There are several types of residential water heaters described below. The most common water heaters in single-family homes are consumer storage or instantaneous water heaters. For multifamily buildings, two options are commonly used: A central domestic hot water system with one or more commercial storage water heaters or one or more boilers coupled with a storage tank to serve the entire building. Alternatively, water heaters are installed in each dwelling unit (similar to single-family).

To comply with the Energy Standards using either the prescriptive or performance approach, the water heater must meet the federal and/or the California Appliance Efficiency Regulations (Title 20).

Instantaneous water heaters, commonly referred to as tankless or on-demand, heat water using natural gas, electricity, or propane. These units do not have a tank for storing heated water but instead use a sensor that detects the flow of water over the heat exchanger that initiates the heating element (typical volumes around 0.5 gallons). Instantaneous units are capable of delivering water at a controlled temperature of less than 180⁰F. The input rating for gas instantaneous water heaters ranges between 50,000 and 200,000 BTU per hour (at least 4,000 BTU per hour per gallon of stored water) with a storage capacity of less than 2 gallons.

Instantaneous water heaters require an electrical connection for controls and the combustion air blower, a direct or power venting system, and a larger gas line (typical input ratings of 140,000 to 200,000 BTU/hr).

Electric instantaneous water heaters are not generally designed for use with solar water heating systems or as heat sources for indirect-fired water heaters. They are also typically inappropriate for use with recirculation systems. Consult manufacturer's literature when considering these applications. Electric instantaneous water heaters are not allowed through the prescriptive approach to compliance but can be installed using the performance approach as long as the total energy budget is not exceeded.

To comply prescriptively with the Energy Standards, a user can choose to install a gas or propane instantaneous water heater that meets the minimum efficiency requirements of California’s Title 20 Appliance Efficiency Regulations Section 1605.1(f) for federally regulated appliances.

5.2.2.1 Consumer Storage Water Heaters

Storage water heaters use gas (natural gas or propane), electricity or oil to heat and store water at a thermostatically controlled temperature (less than 180⁰ F) for delivery on demand. Federal appliance efficiency standards differentiate storage water heaters based on whether the rated storage volume is greater than 55 gallons or less than or equal to 55 gallons.

The U.S. Department of Energy (DOE) classifies consumer gas water heaters as having an input of 75,000 BTU per hour or less and has a storage capacity ranging between 20 and 100 gallons. A basic gas storage water heater is composed of a standing pilot ignition system, a burner, a combustion chamber, a flue baffle, a flue, an insulated water tank, a cold water inlet and hot water outlet, a sacrificial anode, a gas valve, a temperature and pressure relief valve, a thermostat, heat traps, and an outer case.

The DOE classifies consumer electric storage water heaters as having an input of 12 kilowatt (kW) or less and have a storage capacity ranging between 20 and 120 gallons. A basic electric storage consumer water heater differs from gas water heaters by using an electric resistance heating element. As noted in this chapter, electric storage water heaters are not allowed through the prescriptive approach to compliance but can be installed using the performance approach as long as the water heating energy budget is not exceeded.

Recently DOE added a new category of water heaters called grid-enabled water heaters and is defined as an electric resistance water heater that has a rated storage tank volume of more than 75 gallons and is manufactured on or after April 16, 2015. The water heater must have an activation lock at the point of manufacture and is intended for use only as part of an electric thermal storage or demand response program.

5.2.2.2 Heat Pump Water Heater (HPWH)

A heat pump water heater (HPWH) is an electric water heater that works like a refrigerator in reverse. It uses a compressor to transfer heat from the surrounding air to the water tank. It includes all necessary auxiliary equipment such as fans, storage tanks, pumps, or controls. Typically, HPWHs include backup electric resistance elements to ensure hot water delivery when the air temperature is too cold or the hot water demand is too high. Some models entering the market use larger compressors to avoid the need for resistance elements.

The performance of HPWHs depends heavily on air temperature because they rely on extracting heat from the air. Buildings in warm and cold climate zones, and different installation locations such as a garage or vented outdoor closet, all have an impact on performance and must be considered. HPWHs are most efficient in warmer climates, but even in cold climate zones such as Climate Zone 16, HPWHs still use only half as much electricity as conventional electric resistance water heaters. In addition to air temperature sensitivity, HPWH performance is affected by cold water inlet temperatures as introduction and mixing of inlet water during larger draws may trigger second stage electric resistance heating in the tank.

The Northwest Energy Efficiency Alliance (NEEA) Advanced Water Heater Specification was developed to address critical performance and comfort issues of HPWH in colder climates. Tiers are incorporated into this specification recognizing variations in product performance and configuration. An HPWH that meets the NEEA Advanced Water Heater Specification performs significantly better in real world conditions, and an HPWH that meets the NEEA Tier 3 or higher can be used to meet the prescriptive requirement for newly constructed buildings, addition, and alteration.

The list of qualified product list of NEEA HPWH can be found here:

https://neea.org/img/documents/qualified-products-list.pdf

5.2.2.3 Residential-Duty Commercial Water Heater

This appliance is essentially a commercial water heater that can be legally installed in a residential building. It is defined in the Federal Code of Regulations (10 CFR 431.102) as any gas-fired, electric, or oil storage or instantaneous commercial water heater that meets the following conditions:

1. Uses a single-phase external power supply for models that require electricity.

2. Is not designed to provide outlet hot water at temperatures greater than 180°F.

3. Is not excluded by the specified limitations regarding rated input and storage capacity as described in Table 5-2 below. In other words, a residential-duty commercial water heater must have rate input and rated storage volume below the value listed in Table 5-2.

|

Water Heater Type |

Indicator of Nonresidential Application |

|

Gas-Fired Storage |

Rated input >105 kBTU/h; Rated storage volume >120 gallons. |

|

Oil-Fired Storage |

Rated input >140 kBTU/h; Rated storage volume >120 gallons. |

|

Electric Instantaneous |

Rated input >58.6 kW; Rated storage volume >2 gallons. |

Source: U.S. Department of Energy (2014). “Energy Conservation Program for Consumer Products and Certain Commercial and Industrial Equipment: Test Procedures for Residential and Commercial Water Heaters; Final Rule.” http://www.regulations.gov/#!documentDetail;D=EERE-2011-BT-TP-0042-0082

Residential-duty commercial water heaters are rated in uniform energy factor (UEF) and are allowed through the prescriptive approach to compliance but can also be installed using the performance approach as long as the total energy budget is not exceeded.

5.2.2.4 Hot Water Supply Boiler

A hot water supply boiler is industrial water heating equipment with a heat input rate from 300 to 12,500 kBTU per hour and at least 4,000 BTU per hour per gallon of stored water. A hot water boiler should have either the temperature or pressure control necessary for heating potable water for purposes other than space heating, or the boiler manufacturer’s literature should indicate that the intended uses of the boiler include heating potable water for purposes other than space heating. A hot water boiler could be fueled by oil or gas, and it must adhere to the minimum thermal efficiency and maximum standby loss as described in California’s Title 20 Appliance Efficiency Regulations.

Boilers are typically used for doing both space heating and water heating. Use of a boiler will typically require one or more unfired storage tanks to be installed as part of the system. Careful attention should be given to the layout of these systems due to the potential for high energy losses between the boiler and storage tanks. Boilers are not allowed through the prescriptive approach to compliance but can be installed using the performance approach as long as the water heating energy budget is not exceeded.

Water heaters should be maintained according to manufacturer recommendations to ensure proper water heater performance, prolonged useful life, and warranty coverage. If water heaters are not maintained, the useful life of the unit can be shortened and failures that may result may not be covered under the warranty. This section presents the best practices for maintaining the life and efficiency of water heaters.

5.2.3.1 Maintenance of Instantaneous Water Heaters

The primary maintenance activities for instantaneous water heaters are flushing the heat exchanger to remove scale buildup and inspecting and cleaning the inlet water filter screen, which helps minimize the amount of debris or sediment that enters the water heater.

Some manufacturers recommend a maintenance schedule, but the maintenance schedule users deploy may vary based on water quality. In areas with hard water, more frequent maintenance (every two years) is recommended. In areas where the water quality is relatively good, water heater maintenance is recommended every three to four years. Frequent inspection of the inlet water filter screen will enable a user to monitor the amount of sediment entering the water heater. If the filter tends to fill with sediment regularly, then more frequent flushing may be required. Users can also reference local water quality data to determine the level of water quality in their area to help guide maintenance schedules.

To assist in flushing the heat exchanger, manufacturers and plumbers recommend the installation of a drain kit (that is, isolation valves). (See Figure 5-2 below.) The installation of isolation valves on instantaneous units is mandatory in the Energy Standards (Section 110.3[c]7 and Section150.0 [n]4). Isolation valves enable the unit to be isolated from both the inlet cold water and the outlet hot water lines, thereby allowing the heat exchanger to be flushed using a simple procedure. Integral to the kit are hose bibs that allow the flushing hoses to be attached. Instantaneous water heater that has integrated drain ports for servicing are acceptable to meet the requirements of Section §110.3(c)7 and will not require additional isolation valves.

Manufacturers recommend that a licensed professional flush the heat exchanger to avoid potentially damaging the water heater, though some manufacturers sell flush kits so that homeowners can maintain their own water heater. Flush kits consist of a submersible pump, two short hoses, hose connections, and a 5-gallon bucket. These components can be purchased separately or as a preassembled kit. A solution of white vinegar is widely recommended for flushing the heat exchanger as it is food-grade and very effective at removing scale.

In addition to flushing the heat exchanger, manufacturers recommend periodically inspecting and cleaning the inlet water filter screen, which helps minimize the amount of debris or sediment that enters the water heater. This can be done by running the filter screen under hot water and using a brush to remove debris. Replacement of the inlet water filter screen is not necessary unless it is damaged.

Figure 5-2: Isolation Valves

Source: http://www.brasscraft.com/products.aspx?id=266

5.2.3.2 Maintenance of Storage Water Heaters

For storage water heaters, the primary maintenance activities consist of draining the tank, inspecting the anode rod, and replacing the anode rod, if necessary. The recommended frequency of regular maintenance varies by manufacturer. Like instantaneous water heaters, the frequency of maintenance depends on water quality. Most manufacturers recommend draining the tank every six months to once per year to remove sediment that has accumulated in the bottom of the tank. Periodic inspections (every six months to once a year) of the burner, venting system, and temperature and pressure relief valves are also recommended by manufacturers.

Manufacturers typically recommend inspecting the anode rod every two years and replacing it when necessary to prolong tank life, but the frequency of inspection depends on local water conditions. If water is soft or a water softener is used, more frequent inspection of the anode is needed as softened water will corrode the sacrificial anode rod at a much faster rate than unsoftened water. If the setup of the water heater prevents an easy removal of the corroded anode rod, then it might be necessary to completely move the tank from the location to replace the anode rod.

Drain water heat recovery (DWHR) is a technology that captures shower waste heat from the drain line. DWHR devices are counter flow heat exchangers, with cold water entering the building on one side of the device and hot drain water exiting the building on the other.

For the 2019 Title 24 Standards, DWHR is a component of an alternative prescriptive path for multifamily buildings with central water heating. It is also a compliance option for other water heating applications. DWHR technologies are most prevalent and perform best in cold climates in applications with large water heating loads and colder inlet water temperatures. California, being a generally milder climate, will show somewhat diminished performance relative to the preferred applications.

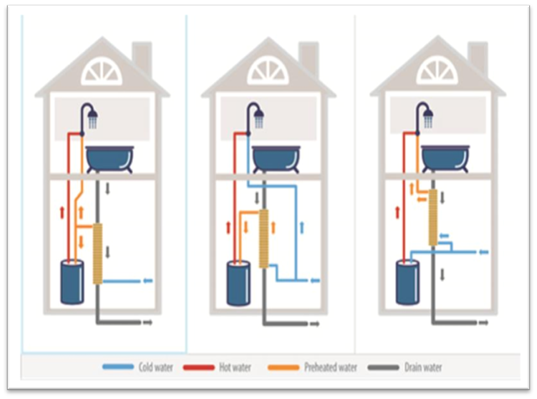

A DHWR device uses the reclaimed heat to preheat potable cold water that is then delivered either to the shower or the water heater. The device can be installed in either an “equal flow” configuration (with preheated water being routed to both the water heater and the shower) or an “unequal flow” configuration (preheated water directed to either the water heater or shower). Figure 5-3 schematically shows the three installation configurations. The energy harvested from a DWHR device is maximized in an equal flow configuration. They are sold in both vertical design configurations, as shown in Figure 5-3, and in horizontal configurations. The two forms each have advantages and disadvantages, which should be evaluated for each potential installation.

To use these systems to comply with Energy Standards, the design and installation must be HERS-verified and meet the Reference Appendix RA4.4.21 requirements.

Figure 5-3: The Three Plumbing Configurations of DWHR Installation (From left to right: Equal Flow, Unequal Flow - Water Heater, Unequal Flow - Fixture)

Source: Frontier Energy