The process of complying with and enforcing the Energy Standards involves many parties. Those involved may include the architect or building designer, building developers, purchasing agent, general contractor, subcontractors/installers, energy consultant, plans examiners, inspectors, realtors, the building owner, and third party inspectors (HERS raters). Communication between these parties is essential for the compliance/enforcement process to run efficiently.

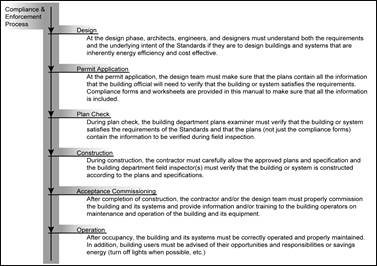

The Energy Standards specify detailed reporting requirements that are intended to provide design, construction, and enforcement parties with needed information to complete the building process and ensure that the energy features are installed. Each party is accountable for ensuring that the building’s energy features are correctly installed as applicable to their area of responsibility. This section outlines and discusses the responsibilities and requirements during each phase of the compliance and enforcement process (see Figure 2-1 for a general overview).

Contingent upon approval of a nonresidential data registry by the Energy Commission, all nonresidential energy compliance documents will need to be registered with a nonresidential data registry prior to submittal to an enforcement agency. The registration of documents prior to submittal to an enforcement agency accomplishes the requirements for the retention of a completed and signed copy of the submitted energy compliance documentation. §10-103 outlines the registration requirements for compliance documents. Document retention is vital to compliance and enforcement follow-up actions and other quality assurance processes that help to ensure realization of energy savings from installed energy features. Although some local enforcement agencies elect to retain copies of submitted energy compliance documents, many jurisdictions do not retain these documents. Thus, Energy Standards requirement for registration of the energy compliance documentation in a nonresidential data registry ensures that document retention is accomplished for all nonresidential construction projects. General information describing registration procedures that are specific to the design, construction and inspection phases follow in this chapter. Refer also to Reference Joint Appendix JA7 and Reference Nonresidential Appendix NA1 for more detailed descriptions of these document registration procedures that apply to each phase of the building energy code compliance and enforcement process.

A. Design Phase and Building Commissioning Certificate(s) of Compliance

During the design phase, the building plans and specifications are developed that define the building or system that will be constructed or installed. The design must incorporate features that are in compliance with applicable codes and Standards. The building or system overall design must be detailed in the construction documents and specifications, and these documents must be submitted to the enforcement agency for approval. Parties associated with the design phase must ensure that the building or system design specifications comply with the Energy Standards, and that the specifications for the energy features given on the construction documents are consistent with the Certificate(s) of Compliance for the building or system.

For buildings larger than 50,000 square ft2, or for buildings with complex mechanical systems, an independent third party (engineer, architect, or contractor ) review of these documents is required to ensure required design features are included. Reviews will be documented by completing Design Review Kickoff Certificate(s) of Compliance and Construction Document Design Review Certificate(s) of Compliance documentation (see Table 2-1). Buildings between 10,000 and 50,000 ft2 will require completion of these Design Certificate(s) of Compliance by an in-house engineer not associated with the project under review. For buildings less than 10,000 ft2, these Design Certificate(s) of Compliance may be completed by the design engineer or architect. The Plans Examiner will be responsible for verifying that the Design Review Kickoff and Construction Document Design Review Certificate(s) of Compliance forms are submitted on the building plans and complete when required. More details regarding these Design Certificate(s) of Compliance forms and the requirements for building commissioning are provided in Chapter 12 of this 'manual.

B. Building Plans and Specifications and Certificate(s) of Compliance

During the design phase, the architect, mechanical engineer and lighting designer must determine whether the building or system design complies with the Energy Standards. An energy consultant or other professional (Documentation Author) may assist the building designer(s) by providing calculations that determine the energy compliance impact of building features being proposed for the design. Additionally, throughout the design phase, recommendations or alternatives may be suggested by energy consultants or energy documentation authors to assist the designer in achieving compliance with the Energy Standards.

The building or system design plans and specifications are required to be complete with regard to specification of the energy efficiency features selected for compliance with the Energy Standards, and those specifications must be detailed on the Certificate(s) of Compliance submitted to the enforcement agency. For newly constructed buildings and additions, Certificate(s) of Compliance documentation shall be submitted that details the energy efficiency features for the building Envelope, Lighting (Indoor, Outdoor, and Sign) and Mechanical systems (see Table 2-1 for a complete list of compliance forms) to demonstrate compliance with the Energy Standards. It is the responsibility of the builder/designer to ensure that the energy efficiency features detailed on the Certificate(s) of Compliance are specified in the respective sections of the building plans. Some examples of specifying the energy efficiency features in the respective sections of the building plans include:

1. Specifying the lighting fixtures and their wattages, lighting controls, etc. from the Lighting Certificate(s) of Compliance for each room in a lighting schedule, lighting fixture legend for the floor plan, etc. on the Electrical Plans;

2. Specifying the window and skylight U-Factor and SHGC values from the Envelope Certificate(s) of Compliance in a window/skylight schedule, window/skylight legend for the floor plan, etc. on the Structural/Architecture Plans;

3. Specifying the wall, floor, and roof/ceiling insulation R-values from the Envelope Certificate(s) of Compliance in a framing plan, the structural details, etc. on the Structural/Architecture Plans; and

4. Specifying the HVAC equipment SEER, EER, AFUE, etc. efficiency values, duct insulation values, etc. from the Mechanical Certificate(s) of Compliance in an Equipment Schedule on the Mechanical Plans.

NOTE: The builder/designer should consult with the enforcement agency regarding methods of specifying energy features on the building plans for approval.

Any change in the design specifications, during any phase of design or construction that changes the energy features specified for the design, necessitates recalculation of the energy code compliance and issuance of revised Certificate(s) of Compliance for approval by the enforcement agency that is consistent with the revised building plans and specifications for the proposed building or system. If recalculation indicates that the building no longer complies, alternate building features must be selected that bring the design back into compliance with the Energy Standards. The building plans and specifications documentation for the design must be revised to be consistent with the energy features shown on the revised Certificate(s) of Compliance, and then the revised building plans and specifications and compliance documentation must be resubmitted to the enforcement agency for approval.

The discussion in this section emphasizes the need to coordinate energy efficiency feature selection considerations concurrently with other building design considerations as part of the overall design development process so that the completed design specifications represented on the final construction documents submitted to the enforcement agency for approval are complete and consistent with the Certificate(s) of Compliance; thus in compliance with the Energy Standards’ requirements. The next section on Integrated Design discusses briefly how concurrent development of other aspects of the design can serve to improve the quality of the final design, and diminish the need for revision of the construction documentation later in the plan review or construction process.

C. Integrated Design

Integrated design is the consideration that brings the design of all related building systems and components together. It brings together the various disciplines involved in designing a building or system and reviews their recommendations as a whole. It recognizes that each discipline's recommendations have an impact on other aspects of the building project. This approach allows for optimization of both building performance and cost. Too often, HVAC systems are designed without regard for lighting systems. Or, lighting systems are designed without consideration of daylighting opportunities. The architect, mechanical engineer, electrical engineer, contractors, and other team members each have their scope of work and often pursue the work without adequate communication and interaction with other team members. This can result in improper system sizing, or systems that are optimized for non-typical conditions.

Even a small degree of integration provides some benefit, allowing professionals working in various disciplines to take advantage of design opportunities that are not apparent when they are working in isolation. This can also point out areas where trade-offs can be implemented to enhance resource efficiency. Design integration is the best way to avoid redundancy or conflicts with aspects of the building project planned by others. The earlier that integration is introduced in the design process, the greater the benefit that can be expected.

For a high performance school project, team collaboration and integration of design choices should begin no later than the programming phase. 'In 'addition, the project team is likely to be more broadly defined than in the past, and may include energy analysts, materials consultants, lighting designers, life-cycle cost consultants and commissioning agents. Design activities may expand to include collaborative modeling exercises, and simulations.

This 'manual provides details and implementation rules for individual design strategies. Though these individual strategies can improve building or system energy efficiency, whole-building analysis and integrated design can balance energy and cost concerns more effectively.

A. Submittal and Signatures

When the design is complete, construction documents are prepared, other approvals (planning department, water, etc.) are secured, and the owner, developer, or architect submits an application for a building permit to the enforcement agency. Permit application is generally the last step in the process of planning and design. At this point, the infrastructure (streets, sewers, water lines, electricity, gas, etc.) is likely to be in place or is under construction, and the process of preparation for the construction or installation of the building or system design can begin.

Certificate(s) of Compliance are required to be submitted along with the construction documents, and these documents must be approved by the enforcement agency. If the prescriptive method is utilized for compliance, the Certificate(s) of Compliance documentation forms for the building envelope, mechanical systems, and the lighting systems must all be submitted. If the performance method is utilized for the entire building, a compiled set of Certificate(s) of Compliance documentation pages is prepared (the PERF-1C form) utilizing one of the compliance software applications approved by the Energy Commission that summarizes the energy features for the building. The compliance software will still produce Certificate(s) of Compliance documentation forms for the building envelope, mechanical systems, and lighting systems 'in 'addition to the PERF-1C form, and all of these forms must be submitted to the enforcement agency for approval. Certificate(s) of Compliance documentation requirements are specified in §10-103(a)1 and §10-103(a)2.

For all buildings, the Certificate(s) of Compliance must be signed by the person(s) eligible under Division 3 of the Business and Professions Code to accept responsibility for the building design to certify conformance with the Energy Standards. If more than one person has responsibility for the building design, each person must sign the Certificate of Compliance document(s) applicable to that portion of the design for which the person is responsible. Alternatively, the person with chief responsibility for the building design may prepare and sign the Certificate of Compliance document(s) for the entire design. The signatures must be original signatures on paper documents or electronic signatures on electronic documents when registration is required (see Reference Joint Appendix JA7 for more details regarding electronic signatures).

B. Design Review Certificate(s) of Compliance

The Design Review Kickoff Certificate(s) of Compliance (NRCC-CXR-01) and Construction Document Design Review Certificate(s) of Compliance (NRCC-CXR-02) must be signed by the approved design reviewer specified in §10-103(a)1 and submitted for approval by the enforcement agency. These forms are required for all projects regardless of the compliance method used (the prescriptive method vs. the performance method). In order to demonstrate compliance, all projects are required to complete Certificate(s) of Compliance forms NRCC-CXR-01 andNRCC-CXR-02. The Certificate(s) of Compliance forms NRCC-CXR-03 and NRCC-CXR-04 are required based on the HVAC system types included in the project, based on the definition of complex mechanical systems. The Building Owner (or owner’s representative), design engineer and design reviewer must all sign and date the Design Review Signature Certificate of Compliance form NRCC-CXR-05 once the design review has been completed. Contractors accepting the responsibilities of the engineer under the provision of the Business and Profession Code may sign the forms in place of the design engineer. All applicable design review compliance forms must be submitted. See Chapter 12 of this 'manual for more details regarding which Design Certificate of Compliance forms are required.

C. Preparation and Incorporation onto the Plans

The length and complexity of the Certificate(s) of Compliance documentation may vary considerably depending upon the size and complexity of the building(s) or system(s) that are being permitted, regardless of whether the performance approach or the prescriptive approach is utilized for compliance. The Certificate(s) of Compliance documents are commonly prepared by an energy consultant or an energy compliance professional (Documentation Author). An energy consultant should be knowledgeable about the details of the requirements of the Energy Standards and can benefit the design team by offering advice for the selection of the compliance methodology (prescriptive or performance), and the selection of the energy features utilized for compliance with the Energy Standards. An energy consultant may also provide recommendations for the most cost effective mix of building energy features for the design.

The Administrative Regulations §10-103(a)2 require that the Certificate(s) of Compliance and any applicable supporting documentation be submitted with permit applications and that the Certificate(s) of Compliance be incorporated into the building plans. Many enforcement agencies require that all of the energy compliance forms be incorporated electronically onto the building plans. This enables the plans examiner to verify that the building or system design specifications shown on construction documentation are consistent with the energy features specified on the Certificate(s) of Compliance. The Certificate(s) of Compliance forms submitted to the enforcement agency to demonstrate compliance shall conform to a format and informational order and content approved by the Energy Commission (see §10-103(a)1A for more details). Samples of the Energy Commission-approved forms are located in Appendix A of this 'manual. A listing of Certificate of Compliance forms is available in Table 2-1 on the next page.

D. Registration

Contingent upon availability and approval of a data registry by the Executive Director, registration will be required for all Certificate(s) of Compliance submitted to the enforcement agency. The registration process requires the builder or designer to submit the Certificate(s) of Compliance information and an electronic signature to an approved nonresidential data registry in order to produce a completed, dated, and signed electronic Certificate(s) of Compliance that is retained by the registry. The Certificate of Compliance is assigned a unique registration number, then copies of the unique registered Certificate of Compliance forms are made available to authorized users of the nonresidential data registry for use in making electronic or paper copies of the registered document(s) for submittal to the enforcement agency as required.

Examples of authorized users of the nonresidential data registry may include energy consultants, builders, building owners, construction contractors and installers, enforcement agencies, the Energy Commission, and other parties to the compliance and enforcement process that the documents are designed to support. Authorized users of the nonresidential data registry will be granted read/write access rights to only the electronic data that pertains to their project(s).

|

Design Review |

Envelope |

Mechanical |

Lighting |

Outdoor Lighting |

Sign Lighting |

|

NRCC-CXR-01-E Design Review Kickoff

NRCC-CXR-02-E Construction Documents– All Buildings

NRCC-CXR-03-E Construction Document Review – HVAC Simple

NRCC-CXR-04-E Construction Document Review – HVAC Complex

NRCC-CXR-05-E Design Review Signature Page |

NRCC-ENV-01-E

NRCC-ENV-02-E

NRCC-ENV-03-E

NRCC-ENV-04-E

NRCC-ENV-05-E Fenestration Certification Label

NRCC-ENV-06-E Area Weighted Average Calculation Worksheet |

NRCC-MCH-01-E

NRCC-MCH-02-E

NRCC-MCH-03-E

NRCC-MCH-04-E

NRCC-MCH-05-E Single Zone Systems Requirements

NRCC-MCH-06-E Maximum Cycles of Concentration Worksheet

NRCC-MCH-07-E Power Consumption of Fans Requirements |

NRCC-LTI-01-E

NRCC-LTI-02-E

NRCC-LTI-03-E

NRCC-LTI-04-E

NRCC-LTI-05-E |

NRCC-LTO-01-E

NRCC-LTO-02-E

NRCC-LTO-03-E Outdoor Lighting Power Allowance |

NRCC-LTS-01-E

|

|

Solar |

Covered Processes |

Electrical |

Plumbing |

| |

|

NRCC-SRA-01-E Solar Ready Areas

NRCC-SRA-2-E Minimum Solar Zone Area Worksheet |

NRCC-PRC-01-E

NRCC-PRC-02-E Garage Exhaust

NRCC-PRC-03-E Commercial Kitchens

NRCC-PRC-04-E Data Centers

NRCC-PRC-05-E Prescriptive/ Performance Commercial Refrigeration

NRCC-PRC-06-E Refrigerated Warehouses |

NRCC-PRC-07-E Refrigerated Warehouses 3,000 ft2 or greater

NRCC-PRC-08-E Refrigerated Warehouses 3,000 ft2 or greater (served by same refrigeration system)

NRCC-PRC-09-E Laboratory Exhaust

NRCC-PRC-10-E Compressed Air Systems

NRCC-PRC-11-E Process Boilers |

NRCC-ELC-01-E Disaggregation of Electrical Circuits |

NRCC-PLB-01-E Water Heating Systems |

|

|

| |||||

|

Refer to Appendix A of this manual for a complete list and samples of Certificate of Compliance forms. | |||||

A. Plans and Specifications

Local enforcement agencies are required to check submitted building plans and specifications to determine whether the design conforms to the applicable codes and standards, thus the plan check must include checking the energy efficiency specifications for the design to confirm compliance with the Energy Standards. Vague, missing, or incorrect information on the construction documents may be identified by the plans examiner as requiring correctio. The permit applicant must then revise the construction documents to make the corrections or clarifications, and resubmit the revised building plans and specifications for verification by the plans examiner. When the permit applicant submits comprehensive, accurate, clearly defined building plans and specifications, it helps to speed the plan review process.

During plan review, the enforcement agency must verify that the building's design details specified on the construction documents conform to the applicable energy code features information specified on the submitted Certificate(s) of Compliance documents. It is important that the building design features represented on the approved building plans and specifications for the proposed building conform to the energy features specified on the approved Certificate(s) of Compliance. This is necessary since materials purchasing personnel and building construction craftsmen in the field may rely solely on a copy of the building plans and specifications approved by the enforcement agency for direction in performing their responsibilities.

It is worthwhile to mention here that later in the construction/installation process, the person responsible for construction will be required to sign a Certificate(s) of Installation confirming that the installed features, materials, components or manufactured devices conform to the requirements specified in the building plans and specifications and the Certificate(s) of Compliance approved by the enforcement agency. If at that time it is determined that the actual construction/installation is not consistent with the approved building plans and specifications or Certificate(s) of Compliance, the applicable documentation is required to be revised to reflect the actual construction/installation specifications, and the revised documentation must indicate compliance with the energy code requirements. If necessary, corrective action must be taken in order to bring the construction/installation into compliance. Thus to emphasize, it is of utmost importance that the building design features represented on the approved building plans and specifications for the proposed building comply with the Energy Standards’ requirements specified on the approved Certificate(s) of Compliance, and that the actual construction/installation is consistent with those approved documents.

B. Energy Plan Review

The enforcement agency is responsible for verifying that all required compliance documents have been submitted for plan review and that they do not contain errors. When the compliance documents are produced by an Energy Commission-approved computer software application, it is unlikely that there will be computational errors on the Certificate(s) of Compliance documents, but it is essential that the plans examiner verifies that the building design represented on the proposed building plans and specifications is the same building design represented in the Certificate(s) of Compliance documents. Some examples of how the plans examiner will verify that the energy efficiency features detailed on the Certificate(s) of Compliance are specified in the respective sections of the building plans include:

1. Verifying the lighting fixtures and their wattages, lighting controls, etc. from the Lighting Certificate(s) of Compliance on the Electrical Plans in a lighting schedule, lighting fixture legend for the floor plan, etc.;

2. Verifying the window and skylight U-Factor and SHGC values from the Envelope Certificate(s) of Compliance on the Structural/Architecture Plans in a window/skylight schedule, window/skylight legend for the floor plan, etc.;

3. Verifying the wall, floor, and roof/ceiling insulation R-values from the Envelope Certificate(s) of Compliance on the Structural/Architecture Plans in a framing plan, the structural details, etc.; and

4. Verifying the HVAC equipment SEER, EER, AFUE, etc. efficiency values from the Mechanical Certificate(s) of Compliance on the Mechanical Plans in an Equipment Schedule.

NOTE: The enforcement agency should clearly articulate to the builder/designer the acceptable methods of specifying energy features on the building plans for approval.

To obtain a list of Energy Commission-approved energy code compliance software applications, visit the Commission Website at:

www.energy.ca.gov; or call the Energy Standards Hotline at 1-800-772-3300.

After the plans examiner has reviewed and approved the building plans and specifications and energy compliance documentation for the project, a building permit may be issued by the enforcement agency at the request of the builder. Issuance of the building permit is the first significant milestone in the compliance and enforcement process. The building permit is the green light for the contractor to begin work. In many cases, building permits are issued in phases. Sometimes there is a permit for site work and grading that precedes the permit for actual building construction. In large Type I or II buildings, the permit may be issued in several phases: site preparation, structural steel, etc.

A. Change Orders

Upon receiving a building permit from the local enforcement agency, the general contractor can begin construction. The permit requires the contractor to construct the building or system in compliance with the approved building plans and specifications, but often there are variations. Some of these variations are formalized by the contractor through change orders. When change orders are issued, it is the responsibility of the design team and the local enforcement agency to verify that compliance with the energy code is not compromised by the change order. In some cases, it is obvious that a change order could compromise energy code compliance; for instance, when an inexpensive single glazed window is substituted for a more expensive high performance dual glazed window. However, it may be difficult to determine whether a change order would compromise compliance; for instance when the location of a window is changed or when the orientation of the building with respect to the direction north is changed. Field changes that result in non-compliance require enforcement agency approval of revised building plans and energy compliance documentation to confirm that the building is still in compliance.

B. Completion and Submittal

During the construction process, the general contractor or specialty subcontractors are required to complete various construction certificates. These certificates verify that the contractor is aware of the requirements of the Energy Standards, and that the actual construction/installation meets the requirements.

Certificate(s) of Installation are required to be completed and submitted to certify compliance of regulated energy features such as windows and skylights, water heater, plumbing, HVAC ducts and equipment, lighting fixtures and controls, and building envelope insulation. The licensed person responsible for the building construction or for the installation of a regulated energy feature must ensure their construction or installation work is done in accordance with the approved building plans and specifications for the building. The responsible person must complete and sign a Certificate of Installation to certify that the installed features, materials, components or manufactured devices for which they are responsible conform to the building plans, specifications and the Certificate(s) of Compliance documents approved by the enforcement agency for the building. A copy of the completed, signed and dated Certificate of Installation must be posted at the building site for review by the enforcement agency, in conjunction with requests for final inspection for the building.

If construction on any regulated feature or portion of the building will be impossible to inspect because of subsequent construction, the enforcement agency may require the Certificate(s) of Installation to be posted upon completion of that feature/portion of the building. The Certificate of Installation forms submitted to the enforcement agency shall conform to a format and informational order and content approved by the Energy Commission (see §10-103(a)3A for more details). Samples of the Energy Commission-approved forms are located in Appendix A of this 'manual. A listing of Certificate of Installation forms is available in Table 2-2. A copy of the Certificate(s) of Installation must be included with the documentation the builder provides to the building owner at occupancy as specified in §10-103(b).

If for any reason the approved plans and specifications and Certificate(s) of Compliance for the building are inconsistent with regard to their requirements for the building, or if the actual construction/installation performed does not conform to the approved plans and specifications and Certificate(s) of Compliance, corrective action must be performed to bring all approved documentation and the actual installation into compliance prior to completion and submittal of the Certificate(s) of Installation.

C. Registration

For building permit applications submitted on or after January 1, 2015, all of the Certificate of Installation forms must be registered documents from an approved nonresidential data registry. When registration is required, the builder or installing contractor must submit information to an approved nonresidential data registry in order to produce a completed, dated, and signed electronic Certificate of Installation that is retained by the registry for use by authorized users of the registry. The Certificate of Installation is assigned a unique registration number, then copies of the unique registered Certificate of Installation forms are made available to authorized users of the nonresidential data registry for use in making electronic or paper copies of the registered document(s) for submittal to the enforcement agency as required, including posting copies in the field for enforcement agency inspections, and providing copies to the building owner (see Section 2.3.2 of this chapter).

Examples of authorized users of the nonresidential data registry may include energy consultants, builders, building owners, construction contractors and installers, enforcement agencies, the Energy Commission, and other parties to the compliance and enforcement process that the documents are designed to support. Authorized users of the nonresidential data registry will be granted read/write access rights to only the electronic data that pertains to their project(s).

|

Component |

Certificate of Installation Form Identifier |

|

Envelope |

NRCI-ENV-01-E |

|

Mechanical |

NRCI-MCH-01-E |

|

Lighting |

NRCI-LTI-01-E |

|

NRCI-LTI-02-E | |

|

Line Voltage Track Lighting |

NRCI-LTI-03-E |

|

Two Interlocked Lighting Systems |

NRCI-LTI-04-E |

|

Power Adjustment Factors |

NRCI-LTI-05-H

|

|

Additional Videoconference Studio Lighting |

NRCI-LTI-06 |

|

Outdoor Lighting |

NRCI-LTO-01-E |

|

EMCS - Lighting Controls Systems |

NRCI-LTO-02-E |

|

Sign Lighting |

NRCI-LTS-01-E |

|

Refrigerated Warehouse |

NRCI-PRC-01-E |

|

Water Heating |

NRCI-PLB-01-E |

|

Solar Photovoltaic |

NRCI-SPV-01-E |

|

Solar Water Heating |

NRCI-STH-01-E |

|

Refer to Appendix A of this 'manual for a complete list and samples of Certificate of Installation forms. | |

Building Commissioning is required for all new nonresidential buildings equal to or greater than 10,000 ft2. The Certificate(s) of Compliance for Building Commissioning form (see Chapter 12) must be signed by the owner/owner’s representative; architect, engineer or designer of record, and the commissioning coordinator and submitted for approval by the enforcement agency. For buildings that are less than 10,000 ft2, only the design review sections must be completed, as outlined in section 2.2.2. More details regarding the Building Commissioning Certificate(s) of Compliance forms and the requirements for building commissioning are provided in Chapter 12 of this 'manual.

A. Acceptance Tests

Acceptance testing or acceptance criteria verification is required for certain lighting, HVAC controls, air distribution ducts, and envelope features, and for equipment that requires proper calibration at the time of initial commissioning in order to ensure that operating conditions that could lead to premature system failure are prevented, and optimal operational efficiency is realized. The features that require acceptance testing are 'listed in Table 2-3 on the next page.

B. Acceptance Test Technician Certification Providers (ATTCP) and Certified Technicians

Technicians who conduct acceptance testing for lighting and mechanical systems, when required by the Standards, will need to be trained and certified by an Energy Commission-approved Acceptance Test Technician Certification Provider (ATTCP). Builder and installers will need to ensure that the technician conducting the required acceptance testing, and completing and signing the required Certificate(s) of Acceptance, for lighting and mechanical systems are certified by an approved ATTCP. Enforcement agency field inspectors will need to verify that the submitted Certificate(s) of Acceptance for lighting and mechanical systems are signed by a technician who is certified with an approved ATTCP at final inspection. www.energy.ca.gov More details regarding the requirements and certification process for ATTCPs are provided in Chapter 13 of this manual.

C. Registration

For building permit applications submitted on or after January 1, 2015, all of the Certificate of Acceptance forms must be registered documents from an approved nonresidential data registry. When registration is required, the builder, installing contractor, or certified technician must submit information to an approved nonresidential data registry in order to produce a completed, dated, and signed electronic Certificate of Acceptance that is retained by the registry for use by authorized users of the registry. The Certificate of Acceptance is assigned a unique registration number, then copies of the unique registered Certificate of Acceptance forms are made available to authorized users of the nonresidential data registry for use in making electronic or paper copies of the registered document(s) for submittal to the enforcement agency as required, including posting copies in the field for enforcement agency inspections, and providing copies to the building owner (see Section 2.3.2 of this chapter).

Examples of authorized users of the nonresidential data registry may include energy consultants, builders, building owners, construction contractors and installers, certified technicians, enforcement agencies, the Energy Commission, and other parties to the compliance and enforcement process that the documents are designed to support. Authorized users of the nonresidential data registry will be granted read/write access rights to only the electronic data that pertains to their project(s).

|

Category |

Measure |

|

Envelope | |

|

Fenestration Acceptance |

Site-Built Fenestration – Label Certificate Verification |

|

Mechanical | |

|

Outdoor Air |

Variable Air Volume Systems Outdoor Air Acceptance Constant Volume System Outdoor Air Acceptance |

|

HVAC Systems |

Constant- Volume Single Zone, Unitary A/C and Heat Pumps |

|

Air Distribution Systems |

Air Distribution Acceptance |

|

Air Economizer Controls |

Economizer Acceptance |

|

Demand Control Ventilation (DCV) Systems |

Packaged Systems DCV Acceptance |

|

Variable Frequency Drive Systems |

Supply Fan Variable Flow Controls |

|

Hydronic System Controls Acceptance |

Valve Leakage Test Hydronic Variable Flow Controls Supply Water Temperature Reset Controls |

|

Mechanical Systems |

Automatic Demand Shed Control Acceptance Fault Detection & Diagnostics for DX Units Automatic Fault Detection & Diagnostics for Air Handling & Zone Terminal Units Distributed Energy Storage DX AC Systems Test Thermal Energy Storage (TES) Systems Supply Air Temperature Reset Controls Condenser Water Supply Temperature Reset Controls Energy Management Control System |

|

Indoor Lighting | |

|

Indoor Lighting Control Systems |

Automatic Daylighting Controls Acceptance • Occupancy Sensor Acceptance • Manual Daylighting Controls Acceptance • Automatic Time Switch Control Acceptance Demand Responsive Controls |

|

Outdoor Lighting | |

|

Outdoor Lighting Control |

Outdoor Motion Sensor Acceptance Outdoor Lighting Shut-off Controls • Outdoor Photocontrol • Astronomical Time Switch • Standard (non-astronomical) Time Switch |

|

Covered Processes | |

|

Refrigerated Warehouses |

Electric Resistance Underslab Heating Systems Evaporators and Evaporator Fan Motor Variable Speed Controls Condensers and Condenser Fan Motor Variable Speed Controls Air-Cooled Condensers and Condenser Fan Motor Variable Speed Controls Variable Speed Screw Compressors Compressed Air System Acceptance |

|

Commercial Refrigeration |

Air-Cooled Condensers and Fluid Coolers Evaporative Condensers, Fluid Coolers and Cooling Towers Compressor Floating Suction Controls Liquid Subcooling Display Case Lighting Controls Refrigeration Heat Recovery |

|

Commercial Kitchens |

Commercial Kitchen Exhaust System Acceptance |

|

Enclosed Parking Garages |

Ventilation System Acceptance Testing |

D. Verification and Documentation

Acceptance testing must be conducted and a Certificate(s) of Acceptance must be completed and submitted before the enforcement agency can issue the Certificate of Occupancy. The procedures for performing the acceptance tests are documented in Reference Nonresidential Appendix NA7. Compliance with the acceptance requirements for a construction/installation project is accomplished by three main categories of verification and documentation that will be discussed in the subsequent segments of this section:

E. Plan Review

The installing contractor, engineer/architect of record, or owner’s agent is responsible for reviewing the plans and specifications and ensuring they conform to the requirements of the Certificate(s) of Compliance and the acceptance requirements applicable to the construction/installation. Plan Review should be done prior to signing a Certificate(s) of Compliance for submittal to plan review, and also prior to completing and signing the Certificate(s) of Installation. The required acceptance tests shall be identified for the applicable building component or system on the respective Certificate(s) of Compliance. Some examples of identifying the required acceptance tests on the Certificate(s) of Compliance include:

1. The fenestration acceptance test shall be identified as required for site-built fenestration on the NRCC-ENV-01 form;

2. The air economizer controls acceptance test shall be identified as required for HVAC systems with economizers on the NRCC-MCH-01 form;

3. The lighting controls acceptance test shall be identified as required for occupancy sensors, automatic time switches, etc. on the NRCC-LTI-01 form;

4. The outdoor lighting controls acceptance test shall be identified as required for motion sensors, photocontrols, astronomical time switches, etc. on the NRCC-LTO-01 form; and

To the extent that making changes on paper documents may be less costly as compared to the cost of altering or replacing a completed but non-compliant building energy feature construction/installation, attention should be given to plan review early in the process, and also at critical decision points such as during subcontractor bid proposal review and materials procurement activities. If design or material specification for the construction/installation is changed subsequent to plan check approval by the enforcement agency, revised building plans and specifications and Certificates of Compliance must be submitted for approval to the enforcement agency.

F. Construction Inspection and Certificate(s) of Installation

The installing contractor, engineer/architect of record or the owner’s agent is responsible for performing construction inspection and completing the required Certificate(s) of Installation to confirm compliance of the regulated energy features. The certified technician (see Chapter 12) responsible for performing the acceptance tests is required to confirm that the Certificate(s) of Installation ha been properly completed and signed as a prerequisite to issuance of a Certificate(s) of Acceptance. A properly completed Certificate(s) of Installation is required to be submitted or posted at the building site prior to proceeding with functional testing and completion of the Certificate of Acceptance.

All regulated energy features, materials, components, or manufactured devices that were incorporated into the completed construction/installation must be inspected to confirm that they conform to the requirements detailed on the building plans and specifications, and the Certificate(s) of Compliance approved by the local enforcement agency. The Certificate(s) of Installation must be verified to be properly completed, signed by the person responsible for the construction/installation, and a copy submitted/posted on the job site with the building permits or made available for applicable inspections. Corrective action must be taken if the installation/construction is not in compliance with the building plans and specifications and Certificate(s) of Compliance approved by the enforcement agency, or if a Certificate of Installation has not been properly completed and posted. Corrective action must be performed prior to proceeding with the acceptance tests and prior to proceeding with completion and submittal or posting of the Certificate(s) of Acceptance.

G. Functional Testing and Completion of the Certificate(s) of Acceptance

The installing contractor, engineer/architect of record or owner’s agent is responsible for ensuring that all applicable acceptance requirement procedures identified in the building plans and specifications and on the Certificate(s) of Compliance and in Reference Nonresidential Appendix NA7 are conducted be a certified technician (see Chapter 12 of this 'manual). All performance deficiencies must be corrected by the builder or installing contractor and the certified technician must repeat the acceptance requirement verification procedures until all specified systems and equipment conform to the required performance criteria, and the construction/installation is confirmed to be in compliance with the Energy Standards.

The certified technician who conducts the applicable acceptance testing is responsible for documenting their results on the required Certificate(s) of Acceptance form. After completion of the acceptance testing and forms, the certified technician shall provide completed, dated, and signed copies of the Certificate(s) of Acceptance to the builder or installing contractor. When registration is applicable, the Certificate(s) of Acceptance must be registered with an approved nonresidential data registry. The builder or installing contractor may facilitate the registration process by entering the certified technicians’ data results on the Certificate(s) of Acceptance into the nonresidential data registry, but the certified technician responsible for the acceptance test must provide their electronic signature in the registry in order for the form to be complete and registered.

A copy of the Certificate(s) of Acceptance must be posted or made available with the building permit(s) issued for the construction/installation, and must be made available to the enforcement agency for all applicable inspections. If construction on any regulated feature or portion of the building will be impossible to inspect because of subsequent construction, the enforcement agency may require the Certificate(s) of Acceptance to be posted upon completion of that portion of the building. A copy of the Certificate(s) of Acceptance must be included with the documentation the builder provides to the building owner at occupancy as specified in §10-103(b).

H. Certificate(s) of Acceptance Forms

Acceptance tests are required to be documented using the applicable acceptance forms. Table 2-4 on the next page lists the Envelope, Indoor Lighting, Outdoor Lighting, Mechanical, and Covered Processes Certificate of Acceptance Forms and provides references to the applicable sections of the Energy Standards and in Reference Nonresidential Appendix NA7. The Certificate(s) of Acceptance forms submitted to the enforcement agency to demonstrate compliance shall conform to a format and informational order and content approved by the Energy Commission (see §10-103(a)1A for more details). Samples of the Energy Commission-approved forms are located in Appendix A of this manual.

