5.4 Space Uses

Each thermal zone discussed above may be subdivided into

spaces. This section presents the building descriptors that relate to the space

uses. Space uses and the defaults associated with them are 'listed in

Appendix

5.4A. Every thermal zone shall have at least one space, as defined in this

section. Daylit spaces should generally be separately defined by space type

and/or orientation.

5.4.1 General Information

|

Space Type |

|

Applicability |

All projects |

|

Definition |

The space function type that defines occupancy,

internal load, and other characteristics, as indicated in Appendix

5.4A.

If lighting compliance is not performed, use either

approach but actual LPDs cannot be entered for the spaces; the LPDs of the

building match the standard design.

The allowed space function types in area category are

available from Appendix

5.4A. The building or space type determines the following baseline

inputs:

Number of occupants (occupant density)

Equipment power density

Lighting power density

Hot water load

Ventilation rate

Schedules (from Appendix

5.4B) |

|

Units |

List |

|

Input Restrictions |

Only selections shown in Appendix

5.4A may be used.

For unconditioned spaces, the user must enter

“unconditioned” as the occupancy and ventilation; internal loads and uses

are set to zero. Compliance software shall require the user to identify if

lighting compliance is performed (lighting plans are included or have

already been submitted). |

|

Standard Design |

Same as proposed |

|

Existing Buildings |

Same as proposed |

|

Floor Area |

|

Applicability |

All projects |

|

Definition |

The floor area of the space

The area of the spaces that make up a thermal zone

shall sum to the floor area of the thermal zone. |

|

Units |

Square feet (ft²) |

|

Input Restrictions |

Area shall be measured to the outside of exterior walls

and to the center line of partitions |

|

Standard Design |

Area shall be identical to the proposed

design |

|

Existing Buildings |

Same as proposed |

5.4.2

Infiltration

|

Infiltration Method |

|

Applicability |

All projects |

|

Definition |

Energy simulation programs have a variety of methods

for modeling uncontrolled air leakage or infiltration. Some procedures use

the effective leakage area which is generally applicable for small

residential scale buildings. The component leakage method requires the

user to specify the average leakage through the building envelope per unit

area (ft²). Other methods require the specification of a maximum rate,

which is modified by a schedule. |

|

Units |

List effective leakage area, component leakage, or air

changes per hour |

|

Input Restrictions |

For the purpose of California compliance and reach, the

component leakage area is prescribed; a fixed infiltration rate shall be

specified and calculated as a leakage per area of exterior envelope,

including the gross area of exterior walls and fenestration but excluding

roofs and exposed floors. |

|

Standard Design |

The infiltration method used for the standard design

shall be the same as the proposed design. |

|

Infiltration Data |

|

Applicability |

All projects |

|

Definition |

Information needed to characterize the infiltration

rate in buildings.

The required information will depend on the

infiltration method selected above. For the effective leakage area method,

typical inputs are leakage per exterior wall area in ft² or other suitable

units and information to indicate the height of the building and how

shielded the site is from wind pressures. Only zones with exterior wall

area are assumed to be subject to infiltration. |

|

Units |

A data structure is required to define the effective

leakage area model.

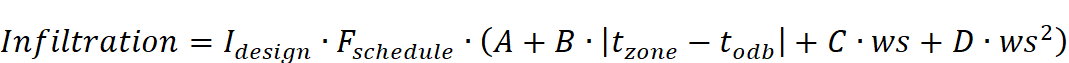

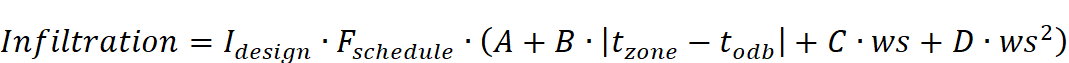

For the purpose of California compliance and reach,

infiltration shall be calculated each hour using the following

equation:

Where:

|

|

zone infiltration airflow (m³/s-m²) |

|

= =

|

design zone infiltration

airflow (m³/s-m²) |

|

= =

|

fractional adjustment

from a prescribed schedule, based on HVAC availability schedules in

Appendix

5.4B(unitless) |

|

= =

|

zone air temperature

(°C) |

|

= =

|

outdoor dry bulb

temperature (°C) |

|

= =

|

the windspeed (m/s) |

|

A = |

overall coefficient

(unitless) |

|

B = |

temperature coefficient

(1/°C) |

|

C = |

windspeed coefficient

(s/m) |

|

D = |

windspeed squared

coefficient (s²/m²) |

|

|

Input Restrictions |

For the proposed design, 2 (0.000228 m³/s-m²) times the

gross wall area exposed to ambient outdoor air. A, B and D shall be fixed

at zero. C shall be fixed at 0.10016 hr/mile (0.224 s/m). 2 (0.000228 m³/s-m²) times the

gross wall area exposed to ambient outdoor air. A, B and D shall be fixed

at zero. C shall be fixed at 0.10016 hr/mile (0.224 s/m).

For nonresidential spaces with operable windows that do

not have interlocks, the CBECC software shall automatically increase

infiltration to the space by 0.15 cfm/ft2 whenever the outside

air temperature is between 50°F and 90°F and when the HVAC system is

operating.

For high-rise residential spaces with operable windows

that do not have interlocks, the CBECC software shall automatically

increase infiltration to the space by 0.02 cfm/ft2 whenever the

outside air temperature is between 50°F and 90°F and when the HVAC system

is operating. |

|

Standard Design |

The standard design shall use the equation listed

above, with coefficients A, B, and D set to 0. C shall be set to 0.10016

hr/mile (0.224 s/m). 2. 2. |

|

Infiltration Schedule |

|

Applicability |

When an infiltration method is used that requires the

specification of a schedule |

|

Definition |

With the ACH method and other methods (see above), it

may be necessary to specify a schedule that modifies the infiltration rate

for each hour or time step of the simulation. Typically the schedule is

either on or off but can also be fractional. |

|

Units |

Data structure: schedule, fractional |

|

Input Restrictions |

The infiltration schedule shall be prescribed based on

the HVAC system operating schedules from Appendix

5.4B. The infiltration schedule shall be set equal to 1 when the HVAC

system is scheduled off and 0.25 when the HVAC system is scheduled on.

This is based on the assumption that when the HVAC system is on it brings

the pressure of the interior space above the pressure of the exterior,

decreasing the infiltration of outside air. When the HVAC system is off,

interior pressure drops below exterior pressure and infiltration

increases.

A possible incorporation of the prescriptive

requirement for interlocks for operable windows will model mixed mode

ventilation as an increased infiltration rate when outside air conditions

allow. |

|

Standard Design |

The infiltration schedule for the standard design shall

be set equal to 1 when the HVAC system is scheduled off and 0.25 when the

HVAC system is scheduled on. |

5.4.3

Occupants

For space level

information on occupancy, lighting, and plug load schedules, as well as occupant

density, allowed lighting power density. Appendix

5.4A provides a table of allowed space types.

|

Fixed Seating in Space |

|

Applicability |

All projects that have a space with fixed seating (such

as a theater or auditorium) |

|

Definition |

This is a flag that indicates that the space has fixed

seating. If checked, this flag allows the user to override the default

occupancy with values that comply with the California Building

Code. |

|

Units |

Boolean |

|

Input Restrictions |

As designed

May not be used with high-rise residential,

hotel/motel, unoccupied, and unleased tenant area spaces. The default is

false. |

|

Standard Design |

Same as proposed |

|

Existing Buildings |

The number of occupants must be identical for both the

proposed and baseline design cases. |

|

Dwelling Units per Space |

|

Applicability |

High-rise residential projects |

|

Definition |

The number of residential living units within a single

compliance model space |

|

Units |

Boolean |

|

Input Restrictions |

As designed |

|

Standard Design |

1 |

|

Existing Buildings |

1 |

|

Number of Bedrooms |

|

Applicability |

High-rise residential projects |

|

Definition |

The number of bedrooms per dwelling unit |

|

Units |

Integer |

|

Input Restrictions |

As designed but constrained to a minimum of 0 (studio)

and a maximum of 5 |

|

Standard Design |

Same as proposed |

|

Existing Buildings |

Same as proposed |

|

Number of Occupants |

|

Applicability |

High-rise residential projects |

|

Definition |

The number of people in a space.

