10.8

Compressed Air Systems (§120.6(e))

10.8.1

Overview

§120.6(e)

applies to all new compressed air systems with a total installed compressor

capacity of ≥25 hp. It also applies to existing compressed air systems

that are being altered on the supply side (equipment upstream of the

distribution system). For alternations there is an exception for systems

that include one or more centrifugal compressors.

As described in the following paragraphs, there are 3 main

requirements in this section:

•

Trim

Compressor and Storage (§120.6(e)1)

•

Controls (§120.6(e)2), and

•

Acceptance (§120.6(e)3)

10.8.2

Mandatory Measures §120.6(e)

A.

Trim

Compressor and Storage (§120.6(e)1)

This requirement targets the performance of a compressed

air system across its full range. This requirement excludes

alterations that are not making a large change to the system. A large

change is defined as adding or replacing more than 50% of the online

capacity.

There are two alternate paths to comply with this

requirement:

•

Using a VSD controlled compressor(s) as the Trim Compressor (§120.6(e)1A)

•

Using a compressor or set of compressors as the Trim Compressor

(§120.6(e)1B)

Both of these paths aim to reduce the amount of cycling of

fixed speed compressors by utilizing a better-suited compressor that operates

well in part-load.

Compliance Option 1: VSD-controlled Trim Compressor

(§120.6(e)1A)

In order to avoid control gaps - portions of the compressed

air system range with poor performance - it’s important to have a trim

compressor sized to handle the gaps between base compressors. This minimum

size is determined with the Largest Net

Capacity Increment - the biggest step increase between combinations

of base compressors.

With equally sized compressors this is fairly intuitive: in a

system with two-100 hp (434 acfm) rotary screw compressor system, the largest

step increase would be the size of one of the compressors (434 acfm). For

systems with uneven compressor sizes, it requires going through the following

steps:

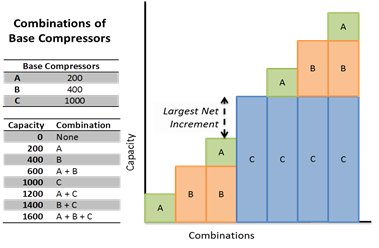

a) Determine all combinations of base

compressors (including all compressors off).

b) Order these combinations in increasing

capacity.

c) Calculate the difference between every

adjacent combination.

d) Choose the largest difference.

This largest difference is what must be covered by the trim

compressor(s) in order to avoid a control gap.

Example

10-55

Question

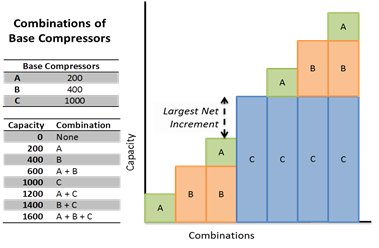

Given

a system with three base compressors with capacities of 200 acfm (Compressor A),

400 acfm (Compressor B) and 1,000 acfm (Compressor C), what is the Largest

Net Capacity Increment?

Answer

As

shown in the image below there are 8 possible stages of capacity ranging from 0

acfm with no compressors to 1,600 acfm with all three compressors

operating. The largest net increment is between stage 4 with compressors A

and B operating (200+400=600acfm) to stage 5 with compressor C operating (1,000

acfm)

For

this system the Largest Net Capacity Increment is 1,000 acfm-600 acfm =

400 acfm

Once the Largest Net Capacity Increment is calculated,

this value can be used to satisfy the first compliance option. Option one

mandates that the rated capacity of the VSD compressor(s) be at least 1.25 times

the largest net increment.

Example

10-56

Question

Using

the system from the previous example, what is the minimum rated capacity of VSD

compressor(s) that are needed to comply with Option 1?

Answer

As

previously shown, the Largest Net Capacity Increment is 1,000 acfm-600

acfm = 400 acfm. The minimum rated capacity for VSD compressor(s) is 400

acfm X 1.25 = 500 acfm.

For compliance option 1, the system must include primary

storage that has a minimum capacity of 1 gallon for every acfm of capacity

of the largest trim compressor.

Example

10-57

Question

What

is the required minimum primary storage capacity for the trim compressor from

the previous example to comply with Option 1?

Answer

Assuming

there is a VSD compressor with a rated capacity of 500 acfm, per §120.6(e)1A

it must have 1 gallon of storage per acfm of rated capacity or 500*1 = 500

gallons of storage.

Compliance Option 2: Other Compressors as Trim Compressor

(§120.6(e)1B).

The second compliance option offers more flexibility but

requires looking at both the Largest Net Capacity Increment of the

system, as well as the Effective Trim Capacity of the trim

compressor(s).

The Effective Trim Capacity is the range across which

a trim compressor has adequate part-load performance. Performance is

measured in power input over air volume output or specific power

(kw/100acfm). Many VSD compressors come with a compressor performance

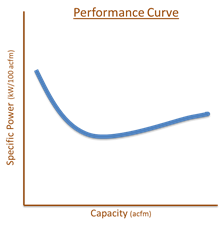

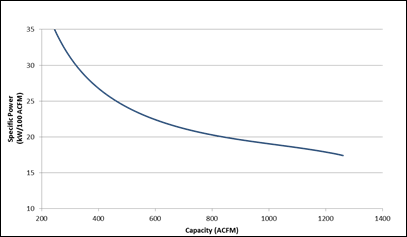

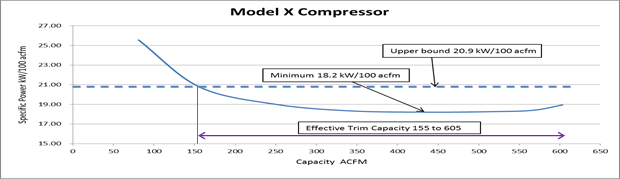

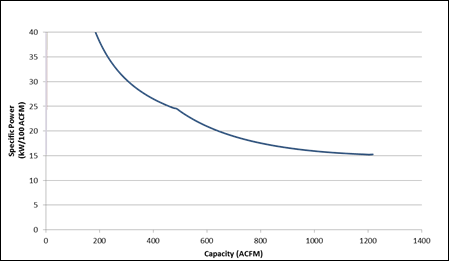

graph in a CAGI data sheet that looks similar to the graph in Figure

10-40.Figure 10-40–Example Compressor Power vs. Capacity Curve

The capacity of the compressor is along the x-axis, while the

power is on the y-axis. The curve in Figure 10-41 is a typical shape

of a performance curve for a VSD compressor. The lower the specific power,

the more energy efficient the compressor is at that condition.

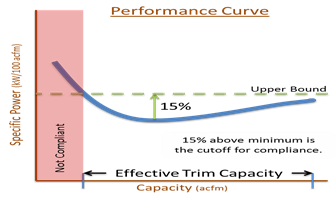

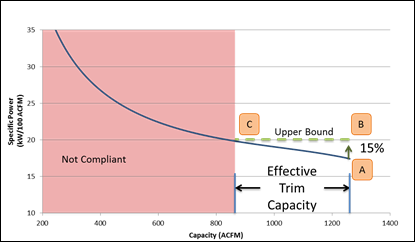

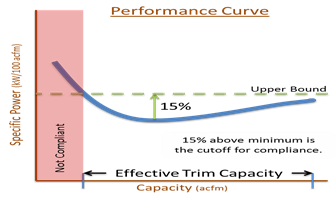

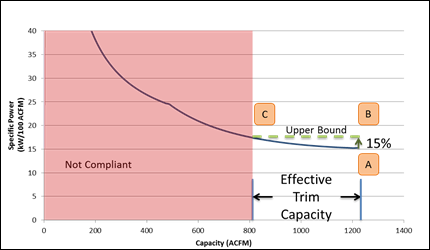

The Effective Trim Capacity uses the minimum of the

compressor power vs. capacity curve to determine the range of adequate part-load

performance. This can be done in the following steps and is illustrated in

the graph below.

a) Find the minimum specific power across the

range.

b) Find the upper bound by calculating 1.15

times the minimum specific power.

c) Determine the endpoints of the capacity

where the specific power is less than or equal to the upper bound.

d) The difference between these two endpoints

is the effective trim capacity.

Figure 10-41 –Determination of Effective Trim

Capacity from a Compressor Curve

This definition of Effective Trim Capacity, along with

the Largest Net Capacity Increment of the system, will be used

to assist in sizing the trim compressor appropriately in the next section.

Example

10-58

Question

Continuing

with the system from the previous examples, what is the required minimum

Effective Trim Capacity of the trim compressor(s) to comply with Option

2?

Answer

As

previously shown, the Largest Net Capacity Increment is 1,000 acfm-600

acfm = 400 acfm. Per §120.6(e)1

the minimum Effective Trim Capacity is equal to the Largest Net

Capacity Increment or 400 acfm.

Example

10-59

Question

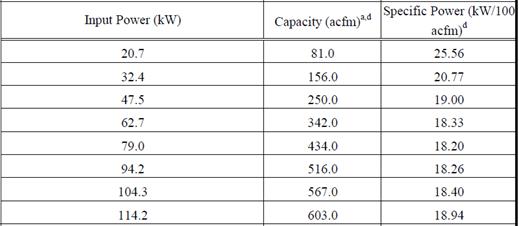

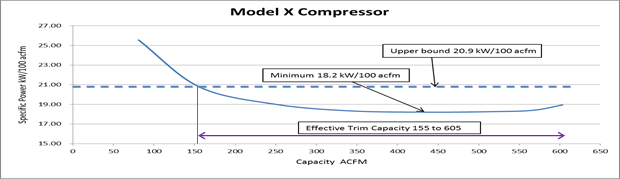

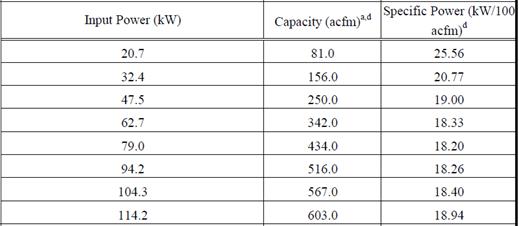

A

manufacturer provided the following data for their compressor; would this

provide the minimum Effective Trim Capacity for this system to comply

with Option 2?

Answer

From

the manufacturer’s data the minimum specific power is 18.2 kW/100 acfm.

The upper limit would be 18.2 * 1.15 = 20.9 kW/100 acfm. Interpolating

from the manufacturer’s data this appears to go from 155 acfm to 605 acfm for an

Effective Trim Capacity of 605-155= 450 acfm. This is larger than the

Largest Net Capacity Increment of 400 acfm so this compressor

would comply as a trim compressor for this system.

For compliance option 2, the system must include primary

storage that has a minimum capacity of 2 gallons for every acfm of capacity

of the largest trim compressor.

Example

10-60

Question

What

is the required minimum primary storage capacity for the trim compressor from

the previous example to comply with Option 2?

Answer

This

compressor has a rated capacity of 603 acfm, per §120.6(e)1B

it must have 2 gallons of storage per acfm of rated capacity or 603*2 = 1,206

gallons of storage.

The last example used a VSD compressor, but other

technologies can be used for compliance option 2. The next example

examines a 250-hp load-unload, single stage, rotary screw compressor coupled

with 10 gallons/cfm of storage. Generally, higher levels of storage

improve part-load performance and this combination was chosen to meet the

part-load performance mandated by code. This data was generated from

theoretical curves used in AirMaster+, a tool created by the U.S. Department of

Energy.

Example

10-61

Question

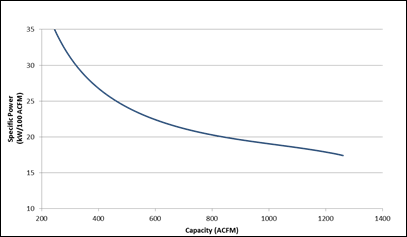

Part-load

data was approximated below for a 250-hp load-unload, single stage, rotary screw

compressor coupled with 10 gallons/cfm of storage; would this provide the

minimum Effective Trim Capacity for this system to comply with Option

2?

Answer

Using

the previous examples, a compressor with an effective trim capacity of at least

400 acfm is necessary.

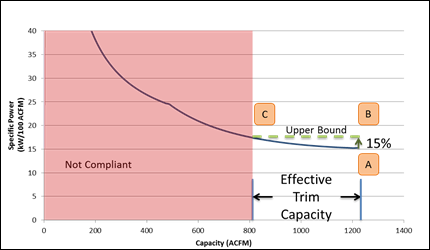

Looking

at the graph, the minimum specific power (labeled as A below) occurs at full

load - a capacity of 1261 acfm, with a specific power of 17.4 kW/100acfm.

Using this minimum specific power, the upper bound is 17.4 * 1.15 = 20.01

kW/100acfm or 15% higher than the minimum specific power. This puts the

ends of the effective trim capacity at 1261 acfm (labeled as B) and 845 acfm

(labeled as C), resulting in an effective trim capacity of 1261 – 845 = 416

acfm. This is larger than the Largest Net Capacity Increment of 400 acfm

so this compressor would comply as a trim compressor for this

system.

For compliance option 2, the system must include primary

storage that has a minimum capacity of 2 gallons for every acfm of capacity of

the largest trim compressor.

Example

10-62

Question

What

is the required minimum primary storage capacity for the trim compressor from

the previous example to comply with Option 2?

Answer

This

compressor has a rated capacity of 1261 acfm, and per §120.6(e)1B

it must have 2 gallons of storage per acfm of rated capacity or 1261 * 2 = 2,522

gallons of storage.

However,

in order to meet the performance necessary for a large enough Effective Trim

Capacity, there must be 10 gallons of storage per acfm of the rated capacity, or

1261 * 10 = 12,610 gallons.

The next example also utilizes option 2, but with a 250-hp

Variable Capacity compressor, with part-load performance approximated by

theoretical curves used in AirMaster+, similar to the last example.

Example

10-63

Question

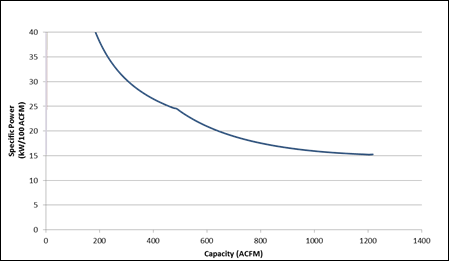

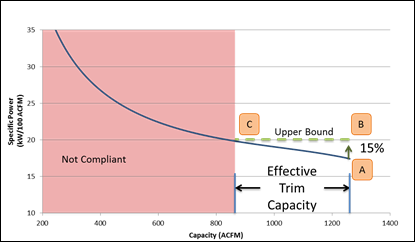

Part-load

data was approximated below for a 250-hp variable capacity compressor; would

this provide the minimum Effective Trim Capacity for this system to

comply with Option 2?

Answer

Using

the previous examples, a compressor with an effective trim capacity of at least

400 acfm is necessary.

Looking

at the graph, the minimum specific power (labeled as A below) occurs at full

load - a capacity of 1218 acfm, with a specific power of 15.3 kW/100acfm.

Using this minimum specific power, the upper bound is 15.3 * 1.15 = 17.56

kW/100acfm or 15% higher than the minimum specific power. This puts the

ends of the effective trim capacity at 1218 acfm (labeled as B) and 804 acfm

(labeled as C), resulting in an effective trim capacity of 1218 – 804 = 414

acfm. This is larger than the Largest Net Capacity Increment of 400 acfm

so this compressor would comply as a trim compressor for this

system.

For compliance option 2, the system must include primary

storage that has a minimum capacity of 2 gallons for every acfm of capacity of

the largest trim compressor.

Example

10-64

Question

What

is the required minimum primary storage capacity for the trim compressor from

the previous example to comply with Option 2?

Answer

This

compressor has a rated capacity of 1218 acfm, and per §120.6(e)1B it must have 2

gallons of storage per acfm of rated capacity or 1218 * 2 = 2,236 gallons of

storage.

G.

