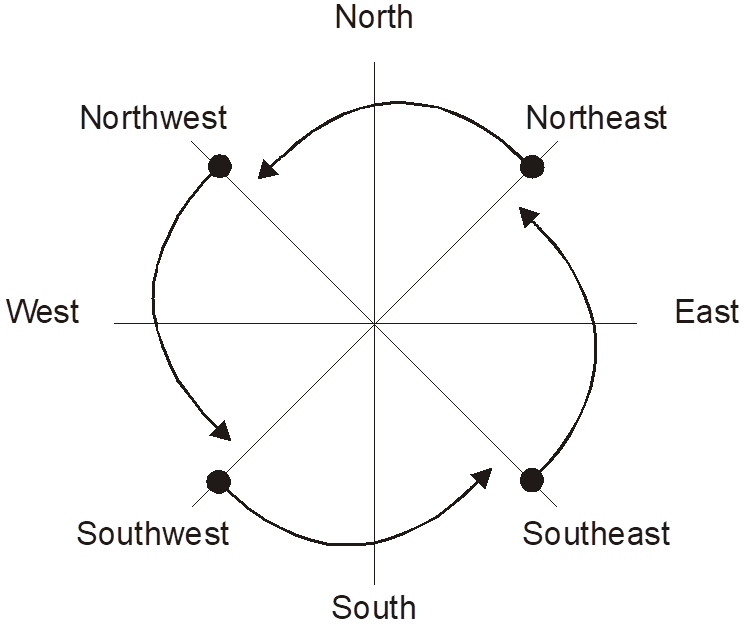

In general, any orientation within 45° of true north, east, south, or west will be assigned to that orientation. The orientation can be determined from an accurate site plan. Figure 3-13 demonstrates how surface orientations are determined and what to do if the surface is oriented exactly at 45° of a cardinal orientation. For example, an east-facing surface cannot face exactly northeast, but it can face exactly southeast. If the surface were facing exactly northeast, it would be considered north-facing.

B. Window U-Factor

Fenestration products are required to use default U-factors and SHGC (see Tables 110.6-A (Table 3-14 and Table 110.6-B (Table 3-15) of the Energy Standards) or have the performance characteristics certified by NFRC. However, each window must meet the prescriptively required maximum U-factor criteria in Table 140.3-B and 140.3-C of the Energy Standards (see Table 3-17 below) for each climate zone. In general, most NFRC-rated double-glazed windows with a low-e coating and a thermally broken frame will comply with the U-factor criterion; however, other window constructions may also comply. See http://www.nfrc.org/, Certified Product Directory database, or use Equation NA6-1in Reference Appendix NA6.

|

|

All Climate Zones | ||||

|

Space Type |

Criterion |

Fixed Window |

Operable Window |

Curtainwall /Storefront |

Glazed Doors |

|

Nonresidential |

Max U-factor |

0.36 |

0.46 |

0.41 |

0.45 |

|

Max Relative Solar Heat Gain (RSHGC) |

0.25 |

0.22 |

0.26 |

0.23 | |

|

Min VT |

0.42 |

0.32 |

0.46 |

0.17 | |

|

Maximum WWR% |

40% | ||||

|

|

All Climate Zones | ||||

|

Residential |

Max U-Factor |

0.36 |

0.46 |

0.41 |

0.45 |

|

Max Relative Solar Heat Gain (RSHGC) |

0.25 |

0.22 |

0.26 |

0.23 | |

|

Min VT |

0.42 |

0.32 |

0.46 |

0.17 | |

|

Maximum WWR% |

40% | ||||

|

From Energy Standards Tables 140.3-B and 140.3-C | |||||

C. Overhang Factor

Relative solar heat gain (RSHGC) is essentially the same as SHGC, except for the external shading correction. It is calculated by multiplying the SHGC of the fenestration product by an overhang factor. If an overhang does not exist, then the overhang factor is 1.0. Relative solar heat gain is applicable only when using the prescriptive compliance approach.

Tables 140.3-B and 140.3-C of the Energy Standards (Table 3-17 above) specify the maximum area-weighted average RSHGC, excluding the effects of interior shading.

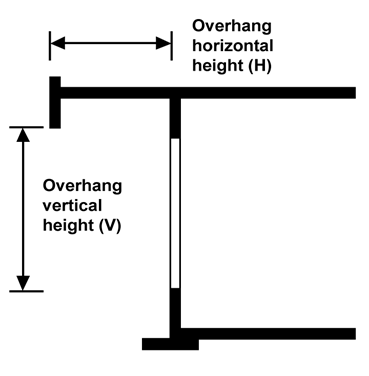

Overhang factors may either be calculated or taken from Table 3-18 below and depend upon the ratio of the overhang horizontal length (H) and the overhang vertical height (V). These dimensions are measured from the vertical and horizontal planes passing through the bottom edge of the window glazing, as shown in Figure 3-14. An overhang factor may be used if the overhang extends beyond both sides of the window jamb a distance equal to the overhang projection (§140.3(a)5Cii). The overhang projection is equal to the overhang length (H), as shown in Figure 3-14. If the overhang is continuous along the side of a building, this restriction will usually be met. If there are overhangs for individual windows, each must be shown to extend far enough from each side of the window.

Equation 3-1 – Relative Solar Heat Gain Coefficient

RSHGC = SHGCwin x OHF

Where:

RSHGC = Relative solar heat gain Coefficient

SHGCwin = Solar heat gain coefficient of the window

Equation 3-2 – Overhang Factor

Where:

H = Horizontal projection of the overhang from the surface of the window in ft, but no greater than V

V = Vertical distance from the windowsill to the bottom of the overhang, in ft.

a = -0.41 for north-facing windows, -1.22 for south-facing windows, and -0.92 for east- and west-facing windows

b =0.20 for north-facing windows, 0.66 for south-facing windows, and 0.35 for east- and west-facing windows

|

H/V |

North |

South |

East/West |

|

0.00 |

1.00 |

1.00 |

1.00 |

|

0.10 |

0.96 |

0.88 |

0.91 |

|

0.20 |

0.93 |

0.78 |

0.83 |

|

0.30 |

0.90 |

0.69 |

0.76 |

|

0.40 |

0.87 |

0.62 |

0.69 |

|

0.50 |

0.85 |

0.56 |

0.63 |

|

0.60 |

0.83 |

0.51 |

0.57 |

|

0.70 |

0.81 |

0.47 |

0.53 |

|

0.80 |

0.80 |

0.45 |

0.49 |

|

0.90 |

0.79 |

0.44 |

0.46 |

|

1.00 or greater |

0.79 |

0.44 |

0.43 |

To use Table 3-18:

1. Measure the horizontal projection of the overhang (H) and the vertical height from the bottom of the glazing to the shading cutoff point of the overhang (V).

2. Calculate H/V.

3. Enter the table at that point.

4. Choose the next higher value to the calculated H/V value if the calculated H/V falls between two values in the table

5. Move across to the column that corresponds to the orientation of the window and find the overhang factor.

Any value of H/V greater than 1 has the same overhang factor (for a given orientation) shown in the last row of the table.

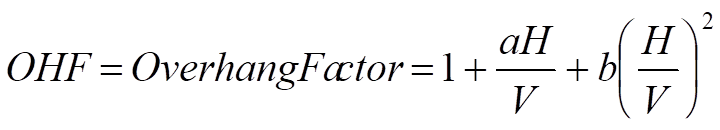

Figure 3-15 graphs the overhang factors of the various orientations as a function of H/V. It shows that overhangs have only a minor effect on the north. (Maximum reduction in SHGC is only about 20 percent.) East, west, and south overhangs can achieve reductions of 55–60 percent. The benefits of the overhang level off as the overhang becomes larger. (This graph is presented only to illustrate the benefits of overhangs.)

Example 3-13

Question:

An east-facing window has glass with a

solar heat gain coefficient of 0.71. It has a fixed overhanging eave that

extends 3 ft out from the plane of the glass (H = 3) and is 6 ft above the

bottom of the glass

(V = 6). The overhang extends more than 3 ft beyond each

side of the glass, and the top of the window is less than 2 ft vertically below

the overhang. What is the RSHGC for this window?

Answer:

First,

calculate H/V. This value is 3 / 6 = 0.50. Next, find the overhang factor from

Table

3-18. For east-facing windows, this value is 0.63. Finally, multiply it by

the solar heat gain coefficient to obtain the RSHGC: 0.63 x 0.71 =

0.45.

D. Visible Light Transmittance (VT)

The prescriptive requirements of Tables 140.3-B and 140.3-C (Table 3-17) of the Energy Standards prescribe specific VT values for all climate zones and glass types. The visible light transmittance is used in the performance method in the calculation of the interior illumination levels and lighting energy savings due to daylight controls. This is discussed in more detail in Chapter 5 of this manual.

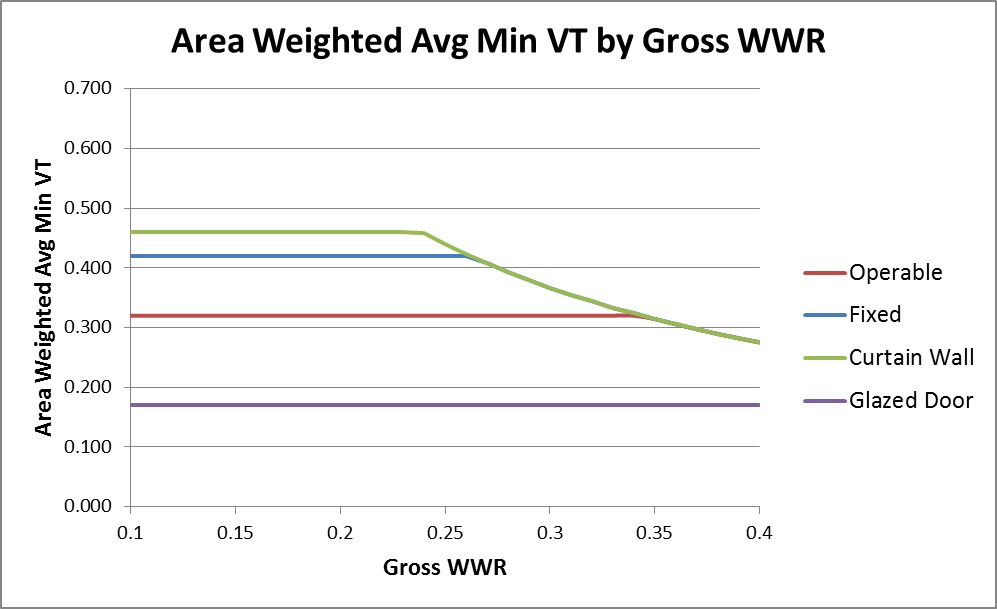

Fenestration must meet the climate zone-specific prescriptive requirement of having an area-weighted average VT of 0.42 or greater for fixed windows, 0.32 or greater for operable windows, 0.46 or greater for curtain walls and 0.17 or greater for glazed doors. Products with spectrally selective “low-e” coatings (also known as single, double or triple silver low-e) are available to meet this requirement.

A combination of high VT glazing in the upper part of a window (clerestory) and lower VT glazing at the lower part of the window (view window) can be used, as long as the area-weighted average meets the prescriptive requirement. This allows daylight to enter the space through the high VT glazing making a better daylighting design.

The Energy Standards also allow a slight variance if the window-to-wall ratio (WWR) is greater than 40 percent. For this case, assume 0.40 for the WWR in the equation below, or if the glazing can comply with the prescriptive requirements if the area-weighted average VT meets the following minimum requirement:

Equation 3-3 – Visible Light Transmittance

VT ≥ 0.11 / WWR

Where:

VT = the visible transmittance of the framed window

WWR = the gross window-to-wall ratio

The graph below shows the allowed area weighted average minimum VT’s by gross WWR for four types of windows

The average VT requirements apply separately to chromatic (dynamic or color changing) glazing and nonchromatic glazing. For chromatic glazing, higher ranges of VT can be used to meet the prescriptive requirements. However, all glazing that is not chromatic must separately meet the area-weighted VT prescriptive requirements.

Example 3-14

Question:

A space has a gross window-to-wall ratio of 30 percent and has a fixed window with a sill height of 2’6” (30”) and a head height of 8’11” (107”), which runs 10’ wide (120”). The window has a break at 6’11” (83”) such that the upper portion or clerestory portion of the window is 2’ (24”) tall and can have a glazing different from that in the lower portion (view window). Can a designer use 0.30 VT glazing in the view window?

Answer:

Using the formula VT ≥ 0.11 / WWR, staff determines the minimum area weighted average VT for this space,

VT ≥ 0.11 / 0.3 = 0.367

So the area weighted minimum VT we need for this window is 0.367.

