A space-conditioning system (also referred to as HVAC system) is made up of the heating subsystem (also referred to as “heating unit,” “heating equipment,” or “heating system”), cooling subsystem (also referred to as “cooling unit,” “cooling equipment,” or “cooling system”), the distribution subsystem details (if any), and fan subsystem (if any). Ventilation cooling systems and indoor air-quality-ventilation systems are defined at the building level for single-family homes or as part of the dwelling unit information for multifamily buildings. (See also Sections 2.4.9 and 2.4.10.)

The heating subsystem describes the equipment that supplies heat to a space-conditioning system. Heating subsystems are categorized according to the types shown in Table 8.

The user selects the type and supplies required inputs for the heating subsystem including the appropriate rated heating efficiency. Except for heat pumps, the rated heating capacity is not used as a compliance variable by the compliance software.

When the proposed space-conditioning system is a heat pump, the user either allows the system capacity to be set automatically by the software or elects to specify rated heating capacity at 47°F and 17°F for the heat pump compressor. The capacity is used to determine the effect of backup electric resistance heat in the simulation. Either the user-entered or software-specified capacities are listed on the CF1R for verification by a HERS rater.

When electricity is used for ducted heating, the heating equipment for the standard design is an electric split-system heat pump with default ducts in the attic and a heating seasonal performance factor (HSPF) meeting the current Appliance Efficiency Regulations minimum efficiency for split-systems. The standard design heat pump compressor size is determined by the software as the larger of the compressor size calculated for air-conditioning load, or the compressor with a 47°F rating that is 75 percent of the heating load (at the heating design temperature).

When electricity is used for a proposed ductless heating system, the standard design is a ductless system with the minimum HSPF from the Appliance Efficiency Regulations.

When proposed heating equipment is a ducted gas system, the equipment used in the standard design building is a gas furnace (or propane if natural gas is not available) with default ducts in the attic and an annual fuel utilization efficiency (AFUE) meeting the Appliance Efficiency Regulations minimum efficiency for central systems. When a proposed design uses both electric and non-electric heat, the standard design is a gas furnace.

See Table 6 for complete details on heating systems noted above and other possible proposed systems.

|

Proposed Design |

Standard Design |

|

Central furnace, ducted |

80 percent AFUE central furnace, default duct |

|

Central heat pump, ducted |

8.2 HSPF central heat pump, auto size capacity, default duct |

|

Wall furnace, gravity |

59 percent AFUE gravity wall furnace |

|

Wall furnace, fan type |

72 percent AFUE fan-type wall furnace |

|

Ducted minisplit, multisplit, and variable refrigerant charge heat pump, ducted |

8.2 HSPF central heat pump, auto-size capacity, default duct |

|

Ductless minisplit, multisplit, and variable refrigerant charge heat pump, ductless |

8.2 HSPF central heat pump, auto-size capacity, default duct |

|

Room heater, ductless |

|

Source: California Energy Commission

The proposed heating system type and rated efficiency are reported in the compliance documentation on the CF1R. For heat pumps, which are supplemented by electric resistance backup heating, the HERS-verified capacity is listed, and the rated heating capacity of each proposed heat pump is reported on the CF1R. Installed capacities must be is equal or larger than the capacities reported for modeled at 47° and 17° (RA 3.4.4.2).

2.4.1.1 Verified Heating Seasonal Performance Factor (HSPF)

The software allows the user to specify the HSPF value for heat pump equipment.

The standard design is based on the default minimum HSPF for the type of heat pump equipment modeled in the proposed design, based on the applicable Appliance Efficiency Regulations. For central-heating and cooling equipment, the minimum efficiency is 8.0 HSPF or 8.2 HSPF.

If an HSPF higher than the default minimum efficiency is modeled in software, the HSPF requires field verification. The HSPF rating is verified using rating data from the AHRI Directory of Certified Product Performance at www.ahridirectory.org or another directory of certified product performance ratings approved by the Energy Commission for determining compliance. Verified SEER is reported in the HERS required verification listings on the CF1R.

|

Name |

Heating Equipment Description |

|

CntrlFurnace |

Gas- or oil-fired central furnaces, propane furnaces, or heating equipment considered equivalent to a gas-fired central furnace, such as wood stoves that qualify for the wood heat exceptional method. Gas fan-type central furnaces have a minimum AFUE=80%. Distribution can be gravity flow or use any of the ducted systems. |

|

WallFurnaceGravity |

Noncentral gas- or oil-fired wall furnace, gravity flow. Equipment has varying efficiency requirements by capacity. Distribution is ductless. |

|

WallFurnaceFan |

Noncentral gas- or oil-fired wall furnace, fan-forced. Equipment has varying efficiency requirements by capacity. Distribution is ductless. |

|

FloorFurnace |

Noncentral gas- or oil-fired floor furnace. Equipment has varying efficiency requirements by capacity. Distribution is ductless. |

|

RoomHeater |

Noncentral gas- or oil-fired room heaters. Noncentral gas- or oil-fired wall furnace, gravity flow. Equipment has varying efficiency requirements by capacity. Distribution is ductless. |

|

WoodHeat |

Wood-fired stove. In areas with no natural gas available, a wood-heating system with any backup heating system is allowed to be installed if exceptional method criteria described in the Residential Compliance Manual are met. |

|

Boiler |

Gas or oil boilers. Distribution systems can be radiant, baseboard, or any of the ducted systems. Boiler may be specified for dedicated hydronic systems. Systems in which the boiler provides space heating and fires an indirect gas water heater (IndGas) may be listed as Boiler/CombHydro Boiler and is listed under “Equipment Type” in the HVAC Systems listing. |

|

Electric |

All electric heating systems other than space-conditioning heat pumps. Included are electric resistance heaters, electric boilers, and storage water heat pumps (air-water) (StoHP). Distribution system can be radiant, baseboard, or any of the ducted systems. |

|

CombHydro |

Water-heating system can be storage gas (StoGas, LgStoGas) or storage electric (StoElec). Distribution systems can be radiant, baseboard, or any of the ducted systems and can be used with any of the terminal units (FanCoil, RadiantFlr, Baseboard, and FanConv). |

|

Name |

|

|

SplitHeatPump |

Central split heat pump system. Distribution system is one of the ducted systems. |

|

SDHVSplitHeatPump |

Small Duct, High Velocity, Central split-system that produces at least 1.2 inches of external static pressure when operated at the certified air volume rate of 220–350 CFM per rated ton of cooling and uses high-velocity room outlets generally greater than 1,000 fpm that have less than 6.0 square inches of free area. |

|

DuctlessMiniSplitHeatPump: |

A heat pump system that has a single outdoor section, and one or more ductless indoor sections. The indoor section(s) cycle on and off in unison in response to a single indoor thermostat. |

|

DuctlessMultiSplitHeatPump |

A heat pump system that has a single outdoor section, and two or more ductless indoor sections. The indoor sections operate independently and can be used to condition multiple zones in response to multiple indoor thermostats. |

|

DuctlessVRFHeatPump |

A variable-refrigerant-flow (VRF) heat pump system that has one or more outdoor sections and two or more ductless indoor sections. The indoor sections operate independently and can be used to condition multiple zones in response to multiple indoor thermostats. |

|

PkgHeatPump |

Central packaged heat pump systems. Central packaged heat pumps are heat pumps in which the blower, coils, and compressor are contained in a single package, powered by single-phase electric current, air-cooled, and rated below 65,000 Btu/h. The distribution system is one of the ducted systems. |

|

LrgPkgHeatPump |

Large packaged units rated at or above 65,000 Btu/hr. The distribution system is one of the ducted systems. |

|

RoomHeatPump |

Noncentral room air-conditioning systems. These include packaged terminal (commonly called “through-the-wall”) units and any other ductless heat pump systems. |

|

AirToWaterHeatPump |

An indoor conditioning coil, a compressor, and a refrigerant-to-water heat exchanger that provides heating and cooling functions. Also able to heat domestic hot water. |

|

GroundSourceHeatPump |

An indoor conditioning coil with air-moving means, a compressor, and a refrigerant-to-ground heat exchanger that provides heating, cooling, or heating and cooling functions. Also able to heat domestic hot water |

Source: California Energy Commission

Combined hydronic space/water heating is a system whereby a water heater is used to provide both space heating and water heating. Dedicated hydronic space-heating systems are also a modeling capability. Space-heating terminals may include fan coils, baseboards, and radiant surfaces (floors, walls or ceilings).

For combined hydronic systems, the water-heating portion is modeled normally. For space heating, an effective AFUE is calculated for gas water heaters. For electric water heaters, an effective HSPF is calculated. The procedures for calculating the effective AFUE or HSPF are described below.

Combined hydronic space-conditioning cannot be combined with zonal control credit.

When a fan coil is used to distribute heat, the fan energy and the heat contribution of the fan motor must be considered. The algorithms for fans used in combined hydronic systems are the same as those used for gas furnaces and are described in Chapter 3.

If a large fan coil is used and air-distribution ducts are located in the attic, crawl space, or other unconditioned space, the efficiency of the air-distribution system must be determined using methods consistent with those described in Section 2.4.6. Duct efficiency is accounted for when the distribution type is ducted.

2.4.2.1 Commercial or Consumer Storage Gas Water Heater

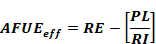

When storage gas water heaters are used in combined hydronic applications, the effective AFUE is given by the following equation:

Equation 1

Where:

AFUEeff = The effective AFUE of the gas water heater in satisfying the space heating load.

RE = The recovery efficiency (or thermal efficiency) of the gas storage water heater. A default value of 0.70 may be assumed if the recovery efficiency is unknown. This value is generally available from the Energy Commission appliance directory.

PL = Pipe losses (kBtu/h). This can be assumed to be zero when less than 10 feet of piping between the water heater storage tank and the fan coil or other heating elements are in unconditioned space.

RI = The rated input of the gas water heater (kBtu/h) available from the Energy Commission appliance directory.

2.4.2.2 Instantaneous Gas Water Heater

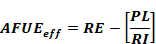

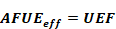

When instantaneous gas water heaters are used in combined hydronic applications, the effective AFUE is given by the following equation:

Equation 2

Where:

AFUEeff = The effective AFUE of the gas water heater in satisfying the space heating load.

UEF = The rated uniform energy factor of the instantaneous gas water heater.

2.4.2.3 Storage Electric Water Heater

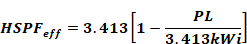

The HSPF of storage water heaters used for space heating in a combined hydronic system is given by the following equations.

Equation 3

Where:

HSPFeff = The effective HSPF of the electric water heater in satisfying the space heating load.

PL = Pipe losses (kBtu/h). Assumed zero when less than 10 feet of piping between the water heater storage tank and the fan coil or other heating elements are in unconditioned space.

kWi = The kilowatts of input to the water heater available from the Energy Commission’s appliance directory.

When a hydronic system is proposed to use electricity is used for heating, the heating equipment for the standard design is an electric split-system heat pump with an HSPF meeting the Appliance Efficiency Regulations requirements for split-systems. The standard design heat pump compressor size is determined by the software based on the compressor size calculated for the air-conditioning system.

When electricity is not used for heating, the equipment used in the standard design building is a gas furnace (or propane if natural gas is not available) with default ducts in the attic and an AFUE meeting the Appliance Efficiency Regulations minimum efficiency for central systems. When a proposed design uses both electric and non-electric heat, the standard design is a gas furnace.

[Not yet implemented]

This listing is completed for hydronic systems that have more than 10 feet of piping (plan view) in unconditioned space. As many rows as necessary may be used to describe the piping system.

The standard design is established for a hydronic system in the same way as for a central system, as described in Section 2.4.1.

A hydronic or combined hydronic system is reported on the CF1R.

Other information reported includes:

•Piping Run Length (ft). The length (plan view) of distribution pipe in unconditioned space, in feet, between the primary heating/cooling source and the point of distribution.

•Nominal Pipe Size (in.). The nominal (as opposed to true) pipe diameter in inches.

•Insulation Thickness (in.). The thickness of the insulation in inches. Enter "none" if the pipe is uninsulated.

•Insulation R-value (hr-ft2-°F/Btu). The installed R-value of the pipe insulation. Minimum pipe insulation for hydronic systems is as specified in Section 150.0(j).

A ground-source heat pump system, which uses the earth as a source of energy for heating and as a heat sink for energy when cooling, is simulated as a minimum efficiency split-system equivalent to the standard design with default duct conditions in place of the proposed system. The mandatory efficiencies for ground-source heat pumps are a minimum coefficient of performance (COP) for heating and EER for cooling.

The cooling subsystem describes the equipment that supplies cooling to a space-conditioning system.

Cooling subsystems are categorized according to the types shown in Table 9. The user selects the type of cooling equipment and enters basic information to model the energy use of the equipment. Enter the cooling equipment type and additional information based on the equipment type and zoning, such as the SEER and EER. For some types of equipment, the user may also specify that the equipment has a multispeed compressor and if the system is zoned or not via checkboxes. For ducted cooling systems, the cooling airflow from the conditioned zone through the cooling coil is input as CFM per ton. The rated cooling capacity is not a compliance variable.

Until there is an approved compliance option for ductless heat pumps (ductless minisplit, multisplit, and variable refrigerant flow [VRF] systems), these systems are simulated as a minimum efficiency split-system equivalent to the standard design with default duct conditions.

See sections below for the details of specific inputs.

The cooling system for the standard design building is a non-zonal control system, of the same equipment type as the proposed system, meeting the minimum requirements of the Appliance Efficiency Regulations. The standard design system shall assume verified refrigerant charge in Climate Zones 2 and 8-15 for all ducted split-systems, ducted package systems, minisplit, multisplit, and VRF systems. Mandatory fan efficacy is assumed in all climate zones.

|

Name |

Cooling Equipment Description |

|

NoCooling |

Entered when the proposed building is not cooled or when cooling is optional (to be installed at some future date). Both the standard design equivalent building and the proposed design use the same default system (refer to Section 2.4.8.3. |

|

SplitAirCond |

Split air-conditioning systems. Distribution system is one of the ducted systems. (Efficiency metric: SEER and EER) |

|

PkgAirCond |

Central packaged air-conditioning systems less than 65,000 Btu/h cooling capacity. Distribution system is one of the ducted systems. (Efficiency metric: SEER and EER) |

|

LrgPkgAirCond |

Large packaged air-conditioning systems rated at or above 65,000 Btu/h cooling capacity. Distribution system is one of the ducted systems. |

|

SDHVSplitAirCond |

Small-duct, high-velocity, split A/C system. |

|

DuctlessMiniSplitAirCond |

Ductless minisplit A/C system. |

|

DuctlessMultiSplitAirCond |

Ductless multisplit A/C system. |

|

DuctlessVRFAirCond |

Ductless variable refrigerant flow (VRF) A/C system. |

|

RoomAirCond |

Same as DuctlessSplitAirCond except that cooling is not supplied to each habitable space in the dwelling unit. |

|

EvapDirect |

Direct evaporative cooling systems. Assume minimal efficiency air-conditioner. The default distribution system location is DuctAttic; evaporative cooler duct insulation requirements are the same as those for air-conditioner ducts. |

|

EvapIndirDirect |

Indirect-direct evaporative cooling systems. Assume energy efficiency ratio of 13 EER. Requires airflow and media saturation effectiveness from the CEC directory. |

|

EvapIndirect |

Indirect cooling systems. The default distribution system location is DuctAttic; evaporative cooler duct insulation requirements are the same as those for air-conditioner ducts. Assume energy efficiency ratio of 13 EER. Requires airflow and media saturation effectiveness from the CEC directory. |

|

EvapCondenser |

Evaporatively Cooled Condensers. A split mechanical system, with a water-cooled condenser coil. |

Source: California Energy Commission

2.4.5.1 Verified Refrigerant Charge or Fault Indicator Display

Proper refrigerant charge is necessary for electrically driven compressor air-conditioning systems to operate at full capacity and efficiency. Software calculations set the compressor efficiency multiplier to 0.90 to account for the effect of improper refrigerant charge or 0.96 for proper charge.