The number of people is modified by an hourly schedule

(see below), which approaches but does not exceed 1.0. Therefore, the

number of people specified by the building descriptor is similar to design

conditions as opposed to average occupancy. |

|

Units |

The number of people may be specified in an absolute

number, ft²/person, or people/1000 ft². |

|

Input Restrictions |

The number of occupants is prescribed, and the values

are given by Space Type in Appendix

5.4A, For high-rise residential spaces, the number of occupants is

defined as: Max (number of bedrooms +1, 2). |

|

Standard Design |

The number of occupants must be identical for both the

proposed and baseline design cases. |

|

Standard Design:

Existing Buildings |

The number of occupants must be identical for both the

proposed and baseline design cases. |

|

Occupant Heat

Rate |

|

Applicability |

All projects |

|

Definition |

The sensible and latent heat produced by each occupant

in an hour.

This depends on the activity level of the occupants and

other factors. Heat produced by occupants must be removed by the air

conditioning system as well as the outside air ventilation rate and can

have a significant impact on energy consumption. |

|

Units |

Btu/h specified separately for sensible and latent

gains |

|

Input Restrictions |

The occupant heat rate is prescribed for California

compliance |

|

Standard Design |

The occupant heat rate for the baseline building shall

be the same as the proposed design. |

|

Standard Design:

Existing

Buildings |

Same as proposed |

|

Occupancy Schedule |

|

Applicability |

All projects |

|

Definition |

The occupancy schedule modifies the number of occupants

to account for expected operational patterns in the building. The schedule

adjusts the heat contribution from occupants to the space on an hourly

basis to reflect time-dependent usage patterns. The occupancy schedule can

also affect other factors such as outside air ventilation, depending on

the control mechanisms specified. |

|

Units |

Data structure: schedule, fractional |

|

Input Restrictions |

The occupant schedule is prescribed for California

compliance. For California compliance, an appropriate schedule from Appendix

5.4B shall be used. |

|

Standard Design |

Occupancy schedules are identical for proposed and

baseline building designs. |

|

Standard Design:

Existing

Buildings |

Same as proposed |

The building descriptors in this s are provided for each

lighting system. Typically a space will have only one lighting system but, in

some cases, it could have two or more. Examples include a general and task

lighting system in offices, or hotel multi-purpose rooms that have lighting

systems for different functions. It may also be desirable to define different

lighting systems for areas that are daylit and those that are not.

|

Lighting Classification Method |

|

Applicability |

Each space in the building |

|

Definition |

Indoor lighting power can be specified using the area

category method or the tailored method.

Area category method can be used for all areas of the

building with space types listed in Appendix

5.4A. This method can be used by itself or with the tailored lighting

method.

Tailored lighting method can be used for spaces with

primary function listed in Table

140.6-D of the standards. The tailored lighting method is intended to

accommodate special lighting applications. The tailored lighting method

can be used by itself for all areas of the building or with the area

category method. For a given area only one classification type can be

used. |

|

Units |

List |

|

Input Restrictions |

Only area category or tailored lighting are

allowed |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing

Buildings |

Same as proposed |

Table 6: Lighting

Specification

|

Options:

Lighting Classification Method |

Area

category method |

Tailored

lighting Method |

|

Allowed combinations with

other lighting classification methods |

May be combined with

tailored method |

May be combined with area

category method |

|

Allowed Regulated lighting

power types |

General lighting

power

Custom lighting

power |

General lighting

power

Custom lighting

power |

|

Allowed

Trade-offs |

General lighting between

conditioned spaces using area category method

General lighting between

conditioned spaces using area category and tailored method |

General lighting between

conditioned spaces using tailored method

General lighting between

conditioned spaces using tailored and area category

method |

|

Exception: With the area

category method, custom lighting power can be used only if the tailored

lighting method is not used in any area of the

building. |

|

Regulated Interior Lighting Power

Density |

|

Applicability |

All projects when lighting compliance is

performed |

|

Definition |

Total connected lighting power density for all

regulated interior lighting power

This includes the loads for lamps and ballasts. The

total regulated interior lighting power density is the sum of general

lighting power and applicable custom lighting power per floor area in a

space. Calculation of lighting power for conditioned spaces is done

separately from unconditioned spaces.

Lighting in unconditioned spaces can be modeled, but

total lighting power in unconditioned spaces is not enforced in the

compliance software. Lighting in unconditioned spaces must follow

prescriptive compliance, and must be documented on appropriate compliance

forms. No tradeoffs are allowed between lighting in conditioned spaces and

lighting in unconditioned spaces. |

|

Units |

W/ft2 |

|

Input Restrictions |

Proposed value is:

a) For the area category

method: the sum of the proposed general lighting power and the proposed

general lighting exceptional power within a conditioned space or a user

input value if no interior lighting systems are modeled.

b) For the tailored lighting method: the sum of

the proposed general lighting power and the proposed custom lighting power

within a conditioned space or a user input value if no interior lighting

systems are modeled.

When lighting compliance is not performed, the lighting

power may not be entered and is set equal to the lighting level of the

baseline building, which is set to the levels for the selected occupancy

from Appendix

5.4A. |

|

Standard Design |

For spaces without special task lighting, wall display

lighting or similar requirements, this input will be the same as the

general lighting power density. See the general lighting power building

descriptor for details.

With the area category and tailored method regulated

interior lighting power for each space will be the sum of general lighting

power and allowed custom lighting power.

For alterations where less than 40 luminaires have been

modified the standard design is the existing lighting condition before the

alteration. If 40 or more luminaires have been modified, the prescriptive

requirements for new construction apply. |

|

General Lighting Power |

|

Applicability |

All spaces or projects |

|

Definition |

General lighting power is the power used by installed

electric lighting that provides a uniform level of illumination throughout

an area, exclusive of any provision for special visual tasks or decorative

effect, and also known as ambient lighting. |

|

Units |

Watts |

|

Input Restrictions |

As designed

For spaces without special task lighting, wall display

lighting or similar requirements, this input will be the same as the

regulated lighting power.

Trade-offs in general lighting power are allowed

between spaces all using the area category method, between spaces all

using the tailored lighting method and between spaces that use area

category and tailored methods. See Table 6: Lighting

Specification for details. |

|

Standard Design |

With the area category method, general lighting power

is the product of the lighting power densities for the space type from Appendix

5.4A and the floor areas for the corresponding conditioned spaces.

With the tailored lighting method, general lighting

power is the product of the lighting power density for the primary

function type in Table

140.6-D of the standards and the floor area of the space. The lighting

power density is given as a function of room cavity ratio (RCR) and

interior illumination level in Table

140.6-G. No interpolation is allowed for this table.

The general lighting power in the tailored method is

calculated by the following steps:

Step 1. Determine illumination level from Table

140.6-D by matching the primary function area in Table 140.6-D with

the space type in Appendix

5.4A.

Step 2. Calculate the room cavity ratio (RCR) by using

the applicable equation in Table

140.6-F.

Rectangular Rooms: RCR = 5 x H x (L+W) / (L x W)

Irregular Rooms: RCR = 2.5 x H x P / A

Where: L = length of room; W = width of room; H =

vertical distance from the work plane to the centerline of the lighting

fixture; P = perimeter of room, and A = area of room

Step 3. Determine the general lighting in the space(s)

using the tailored method by a look-up in Table

140.6-G, where the general lighting LPD is a function of illuminance

level and RCR. No interpolation is allowed for this table. A space between

two illuminance levels (for example, 150 lux) uses the applicable LPD from

the next lower illuminance level (100 lux).

The standard design uses the irregular room RCR

equation for both simplified and detailed geometry models.

The standard design lighting power is modified by a

factor of 1/1.20 (0.833) if the simplified geometry approach is used and

if the visible transmittance of any fenestration in the space does not

meet the prescriptive requirements established in Section

140.3 of the standards. |

|

Standard Design:

Existing Buildings |

When the lighting status is “existing” (and unaltered)

for the space, the standard design is the same as the existing, proposed

design.

