8.3 Separation of Electrical Circuits for

Electrical Energy Monitoring

The purpose of the Separation of

Electrical Circuits requirement is to set up a backbone for monitoring the

specific contributions of separate loads to the overall energy use of the

building. By designing the electrical distribution system with separation of

electrical loads in mind, energy monitoring can be readily setup and implemented

without significant physical changes to the electrical installations. The end

goal is to be able to monitor the electrical energy usage of each load type

specified in Table

130.5-B of the Energy Standards: building owners, facility management, and

others can make use of such energy usage information to better understand how

much energy has been used by each building system during a certain period of

time. Further analysis of such energy information can help facilitate energy

efficiency measures to improve building energy performance for building owners

and operators.

Example 8-5

Question:

My new nonresidential building

is served by a single panel with a service less than 50 kVA.

What is the required separation

of electrical circuit requirement for this building?

Answer:

Since the service is smaller than 50kVA, renewable power

sources and electric vehicle charging stations shall be separated from other

electrical load types and from each other, in accordance with the “Electrical

Service rated 50kVA or less” column of Table

130.5-B and §130.5(b) .

The renewable power source shall be separated by group. All

electric charging vehicle loads can be in aggregate.

If there are no renewable power

sources or electric vehicle charging stations in this building, it is not

required to separate the electrical circuits for electrical energy monitoring

purposes.

8.3.1 Compliance Methods

Electrical power

distribution systems shall be designed so that measurement devices can monitor

the electrical energy usage of load types according to Table 130.5-B. However,

for each separate load

type, up to 10 percent of the connected load may be of any other load type.

Also, note that the 2016 requirements have moved to become more flexible than

the 2013 requirements: where the 2013 Energy Standards prescribed specific

methods for ensuring separation of electrical loads, the 2016 Energy Standards

allow any approach that provides the ability to measure the separate loads of

the building.

The separation of

electrical circuit requirement of §130.5(b) , may be accomplished by any

of the following example methods:

A. Method

1:

Switchboards, motor control centers, or panelboards loads can be disaggregated

for each load type, allowing their independent energy measurement. This method

must permit permanent measurement and determination of actual interval demand

load value for each disaggregated load in the system.

This is a straightforward

approach, as each distribution equipment serves a single load type. Summation of

the kVA measurement of the distribution equipment in accordance with the

respective load type can result in the energy usage of each load type. This

method is simple and straightforward in terms of the effort required in

compiling the measurement data.

B. Method

2:

Switchboards, motor control centers, or panelboards may supply other

distribution equipment with their loads disaggregated for each load type. The

measured interval demand load for each piece of distribution equipment must be

able to be added or subtracted from other distribution equipment supplying them.

This method must permit permanent measurement and determination of actual

interval demand load value for each disaggregated load in the system.

This method allows

distribution equipment to serve more than one load type while still allowing the

separate energy use of each load to be determined. More effort may be required

in terms of treatment of the measured energy data in order to obtain the energy

usage of each load type.

C. Method

3:

Buildings for which a complete metering and measurement system is provided that

at a minimum, measures and reports the loads by type.

This method

allows a complete metering system to be used to meet the requirements of

§130.5(b), provided that at a minimum measures and reports the loads called for

in Table

130.5-B of the Energy Standards. Such an installation goes beyond the

requirement of the Energy Standards as it meters and measures the power and

energy usage of each load type.