The software allows the user to indicate if systems will have diagnostically tested refrigerant charge or a field-verified fault indicator display (FID). This applies only to ducted split-systems and packaged air-conditioners and heat pumps.

The standard design building is modeled with either diagnostically tested refrigerant charge or a field-verified FID if the building is in Climate Zone 2 or 8-15, and refrigerant charge verification is required by Section 150.1(c) and Table 150.1-A or 150.1-B for the proposed cooling system type.

|

Measure |

Description |

Procedures |

|

Verified Refrigerant Charge |

Air-cooled air-conditioners and air-source heat pumps must be tested diagnostically to verify that the system has the correct refrigerant charge. The system must also meet the system airflow requirement. |

|

|

Verified Fault Indicator Display |

A fault indicator display can be installed as an alternative to refrigerant charge testing. |

|

|

Verified System Airflow |

When compliance requires verified system airflow greater than or equal to a specified criterion. |

|

|

Verified Air-handling Unit Fan Efficacy |

To verify that fan efficacy (watt/CFM) is less than or equal to a specified criterion. |

|

|

Credit for increased efficiency by installation of specific air-conditioner or heat pump models. |

||

|

Verified Heat Pump Capacity |

Optional verification of heat pump system capacity. |

|

|

Evaporatively Cooled Condensers |

Must be combined with duct leakage testing, refrigerant charge, and verified EER. |

|

|

Whole-House Fan |

When verification of the whole-house fan is selected or required, airflow, watt draw and capacity are verified. |

|

|

Central Fan Ventilation Cooling System |

When compliance includes this type of ventilation cooling, airflow and fan efficacy are verified. |

Source: California Energy Commission

Refrigerant charge or FID require field verification or diagnostic testing and are reported in the HERS required verification listings on the CF1R. Details on refrigerant charge measurement are discussed in Reference Residential Appendix RA3.2. Information on the requirements for FIDs is located in Reference Joint Appendix JA6.1.

2.4.5.2 Verified System Airflow

Adequate airflow from the conditioned space is required to allow ducted air-conditioning systems to operate at full efficiency and capacity. Efficiency is achieved by the air distribution system design by improving the efficiency of motors or by designing and installing air distribution systems that have less resistance to airflow. Software calculations account for the effect of airflow on sensible heat ratio and compressor efficiency.

For systems other than small-duct, high-velocity types, a value less than 350 CFM/ton (minimum 150 CFM/ton) is a valid input only if zonally controlled equipment is selected and multispeed compressor is not selected. Inputs less than 350 cfm/ton for zonally controlled systems require verification using procedures in Reference Residential Appendix RA3.3.

Section 150.0(m)13 requires verification that the central air-handling unit airflow rate is greater than or equal to 350 CFM/ton for systems other than small-duct, high-velocity types or 250 CFM/ton for small-duct, high-velocity systems. Values greater than the required CFM/ton may be input for compliance credit, which requires diagnostic testing using procedures in Reference Residential Appendix RA3.3.

For Single-Zone Systems:

• As an alternative to verification of 350 CFM/ton for systems other than small-duct, high-velocity types or 250 CFM/ton for small-duct, high-velocity systems, HERS verification of a return duct design that conforms to the specification given in Table 150.0-B or C may be used to demonstrate compliance.

• The return duct design alternative is not an input to the compliance software, but must be documented on the certificate of installation.

• If a value greater than 350 CFM/ton for systems other than small-duct, high-velocity types or greater than 250 CFM/ton for small-duct, high-velocity systems is modeled for compliance credit, the alternative return duct design method using Table 150.0-B or C is not allowed for demonstrating compliance.

• Multispeed or variable-speed compressor systems must verify airflow rate (CFM/ton) for system operation at the maximum compressor speed and the maximum air handler fan speed.

For Zonally Controlled Systems:

• The Table 150.0-B or C return duct design alternative is not allowed for zonally controlled systems.

• Multispeed, variable-speed, and single-speed compressor systems must all verify airflow rate (CFM/ton) by operating the system at maximum compressor capacity and maximum system fan speed with all zones calling for conditioning.

• Single-speed compressor systems must also verify airflow rate (CFM/ton) in every zonal control mode.

•For systems that input less than 350 CFM/ton, HERS verification compliance cannot use group sampling.

The default cooling airflow is 150 CFM/ton for a system with “zonally controlled” selected and “multispeed compressor” not selected (single-speed). Users may model airflow for these systems greater than or equal to 150 CFM/ton, which must be verified using the procedures in Reference Residential Appendix RA3.3. Inputs less than the rates required by Section 150.0(m)13 will be penalized in the compliance calculation.

The default cooling airflow is 350 CFM/ton for systems other than small-duct, high-velocity types or 250 CFM/ton for small-duct, high-velocity systems. Users may model a higher-than-default airflow for these systems and receive credit in the compliance calculation if greater-than-default system airflow is diagnostically tested using the procedures of Reference Residential Appendix RA3.3.

The standard design shall assume a system that complies with mandatory (Section 150.0) and prescriptive (Section 150.1) requirements for the applicable climate zone.

The airflow rate verification compliance target (CFM or CFM/ton) is reported in the HERS required verification listings of the CF1R. When there is no cooling system, it is reported on the CF1R as a special feature.

2.4.5.3 Verified Air-Handling Unit Fan Efficacy

The mandatory requirement in Section 150.0(m)13 is for an air-handling unit fan efficacy less than or equal to 0.45 watts/CFM for gas furnace air-handling units, 0.58 watts/CFM for air-handling units that are not gas furnaces, and 0.62 W/CFM for small-duct, high-velocity systems as verified by a HERS rater. Users may model a lower fan efficacy (W/CFM) and receive credit in the compliance calculation if the proposed fan efficacy value is diagnostically tested using the procedures in Reference Residential Appendix RA3.3.

For Single-Zone Systems:

• Installers may elect to use an alternative to HERS verification of the watts/CFM required by Section 150.0(m)13: HERS verification of a return duct design that conforms to the specification given in Table 150.0-B or C.

•The return duct design alternative is not an input to the compliance software, but must be documented on the certificate of installation.

• If a value less than the watts/CFM required by 150.0(m)13 is modeled by the software user for compliance credit, the alternative return duct design method using Table 150.0-B or C is not allowed for use in demonstrating compliance.

• Multispeed or variable-speed compressor systems must verify fan efficacy (watt/CFM) for system operation at the maximum compressor speed and the maximum air handler fan speed.

For Zonally Controlled Systems:

• The Table 150.0-B or C return duct design alternative is not allowed for zonally controlled systems.

• Multispeed, variable-speed and single-speed compressor systems must all verify fan efficacy (watt/CFM) by operating the system at maximum compressor capacity and maximum system fan speed with all zones calling for conditioning.

• Single-speed compressor systems must verify fan efficacy in every zonal control mode.

The software shall allow the user to enter the fan efficacy. The default mandatory value is 0.45, 0.58, or 0.62 W/CFM depending on the applicable system type. However, users may specify a lower value and receive credit in the compliance calculation if verified and diagnostically tested using the procedures of Reference Appendices, Residential Appendix RA3.3.

If no cooling system is installed, a default value of 0.45 W/CFM is assumed.

