Boiler Part-Load Performance Curve

Applicability

All boilers

Definition

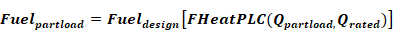

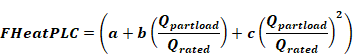

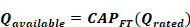

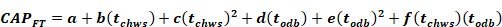

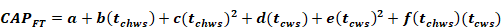

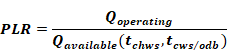

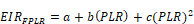

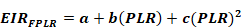

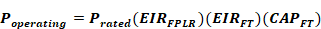

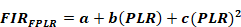

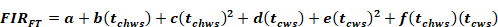

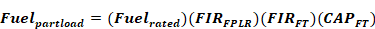

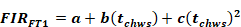

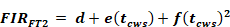

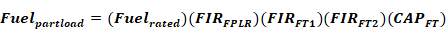

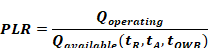

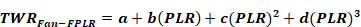

An adjustment factor that represents the percentage full load fuel consumption as a function of the percentage full load capacity. This curve shall take the form of a quadratic equation as follows:

Where:

|

FHeatPLC |

The fuel heating part-load efficiency curve |

|

Fuelpartload |

The fuel consumption at part-load conditions (Btu/h) |

|

Fueldesign |

The fuel consumption at design conditions (Btu/h) |

|

Qpartload |

The boiler capacity at part-load conditions (Btu/h) |

|

Qrated |

The boiler capacity at design conditions (Btu/h) |

|

a |

Constant |

|

b |

Constant |

|

c |

Constant |

Units

Ratio

Input Restrictions

Prescribed to the part-load performance curve in the ACM Appendix 5.7, based on the boiler draft type.

Standard Design

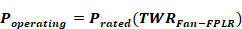

The standard design uses the mechanical draft fan curve in Appendix 5.7.

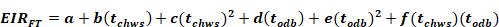

Standard Design:

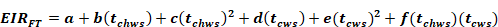

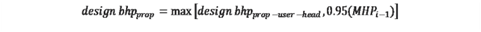

Existing Buildings

Where:

Where: