To ensure that the simulated space-conditioning loads are adequately met, adequate capacity must be available in each of the components of the HVAC system; for example, supply-air flow rates, cooling coils, chillers, and cooling towers. If any component of the system is incapable of adequate performance, the simulation may understate the required energy inputs for space conditioning and report unmet load hours. Adequate capacities are required in the simulations of both the proposed design and standard design. The subchapters below describe the procedures that shall be followed to ensure that both versions of the design are simulated with adequate space-conditioning capacities.

The UMLH requirement may be updated to prevent HVAC systems that show as undersized according to compliance software modeling constraints from receiving a compliance credit. This requirement does not mandate that a specific cooling or heating capacity be specified; that is the role of the engineer of record for the building. With this change, if the proposed design appears as undersized, the user will be prompted to adjust plant, system, zonal capacities or a combination as needed to meet the UMLH criteria.

The special case of a building designed with no cooling system (typically, in a temperate coastal climate) is accommodated by the compliance software automatically adding a minimally compliant packaged constant volume single zone system.

As described in Chapter 2.5 Calculation Procedures, the proposed design shall have no more than 150 UMLH for any thermal zone. If this limit is exceeded, the compliance software allows the user to make changes to the proposed design building description to bring the UMLH equal to or below 150. This process is not automated by the compliance software.

If the proposed design does not meet the UMLH criteria, the user should indicate the condition on the forms to add necessary equipment capacity to the proposed design. If the space conditioning criteria are not met because the HVAC equipment in the proposed design lacks the capability to provide either heating or cooling, equipment capable of providing the needed space conditioning must be specified by the user.

Equipment sizes for the proposed design shall be entered into the model by the energy analyst and shall agree with the equipment sizes specified in the construction documents. When the simulations of these actual systems indicate that specified space conditions are not being adequately maintained in one or more thermal zone(s), the user shall be prompted to make changes to equipment sizes or zones as necessary. Space conditions are not being adequately met when the UMLH exceed 150 for the year. The use of equipment sizes that do not match the actual equipment sizes as indicated on construction documents triggers an exceptional condition that is noted on the compliance forms.

For sizing heating and cooling equipment capacities, the compliance software shall use design day schedules as specified in Chapter 5.2 Project Data. For cooling capacity sizing, compliance software shall use the OnDay schedule from Appendix 5.4B for occupant, lighting, and equipment schedules, respectively. For heating capacity sizing, compliance software shall use the OffDay schedule from Appendix 5.4B for occupant, lighting, and equipment schedules, respectively.

Equipment in the standard design is automatically sized by the program as described below. Net coil capacities are calculated using the adjustments described in Section 5.7.5 Cooling Systems and Section 5.7.6 Heating Systems The compliance software will tabulate the zone UMLH for the standard design in the same manner as the proposed design. However, standard design UMLHs will not influence compliance analysis results.

Single-Zone Air-Source Heat Pump Systems: Fan or pump capacity is 1.15 times the maximum of the autosized heating or cooling air flow, or the minimum ventilation air flow, whichever is greater. The heat pump gross coil capacity for heating at standard rating conditions is 1.15 times the maximum of either the autosized gross cooling capacity plus the calculated design fan heat, or the autosized gross heating capacity as determined using the equation for gross heating capacity below minus the calculated design fan heat, multiplied by 0.75. The heat pump gross coil capacity for cooling at standard rating conditions is the same as the heating capacity. The final calculated cfm/tongross shall not be less than 280 and not more than 450.

All Other Secondary Systems: Fan or pump capacity is 1.15 times the maximum of the autosized heating or cooling air flow, or the minimum ventilation air flow, whichever is greater. The gross coil capacity for heating at standard rating conditions is 1.25 times the autosized gross heating capacity. The gross coil capacity for cooling at standard rating conditions is 1.15 times the autosized gross cooling capacity plus the calculated design fan heat. For DX coils, the final calculated cfm/tongross shall not be less than 280 and not more than 450.

Plant Equipment: Fan or pump capacity is 1.0 times the design day peak loop flow. The gross coil capacity for boilers at standard rating conditions is 1.25 times the design day peak loop load. The gross coil capacity for chillers/heat rejection at standard rating conditions is 1.15 times the design day peak loop load.

For standard design single-zone air-source heat pump systems, the sizing run shall be performed using an electric resistance heating coil. This autosized electric resistance coil capacity is then used as an input to

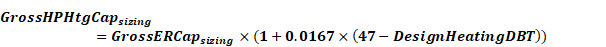

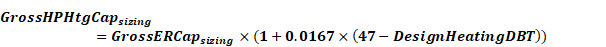

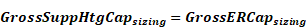

determine the gross heating capacity of the heat pump at 47 F and the heat pump supplemental heating coil using the equation below, which is used for determining the annual heat pump heating coil capacities for the annual compliance simulation as described for Single-Zone Air-Source Heat Pump Systems.

Where:

GrossHPHtgCapsizing= the estimated gross heating capacity of the heat pump at 47°F outdoor air temperature

GrossERCapsizing = the autosized gross electric resistance heating capacity from the sizing run

DesignHeatingDBT = the design heating outdoor air temperature used for sizing run

If mechanical system compliance is included, as described in Chapter 5.2.3 Partial Compliance Model Input Classification, and a compliance model does not contain an HVAC system, the compliance software will generate an error and not run the simulation. For zones designed to not have a cooling system the software will automatically generate a minimally compliant single zone HVAC system to meet the cooling loads for the zone. In cases where the design has cooling but it is insufficient to meet the UMLH criteria, the user can select “Add cooling system to meet load” and the compliance software will automatically generate a minimally compliant single zone HVAC system to meet the cooling loads for the zone. The compliance software shall make an appropriate note on compliance documentation indicating that the modeled HVAC system does not match design requirements. If the compliance software provides a means for the user to identify that the building has no cooling system, this information is reported on the compliance reports.