I.e. (View window Area x View window VT) + (Clerestory Area x Clerestory VT) / Total Window Area = 0.367

In this case:

Clerestory area = 24” height x 120” width = 2,880 sq.in

View window area = (83” - 30”) height x 120” width = 6,360 sq.in.

If the designer wants to use a 0.30 VT glazing in the view window then View window VT = 0.30

Total window area = (107” - 30”) height x 120” width = 9,240 sq.in.

Solving the above equation for Clerestory VT, staff gets:

Clerestory VT = 0.515

(6360 x 0.367) + (2880 x VTCL)/9240

So, to use a 0.3 VT glazing in the view window, the designer must use a 0.515 VT window in the clerestory.

3.3.2.3 Compliance Options

A. Dynamic Glazing − Chromatic Glazing

Chromatic-type fenestration has the ability to change performance properties (U-factor, SHGC, and VT). The occupant can manually or automatically control his or her environment by tinting or darkening a window with the flip of a switch or by raising/lowering a shade positioned between panes of glass. Some windows and doors change the performance automatically in response to a control or environmental signal. These “smart windows” provide a variety of benefits, including reduced energy costs due to controlled daylighting and unwanted heat gain or heat loss. While still a relatively new technology, high-performance windows are expected to grow substantially in the coming years.

Look for the NFRC Dynamic Glazing Label to compare and contrast the energy performance for these new products. See the example of a Dynamic Glazing NFRC label in Figure 3-17 below. The unique rating identifiers help consumers understand the “dynamics” of the product and allow comparison with other similar fenestration products.

If the product can operate at intermediate states, a dual directional arrow, (↔), with the word “variable” underneath will appear on the label. Some dynamic glazing is able to adjust to intermediate states, allowing for a performance level between the endpoints. The low value rating is displayed to the left (in the closed position), and the high value rating is displayed to the right (in the open position). This lets the consumer know at a glance the best and worst case performance of the product and what the default or de-energized performance level will be.

The label references the following information:

1. U-factor measures the rate of heat loss through a product. Therefore, the lower the U-factor, the lower the amount of heat loss. In cold climates where heating bills are a concern, choosing products with lower U-factors will reduce the amount of heat that escapes from inside the house.

2. The solar heat gain coefficient (SHGC) measures the rate of heat gain from solar energy passing through a product. Therefore, the lower the SHGC, the less amount of solar heat gain. In hot climates where air conditioning bills are a concern, choosing products with a lower SHGC will reduce the amount of heat that comes in from the outside.

3. Visible transmittance (VT) measures the amount of light that comes through a product. The higher the VT rating, the more light is allowed through a window or door.

4. Air Leakage (AL) is a measurement of heat loss and gain by infiltration through cracks in the window assembly which affects occupant comfort. The lower the AL, the less air will pass through cracks in the window assembly.

To receive chromatic glazing credit, the following must be met:

1. Optional prescriptive − default to Table 140.3-B and 140.3-C, U-factor and SHGC

2. Performance approach compliance − maximum credit allowance for best rating

3. Automatic controls to receive best rating values or

4. NFRC Dynamic Glazing Compliance Label is required; otherwise, default to Table 110.6-A and Table 110.6-B values.

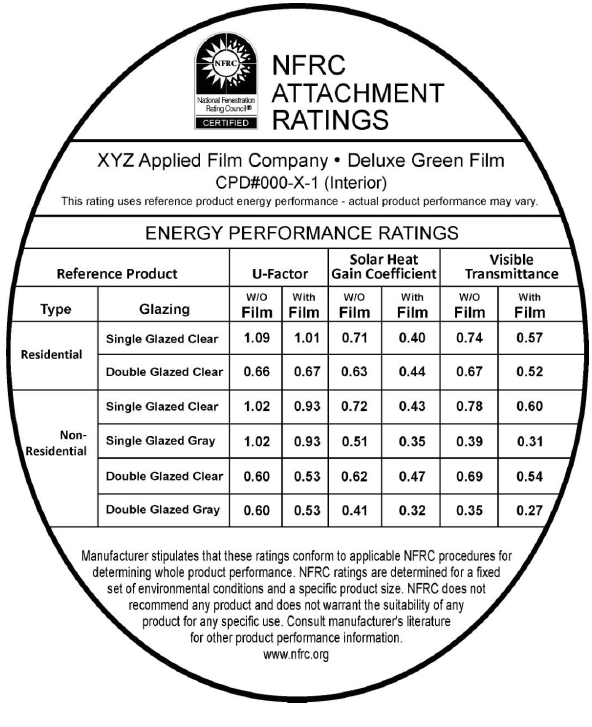

B. Window Films

Developed in the early 1950s, window films are made of mostly polyester substrate that is durable, tough, and highly flexible. It absorbs little moisture and has both high and low temperature resistances. Polyester film offers crystal clarity and can be pretreated to accept different types of coatings for energy control and long-term performance. Window films are made with a special scratch-resistant coating on one side and with a mounting adhesive layer on the other side. The adhesive is normally applied to the interior surface (room side) of the glass, unless a film is specifically designed to go on the exterior window surface.

Polyester film can be metalized and easily laminated to other layers of polyester film.

There are three basic categories of window films:

1. Clear (nonreflective) films are used as safety or security films and to reduce ultraviolet (UV) light, which contributes to fading of finished surfaces and furnishings. However, they are not normally used for solar control or energy savings.

2. Tinted or dyed (nonreflective) films reduce both heat and light transmission, mostly through increased absorptance and can be used in applications where the primary benefit desired is glare control with energy savings as secondary benefit.

3. Metalized (reflective) films can be metalized though vacuum coating, sputtering, or reactive deposition and may be clear or colored. Metalized (reflective) films are the preferred window films in most energy-saving applications, since they reduce transmission primarily through reflectance and are manufactured to selectively reflect heat more than visible light through various combinations of metals.

Look for the NFRC–certified attachment ratings energy-performance label, which helps consumers understand the contrast in energy performance of window films. An example of a window film energy performance label is shown on Figure 3-18 given below.

Window Film Compliance

To receive window film credit the, following must be met:

1. The performance approach must be used.

2. Use only the alteration to existing building compliance method.

a. The NFRC window film energy performance label is required for each film; otherwise, use the Default Table 110.6-A and Table 110.6-B values.

b. Window films shall have a 10-year or longer warranty.