When the lighting status is “altered” for the space,

and at least 10 percent of existing luminaires have been altered:

a)

If the lighting status is “existing”, then the standard design LPD is the

same as the proposed design.

b)

If the lighting status is “new”, then the standard design LPD is same as

new construction.

c)

If the lighting status is “altered”, then the standard design LPD is the

same as new construction. |

|

General Lighting

Exceptional Power |

|

Applicability |

Spaces that use the area

category method; note that some exceptional allowances are only applicable

to certain space types. See Table

140.6-C of the standards. |

|

Definition |

The standards provide an

additional lighting power allowance for special cases. Each of these

lighting system cases is treated separately as “use-it-or-lose-it”

lighting--the user receives no credit (standard design matches proposed)

but there is a maximum power allowance for each item). There are eight

lighting power allowances, as defined in the standards Table 140.6-C

footnotes: |

|

Units |

Data structure. This

input has eight data elements:

1. Specialized task work, laboratory

(W/ft2)

2. Specialized task work, other

approved areas (W/ft2)

3. Ornamental lighting

(W/ft2)

4. Precision commercial and industrial

work (W/ft2)

5. White board or chalk board lighting

(W/linear foot)

6. Accent, display and feature

lighting (W/ft2)

7. Decorative Lighting

(W/ft2)

8. Videoconferencing studio lighting

(W/ft2) |

|

Input

Restrictions |

As

designed |

|

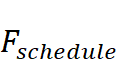

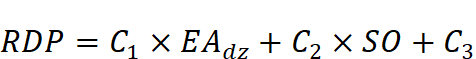

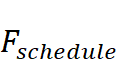

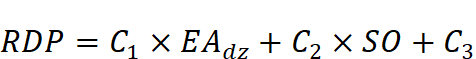

Standard

Design |

The standard design

general lighting exceptional power (GLEP) is given by the following

equation:

Where:

|

|

The GLEP of the

standard design |

|

|

The proposed GLEP

of the footnote allowance i in the data structure above, or in the

footnotes to Table

140.6-C of the standards |

|

|

The general

lighting exceptional allowance (GLEA) , which is the maximum allowed

added lighting power in the rightmost column in Table 140.6-C of the

standards; these allowances are, for GLEA1 through GLEA8, 0.2

W/ft2, 0.5 W/ft2, 0.5 W/ft2, 1.0

W/ft2, 5.5 W/linear foot, 0.3 W/ft2, 0.2

W/ft2 and 1.5 W/ft2,

respectively |

|

|

The general

lighting exceptional task area (GLETA) for the ith

exception, where the exception number corresponds to the area

category exception number in the footnotes to Table 140.-C of the

standards |

|

|

Standard

Design:

Existing

Buildings |

|

|

General Lighting Exceptional Task Area |

|

Applicability |

Spaces that use area category method |

|

Definition |

The area associated with each of the exceptional

lighting allowances in the GLEP building descriptor |

|

Units |

ft2 |

|

Input Restrictions |

As designed but cannot exceed the floor area of the

space |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

White Board Length |

|

Applicability |

Spaces that use area category method and take GLEP

allowance #5 |

|

Definition |

The linear length of the white board or chalk board in

feet |

|

Units |

Ft |

|

Input Restrictions |

As designed |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Custom Lighting Power |

|

Applicability |

All spaces or projects that use the tailored lighting

method |

|

Definition |

Custom lighting power covers lighting sources that are

not included as general lighting, including task lighting, display

lighting, and other specialized lighting designated in the footnotes to Table

140.6-C and lighting systems in Table

140.6-D of the standards. This lighting must be entered separately

from the general lighting because it is not subject to tradeoffs.

Software shall allow the user to input a custom

lighting input for the allowed lighting system. If area category method is

used, custom lighting power cannot be used if the tailored method is used

for any area of the building. See Table 6: Lighting

Specification for details. |

|

Units |

Watts |

|

Input Restrictions |

As designed |

|

Standard Design |

Same as proposed but subject to the maximum limits

specified in the footnotes to Table 140.6-C and Table

140.6-D of the standards. For spaces using the tailored method, the

maximum allowed custom power is defined by the following procedure:

The standard design custom lighting power is calculated

by the sum of the following four terms:

1) The product of the standard design wall

display power and the standard design wall display length;

2) The product of the standard design floor and

task lighting power and the standard design floor and task lighting

area;

3) The product of the standard design ornamental

and special effect lighting power, and the standard design ornamental and

special effect lighting area; and

4) The product of the standard design very

valuable display case power and the standard design very valuable display

case area. |

|

Standard Design:

Existing Buildings |

For alterations where less than 10 percent of existing

luminaires have been modified, the baseline is the existing lighting

condition before the alteration. If 10 percent or more luminaires have

been altered, the custom lighting power for the baseline is the same as

proposed, but subject to the limits specified in the footnotes to Table

140.6-C of the standards. |

|

Wall Display Power |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting power allowed for wall display, as

specified in standards Table

140.6-D, column 3 |

|

Units |

W/ft |

|

Input Restrictions |

As designed |

|

Standard Design |

The standard design lighting power is the lesser of the

proposed design wall display power or the limit specified in Table 140.6-D

for the applicable space type. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Wall Display Length |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The horizontal length of the wall display lighting area

using the tailored method for the space |

|

Units |

ft |

|

Input Restrictions |

As designed but this value cannot exceed the floor area

of the space |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Floor and Task Lighting Power |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting power allowed for floor display and task

lighting, as specified in Table

140.6-D, column 4, of the standards |

|

Units |

W/ft2 |

|

Input Restrictions |

As designed |

|

Standard Design |

The standard design floor and task lighting power is

the lesser of the proposed design floor and task lighting power or the

limit specified in Table 140.6-D, column 4, for the applicable space

type. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Floor and Task Lighting Area |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting area that is served by the floor and task

lighting defined using the tailored method for the space |

|

Units |

ft2 |

|

Input Restrictions |

As designed but this value cannot exceed the floor area

of the space |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Ornamental and Special Effect Lighting

Power |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting power allowed for ornamental and special

effect lighting, as specified in Table

140.6-D, column 5, of the standards |

|

Units |

W/ft2 |

|

Input Restrictions |

As designed |

|

Standard Design |

The standard design ornamental and special effect

lighting power is the lesser of the proposed design ornamental and special

effect lighting power or the limit specified in Table 140.6-D, column 5,

for the applicable space type. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Ornamental and Special Effect Lighting

Area |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting area that is served by the ornamental and

special effect lighting defined using the tailored method for the

space |

|

Units |

ft2 |

|

Input Restrictions |

As designed but this value cannot exceed the floor area

of the space |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Very Valuable Display Case Lighting

Power |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The lighting power allowed for very valuable display

case lighting, as specified in standards section

140.6(c)3L |

|

Units |

W/ft2 |

|

Input Restrictions |

As designed |

|

Standard Design |

The standard design very valuable display case lighting

power is the lesser of:

a) The product

of the area of the primary function and 0.8 W/ft2;

b) The product

of the area of the display case and 12 W/ft2; or

c) The

proposed very valuable display lighting power. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Very Valuable Display Case Lighting

Area |

|

Applicability |

All spaces that use the tailored method |

|

Definition |

The area of the very valuable display case(s) in plan

view |

|

Units |

ft2 |

|

Input Restrictions |

As designed but this value cannot exceed the floor area

of the space |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Non-Regulated Interior Lighting Power |

|

Applicability |

All projects |

|

Definition |

For California, §140.6(a)3

of the energy efficiency standards identifies non-regulated (exempted)

lighting. |

|

Units |

W/ft2 or Watts |

|

Input Restrictions |

As designed

The non-regulated lighting power should be

cross-referenced to the type of exception and to the construction

documents. The default for non-regulated lighting power is zero. |

|

Standard Design |

The non-regulated interior lighting in the baseline

building shall be the same as the proposed design. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Lighting Schedules |

|

Applicability |

All projects |

|

Definition |

Schedule of operation for interior lighting power used

to adjust the energy use of lighting systems on an hourly basis to reflect

time-dependent patterns of lighting usage |

|

Units |

Data structure: schedule, fractional |

|

Input Restrictions |

The lighting schedule is prescribed for California

compliance. An appropriate schedule from Appendix

5.4B shall be used. |

|

Standard Design |

The non-regulated interior lighting in the baseline

building shall be the same as the proposed design. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Tailored Lighting General Illumination

Height |

|

Applicability |

Spaces that have special tailored lighting power

allowances |

|

Definition |

The illumination height is the vertical distance from

the work plane to the centerline of the luminaire. This distance is used

in the room cavity ratio (RCR) calculation which determines the allowed

general lighting power density for a tailored lighting space. |

|

Units |

Ft |

|

Input Restrictions |

As designed |

|

Standard Design |

Same as proposed

The illumination height, H, is used to calculate the

RCR and therefore the baseline general lighting power. See general

lighting power for details. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Floor/Wall Display Mounting Height Above