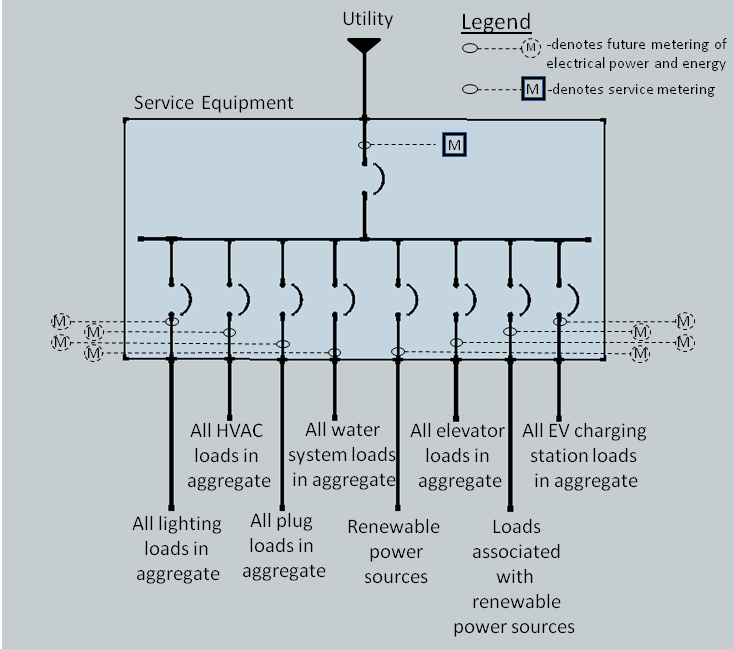

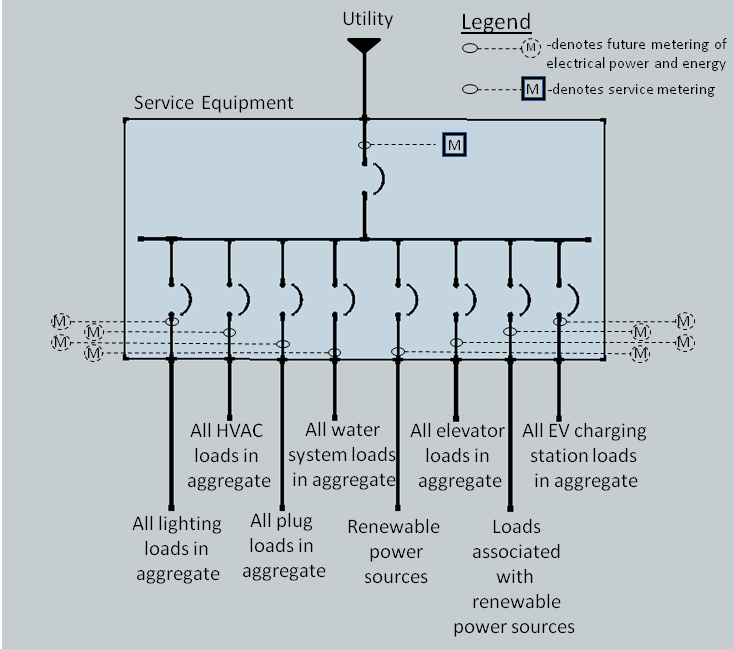

Example 8-6

Question:

I am

working on a new building project of a nonresidential building with a service

less than 250 kVA but more than 50kVA. Following is the proposed concept layout

of separation of circuits for connecting different load types to the service

equipment. Does this meet the requirements of the Energy Standards?

Answer:

The proposed design meets the separation of electrical

circuit requirement of §130.5(b) as there are separations of circuits for

connecting different load types to the service equipment. There should be

provisions including physical spaces for future setup of measurement devices for

energy monitoring at each electrical installation location.