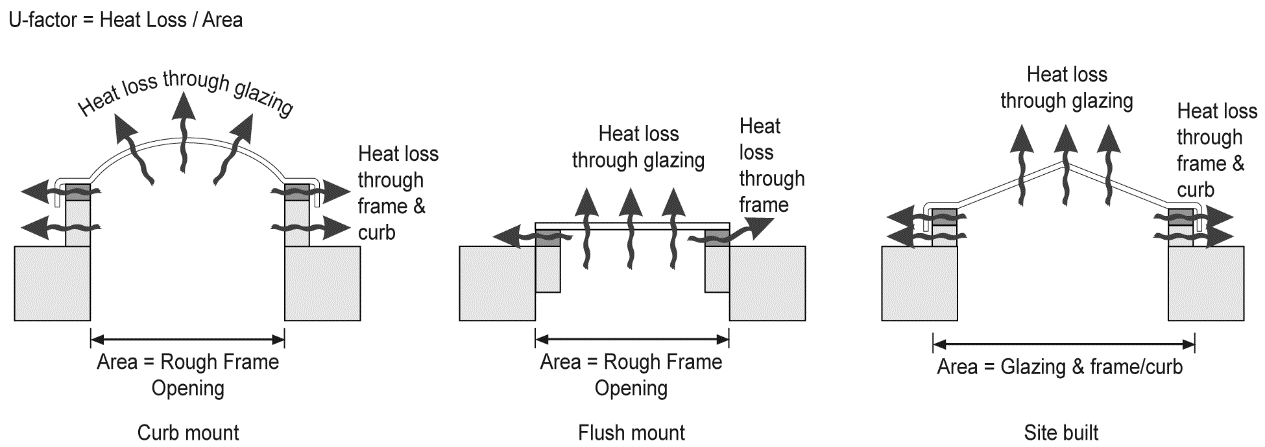

There are two ways that skylights can be mounted into a roof system, either flush-mounted or curb-mounted. To ensure water flows around them, skylights are often mounted on "curbs" set above the roof plane. These curbs, rising 6 to 12 inches above the roof, create additional heat loss surfaces.

When skylights are specified, the designer must show the skylit daylight zones on the building plans. Automatic daylighting controls are required when the installed power in the daylit zones of a room is greater than 120W. See Chapter 5 of this manual for a detailed discussion of the daylight zones.

3.3.3.1 Skylight Mandatory Measures

There are no mandatory measures for skylights, so the prescriptive or performance approach must be used. However, there are mandatory requirements for lighting controls related to daylighting, as discussed below.

A. Controls

Electric lighting in skylight daylit zones shall meet the mandatory control requirements in §130.1(d). Chapter 5 contains information about lighting control requirements and daylighting control requirements. As described above, obstructions are ignored for evaluating the architectural area served by skylights. However, for controlling lighting, one must consider the area shaded that is behind permanent obstructions that are greater than half the ceiling height. As a result, those luminaires behind tall obstructions are not part of the skylit daylit area and, therefore, not controlled by automatic daylighting controls.

3.3.3.2 Skylight Prescriptive Requirements

As with windows, there are four aspects of the prescriptive envelope approach for skylights:

1. Maximum total area.

2. Maximum U-factor.

3. Maximum solar heat gain coefficient (SHGC).

4. Minimum visible transmittance (VT).

|

|

All Climate Zones | |||

|

Glass, Curb Mounted |

Glass, Deck-Mounted |

Plastic, Curb-Mounted | ||

|

Nonresidential |

U-factor |

0.58 |

0.46 |

0.88 |

|

SHGC |

0.25 |

0.25 |

NR | |

|

VT |

0.49 |

0.49 |

0.64 | |

|

Maximum SRR% |

5% | |||

|

High-Rise Residential |

U-factor |

0.58 |

0.46 |

0.88 |

|

SHGC |

0.25 |

0.25 |

NR | |

|

VT |

0.49 |

0.49 |

0.64 | |

|

Maximum SRR% |

5% | |||

Excerpt from Energy Standards Tables 140.3-B and 140.3-C, Skylight Roof Ratio, SRR

A. Skylight Area

Skylight area is defined in JA1 as the area of the rough opening of a skylight. The area limit for skylights is 5 percent of the gross exterior roof area, sometimes called the skylight roof ratio (SRR). The limit increases to 10 percent for buildings with an atrium more than 55 ft high). The 55-ft height is also the threshold at which the California Building Code requires a mechanical smoke-control system for atriums (CBC Sec. 909). In practice, this means that the 10 percent SRR is not allowed for atriums unless they also meet this smoke control requirement.

Site-built monumental or architectural skylights equipped with integral built-in or site-built curbs (that is not part of the roof construction) are often used for atrium roofs, malls, and other applications that need large skylights. These are treated differently within the Energy Standards: in these cases the skylight area is the surface area of the glazing and frame/curb, not the area of the rough-framed opening. This is regardless of the geometry of the skylight, that is, it could be flat pyramid, bubble, barrel vault, or other three-dimensional shape – what matters is the anticipated heat exchanged through the glazing, which is a function of its area. Also, for special cases such as clerestory, rooftop monitor or tubular skylights, see Chapter 5 of this manual.

§140.3(c)4 also requires that the skylight area be at least 3 percent of the floor area (not accounting for obstructions), or that the product of the skylight area and the area-weighted average visible transmittance of the skylights be at least 1.5 percent of the floor area (not accounting for obstructions). This assures that enough light reaches the skylighted spaces. The visual transmittance option acknowledges that more skylight area is not needed for buildings with highly transmitting skylights. For example, if plastic skylights are installed with the prescriptive minimum transmittance of 0.64, the maximum ratio of skylight area to floor area within 0.7 times the ceiling height of skylights is 2.3 percent.

B. Skylight U-Factor

The U-factor for skylights is an inclusive measurement of its heat losses, and includes heat losses through the glazing, the frame, and the integral curb (when one exists). If an NFRC rating does not exist, such as for projecting plastic skylights, the designer can make use of default fenestration U-factors found in Table 110.6-A of the Energy Standards.

For skylights, the U-factor criteria depend on whether the skylight glazing material is plastic or glass, and whether the skylight is curb-mounted, noting that plastic skylights are assumed to be mounted on a curb. These criteria are shown in Tables 140.3-B, C, and D.