Floor |

|

Applicability |

Spaces that have wall display or floor display lighting

and tailored lighting power allowances |

|

Definition |

The mounting height of wall display or floor display

lighting above the floor |

|

Units |

List one of three choices:

a)

<12 ft

b)

12-16 ft

c)

> 16 ft |

|

Input Restrictions |

As designed |

|

Standard Design |

As designed

The entered value maps to Table

140.6-E of the standards, that provides an adjustment multiplier for

the tailored lighting wall power allowance in Table

140.6-D. The multiplier is 1.15 if the mounting height is 12’ to 16’,

and 1.30 if greater than 16’. The compliance software must perform input

processing to perform the necessary requirements. |

|

Standard Design:

Existing Buildings |

Same as proposed |

|

Fixture Type |

|

Applicability |

All interior light fixtures |

|

Definition |

The type of lighting fixture, which is used to

determine light heat gain distribution |

|

Units |

List: one of three choices:

a)

Recessed with lens

b)

Recessed/downlight

c)

Not in ceiling |

|

Input Restrictions |

As designed |

|

Standard Design |

Recessed/downlight |

|

Standard Design:

Existing Buildings |

Recessed/downlight |

|

Luminaire Type |

|

Applicability |

All interior light fixtures |

|

Definition |

The type of lighting luminaire used to determine the

light heat gain distribution

The dominant luminaire type determines the daylight

dimming characteristics, when there is more than one type of luminaire in

the space. |

|

Units |

List one of three choices:

a)

Linear fluorescent

b)

Compact fluorescent lamp

c)

Incandescent

d)

Light emitting diode

e)

Metal halide

f)

Mercury vapor

g)

High pressure sodium |

|

Input Restrictions |

As designed |

|

Standard Design |

Linear fluorescent |

|

Standard Design:

Existing Buildings |

Linear fluorescent |

|

Light Heat Gain Distribution |

|

Applicability |

All projects |

|

Definition |

The distribution of the heat generated by the lighting

system that is directed to the space, the plenum, the HVAC return air, or

to other locations

This input is a function of the luminaire type and

location. Luminaires recessed into a return air plenum contribute more of

their heat to the plenum or the return air stream if the plenum is used

for return air; while pendant mounted fixtures hanging in the space

contribute more of their heat to the space. Common luminaire type/space

configurations are listed in Table 3, Chapter 18, 2009 ASHRAE Handbook of

Fundamentals, summarized in Table

7. Typically the data

will be linked to list of common luminaire configurations similar to Table 7 so that

the user chooses a luminaire type category and heat gain is automatically

distributed to the appropriate locations. |

|

Units |

List (of luminaire types) or data structure consisting

of a series of decimal fractions that assign heat gain to various

locations |

|

Input Restrictions |

Heat gain distribution is fixed to Table 7 values based on the

luminaire, fixture, and distribution type.

Where lighting fixtures having different heat venting

characteristics are used within a single space, the wattage weighted

average heat-to-return-air fraction shall be used. |

|

Standard Design |

The baseline building shall use the values in Table

7 for recessed

fluorescent luminaires without lens. |

|

Standard Design:

Existing Buildings |

Same as new construction |

Table 7: Light Heat Gain Parameters for

Typical Operating Conditions

Based on Table 3, Chapter 18, 2009 ASHRAE Handbook –

Fundamentals

|

Fixture

Type |

Luminaire

Type |

Return

Type |

Space

Fraction |

Radiative

Fraction |

|

Recessed with

Lens |

Linear

Fluorescent |

Ducted/Direct |

1.00 |

0.67 |

|

Plenum |

0.45 |

0.67 |

|

Recessed/

Downlight |

Linear

Fluorescent |

Ducted/Direct |

1.00 |

0.58 |

|

Plenum |

0.69 |

0.58 |

|

CFL |

Ducted/Direct |

1.00 |

0.97 |

|

Plenum |

0.20 |

0.97 |

|

Incandescent |

Ducted/Direct |

1.00 |

0.97 |

|

Plenum |

0.75 |

0.97 |

|

LED |

Ducted/Direct |

1.00 |

0.97 |

|

Plenum |

0.20 |

0.97 |

|

Metal Halide |

Ducted/Direct |

1.00 |

0.97 |

|

Plenum |

0.75 |

0.97 |

|

Non In

Ceiling |

Linear

Fluorescent |

Ducted/Direct |

1.00 |

0.54 |

|

Plenum |

1.00 |

0.54 |

|

CFL |

Ducted/Direct |

1.00 |

0.54 |

|

Plenum |

1.00 |

0.54 |

|

Incandescent |

Ducted/Direct |

1.00 |

0.54 |

|

Plenum |

1.00 |

0.54 |

|

LED |

Ducted/Direct |

1.00 |

0.54 |

|

Plenum |

1.00 |

0.54 |

|

Metal Halide |

Ducted/Direct |

1.00 |

0.54 |

|

Plenum |

1.00 |

0.54 |

|

Mercury

Vapor |

Ducted/Direct |

1.00 |

0.54 |

|

|

Plenum |

1.00 |

0.54 |

|

High Pressure

Sodium |

Ducted/Direct |

1.00 |

0.54 |

|

|

Plenum |

1.00 |

0.54 |

In this table, the Space Fraction is the fraction of the

lighting heat gain that goes to the space; the radiative fraction is the

fraction of the

heat gain to the space that is due to radiation, with the

remaining heat gain to the space due to convection.

|

Power Adjustment Factors (PAF) |

|

Applicability |

All projects |

|

Definition |

Automatic controls that are not already required by the

baseline standard and which reduce lighting power more or less uniformly

over the day can be modeled as power adjustment factors. Power adjustment

factors represent the percent reduction in lighting power that will

approximate the effect of the control. Models account for such controls by

multiplying the controlled watts by (1–PAF).

Eligible California power adjustment factors are

defined in Table 140.6-A. Reduction in lighting power using the PAF method

can be used only for nonresidential controlled general lights. Only one

PAF can be used for a qualifying lighting system unless multiple

adjustment factors are allowed in Table 140.6.A of the standards. Controls

for which PAFs are eligible are listed in Table 140.6-A of the standards

and include:

a)

Occupancy Sensing Controls for qualifying enclosed spaces and open

offices.

b)

Demand Response Controls – Demand responsive lighting control that reduces

lighting power consumption in response to a demand response signal for

qualifying building types.

c)

Institutional tuning – lighting tuned to not use more than 85 percent of

rated power, per Section

140.6 of the standards.

d)

Daylight dimming plus off controls – daylight dimming controls that

automatically shut off luminaires when natural lighting provides an

illuminance level of at least 150 percent of the space requirement, as

specified by the standards. |

|

Units |

List: eligible control types (see above) linked to

PAFs |

|

Input Restrictions |

PAF shall be fixed for a given control and area

type |

|

Standard Design |

PAF is zero |

|

Standard Design:

Existing Buildings |

PAF is zero |

This group of building descriptors

is applicable for spaces that have daylighting controls or daylighting control

requirements.

California prescribes a modified

version of the split flux daylighting methods to be used for compliance. This is

an internal daylighting method because the calculations are automatically

performed by the simulation engine. For top-lighted or sidelit daylighted areas,

California compliance prescribes an internal daylighting model consistent with

the split flux algorithms used in many simulation programs. With this method the

simulation model has the capability to model the daylighting contribution for

each hour of the simulation and make an adjustment to the lighting power for

each hour, taking into account factors such as daylighting availability,

geometry of the space, daylighting aperture, control type, and the lighting

system. The assumption is that the geometry of the space, the reflectance of

surfaces, the size and configuration of the daylight apertures, and the light

transmission of the glazing are taken from other building descriptors.

For daylight control using a

simplified geometry approach, daylight control for both the primary daylit zone

(mandatory) and secondary daylit zone (prescriptive) must be indicated on the

compliance forms. If the simplified geometry approach is used and the visible

transmittance of fenestration does not meet prescriptive requirements, the

standard design lighting power is reduced by 20 percent as a penalty. See

Interior Lighting.

|

Daylight

Control Requirements |

|

Applicability |

All spaces with exterior fenestration |

|

Definition |

The extent of daylighting controls in skylit and

sidelit areas of the space |

|

Units |

List |

|

Input Restrictions |

When the installed general lighting power in the

primary daylit zone exceeds 120W, daylighting controls are required, per

the Title 24 mandatory requirements. |

|

Standard Design |

For nonresidential spaces, when the installed general

lighting power in the skylit or primary sidelit daylit zone exceeds 120W,

daylighting controls are required in the primary daylit zone, per the

Title 24 mandatory requirements.

For parking garages, when the installed general

lighting power in the primary sidelit or secondary sidelit daylit zone

exceeds 120W, daylighting controls are required, per the Title 24

mandatory requirements. Luminaires located in daylit transition zones or

dedicated ramps are exempt from this requirement.

For nonresidential spaces, daylighting controls are

specified when the installed general lighting power in the skylit, primary

sidelit, or secondary sidelit daylit zone(s) exceeds 120W.

For parking garages, when the installed general

lighting power in the primary sidelit or secondary sidelit daylit zone

exceeds 120W, daylighting controls are required. Luminaires located in

daylit transition zones or dedicated ramps are exempt from this

requirement. |

|

Standard Design:

Existing Buildings |

When lighting systems in an existing altered building

are not modified as part of the alteration, daylighting controls are the

same as the proposed design.

When an alteration increases the area of a lighted

space, increases lighting power in a space, or when luminaires are

modified in a space where proposed design lighting power density is

greater than 85 percent of the standard design LPD, daylighting control

requirements are the same as for new construction. |

|

Skylit, Primary, and Secondary Daylighted

Area |

|

Applicability |

All daylighted spaces |

|

Definition |

The floor area that is daylighted.

The skylit area is the portion of the floor area that

gets daylighting from a skylight. Two types of sidelit daylighted areas

are recognized. The primary daylighted area is the portion that is closest

to the daylighting source and receives the most illumination. The

secondary daylighted area is an area farther from the daylighting source,

which still receives useful daylight.

The primary daylight area for sidelighting is a band

near the window with a depth equal to the distance from the floor to the

top of the window and width equal to window width plus 0.5 times window

head height wide on each side of the window opening. The secondary

daylight area for sidelighting is a band beyond the primary daylighted

area that extends a distance double the distance from the floor to the top

of the window and width equal to window width plus 0.5 times window head

height wide on each side of the window opening. Area beyond a permanent

obstruction taller than 6 feet should not be included in the primary and

secondary daylight area calculation.

The skylit area is a band around the skylight well that

has a depth equal to the 70 percent of the ceiling height from the edge of

the skylight well. The geometry of the skylit daylit area will be the same

as the geometry of the skylight. Area beyond a permanent obstruction

taller than 50 percent of the height of the skylight from the floor should

not be included in the skylit area calculation.

Double counting due to overlaps is not permitted. If

there is an overlap between secondary and primary or skylit areas, the

effective daylit area used for determining reference position shall be the

area minus the overlap. |

|

Units |

ft2 |

|

Input Restrictions |

The daylit areas in a space are derived using other

modeling inputs like dimensions of the fenestration and ceiling height of

the space. |

|

Standard Design |

The daylit areas in the baseline building are derived

from other modeling inputs, including the dimensions of the fenestration

and ceiling height of the space. Daylit area calculation in the standard

design is done after window to wall ratio and skylight to roof ratio rules

in Section 5.5.7 of

this manual are applied. |

|

Standard Design:

Existing Buildings |

Same as new construction when skylights are

added/replaced and general lighting altered |

|

Installed General Lighting Power in the Primary and

Skylit Daylit Zone |

|

Applicability |

All spaces |

|

Definition |

The installed lighting power of general lighting in the

primary and skylit daylit zone.

The primary and skylit daylit zone shall be defined on

the plans, and be consistent with the definition of the primary and skylit

daylit zone in the standards. Note that a separate building descriptor,

fraction of controlled lighting, defines the fraction of the lighting

power in the space that is controlled by daylighting. |

|

Units |

Watts |

|

Input Restrictions |

As designed |

|

Standard Design |

The installed lighting power for the standard design is

the product of the primary daylit area and the LPD for general lighting in

the space. |

|

Standard Design:

Existing Buildings |

Same as new construction when skylights are

added/replaced and general lights are altered |

|

Installed General Lighting Power in the Secondary

Daylit Zone |

|

Applicability |

All spaces |

|

Definition |

The installed lighting power of general lighting in the

secondary daylit zone.

The secondary daylit zone shall be defined on the plans

and be consistent with the definition of the secondary daylit zone in the

standards. Note that a separate building descriptor, fraction of

controlled lighting, defines the fraction of the lighting power in the

space that is controlled by daylighting. |

|

Units |

W |

|

Input Restrictions |

As designed |

|

Standard Design |

The installed lighting power for the standard design is

the product of the secondary daylit area and the LPD for general lighting

in the space. |

|

Standard Design:

Existing Buildings |

Same as new construction when skylights are

added/replaced and general lights are altered |

|

Reference Position for

Illuminance Calculations |

|

Applicability |

All spaces or thermal

zones, depending on which object is the primary container for daylighting

controls |

|

Definition |

The position of the two

daylight reference points within the daylit space.

Lighting controls are

simulated so that the illuminance at the reference position is always

maintained at or above the illuminance setpoint. For step switching

controls, the combined daylight illuminance plus uncontrolled electric

light illuminance at the reference position must be greater than the

setpoint illuminance before the controlled lighting can be dimmed or tuned

off for stepped controls. Similarly, dimming controls will be dimmed so

that the combination of the daylight illuminance plus the controlled

lighting illuminance is equal to the setpoint illuminance.

Preliminary reference

points for primary and secondary daylit areas are located at the farthest

end of the daylit area aligned with the center of the each window. For

skylit area, the preliminary reference point is located at the center of

the edge of the skylit area closest to the centroid of the space. In each

case, the Z – coordinate of the reference position (elevation) shall be

located 2.5 feet above the floor.

Up to two final reference

positions can be selected from among the preliminary reference positions

identified in for each space. |

|

Units |

Data

structure |

|

Input

Restrictions |

The user does not specify

the reference position locations; reference positions are automatically

calculated by the compliance software based on the procedure outlined

below. Preliminary reference positions are each assigned a relative

daylight potential (RDP) which estimates the available illuminance at each

position, and the final reference position selection is made based on the

RDP.

RDP: An estimate of daylight potential at a specific

reference position. This is NOT used directly in the energy simulation,

but it used to determine precedence for selecting the final reference

points. The relative daylight potential is calculated as a function of

effective aperture, azimuth, illuminance setpoint and the type (skylit,

primary sidelit, or secondary sidelit) of the associated daylit zone. RDP

is defined as:

Where: , , , and , and  are selected from the following

table. are selected from the following

table.

|

|

Skylit Daylit

Zones |

Primary Sidelit

Daylit Zones |

Secondary Sidelit

Daylit Zones |

|

Illuminance

Setpoint |

|

|

|

|

|

|

|

|

|

|

≤ 200 lux |

3927 |

0 |

3051 |

1805 |

-0.40 |

3506 |

7044 |

-3.32 |

1167 |

|

≤ 1000

lux |

12046 |

0 |

-421 |

6897 |

-7.22 |

475 |

1512 |

-2.88 |

-22 |

|

> 1000

lux |

5900 |

0 |

-516 |

884 |

-5.85 |

823 |

212 |

-0.93 |

57 |

Illuminance

Setpoint: This is defined by the

user, and is entered by the user, subject to the limits specified in

Appendix 5.4A, determined from the space type.

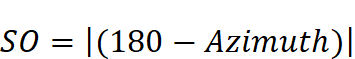

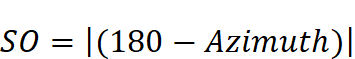

Source Orientation

(SO): The angle of the

outward facing normal of the daylight source’s parent surface projected

onto a horizontal plane, expressed as degrees from south. This is not a

user input but is calculated from the geometry of the parent surface. For

skylights, the source orientation is not applicable. For vertical

fenestration, it is defined:

Where: Azimuth is defined

as the azimuth of the parent object containing the fenestration associated

with the preliminary reference point.

Effective Aperture

(EA): For this calculation,

effective aperture represents the effectiveness of all sources which

illuminate a specific reference position in contributing to the daylight

available to the associated daylit zone. In cases where daylit zones from

multiple fenestration objects intersect, the effective aperture of an

individual daylit zone is adjusted to account for those intersections

according to the following rules:

•

For skylit and primary sidelit

daylit zones, intersections with other skylit or primary sidelit daylit

zones are considered.

•

For secondary sidelit daylit

zones, intersections with any toplit or sidelit (primary or secondary)

daylit zones are considered.

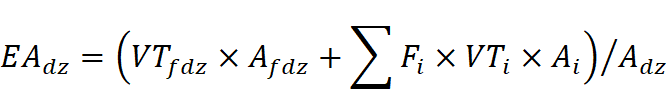

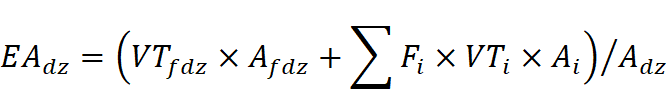

Effective aperture is

defined as follows:

Where:

|

|

is the combined

effective aperture of all daylight sources illuminating a specific

daylit zone |

|

|

is the user

specified visible transmittance of the fenestration object directly

associated with the daylit zone |

|

|

is the area of the

fenestration object directly associated with the daylit

zone |

|

|

is the user

specified visible transmittance of the fenestration object

associated with each intersecting daylit zone |

|

|

is the area of the

fenestration object directly associated with each intersecting

daylit zone |

|

|

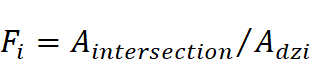

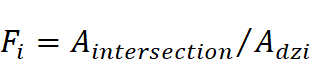

is the fraction of

intersecting area between the daylit zone in question and each

intersecting daylit zone:

|

|

|

is the area of each

intersecting daylit zone (including area that might fall outside a

space or exterior boundary) |

|

|

is the area of the

daylit zone (including area that might fall outside a space or

exterior boundary). |

First Reference

Position: Select the preliminary

reference point with the highest relative daylight potential (RDP) from

among all preliminary reference points located within either top or

primary sidelit daylit zones. If multiple reference points have identical

RDPs, select the reference point geometrically closest to the centroid of

the space.

Second Reference

Position: Select the preliminary

reference point with the highest RDP from amongst all remaining

preliminary reference points located within either top or primary sidelit

daylit zones. If multiple reference points have identical RDPs, select the

reference point geometrically closest to the centroid of the

space. |

|

Standard

Design |

Reference positions for

the standard design shall be selected using the same procedure as those

selected for the proposed design. |

|

Standard

Design:

Existing

Buildings |

Additions or alternations

of lighting in spaces trigger the daylighting control requirements

whenever the total installed lighting in the daylit zone is 120 W or

greater, and the reference positions shall be determined in the same

manner as with new construction. This only applies when alterations or

additions to the lighting in an existing building trigger daylighting

control requirements. |

|

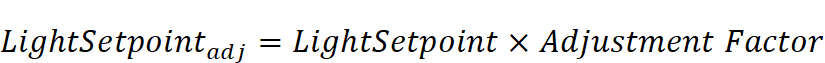

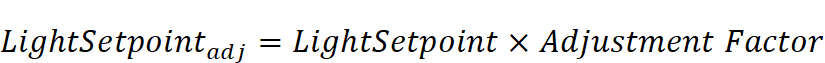

Illumination

Adjustment Factor |

|

Applicability |

All Daylighted

Spaces |

|

Definition |

Recent studies have shown

that the split flux interreflection component model used in many

simulation programs overestimates the energy savings due to daylighting,

particularly deep in the space. A set of two adjustment factors is

provided, one for the primary daylit zone and one for the secondary daylit

zone.

For simulation purposes,

the input daylight illuminance setpoint will be modified by the

illuminance adjustment factor as follows:

|

|

Units |

Unitless |

|

Input

Restrictions |

Prescribed values for

space type in Appendix 5.4A |

|

Standard

Design |

The baseline building

illumination adjustment factors shall match the proposed |

|

Standard

Design:

Existing

Buildings |

Same as new construction

when skylights are added/replaced and general light is

altered. |

|

Fraction of Controlled

Lighting |

|

Applicability |

Daylighted

Spaces |

|

Definition |

The fraction of the

general lighting power in the (daylighted) primary and skylit daylit zone,

or secondary sidelit daylit zone that is controlled by daylighting

controls. |

|

Units |

Numeric: fraction for

primary and skylit daylit zone, and fraction for secondary

zone |

|

Input

Restrictions |

As designed for secondary

daylit areas. If the proposed design has no daylight controls in the

secondary daylit area the value is set to 0 for the general lights in the

secondary daylit area. Primary and skylit daylit area fraction of

controlled general lighting shall be as designed when the daylight control

requirements building descriptor indicates that they are not required, and

shall be 1 when controls are required. |

|

Standard

Design |

When daylight controls

are required according to the daylight control requirements building

descriptor in either the primary daylit and skylit zone, or the secondary

daylit zone, or both, the fraction of controlled lighting shall be

1. |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction when skylights are added/replaced, and general light is

altered. |

|

Daylighting Control

Type |

|

Applicability |

Daylighted

Spaces |

|

Definition |

The type of control that

is used to control the electric lighting in response to daylight available

at the reference point.

Options:

•

Stepped switching controls

vary the electric input power and lighting output power in discrete

equally spaced steps. At each step, the fraction of light output is equal

to the fraction of rated power.

•

Continuous dimming controls

have a fraction to rated power to fraction of rated output that is a

linear interpolation of the minimum power fraction at the minimum diming

light fraction to rated power (power fraction = 1.0) at full light output.