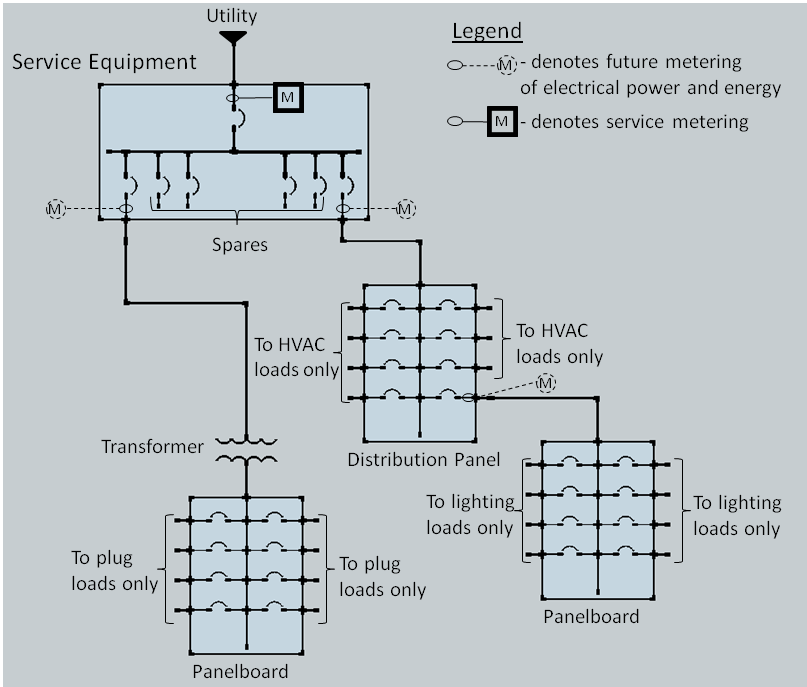

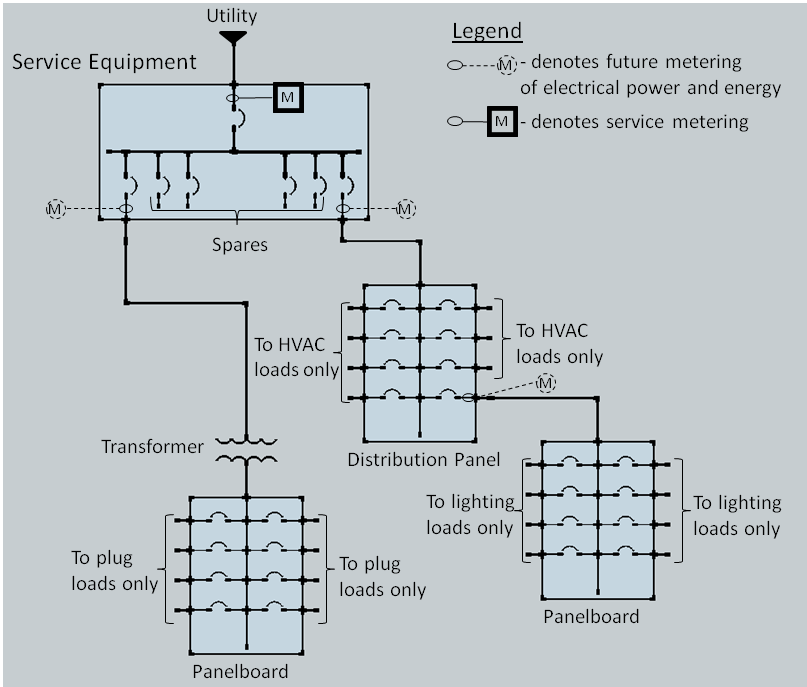

Example 8-7

Question:

Part of my proposed design is

to use a distribution panel serving HVAC loads, with the panel also feeding a

lighting panelboard. There is another, separate panelboard serving plug loads

only.

Does this design meet the

requirements of the Energy Standards?

Answer:

The proposed design meets the separation of electrical

circuit requirement of §130.5(b) as each load type of load in the building can

be accounted for by addition and subtraction of the measured energy data as

indicated in Method 2.

Example 8-8

Question:

Can a panelboard with provisions allowing branch circuit

energy monitoring be used to meet the separation of electrical circuits

requirement? Each circuit would serve no more than one load type. Does this

design meet the requirements of the Energy Standards?

Answer:

The

proposed design allows each load type to be separately measured for energy

usage, and therefore meets the requirements of §130.5(b) .

8.3.2 Application

Considerations

The Energy Standards envision the

use of conventional panelboards, motor control centers, panelboards, and other

standard wiring methods for meeting the requirement to separate electrical

loads. The requirement may also achieved by a well-planned wiring approach, such

as connecting all HVAC units to a single feeder from the service using a

combination of through feeds and taps. The regulations are intentionally written

to specify the “what” without prescribing the “how”, and thus provide as much

flexibility as possible.

In a “typical” small building with

a service less than 50kVA, separation of electrical loads is not required at

all. Slightly larger buildings are able to comply by using carefully laid-out

panelboards.

In larger buildings, separate

risers for lighting, receptacles/equipment, and HVAC are allowed to be used for

meeting the separation of electrical circuits requirement. Single large

loads or groups of loads, such as an elevator machine room, or a commercial

kitchen, may be connected to panelboards or motor control centers served by a

dedicated feeder and the electrical power and energy of the entire group of

loads can be measured by metering the feeder.

For services rated more than 250

kVA, lighting and plug loads are required to be separated “by floor, type or

area”. So, in a single-story building, all the lighting loads could be fed

from a single panel, and all the plug loads could be fed from another panel (or,

alternatively, both types of loads could be fed from one panel with a split

bus).

In a multi-story building, a simple

way to comply would be to install a separate lighting panel and a separate

plug-load panel for each floor of the building. However, it would be equally

acceptable (and may be more useful) to divide the load according to which area

of the building it serves (office, warehouse, corridors etc.), or by the type of

light fixture (metal halide vs. fluorescent, dimmable vs. fixed output, etc.).

So, for instance, both the first and second floor office lights could be fed

from the same panel, while the warehouse lights would be fed from a second

panel. Dividing the load by area or by type instead of by floor is more likely

to yield useful information when the loads are analyzed in an energy audit. All

of these approaches are available to designers and installers, and are

acceptable methods of complying with the Energy Standards.