C. Skylight SHGC

Skylights are regulated for SHGC rather than RSHGC because skylights cannot have overhangs. The SHGC criteria vary with the SRR, and the criteria can be found in Tables 140.3-B, C, and D (Table 3-19). The designer can make use of default SHGC values in Table 110.6-B of the Energy Standards, or can use the Nonresidential Reference Appendix NA6 if all site-built fenestration (skylights and vertical fenestration) is less than 1,000 ft².

Skylights shall have an area-weighted average visible transmittance (VT) of no less than the value required by §140.3(a)6D.

E. Minimum Daylighting Prescriptive Requirements in Large Enclosed Spaces

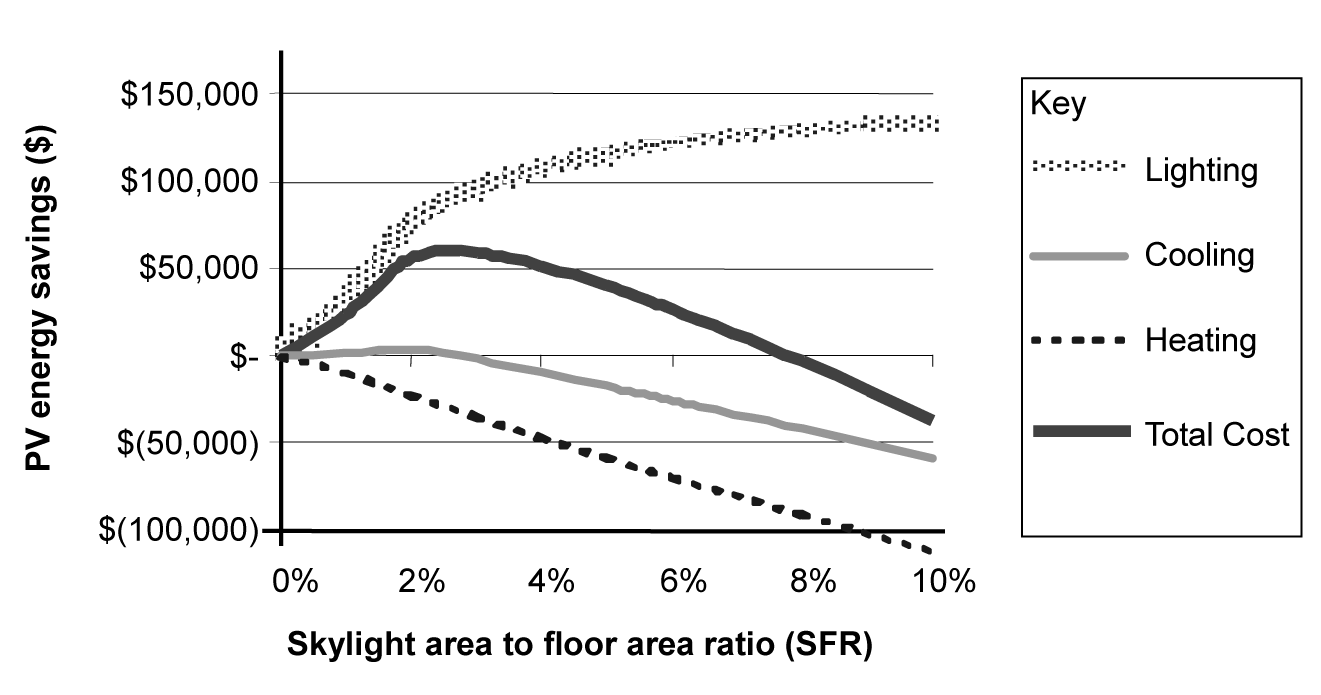

Appropriately sized skylight systems can dramatically reduce the lighting energy consumption of a building when combined with appropriate daylighting controls. Daylighting control requirements under skylights are discussed in Chapter 5 of this manual. Sizing is important: with too little skylight area, insufficient light is available to turn off electric lighting; with too much skylight area, solar gains and heat losses through skylights negate the lighting savings by adding heating and cooling loads.

Skylights and automatic daylighting controls are most cost-effective in large open spaces and are prescriptively required in enclosed spaces (rooms) that:

•Are larger than 5,000 ft².

•Are directly under a roof.

•Have ceiling heights greater than 15 ft.

•Have lighting power densities greater than 0.3 W/ft².

The Energy Standards require that at least 75 percent of the floor area be within one or more of the following:

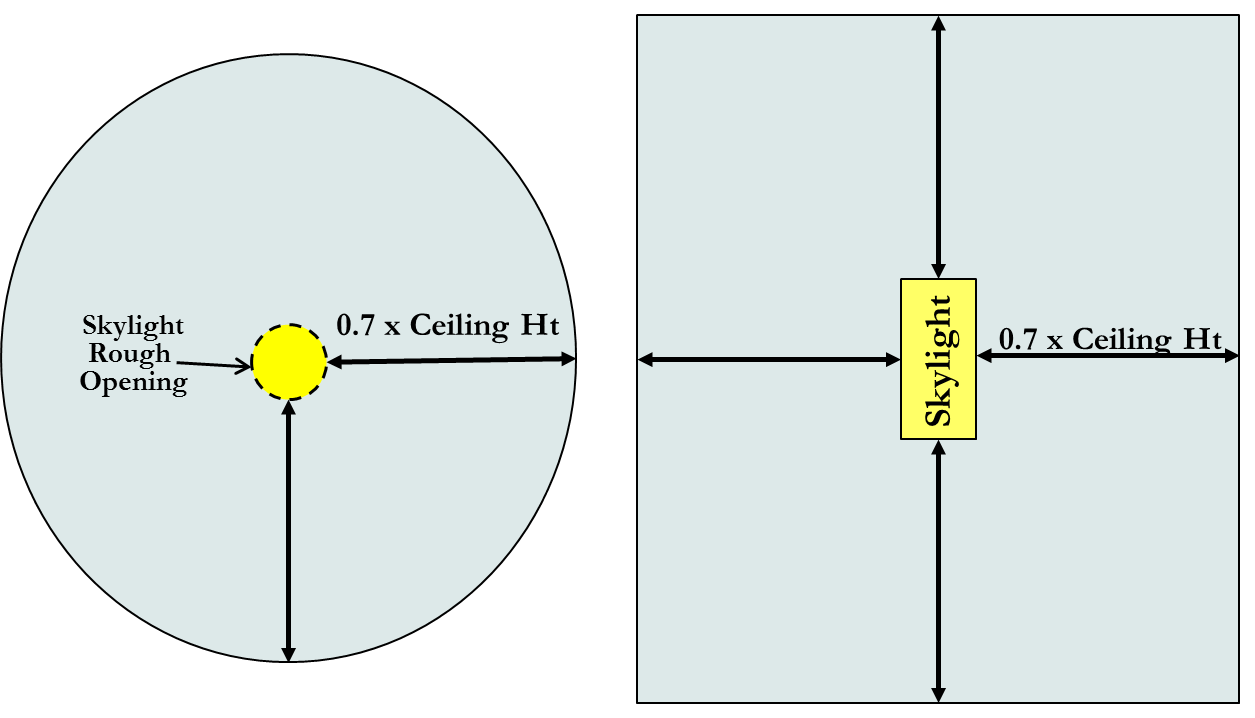

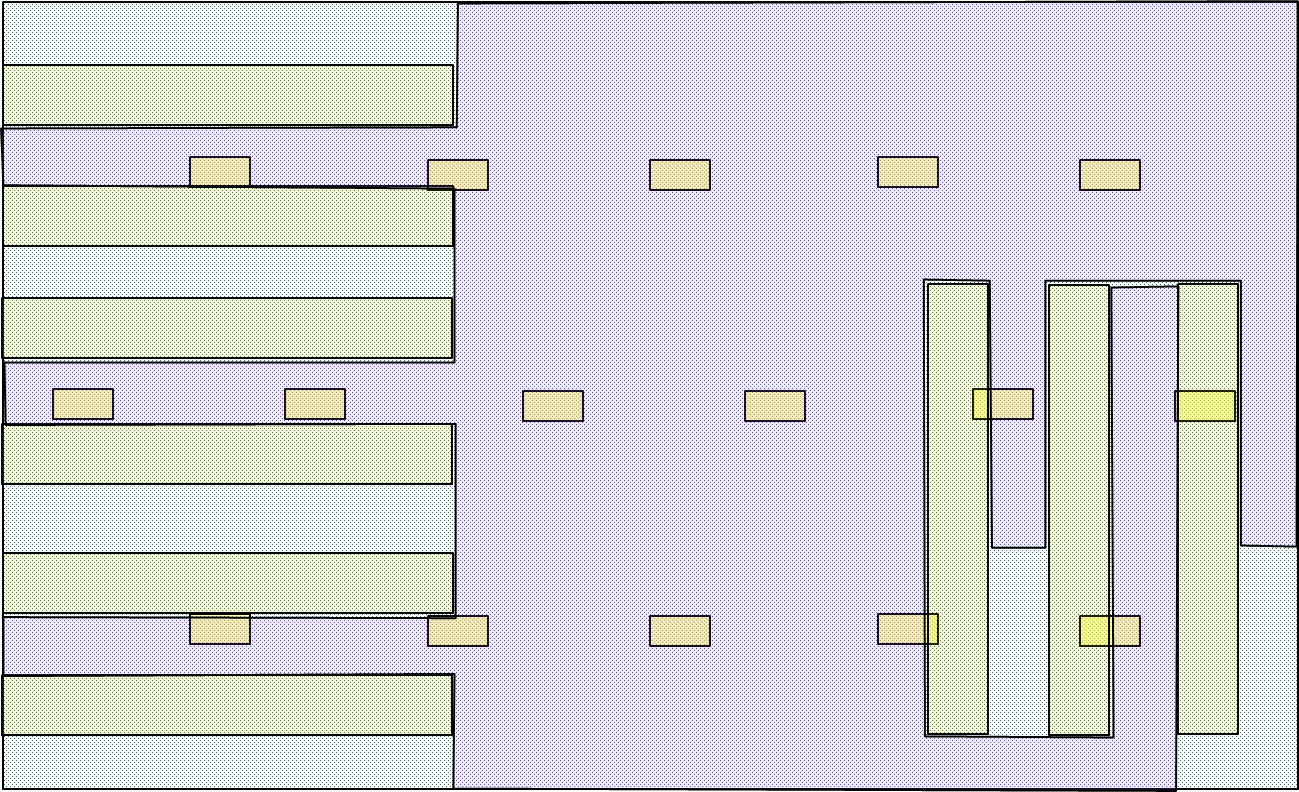

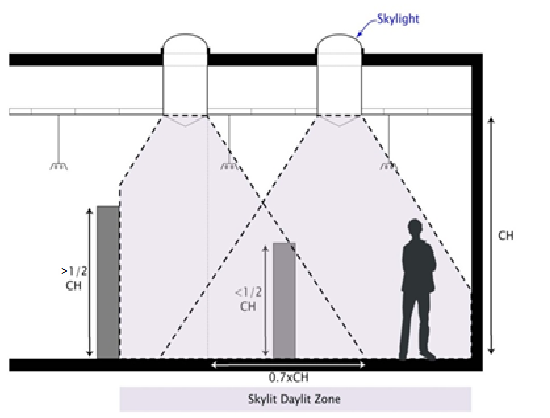

1. A skylit daylit zone, meaning an area in plan view that is directly under a skylight or within 0.7 times the average ceiling height in each direction from the edges of the rough opening of the skylight (see Figure 3-21), or

2. A primary sidelit daylit zone, meaning an area in plan view that is directly adjacent to vertical glazing, one window head height deep into the area, and window width plus 0.5 times window head height wide on each side of the rough opening of the window based on §130.1(d).

The shape of the skylit daylit zone will be similar in shape to the rough opening of the skylight, as shown in Figure 3-21.

Examples: If the skylight is circular, the area that is within a horizontal distance 0.7 times the average ceiling height from the edge of the rough opening, is also a circle, with the radius of the circle being the radius of the skylight + 0.7 x the ceiling height.