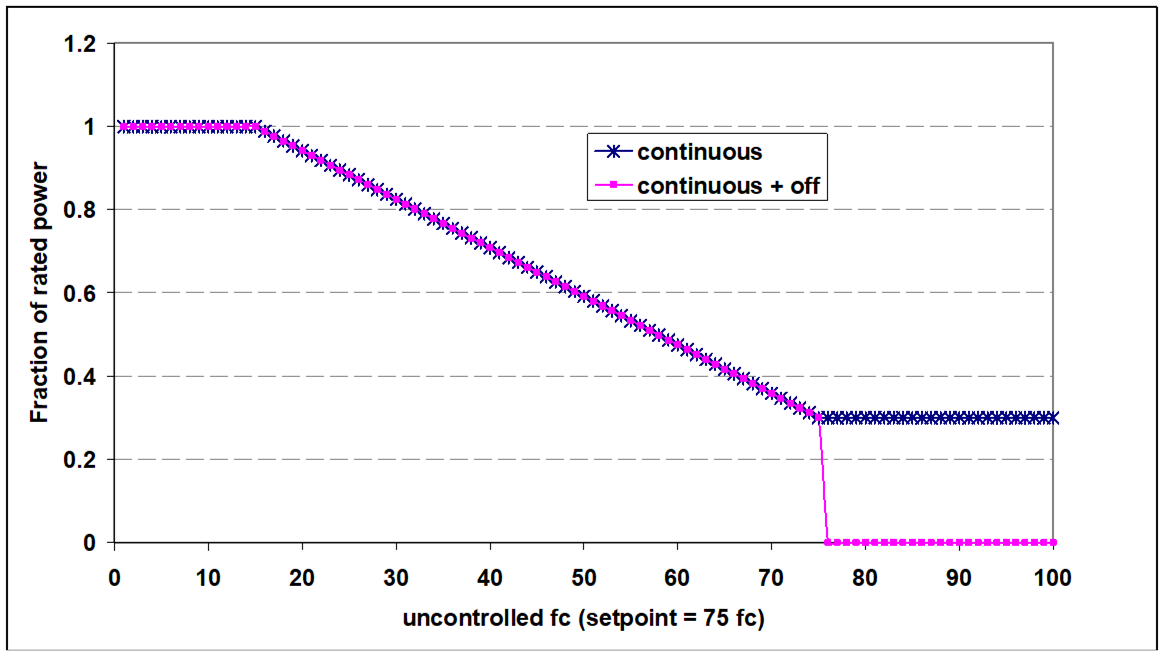

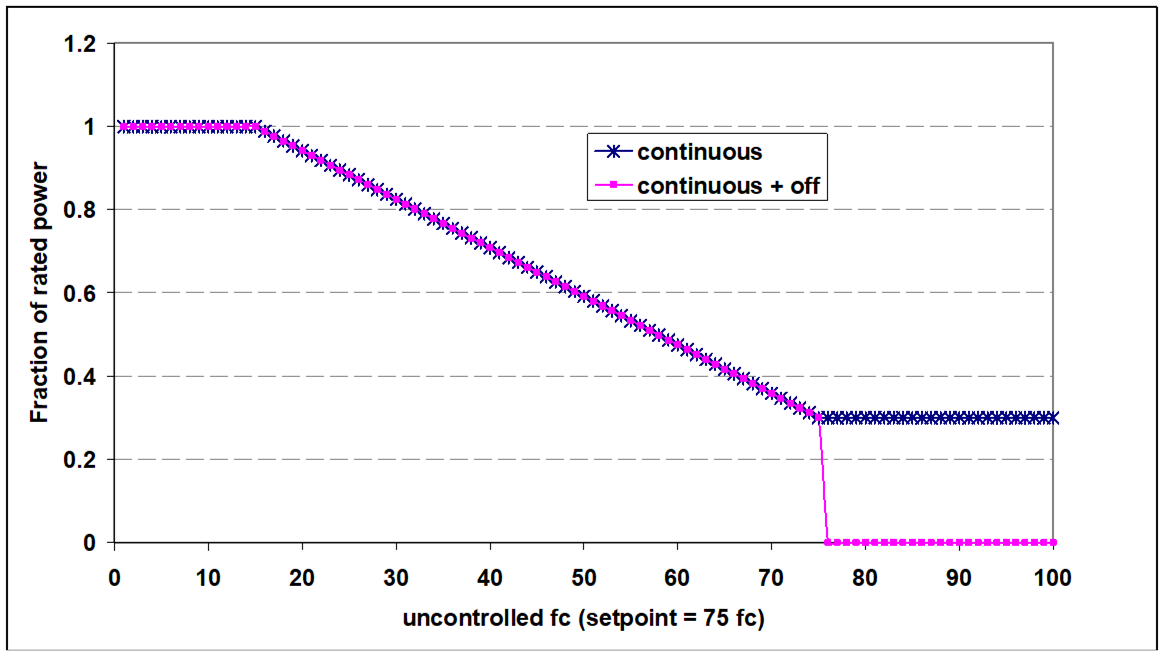

See Figure 8: Example Continuous Dimming

Control

Continuous dimming + off

controls are the same as continuous dimming controls except that these

controls can turn all the way off when none of the controlled light output

is needed. See the example control chart below.

|

|

Units |

List (see

above) |

|

Input

Restrictions |

As

designed |

|

Standard

Design |

Baseline does not have

daylighting control (continuous). |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction when skylights are added/replaced, and general light is

altered. |

|

Minimum Dimming Power

Fraction |

|

Applicability |

Daylit

spaces |

|

Definition |

The minimum power

fraction when controlled lighting is fully dimmed. Minimum power fraction

= minimum power / full rated power. |

|

Units |

Numeric:

fraction |

|

Input

Restrictions |

As designed, specified

from luminaire type (not a user input) |

|

Standard

Design |

Baseline building uses

continuous dimming control with a minimum dimming power fraction from

Table 8: Baseline Power/Light Output

Fraction. Where the controlled luminaire type, input by

the user, determines the minimum dimming power fraction. |

|

Standard Design:

Existing Buildings |

Same as for new

construction when skylights are added/replaced, and general light is

altered. |

|

Minimum Dimming Light

Fraction |

|

Applicability |

Daylighting and dimming

controls |

|

Definition |

The minimum light output

when controlled lighting is fully dimmed. Minimum light fraction = minimum

light output / rated light output. |

|

Units |

Numeric:

fraction |

|

Input

Restrictions |

As

designed |

|

Standard

Design |

Baseline building uses

continuous dimming control with a minimum dimming light fraction from

Table 8: Baseline Power/Light Output

Fraction. Where the

controlled luminaire type, input by the user, determines the minimum

dimming power fraction. |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction when skylights are added/replaced, and general light is

altered. |

Table 8: Baseline Power/Light Output Fraction

|

Light Source |

Power Fraction |

Light Output Fraction |

|

LED |

0.1 |

0.1 |

|

Linear

Fluorescent |

0.2 |

0.2 |

|

Mercury

Vapor |

0.3 |

0.2 |

|

Metal Halide |

0.45 |

0.2 |

|

High Pressure

Sodium |

0.4 |

0.2 |

|

CFL |

0.4 |

0.2 |

|

Incandescent |

0.5 |

0.2 |

5.4.6

Receptacle Loads

Receptacle loads

contribute to heat gains in spaces and directly use energy.

|

Receptacle

Power |

|

Applicability |

All building

projects |

|

Definition |

Receptacle power is power

for typical general service loads in the building. Receptacle power

includes equipment loads normally served through electrical receptacles,

such as office equipment and printers, but does not include either task

lighting or equipment used for HVAC purposes. Receptacle power values are

slightly higher than the largest hourly receptacle load that is actually

modeled because the receptacle power values are modified by the receptacle

schedule, which approaches but does not exceed 1.0. |

|

Units |

Total power (W) or the

space power density (W/ft²)

Compliance software shall

also use the following prescribed values to specify the latent heat gain

fraction and the radiative/convective heat gain split.

For software that

specifies the fraction of the heat gain that is lost from the space, this

fraction shall be prescribed at 0.

Heat Gain

Fractions:

|

|

Radiative |

Latent |

Convective |

|

Receptacle

Power |

0.20 |

0.00 |

0.80 |

|

Gas Equipment

Power |

0.15 |

0.00 |

0.00 |

|

|

Input

Restrictions |

Prescribed to values from

Appendix 5.4A |

|

Standard

Design |

Same as

proposed |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction |

|

Receptacle

Schedule |

|

Applicability |

All

projects |

|

Definition |

Schedule for receptacle

power loads used to adjust the intensity on an hourly basis to reflect

time-dependent patterns of usage. |

|

Units |

Data structure: schedule,

fraction |

|

Input

Restrictions |

Prescribed to schedule in

Appendix 5.4A |

|

Standard

Design |

Same as

proposed |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction |

5.4.7

Commercial Refrigeration Equipment

Commercial

refrigeration equipment includes the following:

• Walk-in

refrigerators

• Walk-in

freezers

• Refrigerated

casework

Walk-in

refrigerators and freezers typically have remote condensers. Some refrigerated

casework has remote condensers, while some have a self-contained condenser built

into the unit. Refrigerated casework with built-in condensers rejects heat

directly to the space while remote condensers reject heat in the remote

location, typically on the roof or behind the building.

Refrigerated

casework can be further classified by the purpose, the type of doors and, when

there are no doors, the configuration: horizontal, vertical or semi-vertical.