The standard design shall assume a verified fan efficacy complying with the mandatory requirement of less than or equal to 0.45, 0.58, or 0.62 watts/CFM, depending on the applicable system type.

For user inputs lower than the default mandatory 0.58 watts/cfm, Fan efficacy is reported in the HERS required verification listings of the CF1R.

For default mandatory 0.45 or 0.58 watts/cfm, the choice of either fan efficacy or alternative return duct design according to Table 150.0-B or C is reported in the HERS required verification listings of the CF1R.

No cooling system is reported as a special feature on the CF1R.

2.4.5.4 Verified Energy Efficiency Ratio (EER)

Software shall allow the user the option to enter an EER rating for central cooling equipment. For equipment that is rated only with an EER (room air-conditioners), the user will enter the EER. The Appliance Efficiency Regulations require a minimum SEER and EER for central cooling equipment. Only if a value higher than a default minimum EER is used is it reported as a HERS-verified measure.

The standard design for central air-conditioning equipment is 11.7 EER.

EER verification is required only if higher than 11.7 EER with 14 SEER is modeled or higher than the standard EER. The EER rating is verified using rating data from AHRI Directory of Certified Product Performance at www.ahridirectory.org or another directory of certified product performance ratings approved by the Energy Commission for determining compliance. Verified EER is reported in the HERS required verification listings on the CF1R.

2.4.5.5 Verified Seasonal Energy Efficiency Ratio (SEER)

The software allows the user to specify the SEER value.

The standard design is based on the default minimum efficiency SEER for the type of cooling equipment modeled in the proposed design, based on the applicable Appliance Efficiency Regulations. For central-cooling equipment, the minimum efficiency is 14 SEER and 11.7 EER.

If a SEER higher than the default minimum efficiency is modeled in software, the SEER requires field verification. The higher than minimum SEER rating is verified using rating data from AHRI Directory of Certified Product Performance at www.ahridirectory.org or another directory of certified product performance ratings approved by the Commission for determining compliance. Verified SEER is reported in the HERS required verification listings on the CF1R.

2.4.5.6 Verified Evaporatively-Cooled Condensers

Software shall allow users to specify an evaporatively-cooled condensing unit. The installation must comply with the requirements of RA4.3.2 to ensure the predicted energy savings are achieved. This credit must be combined with verified refrigerant charge testing, EER, and duct leakage testing.

The standard design is based on a split-system air-conditioner meeting the requirements of Section 150.1(c) and Table 150.1-A or 150.1-B.

An evaporatively-cooled condensing unit, verified EER, and duct leakage testing are reported in the HERS required verification listings on the CF1R.

Evaporative cooling technology is best suited for dry climates where direct, indirect, or indirect-direct cooling of the supply air stream can occur without compromising indoor comfort. Direct evaporative coolers are the most common system type currently available but provide less comfort and deliver more moisture to the indoor space. They are assumed equivalent to a minimum split-system air-conditioner. The evaporative cooling modeling method addresses two performance issues. The first performance issue is the increase in indoor relative humidity levels during periods with extended cooler operation. Since modeling of indoor air moisture levels is beyond the capability of simulation models, a simplified algorithm is used to prohibit evaporative cooler operation during load hours when operation is expected to contribute to uncomfortable indoor conditions. The algorithm disallows cooler operation when outdoor wet bulb temperatures are 70°F, or above. The second performance issue relates to evaporative cooler capacity limitations. Since evaporative coolers are 100 percent outdoor air systems, the related capacity is limited by the outdoor wet bulb temperature. Each hour with calculated cooling load, the algorithm will verify that the cooling capacity is greater than the calculated cooling load.

Software shall allow users to specify one of three types of evaporative cooling: (1) direct evaporative cooler, the most commonly available system type;, (2) indirect; or (3) indirect-direct. Product specifications and other modeling details are found in the Energy Commission appliance directory for evaporative cooling. Direct system types are assigned an efficiency of 14 SEER (or minimum appliance efficiency standard for split-system cooling). The default system type is evaporative direct. For indirect or indirect-direct, select the appropriate type from the Energy Commission appliance directory and input a 13 EER as well as the airflow and media saturation effectiveness or cooling effectiveness from the Energy Commission appliance directory.

The standard design is based on a split-system air-conditioner meeting the requirements of Section 150.1(c) and Table 150.1-A or 150.1-B.

When a direct evaporative cooling system is modeled, the system type and minimum efficiency are shown in the appropriate section of the CF1R. When indirect or indirect-direct evaporative cooling are modeled, the EER verification is shown in the HERS verification section of the CF1R along with the system type, airflow, and system effectiveness.

If multiple HVAC distribution systems serve a building, each system and the conditioned space it serves may be modeled in detail separately or the systems may be aggregated and modeled as one large system. If the systems are aggregated, they must be the same type and all meet the same minimum specifications.

For duct efficiency calculations, the supply duct begins at the exit from the furnace or air handler cabinet.

2.4.6.1 Distribution Type

Fan-powered, ducted distribution systems can be used with most heating or cooling systems. When ducted systems are used with furnaces, boilers, or combined hydronic/water heating systems, the electricity used by the fan is calculated. R-value and duct location are specified when a ducted system is specified.

The compliance software shall allow the user to select from the basic types of HVAC distribution systems and locations listed in Table 11. For ducted systems, the default location of the HVAC ducts and the air handler are in conditioned space for multifamily buildings and in the attic for all other buildings.

|

Name |

HVAC Distribution Type and Location Description |

|

Ducts located in attic (Ventilated and Unventilated) |

Ducts located overhead in the attic space. |

|

Ducts located in a crawl space |

Ducts located under floor in the crawl space. |

|

Ducts located in a garage |

Ducts located in an unconditioned garage space. |

|

Ducts located within the conditioned space (except < 12 linear ft) |

Ducts located within the conditioned floor space except for less than 12 linear feet of duct, furnace cabinet, and plenums - typically an HVAC unit in the garage mounted on return box with all other ducts in conditioned space. |

|

Ducts located entirely in conditioned space |

HVAC unit or systems with all HVAC ducts (supply and return) located within the conditioned floor space. Location of ducts in conditioned space eliminates conduction losses, but does not change losses due to leakage. Leakage either from ducts that are not tested for leakage or from sealed ducts is modeled as leakage to outside the conditioned space. |

|

Distribution system without ducts (none) |

Air distribution systems without ducts such as ductless split-system air-conditioners and heat pumps, window air-conditioners, through-the-wall heat pumps, wall furnaces, floor furnaces, radiant electric panels, combined hydronic heating equipment, electric baseboards, or hydronic baseboard finned-tube natural convection systems, etc. |

|

Ducts located in outdoor locations |

Ducts located in exposed locations outdoors. |

|

Verified low-leakage ducts located entirely in conditioned space |

Duct systems for which air leakage to outside is equal to or less than 25 CFM when measured in accordance with Reference Residential Appendix RA3.1.4.3.8. |

|

Ducts located in multiple places |

Ducts with different supply and return duct locations. |

Source: California Energy Commission

|

Measure |

Description |

Procedures |

|

|

Verified Duct Sealing |

Mandatory measures require that space-conditioning ducts be sealed. Field verification and diagnostic testing are required to verify that approved duct system materials are used and that duct leakage meets the specified criteria. |

| |

|

Verified Duct Location, Reduced Surface Area and R-value |

Compliance credit can be taken for improved supply duct location, reduced surface area, and R-value. Field verification is required to verify that the duct system was installed according to the duct design, including location, size and length of ducts, duct insulation R-value, and installation of buried ducts.1 For buried duct measures, verified quality insulation installation (QII) is required as well as duct sealing. |