If the skylight is rectangular, the zone is rectangular, with the edges increased in each direction by 0.7 times the ceiling height.

|

a) Entire space is within 0.7 x ceiling height of skylights for meeting minimum daylit area (§140.3(c)) |

b)Skylit daylit zone (§130.1(d)) for controlling luminaires is limited by racks blocking daylight |

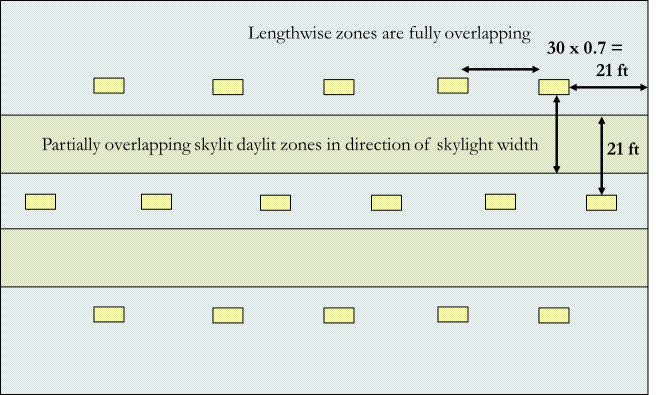

The specifications for daylighting controls in §130.1(d) describe which luminaires must be controlled, and consider the daylight obstructing effects of tall racks, shelves, and partitions taller than one-half the distance from the floor to the bottom of the skylight when determining if daylight will reach a given space. As shown in Figure 3-22, it is considerably easier to calculate.

(a) The total floor area in the space within a horizontal distance of 0.7 times the average ceiling height from the edge of rough opening of skylights.

Versus

(b) The total floor area in the space within a horizontal distance of 0.7 times the average ceiling height from the edge of rough opening of skylights, minus any area on a plan beyond a permanent obstruction that is taller than the following: A permanent obstruction that is taller than one-half the distance from the floor to the bottom of the skylight.

(a) is required to be calculated to comply with minimum skylight area requirements of §140.3(c), and (b), is required to comply with the automatic daylighting control requirements of §130.1(d) (essentially, to ensure that daylighting controls are not installed where they would not be effective).

In §130.1(d), the skylit daylit areas are required to be drawn on the plans, and any general lighting luminaires that are in the daylit zones must be separately controlled by automatic daylighting controls. (See the daylighting requirements in Chapter 5 Lighting).

Two exemptions from §140.3(c) include:

1. Auditoriums, churches, museums and movie theaters due to the demanding lighting control needs.

2. Refrigerated warehouses to minimize heat gains.

Since skylights paired with daylighting controls can significantly reduce energy demands from lighting, they are mandatory on all nonresidential occupancies that meet the above criteria whether the space is conditioned or unconditioned. Further information can be found in Section 3.3.3.1.

For large buildings with high ceilings, skylighting 75 percent of the floor area can be achieved by evenly spacing skylights across the roof of the building. As a general rule, a space can be fully skylighted by having skylights spaced so that the edges of the skylights are not further than 1.4 times the ceiling height apart. For example, in a space having a ceiling height of 20 feet, the space can be fully skylighted if the edges of skylights are no more than 28 feet apart.

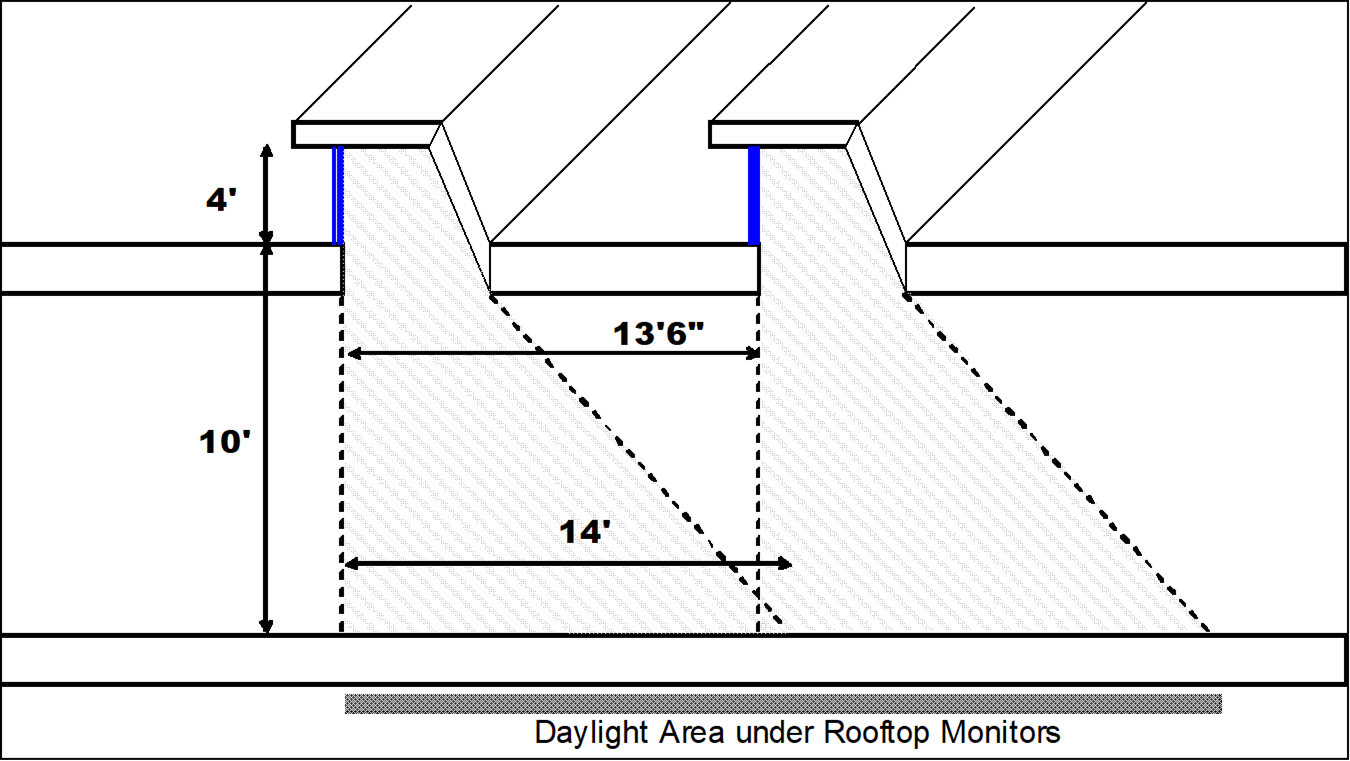

F. Rooftop Monitors

Rooftop monitors are considered vertical fenestration, and the daylight area next to them is the same as the daylit area next to other vertical fenestration. The daylit area is from the inward facing plane of the fenestration one window head height and in the direction parallel to the fenestration 0.5 window head heights on either side.