Controls (§120.6(e)2)

This requirement applies to new and existing facilities that

are being altered with ≥100 hp of installed compressor capacity. The

section requires an automated control system which will optimally stage the

compressors to minimize energy for the given load. With new systems, this

ideally means that at any given load, the only compressors running at part-load

are the trim compressors. Because not all systems are required to upgrade

the trim compressor, the installed controls must stage the compressors in the

most efficient manner.

This requirement also mandates the measurement of air

demand. The control system must be able to measure or calculate the

current system demand (in terms of actual cubic feet per minute of

airflow). There are a variety of ways to accomplish this, including but

not limited to the following sensors:

•

A flow meter

•

Pressure transducers, or

A combination of pressure transducers and power meters

H.

Acceptance (§120.6(e)3)

New systems and altered systems must be tested per NA7.13.

10.8.3

Prescriptive Measures §140.9

There are no prescriptive measures for compressed air

systems.

10.8.4

Additions and Alterations

These requirements apply to existing systems which are being

altered and which have a total compressor capacity of ≥25 hp. These

requirements will be triggered by replacing a compressor, adding a compressor,

or removing a compressor.

10.8.5

Compliance Documentation

NRCC-PRC-10-E for Compressed Air Systems

Requirements

Page 1 of 3

Page 1 of 3 includes system capacity and controls

Details.

Project Description

PROJECT NAME is the title of the project, as shown on the

plans and known to the enforcement agency.

DATE PREPARED is the last revision date of the plans.

If the plans are revised after this date, it may be necessary to re-submit the

compliance documentation to reflect the altered design. Note that it is

the enforcement agency’s discretion whether or not to require new compliance

documentation.

General Information

PHASE OF CONSTRUCTION indicates the status of the building project

described in the compliance documents. Refer to Section 1.7 for detailed discussion of the

various choices.

NEW CONSTRUCTION should be checked for all new buildings, newly

conditioned space or for new construction in existing buildings (tenant

improvements, see Section

1.7.11 and 1.7.12)

that are submitted for envelope compliance.

ADDITION should be checked for an addition which is not treated

as a stand-alone building, but which uses option 2 described in Section

1.7.14. Tenant improvements that increase conditioned floor area

and volume are additions.

ALTERATION should be checked for alterations to an existing

building mechanical systems (see Section

1.7.13). Tenant improvements are usually alterations.

Mandatory Measures Note Block

List the total horsepower of the compressed air system

capacity for the current system (if applicable) and the proposed system in the

provided spaces. The person with overall responsibility must ensure that the

proposed system meet the requirements of 120.6 of the

standards by completing this section.

Documentation Author’s Declaration Statement

The CERTIFICATE of COMPLIANCE – Compressed Air Systems

Requirements is signed by both the Documentation Author and

the Principal Designer who is responsible for preparation of the plans of

building. This latter person is also responsible for this compliance

documentation, even if the actual work is delegated to a different person acting

as Documentation Author. It is necessary that the compliance documentation

be consistent with the plans.

DOCUMENTATION AUTHOR is the person who prepared the

compliance forms and who signs the Declaration Statement. The person’s

telephone number is given to facilitate response to any questions that

arise. A Documentation Author may have additional certifications such as

an Energy Analyst or a Certified Energy Plans Examiner certification

number. Enter number in the EA# or CEPE# box.

Principal Designer’s Declaration Statement

The Declaration Statement is signed by the person responsible

for preparation of the plans for the building. This principal designer is

also responsible for this compliance form, even if the actual work is delegated

to someone else (the Documentation Author as described above). It is

necessary that the compliance documentation be consistent with the plans.

The Business and Professions Code governs who is qualified to prepare plans and

therefore to sign

this statement. See Section

2.2.2 Permit Application for applicable text from the Business and

Professions Code.

Page 2 of 3

Page 2 of 3 includes mandatory requirements for Trim

compressor and storage requirements. As stated on the page, the

required information should be either 'listed on the form or the page from the

plans or specifications section and the paragraph displaying the required

information should be indicated on the form.

Page 3 of 3

Page 3 of 3 includes Acceptance Testing and

declaration statement. Please refer to the Nonresidential Appendices,

NA 7.13 for relevant

tests.