| |

|

Low-Leakage Ducts in Conditioned Space |

When the standards specify use of the procedures in Section RA3.1.4.3.8 to determine if the space-conditioning system ducts are located entirely in directly conditioned space, the duct system location is verified by diagnostic testing. Compliance credit can be taken for verified duct systems with low air leakage to the outside when measured in accordance with Reference Appendices, Residential Appendix Section RA3.1.4.3.8. Field verification for ducts in conditioned space is required. Duct sealing is required. |

| |

|

Low-Leakage Air-Handling Units |

Compliance credit can be taken for installing a factory-sealed air-handling unit tested by the manufacturer and certified to the Energy Commission to have met the requirements for a low-leakage air-handling unit. Field verification of the air handler model number is required. Duct sealing is required. |

| |

|

Verified Return Duct Design |

Verification to confirm that the return duct design conforms to the criteria given in Table 150.0-B or Table 150.0C. as an alternative to meeting 0.45 or 0.58 W/CFM fan efficacy of Section 150.0(m)0. |

| |

|

Verified Bypass Duct Condition |

Verification to determine if system is zonally controlled and confirm that bypass ducts condition modeled matches installation. |

| |

|

1. Compliance credit for increased duct insulation R-value (not buried ducts) may be taken without field verification if the R-value is the same throughout the building, and for supply ducts located in crawl spaces and garages where all supply registers are either in the floor or within 2 feet of the floor. If these conditions are met, HERS rater verification is not required. | |||

Source: California Energy Commission

The software will allow users to select default assumptions or specify any of the verified or diagnostically tested HVAC distribution system conditions in the proposed design (see Table 12), including duct leakage target, R-value, supply and return duct area, diameter and location.

The standard heating and cooling system for central systems is modeled with non-designed air distribution ducts located as described in Table 13 with duct leakage as specified in Table 18. The standard design duct insulation is determined by Table 150.1-A or 150.1-B (assuming attic option B) as R-6 in climate zones 3 and 5-7, and R-8 in Climate Zones 1, 2, 4, and 8 through16. The standard design building is assumed to have the same number of stories as the proposed design for determining the duct efficiency.

|

Configuration of the |

Standard Design | |

|

Standard Design Duct Location |

Detailed Specifications | |

|

Attic over the dwelling unit |

Ducts and air handler located in the attic |

Ducts sealed (mandatory requirement) No credit for verified R-value, location or duct design |

|

No attic but crawl space or basement |

Ducts and air handler located in the crawl space or basement | |

|

Multi-family buildings and buildings with no attic, crawl space or basement |

Ducts and air handler located indoors | |

This table is applicable only when the standard design system has air-distribution ducts.

Source: California Energy Commission

Distribution type, location, R-value, and whether tested and sealed will be shown on the CF1R. If there are no ducts, the absence of ducts is shown as a special feature on the CF1R. Any duct location other than attic (for example, crawl space) is shown as a special feature on the CF1R. Ducts in crawl space or the basement shall include a special feature note if supply registers are located within 2 feet of the floor. Measures that require HERS verification will be shown in the HERS required verification section of the CF1R.

Duct location determines the external temperature for duct conduction losses, the temperature for return leaks, and the thermal regain of duct losses.

If any part of the supply or return duct system is in an unconditioned attic, that entire duct system is modeled with an attic location. If no part of the supply or return duct system is located in the attic, but the duct system is not entirely in conditioned space, it is modeled in the unconditioned zone, which contains the largest fraction of the surface area. If the supply or return duct system is entirely in conditioned space, the duct system is modeled in conditioned space.

For ducted HVAC systems with some or all ducts in unconditioned space, the user specifies the R-value and surface area of supply and return ducts and the duct location.

Duct location and areas other than the defaults shown in Table 14 may be used following the verification procedures in Reference Residential Appendix RA3.1.4.1.

The standard design duct location is determined from the building conditions (Table 13).

Duct location is reported on the CF1R. Ducts entirely in conditioned space and verified low-leakage ducts entirely in conditioned space are reported in the HERS required verification listing on the CF1R.

Default duct locations are shown in Table 14. The duct surface area for crawl space and basement applies only to buildings or zones with all ducts installed in the crawl space or basement. If the duct is installed in locations other than crawl space or basement, the default duct location is “Other.” For houses with two or more stories, 35 percent of the default duct area may be assumed to be in conditioned space, as shown in Table 14.

The surface area of ducts in conditioned space is ignored in calculating conduction losses.

|

Supply Duct Location |

Location of Default Duct Surface Area | |

|

One story |

Two or more stories | |

|

All in crawl space |

100% crawl space |

65% crawl space, 35% conditioned space |

|

All in basement |

100% basement |

65% basement, 35% conditioned space |

|

Other |

100% attic |

65% attic, 35% conditioned space |

Source: California Energy Commission

The supply-side and return-side duct surface areas are treated separately in distribution efficiency calculations. The duct surface area is determined using the following methods.

2.4.6.4 Default Return Duct Surface Area

Default return duct surface area is calculated using:

Equation 4

Ar,out =Kr ×Afloor

Where Kr (return duct surface area coefficient) is 0.05 for one-story buildings and 0.1 for two or more stories.

2.4.6.5 Default Supply Duct Surface Area

The standard design and default proposed design supply duct surface area is calculated using Equation 5.

Equation 5

As,out = 0.27×A_floor×KS

Where Ks (supply duct surface area coefficient) is 1 for one-story buildings and 0.65 for two or more stories.

2.4.6.6 Supply Duct Surface Area for Less Than 12 feet of Duct In Unconditioned Space

For proposed design HVAC systems with air handlers outside the conditioned space but with less than 12 linear feet of duct outside the conditioned space, including air handler and plenum, the supply duct surface area outside the conditioned space is calculated using Equation 6. The return duct area remains the default for this case.

Equation 6

2.4.6.7 Diagnostic Duct Surface Area

Proposed designs may claim credit for reduced surface area using the procedures in Reference Residential Appendix RA3.1.4.1.

2.4.6.8 Bypass Duct

Section 150.1(c)13 prohibits use of bypass ducts unless a bypass duct is otherwise specified on the certificate of compliance. A bypass duct may be needed for some single-speed outdoor condensing unit systems. The software allows users to specify a bypass duct for the system. Selection of a bypass duct does not trigger changes in the ACM modeling defaults, but verification by a HERS rater is required utilizing the procedure in Reference Residential Appendix Section RA3.1.4.6.

Note: specification of a zonally controlled system with a single-speed condensing unit will trigger a default airflow rate value of 150 CFM/ton for the calculations. User input less than 350 CFM/ton reduces the compliance margin as compared to systems that model 350 CFM/ton as described in Section 2.4.5.2.

Software shall allow users to specify whether a bypass duct is used for a zonally controlled forced air system.

The standard design is based on a split-system air-conditioner meeting the requirements of Section 150.1(c) and Table 150.1-A or 150.1-B. The system is not a zonally controlled system.

An HVAC system with zonal control, and whether the system is assumed to have a bypass duct or have no bypass duct, is reported in the HERS required verification listings on the CF1R.

2.4.6.9 Duct System Insulation

For conduction calculations in the standard and proposed designs, 85 percent of the supply and return duct surface is assumed duct material at the related specified R-value, and 15 percent is assumed air handler, plenum, connectors, and other components at the mandatory minimum R-value.

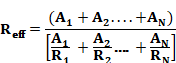

The area weighted effective R-value is calculated by the compliance software using Equation 7, including each segment of the duct system that has a different R-value.

Equation 7

Where:

Reff = Area weighted

effective R-value of duct system for use in calculating duct efficiency,

(h-ft²-°F/Btu)

AN = Area of duct segment n, square feet

Rn =

R-value of duct segment n including film resistance (duct insulation rated R + 0.7)

(h-ft²-°F/Btu)

The software user inputs the R-value of the proposed duct insulation and details. The default duct thermal resistance is based on Table 150.1-A or 150.1-B, Attic Option B, which is R-6 in Climate Zones 3 and 5-7, R-8 in Zones 1, 2, 4, and 8-16.

Duct location and duct R-value are reported on the CF1R. Credit for systems with mixed insulation levels, nonstandard supply and return duct surface areas, or ducts buried in the attic require the compliance and diagnostic procedures in Reference Residential Appendix RA3.1.4.1.

If a verified duct design is selected, nonstandard values for the supply-duct surface area and the return-duct surface area may be input by the user. A verified duct design must be verified by a HERS rater according to the procedures in Reference Residential Appendix RA3.1.4.1.1. Supply and return duct R-values, location, and areas are reported on the CF1R when nonstandard values are specified.

The required duct insulation R-value for attic Option B is from Table 150.1-A or 150.1-B for the applicable climate zone used in the standard design.

Duct location, duct R-value, supply, and return duct areas are reported on the CF1R. Verified duct design is reported in the HERS required verification listing on the CF1 R.

2.4.6.10 Buried Attic Ducts

Ducts partly, fully, or deeply buried in blown attic insulation in dwelling units meeting the requirements for verified quality insulation installation may take credit for increased effective duct insulation. To qualify for buried duct credit, ducts must meet mandatory insulation levels (R-6) prior to burial, be directly or within 3.5 inches of ceiling gypsum board, and be surrounded by at least R-30 attic insulation. Moreover, credit is available only for duct runs where the ceiling is level, there is at least 6 inches of space between the duct outer jacket and the roof sheathing, and the attic insulation has uniform depth. Existing ducts are exempt from mandatory minimum insulation levels, but to qualify for buried duct credit, they must have greater than R-4.2 insulation before burial.

In addition to the above requirements, deeply buried ducts must be buried by at least 3.5 inches of insulation above the top of the duct insulation jacket and located within a lowered area of the ceiling, a deeply buried containment system, or buried by at least 3.5 inches of uniformly level insulation. Mounding insulation to achieve the 3.5-inch burial level is not allowed.

Deeply buried duct containment systems must be installed such that the walls of the system are at least 7 inches wider than the duct diameter (3.5 inches on each side of duct), extend at least 3.5 inches above the duct outer jacket, and the containment area surrounding the duct must be completely filled with blown insulation.

The duct design shall identify the segments of the duct that meet the requirements for being buried, and these are input into the software separately from nonburied ducts. For each buried duct, the user must enter the duct size, R-value, and length, and whether the duct qualifies as deeply buried. The user must also indicate if a duct uses a deeply buried containment system. The software calculates the weighted average effective duct system R-value based on the user entered duct information, blown insulation type (cellulose or fiberglass), and R-value.

Duct-effective R-values are broken into three categories: partially, fully, and deeply, with each having different burial levels and requirements. Partially buried ducts have less than 3.5 inches of exposed duct depth, fully buried ducts have insulation depth at least level with the duct jacket, and deeply buried ducts have at least 3.5 inches of insulation above the duct jacket in addition to the above requirements. Effective duct R-value used by the software are listed in Table 15, Table 16, and Table 17.

|

|

R-8 Insulated: Nominal Round Duct Diameter | ||||||||||||||

|

3" |

4" |

5" |

6" |

7" |

8" |

9" |

10" |

12" |

14" |

16" |

18" |

20" |

22" |

24" | |

|

|

Effective Duct Insulation R-Value for Blown Fiberglass Insulation | ||||||||||||||

|

R-30 |

R-18 |

R-13 |

R-13 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-38 |

R-26 |

R-18 |

R-18 |

R-18 |

R-13 |

R-13 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-40 |

R-26 |

R-26 |

R-18 |

R-18 |

R-18 |

R-13 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-43 |

R-26 |

R-26 |

R-26 |

R-18 |

R-18 |

R-18 |

R-13 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-49 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-18 |

R-18 |

R-18 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-60 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-26 |

R-18 |

R-13 |

R-13 |

R-8 |

R-8 |

R-8 |

|

|

Effective Duct Insulation R-Value for Blown Cellulose Insulation | ||||||||||||||

|

R-30 |

R-14 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-38 |

R-20 |

R-14 |

R-14 |

R-14 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-40 |

R-20 |

R-20 |

R-14 |

R-14 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-43 |

R-20 |

R-20 |

R-20 |

R-14 |

R-14 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-49 |

R-32 |

R-20 |

R-20 |

R-20 |

R-20 |

R-14 |

R-14 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

|

R-60 |

R-32 |

R-32 |

R-32 |

R-32 |

R-20 |

R-20 |

R-20 |

R-20 |

R-14 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

R-8 |

Source: California Energy Commission

|

|

R-6 Insulated: Nominal Round Duct Diameter | ||||||||||||||

|

3" |

4" |

5" |

6" |

7" |

8" |

9" |

10" |

12" |

14" |

16" |

18" |

20" |

22" |

24" | |

|

|

Effective Duct Insulation R-Value for Blown Fiberglass Insulation | ||||||||||||||

|

R-30 |

R-15 |

R-15 |

R-11 |

R-11 |

R-11 |

R-11 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-38 |

R-24 |

R-24 |

R-15 |

R-15 |

R-15 |

R-15 |

R-11 |

R-11 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-40 |

R-24 |

R-24 |

R-24 |

R-15 |

R-15 |

R-15 |

R-11 |

R-11 |

R-11 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-43 |

R-24 |

R-24 |

R-24 |

R-24 |

R-15 |

R-15 |

R-15 |

R-15 |

R-11 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-49 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-15 |

R-15 |

R-11 |

R-11 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-60 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-24 |

R-15 |

R-15 |

R-11 |

R-11 |

R-6 |

R-6 |

|

|

Effective Duct Insulation R-Value for Blown Cellulose Insulation | ||||||||||||||

|

R-30 |

R-12 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-38 |

R-18 |

R-18 |

R-12 |

R-12 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-40 |

R-18 |

R-18 |

R-18 |

R-12 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-43 |

R-18 |

R-18 |

R-18 |

R-18 |

R-12 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-49 |

R-31 |

R-31 |

R-18 |

R-18 |

R-18 |

R-18 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

|

R-60 |

R-31 |

R-31 |

R-31 |

R-31 |

R-31 |

R-31 |

R-18 |

R-18 |

R-12 |

R-12 |

R-6 |

R-6 |

R-6 |

R-6 |

R-6 |

Source: California Energy Commission

|

|

R-4.2 Insulated: Nominal Round Duct Diameter | ||||||||||||||

|

3" |

4" |

5" |

6" |

7" |

8" |

9" |

10" |

12" |

14" |

16" |

18" |

20" |

22" |

24" | |

|

|

Effective Duct Insulation R-Value for Blown Fiberglass Insulation | ||||||||||||||

|

R-30 |

R-13 |

R-13 |

R-13 |

R-13 |

R-9 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-38 |

R-22 |

R-22 |

R-22 |

R-13 |

R-13 |

R-13 |

R-13 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-40 |

R-22 |

R-22 |

R-22 |

R-22 |

R-13 |

R-13 |

R-13 |

R-13 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-43 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-13 |

R-13 |

R-13 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-49 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-13 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-60 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-22 |

R-13 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

|

|

Effective Duct Insulation R-Value for Blown Cellulose Insulation | ||||||||||||||

|

R-30 |

R-15 |

R-9 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-38 |

R-15 |

R-15 |

R-15 |

R-9 |

R-9 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-40 |

R-29 |

R-15 |

R-15 |

R-15 |

R-9 |

R-9 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-43 |

R-29 |

R-15 |

R-15 |

R-15 |

R-15 |

R-9 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-49 |

R-29 |

R-29 |

R-29 |

R-15 |

R-15 |

R-15 |

R-15 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

|

R-60 |

R-29 |

R-29 |

R-29 |

R-29 |

R-29 |

R-29 |

R-15 |

R-15 |

R-15 |

R-9 |

R-9 |

R-4.2 |

R-4.2 |

R-4.2 |

R-4.2 |

Source: California Energy Commission

The software calculates the effective R-value of buried ducts based on user-entered duct size, R-value, and length; attic insulation level and type; and whether the duct meets the requirements of a deeply buried duct by using a lowered ceiling chase or a containment system. This feature must be combined with verified quality insulation installation, verified duct location, reduced surface area and R-value, and verified minimum airflow. The software will allow any combination of duct runs and the associated buried condition, and the overall duct system effective R-value will be a weighted average of the combination. The default is no buried ducts.