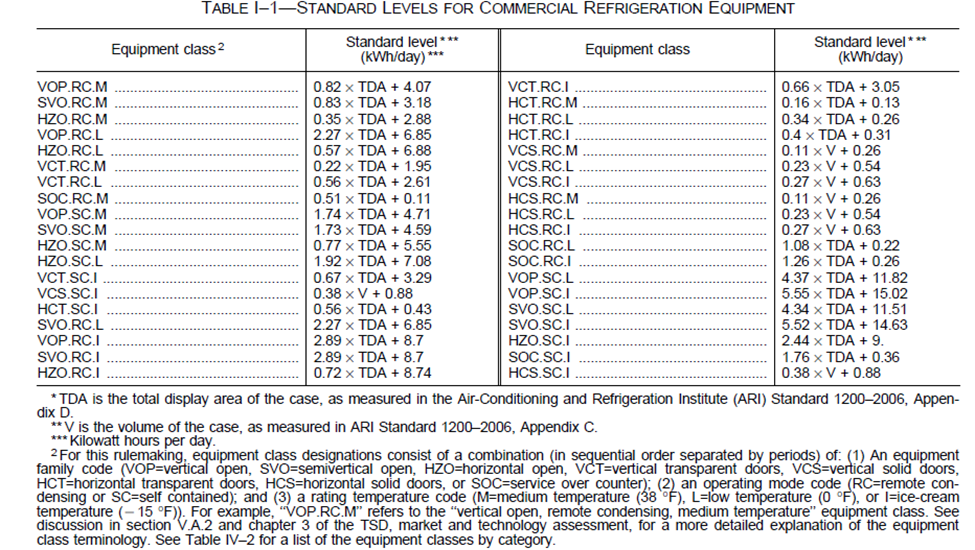

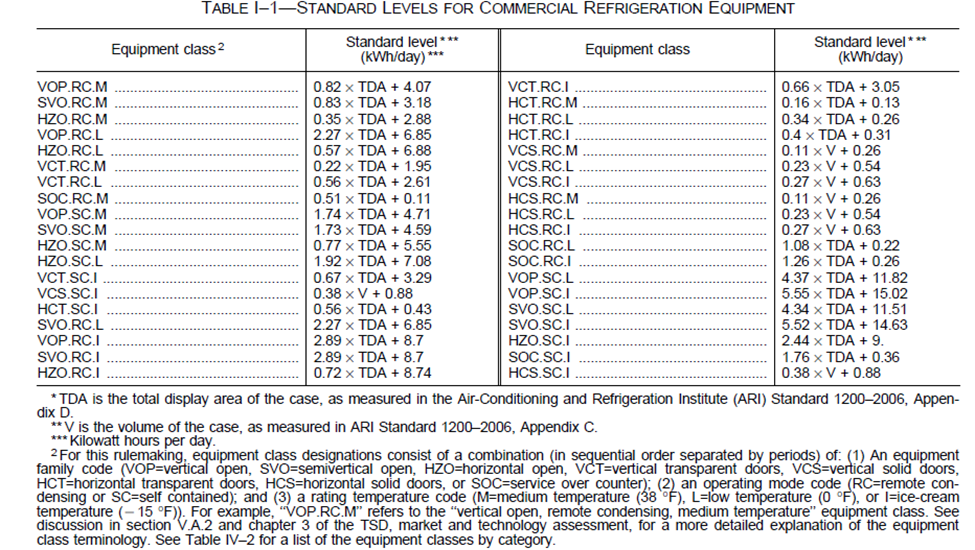

DOE has developed standards for refrigerated casework.

Table 9 shows

these classifications along with the standard level of performance, expressed in

kWh/d, which depends on the class of equipment, the total display area, and the

volume of the casework.

Walk-in refrigerators and

freezers are not covered by the DOE standards and test procedures. Title 24

default values for these are given in Table

10: Default Power for Walk-In Refrigerators and Freezers

(W/ft²). These values are

expressed in W/ft² of refrigerator or freezer area. This power is assumed to

occur continuously. Some walk-ins have glass display doors on one side so that

products can be loaded from the back. Glass display doors increase the power

requirements of walk-ins. Additional power is added when glass display doors are

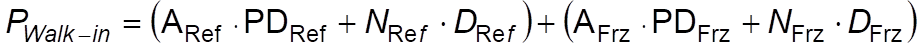

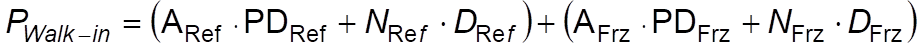

present. The total power for walk-in refrigerators and freezers is given in

Equation 1.

Equation 1:

Where:

PWalk-in is the

estimated power density for the walk-in refrigerator or freezer in (W)

Axxx the

area of the walk-in refrigerator or freezer (ft²)

Nxxx the number

of glass display doors (unitless)

PDxxx the

power density of the walk-in refrigerator or freezer taken from Table 10:

Default Power for Walk-In Refrigerators and Freezers (W/ft²) (W/ft²)

Dxxx the power

associated with a glass display door for a walk-in refrigerator or freezer

(W/door)

xxx

subscript indicating a walk-in freezer or refrigerator (Ref or

Frz)

Table 10: Default Power for

Walk-In Refrigerators and Freezers (W/ft²)

|

Floor Area |

Refrigerator |

Freezer |

|

100 ft² or

less |

8.0 |

16.0 |

|

101 ft² to 250

ft² |

6.0 |

12.0 |

|

0251 ft² to 450

ft² |

5.0 |

9.5 |

|

451 ft² to 650

ft² |

4.5 |

8.0 |

|

651 ft² to 800

ft² |

4.0 |

7.0 |

|

801 ft² to 1,000

ft² |

3.5 |

6.5 |

|

More than 1,000

ft² |

3.0 |

6.0 |

|

Additional Power for each

Glass Display Door |

105 |

325 |

Source: These

values are determined using the procedures of the Heatcraft Engineering Manual,

Commercial Refrigeration Cooling and Freezing Load Calculations and Reference

Guide, August 2006. The EER is assumed to be 12.39 for refrigerators and 6.33

for Freezers. The specific efficiency is assumed to be 70 for refrigerators and

50 for freezers. Operating temperature is assumed to be 35 F for refrigerators

and -10 F for freezers.

|

Refrigeration Modeling

Method |

|

Applicability |

All buildings that have

commercial refrigeration for cold storage or display |

|

Definition |

The method used to

estimate refrigeration energy and to model the thermal interaction with

the space where casework is located. Two methods are included in this

manual:

•

Title 24 defaults. With this

method, the power density values provided in Appendix 5.4A are used; schedules are assumed to be continuous

operation.

•

DOE performance ratings. With

this method, the energy modeler takes inventory of the refrigerated

casework in the rated building and sums the rated energy use (typically in

kWh/day). Walk-in refrigerators and freezers shall use the defaults from

Equation 1 and the values from Table

9. All refrigeration equipment is then assumed to operate

continuously.

The remaining building

descriptors in this section apply to buildings that use either the Title

24 defaults or the DOE performance ratings. |

|

Units |

List (see

above) |

|

Input

Restrictions |

None. For California

compliance, the Title 24 defaults shall be used. Otherwise, there are no

input restrictions. |

|

Standard

Design |

Same as

proposed |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction |

See Table C-43, p. 146 of NREL/TP-550-41956, Methodology for Modeling Building

Energy Performance across the Commercial Sector, Technical Report, Appendix C,

March 2008. The values in this report were taken from Table 8-3 of the

California Commercial End-Use Survey, Consultants Report, March 2006,

CEC-400-2006-005

|

Refrigeration

Power |

|

Applicability |

All buildings that have

commercial refrigeration for cold storage or display |

|

Definition |

Commercial refrigeration

power is the average power for all commercial refrigeration equipment,

assuming constant year-round operation. Equipment includes walk-in

refrigerators and freezers, open refrigerated casework, and closed

refrigerated casework. It does not include residential type refrigerators

used in kitchenettes or refrigerated vending machines. These are covered

under receptacle power. |

|

Units |

W/ft2 |

|

Input

Restrictions |

With the Title 24

defaults method, the values in Appendix 5.4A are prescribed. These values are multiplied times

the floor area of the rated building to estimate the refrigeration power.

With the DOE performance ratings method, refrigeration power is estimated

by summing the kWh/day for all the refrigeration equipment in the space

and dividing by 24 hours. The refrigeration power for walk-in

refrigerators and freezers is added to this value. |

|

Standard

Design |

Refrigeration power is

the same as the proposed design when the Title 24 defaults are used. When

the DOE performance ratings method is used, refrigeration power for

casework shall be determined from Table

9 the power for walk-in refrigerators and freezers shall be the same

as the proposed design. |

|

Standard

Design:

Existing

Buildings |

Same as for new

construction |

|

Remote Condenser

Fraction |

|

Applicability |

All buildings that have

commercial refrigeration for cold storage or display and use the Title 24

defaults or DOE performance ratings methods |

|

Definition |

The fraction of condenser

heat that is rejected to the outdoors. For self-contained refrigeration

casework, this value will be zero. For remote condenser systems, this

value is 1.0. For combination systems, the value should be weighted

according refrigeration capacity.

For refrigeration with

self-contained condensers and compressors, the heat that is removed from

the space is equal to the heat that is rejected to the space, since the

evaporator and condenser are both located in the same space. There may be

some latent cooling associated with operation of the equipment, but this

may be ignored with the Title 24 defaults or DOE performance ratings

methods. The operation of self-contained refrigeration units may be

approximated by adding a continuously operating electric load to the space

that is equal to the energy consumption of the refrigeration units.

Self-contained refrigeration units add heat to the space that must be

removed by the HVAC system.

When the condenser is

remotely located, heat is removed from the space but rejected outdoors. In

this case, the refrigeration equipment functions similar to a continuously

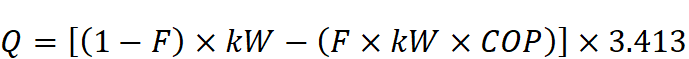

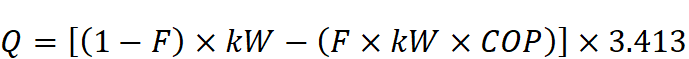

running split system air conditioner. Some heat is added to the space for