G. Exceptions for Shading

Occasionally there is not a solar resource available for skylighting. This situation occurs, for example, if a short building is shadowed by surrounding taller buildings. To account for this, minimum daylighting requirements are exempted for spaces where permanent architectural features of the building, existing structures or natural objects block direct beam sunlight on at least half of the roof over the enclosed space for more than 1,500 daytime hours per year between 8 a.m. and 4 p.m. This can be documented to the local building official using a variety of tools including equipment that superimposes the sun path diagram on a photograph of the sky taken at the site, hand calculation tools such as the sun path calculator, and computer-aided design software tools that automate this calculation.

3.3.3.3 Ignoring Partitions and Shelves

The rationale for ignoring the presence of partitions for specifying minimum skylight area and spacing is that the design of the envelope may be developed before there is any knowledge of the location of the partial height partitions or shelves, as is often the case for core and shell buildings. Thus, the architectural daylit zone requirement of 75 percent of the space area indicates the possibility of the architectural space being mostly daylit. By not accounting for partial ceiling height partitions and racks, the Energy Standards are consistent in addressing architectural daylit areas, regardless of whether the design is core and the shell or a complete design development, including interior design. This approach does not require the addition of extra skylights or windows if racks and partial height partitions are added later.

Example 3-15

Question:

What is the maximum spacing and recommended range for skylights in a 40,000 ft2 warehouse with 30-foot-tall ceiling and a roof deck?

Answer:

From the definition of Skylit Daylit Zone in Section 130.1(d), the maximum spacing of skylights that will result in the space being fully skylit is:

Maximum skylight spacing = 1.4 x Ceiling Height + Skylight width

Spacing skylights closer together results in more lighting uniformity and thus better lighting quality, – but costs more as more skylights are needed. However as a first approximation, one can space the skylights 1.4 times the ceiling height. For this example, skylights can be spaced 1.4 x 30 = 42 feet. In general the design will also be dictated by the size of roof decking materials (such as 4’ by 8’ plywood decking) and the spacing of roof purlins so the edge of the skylights line up with roof purlins. For this example, staff assumes that roof deck material is 4’ by 8’ and skylights are spaced on 40-foot centers.

Each skylight is serving a 40-foot by 40-foot area of 1,600 sf. A standard skylight size for warehouses is

often 4’ by 8’ (so it displaces one piece of roof decking). The ratio of skylight area to daylit area is 2 percent (32/1600 = 0.02). Assuming this is a plastic skylight and it has a minimally compliant visible light transmittance of 0.64, the product of skylight transmittance and skylight area to daylit area ratio is

(0.64)(32/1,600) = 0.013 = 1.3%

This is a little less than the 2 percent rule of thumb described earlier for the product of skylight transmittance and skylight area to daylit area ratio. If one installed an 8 ft by 8 ft skylight (two 4 ft by 8 ft skylights) on a 40 foot spacing, it would yield a 2.6 percent product of skylight transmittance and skylight area to daylit area ratio and provide sufficient daylight. With 64 square feet of skylight area for each 1,600 square feet of roof area, the skylight-to-roof area ratio (SRR) is 4 percent, which is less than the maximum SRR of 5 percent allowed by Section 140.3(a) and thus complies with the maximum skylight requirement.

An alternate (and improved) approach would be to space 4 ft x 8 ft skylights closer together, which would provide more uniform daylight distribution in the space and could more closely approach the desired minimum VT skylight area product. A 32-foot center-to-center spacing of skylights results in (32 x 32) = 1,024 square feet of daylit area per skylight. By taking the product of the skylight VT and the skylight area and dividing by 0.02 (the desired ratio), it yields the approximate area the skylight should serve. In this case, with a VT of 0.65 and a skylight area of 32 square feet, each skylight should serve around:

(0.64 x 32 /0.02) = 1,024 sf.

For a minimally compliant 4 ft by 8 ft plastic skylight with a visible light transmittance of 0.65, the product of skylight transmittance and skylight area to daylit area ratio is:

(0.64)(32/1,024) = 0.020 = 2.0%

Energy savings can be improved than this rule of thumb approach by using a whole-building energy performance analysis tool that enhances the trade-offs among daylight, heat losses and gains, and electric lighting energy consumption.

3.3.3.4 Glazing Material and Diffusers

Skylights shall have a glazing material or diffuser that has a measured haze value greater than 90 percent, tested according to ASTM D1003 (notwithstanding its scope) or other test method approved by the Energy Commission.

For conditioned spaces the Energy Standards require the use of double-glazed skylights. When the skylights are above unconditioned spaces, there is no limitation placed on the maximum skylight area or the U-factor or SHGC.

Regardless of whether the space is conditioned, the code requires that the skylights diffuse and bring in enough sunlight so that, when the electric lights are turned off, the occupants have relatively uniform daylight in the space. If the space is unconditioned, single-glazed skylights will comply with the code requirements as long as they are sufficiently diffusing (that is, the glazing or diffuser material has a haze rating greater 90 percent) and the visible transmittance is above the VT requirements in Table 140.3-B or C of the Energy Standards. Products that have such a rating include prismatic diffusers, laminated glass with diffusing interlayers, pigmented plastics, and so forth. This requirement assures that light is diffused over all sun angles. Any unconditioned space that later becomes conditioned must meet the new construction envelope requirements. Therefore, if the space may become conditioned in the future, it is recommended that the envelope meet the conditioned envelope thermal requirements.

Other methods of diffusion that result in sufficient diffusion of light over the entire year would also be acceptable in lieu of using diffusing glazing. Acceptable alternatives are baffles or reflecting surfaces that ensure direct beam light is reflected off a diffuse surface before entering the space over all sun angles encountered during a year. This alternative method of diffusion would have to be documented by the designer and approved by the code authority in your jurisdiction.

Example 3-16

Question:

A designer is using a U-factor of 0.57 for compliance with a curtain wall system. The glazing system uses two lites of 1/4 in (6mm) glass with a low-e= 0.1 coating on the second surface. The air gap is 1/2 in (12 mm). A standard metal frame is proposed for the curtain wall system. Is 0.57 a reasonable U-factor for compliance, and can it reasonably be achieved by the glazing contractor through the NFRC process for site-built fenestration?

Answer:

The default U-factor for this glazing combination from Reference Nonresidential Appendix NA6 is 0.59. If no NFRC rating information is available, a U-factor of 0.59 must be used. The design U-factor of 0.57 cannot be used.