The standard design has no buried ducts.

Buried duct credit is reported in the HERS required verification listing on the CF1R.

2.4.6.11 Duct/Air Handler Leakage

The total duct/air handler leakage shown in Table 18 is used in simulating the duct system. The supply duct leakage for each case is the table value times 0.585. The return leakage is the table value times 0.415.

For each ducted system, the software user specifies one of the duct/air handler leakage cases shown in Table 18.

For ducted systems, the standard design is sealed and tested duct systems in existing dwelling units or new duct systems.

Sealed and tested duct systems are listed in the HERS verification section of the CF1R. Duct leakage is measured in accordance with procedures and values specified in Reference Appendices, Residential Appendix RA3.

2.4.6.12 Low Leakage Air Handlers

A low-leakage air handler may be specified as well as a lower duct leakage value (see Section 2.4.6.11). Installation requires installing one of the list of approved low-leakage air handling units published by the Energy Commission. The manufacturer certifies that the appliance complies with the requirements of Reference Joint Appendices 9.2.1, 9.2.2, 9.2.3, and 9.2.4.

|

Case |

Duct Leakage |

Air Handler Leakage |

Total Duct/Air Handler Leakage |

|

Duct systems in existing single-family houses |

15% |

Included in duct leakage |

15% |

|

Sealed and tested new or altered duct systems in unconditioned or conditioned space in a multifamily dwelling unit |

12% |

Included in duct leakage |

12% |

|

Sealed and tested new or altered duct systems in unconditioned or conditioned space in a townhome or single-family home |

5% |

2% |

7% |

|

Verified low-leakage ducts in conditioned space |

0% |

0% |

0% |

|

Low leakage air handlers in combination with sealed and tested new duct systems |

5% or as measured |

0% |

5% or as measured |

Source: California Energy Commission

Credit can be taken for installing a factory-sealed air-handling unit tested by the manufacturer and certified to the Energy Commission to meet the requirements for a low-leakage air-handler. Field verification of the air handler model number is required.

The standard design has a normal air handler.

A low-leakage air handler is reported on the compliance report and field verified in accordance with the procedures specified in Reference Appendices, Residential Appendix RA3.1.4.3.9.

2.4.6.13 Verified Low-Leakage Ducts in Conditioned Space

For ducted systems, the user may specify that all ducts are entirely in conditioned space, and the software will model the duct system with no leakage and no conduction losses.

The standard design has ducts in the default location.

Systems that have all ducts entirely in conditioned space are reported on the compliance documents, and this is verified by measurements showing duct leakage to outside conditions is equal to or less than 25 CFM when measured in accordance with Reference Appendices, Residential Appendix RA3.

Fan systems move air for air-conditioning, heating, and ventilation systems. The software allows the user to define the fans to be used for space-conditioning, indoor air quality, and ventilation cooling. Indoor air quality and ventilation cooling are discussed in Sections 2.4.9 and 2.4.10.

For the space-conditioning fan system, the user selects the type of equipment and enters basic information to model the energy use of the equipment. For ducted central air-conditioning and heating systems, the fan efficacy default is the mandatory minimum verified efficacy of 0.45, 0.58, or 0.62 W/CFM, depending on applicable system type (also assumed when there is no cooling system).

The standard design fan shall meet the minimum Section 150.1(c) and Table 150.1-A or 150.1-B requirements.

Minimum verified fan efficacy is mandatory for all ducted cooling systems. Fan efficacy is reported in the HERS required verification listings on the CF1R.

This section describes the general procedures for heating and cooling systems in low-rise residential buildings. The system includes the cooling system, the heating system, distribution system, and mechanical fans.

If multiple systems serve a building, each system and the conditioned space it serves may be modeled in detail separately or the systems may be aggregated and modeled as one large system. If the systems are aggregated, they must be the same type and all meet the same minimum specifications.

2.4.8.1 Multiple System Types Within Dwelling

For proposed designs using more than one heating system type, equipment type, or fuel type, and the types do not serve the same floor area, the user shall zone the building by system type.

The standard design shall have the same zoning and heating system types as the proposed design.

The heating system type of each zone is shown on the CF1R.

2.4.8.2 Multiple Systems Serving Same Area

If a space or a zone is served by more than one heating system, compliance is demonstrated with the most time-dependent valuation (TDV) energy-consuming system serving the space or the zone. For spaces or zones that are served by electric resistance heat in addition to other heating systems, the electric resistance heat is deemed the most TDV energy-consuming system unless the supplemental heating meets the exception to Section 150.1(c)6. See eligibility criteria in Residential Compliance Manual Section 4.2.2 for conditions under which the supplemental heat may be ignored.

For floor areas served by more than one cooling system, equipment, or fuel type, the system, equipment, and fuel type that satisfy the cooling load are modeled.

When the proposed design has no cooling system, the proposed design is required to model the standard design cooling system defined in Section 150.1(c) and Table 150.1-A or 150.1-B. Since the proposed design system is identical to the standard design system, there is no penalty or credit.

The standard design system is the specified in Section 150.1(c) and Table 150.1-A or 150.1-B for the applicable climate zone.

No cooling is reported as a special feature on the CF1R.

2.4.8.4 Zonally Controlled Forced-Air Cooling Systems

Zonally controlled central forced-air cooling systems must be able to deliver, in every zonal control mode, an airflow to the dwelling of > 350 CFM per ton of nominal cooling capacity, and operating at an air-handling unit fan efficacy of < 0.45 or 0.58 W/CFM depending on the applicable system type. This is a HERS-verified measure, complying with Residential Appendix RA3.3.

An exception allows multispeed or variable-speed compressor systems, or single-speed compressor systems to meet the mandatory airflow (CFM/ton) and fan efficacy (watt/CFM) requirements by operating the system at maximum compressor capacity, and system fan speed with all zones calling for conditioning, rather than in every zonal control mode.

The user selects zonally controlled as a cooling system input.

The standard design building does not have a zonally controlled cooling system.

Zonally controlled forced-air cooling systems are required to have the system bypass duct status verified by a HERS rater according to the procedures in Reference Residential Appendix RA3.1.4.6, and the fan efficacy and airflow rate are required to be verified according to the procedures in RA3.3.

The standards include a mandatory requirement for mechanical ventilation to provide acceptable indoor air quality for all newly constructed buildings and additions greater than 1,000 square feet. ASHRAE Standard 62.2-2016 as published in the 2017 supplement except Addendum k.

Amendments to ASHRAE 62.2:

Single-family homes use a default envelope leakage value of 2 ACH50 in place of a blower door measurement in section 4.1 of ASHRAE 62.2.

For single-family and multifamily dwelling units, increase filter efficiency in section 6.7 of ASHRAE 62.2 from MERV 6 to MERV 13.

For multifamily dwelling units, require sealing of the dwelling unit enclosures and enforce a HERS-verified maximum allowable leakage rate of 0.3 cfm/ft2 of enclosure area when unbalanced system types (exhaust, or supply) are used.

For estimating the energy impact of this requirement in compliance software, the minimum ventilation rate is met by either a standalone indoor air quality (IAQ) fan system or a central air handler fan system that can introduce outdoor air. In many cases, this energy is substantially compliance-neutral because the standard design is typically set equal to the proposed design.

The simplest IAQ fan system is an exhaust fan/bathroom fan that meets the criteria in ASHRAE Standard 62.2 for air delivery and minimal noise. More advanced IAQ fan systems that have a supply or both supply and exhaust fans are possible. To calculate the energy use of standalone IAQ fan systems, the systems are assumed to be on continuously.

To calculate the energy use of central fan integrated ventilation, the systems are assumed to be on for at least 20 minutes each hour as described below. The fan flow rate and fan power ratio may be different from the values used when the system is on to provide for heating or cooling, depending on the design or controls on the IAQ ventilation portion of the system.

The minimum ventilation rate for continuous ventilation of each single-family home or horizontally attached single-family dwelling unit is based on ASHRAE 62.2 Section 4.1.2 and given in Equation 8.

Equation 8

Qtotal = 0.03Afloor + 7.5(Nbr + 1)

Where:

Qtotal = total required ventilation rate (CFM)

Afloor = conditioned floor area in square feet (ft2)

Nbr = number of bedrooms (not fewer than one)

Equation 9

Q50 = Vdu x ACH50 / 60min

Where:

Q50 = leakage rate at 50 Pa

Vdu = dwelling unit conditioned volume, ft3

ACH50 = air changes per hour at 50 Pa (0.2 inch water)

Equation 10

Qinf = 0.052 X Q50 x wsf x [H/Hr]z

Where:

Qinf = effective annual infiltration rate, CFM (L/s)

Q50 = leakage rate at 50 Pa (from equation 150.0-C or 150.0-D)

wsf = weather and shielding factor from Table 150.0-D

H = vertical distance between the lowest and highest above-grade points within the boundary, ft (m)

Hr = reference height, 8.2 ft (2.5 m)

Z = 0.4 for calculating the effective annual average infiltration rate

Single-family horizontally attached dwelling units calculate Qfan as:

Equation 11

Qfan = Qtotal

Where:

Qfan = fan flow rate in cubic feet per minute (CFM)

Qtotal = total required ventilation rate (CFM)

Qinf = effective annual average infiltration rate, CFM (L/s) from Equation 150.0-B

Aext = for single-family detached homes, or the ratio of exterior envelope surface area that is not attached to garages or other dwelling units to the total envelope surface area for attached dwelling units not sharing ceilings or floor with other dwelling units, occupiable spaces, public garages, or commercial spaces

Qinf/Qtot otherwise

For multifamily or horizontally attached dwelling units, the minimum ventilation rate for continuous ventilation is based on ASHRAE 62.2-2016 Section 4.1.1 and given in Equation 13.

Equation 12

Qfan = 0.03Afloor + 7.5(Nbr + 1)

Where:

Qfan = fan flow rate in cubic feet per minute (CFM)

Afloor = conditioned floor area in square feet (ft2)

Nbr = number of bedrooms (not less than one)

The required ventilation rate to comply with ASHRAE Standard 62.2 and the means to achieve compliance are indicated on the CF1R (Table 20). The IAQ system characteristics are reported in the HERS required verification listing on the CF1R. The diagnostic testing procedures are in RA3.7.

Balanced IAQ fan requires HERS verification of airflow.

The proposed design shall incorporate a mechanical ventilation system fan. This requirement is a mandatory measure. The compliance software allows the user to specify the IAQ ventilation type (see Table 19) and the CFM of outdoor ventilation air that must be equal to or greater than what is required by ASHRAE Standard 62.2. The default is a standalone exhaust system meeting standard 62.2.

The mechanical ventilation system in the standard design is the same as the proposed design. The airflow rate is equal to the proposed design for exhaust, supply, and balanced fans with no heat or energy recovery. For balanced fans with heat or energy recovery, the airflow rate is equal to the proposed design up to a maximum of 1.5 times the minimum CFM required by ASHRAE 62.2. The sensible heat recovery effectiveness is zero. For standalone IAQ fan systems, the fan power ratio is equal to the proposed design value or 1.2 W/CFM, whichever is smaller. For central air handler fans, the fan power ratio is 0.45 (gas furnaces) or 0.58 W/CFM (heat pumps) of central system airflow in ventilation mode.

The required ventilation rate to comply with ASHRAE Standard 62.2 and the means to achieve compliance are indicated on the CF1R (Table 20). The IAQ system characteristics are reported in the HERS required verification listing on the CF1R. The diagnostic testing procedures are in RA3.7.

Balanced IAQ fan requires HERS verification of airflow. This feature is reported as a special feature.

|

Type |

Description |

Inputs |

|

Standalone IAQ Fan(exhaust, supply, or balanced) |

Dedicated fan system that provides indoor air quality ventilation to meet or exceed the requirements of ASHRAE Standard 62.2. |

CFM, watts/CFM, recovery effectiveness for balanced only |

|

Central Fan Integrated (CFI) (variable or fixed speed) [NOT YET IMPLEMENTED] |

Automatic operation of the normal furnace fan for IAQ ventilation. Ventilation type uses a special damper to induce outdoor IAQ ventilation air and distribute it through the HVAC duct system. Mixing type distributes and mixes IAQ ventilation air supplied by a separate standalone IAQ fan system. |

CFM, watts/CFM |

Source: California Energy Commission

|

IAQ System Name |

IAQ System Type |

Whole Building IAQ Airflow Rate (CFM) |

Standalone IAQ Fan Power Ratio (W/CFM) |

|

SFam IAQVentRpt |

Default |

28.5 |

0.25 |

Source: California Energy Commission

Ventilation cooling systems operate at the dwelling-unit level using fans to bring in outside air to cool the house when the air can reduce cooling loads and save cooling energy. System operation is limited to single-family dwellings and operate according to the schedule and setpoints shown in Table 22. Whole-house fans require either window operation and attic venting or ducting to exhaust hot air. Central fan ventilation cooling systems (fixed and variable-speed) use the HVAC duct system to distribute outside air and require attic venting. Whole-house fans, which exhaust air through the attic, require at least 1 ft2 of free attic ventilation area per 750 CFM of rated capacity for relief or the manufacturer specifications (see Section 150.1(c)12 of the standards).

Software allows the user to specify whether a ventilation cooling system (Table 21 for system types) is included in conditioned and living zones. The user can specify the airflow and watts/CFM (HERS verification required) or a default prescriptive whole-house fan with a capacity of 1.5 CFM/ft2 of conditioned floor area. When the default capacity is selected, the user can select HERS verification of the airflow and watts to receive full credit for the system capacity. When HERS verification is not selected, the fan capacity is reduced by a factor of 0.67 (33 percent reduction).

The standard design building for a newly constructed single-family building or for an addition greater than 1,000 square feet to a single-family building has a whole-house fan in Climate Zones 8-14 and no ventilation cooling in other climate zones. (See Section 150.1[c] and Table 150.1-A.) The whole-house fan has 1.5 CFM/ft2 of conditioned floor area, 0.14 watts/CFM, with 1 ft2 of attic vent free area for each 750 CFM of rated whole-house fan airflow CFM.

A ventilation cooling system is either a special feature or a HERS verification requirement, the size and type of which are reported on the CF1R (Table 21).

|

Measure |

Description |

HERS Verification |

|

Whole-House Fan |

Traditional whole-house fan mounted in the ceiling to exhaust air from the house to the attic, inducing outside air in through open windows. Whole-house fans are assumed to operate between dawn and 11 p.m. only at 33 percent of rated CFM to reflect manual operation of fan and windows by occupant. Fans must be listed in the California Energy Commission’s Whole House Fan directory. If multiple fans are used, enter the total CFM. |

Optional RA3.9 |

|

Central Fan Ventilation Cooling Variable or fixed-speed |

Central fan ventilation cooling system. Ventilation type uses a special damper to induce outdoor air and distribute it through the HVAC duct system. |

Required RA3.3.4 |

Source: California Energy Commission