|

Component |

Form Name |

Standards Reference |

|

|

Envelope |

NRCA-ENV-02-F – Fenestration Acceptance |

||

|

Mechanical

|

NRCA-MCH-02-A – Outdoor Air |

||

|

NRCA-MCH-03-A – Constant Volume Single Zone HVAC |

|||

|

NRCA-MCH-04-A – Air Distribution Duct Leakage Testing |

|||

|

NRCA-MCH-05-A – Air Economizer Controls |

|||

|

NRCA-MCH-06-A – Demand Control Ventilation (DVC) |

|||

|

NRCA-MCH-07-A – Supply Fan Variable Flow |

|||

|

NRCA-MCH-08-A – Valve Leakage Test |

|||

|

NRCA-MCH-09-A – Supply Water Temperature Reset Controls |

§120.5(a)9 & §144(k)4 |

||

|

NRCA-MCH-10-A – Hydronic System Variable Flow Controls |

§120.5(a)7 & §144(k)1 |

||

|

NRCA-MCH-11-A – Automatic Demand Shed Controls |

|||

|

NRCA-MCH-12-A – Fault Detection and Diagnostics for DX Units |

|||

|

NRCA-MCH-13-A – Automatic Fault Detection and Diagnostics for Air Handling and Zone Terminal Units |

|||

|

NRCA-MCH-14-A – Distributed Energy Storage DX AC Systems Test |

|||

|

NRCA-MCH-15-A – Thermal Energy Storage (TES) Systems |

|||

|

NRCA-MCH-16-A – Supply Air Temperature Reset Controls |

|||

|

NRCA-MCH-17-A – Condenser Water Temperature Reset Controls |

|||

|

NRCA-MCH-18-A – Energy Management Control System |

----- | ||

|

Indoor Lighting |

NRCA-LTI-02-A – Lighting Controls |

||

|

NRCA-LTI-03-A – Automatic Daylighting Controls |

|||

|

NRCA-LTI-04-A – Demand Responsive Controls |

|||

|

Outdoor Lighting |

NRCA-LTO-02-A – Outdoor Motion Sensor and Lighting Shut-off Controls Acceptance |

||

|

Covered Processes |

NRCA-PRC-01-FA– Compressed Air Systems |

||

|

NRCA-PRC-02-FA-Parking Garage Exhaust |

|||

|

NRCA-PRC-03-F – Commercial Kitchen Exhaust System Acceptance |

|||

|

NRCA-PRC-04-FA– Refrigerated Warehouse Evaporator Fan Motor Controls |

|||

|

NRCA-PRC-05-FA – Refrigerated Warehouse Evaporative Condenser Controls |

|||

|

NRCA-PRC-06-FA– Refrigerated Warehouse Air- Cooled Condenser Controls |

|||

|

NRCA-PRC-07-FA – Refrigerated Warehouse Variable Speed Compressor |

|||

|

NRCA-PRC-08-FA– Refrigerated Warehouse Electric Resistance Underslab Heating System |

|||

|

Refer to Appendix A of this 'manual for a complete list and samples of Certificate of Acceptance forms. | |||

When single-zone, constant volume space-conditioning systems serving less than 5,000 ft² of floor area have more than 25% of the system surface duct area located in unconditioned space, duct sealing is prescriptively required by §140.4(l) for newly constructed buildings and by §141.0(b)2C, D, and E for HVAC alterations. A third-party inspection and diagnostic test of the duct system must be conducted by a certified HERS rater to verify that the system’s air distribution duct leakage is within specifications required by the Energy Standards.

http://www.eacsinc.com/ The Energy Commission approves Home Energy Rating System (HERS) providers, subject to the Energy Commission’s HERS Regulations (Title 20, Chapter 4, Article 8, Sections 1670 through 1675). Approved HERS providers are authorized to train and certify HERS raters and are required to maintain quality control over HERS rater field verification and diagnostic testing activities. In California, the certified HERS providers are:

1. ConSol Home Energy Efficiency Rating Services (CHEERS);

2. California Certified Energy Rating & Testing Services (CalCERTS); and,

3. U.S. Energy Raters Association (USERA) who was formerly CBPCA.

4. Energy Analysis & Comfort Solutions, Inc., (EACS)

The HERS provider must maintain a HERS provider data registry and database that incorporates an internet website‐based user interface that has sufficient functionality to accommodate the needs of the authorized users of the data registry who must participate in the administration of HERS compliance, document registration, and Energy Standards enforcement activities.

The HERS provider data registry must receive and record information input sufficient to identify and track measures that require HERS verification in a specific building/system, and must have the capability to determine compliance based on the information from the results of applicable testing or verification procedures reported as input to the registry for the building/system. When the requirements for compliance are met, the HERS provider’s data registry must make available to enforcement agencies, builders, building owners, HERS raters, and other interested parties a unique "registered" Certificate of Field Verification to show compliance with the document submittal requirements of §10-103. The HERS provider data registry must have the capability to facilitate electronic submittal of the registered Certificate(s) of Verification to an Energy Commission document repository for retention of the certificates for use in enforcement of the regulations.

The HERS provider must make available via phone or internet communications interface a way for building officials, builders, HERS raters, and other authorized users of the HERS provider data registry to verify the information displayed on copies of the submitted Certificate of Verification documentation. Refer to Reference Nonresidential Appendix NA1and Reference Joint Appendix JA7 for additional information describing the HERS provider’s role and responsibilities.

An approved HERS provider may also be approved as a Registration Provider and facilitate the documentation registration process for nonresidential buildings and projects. Contingent upon approval of a nonresidential data registry by the Energy Commission, all nonresidential compliance forms will need to be registered. This requirement will apply to all Certificate(s) of Compliance (NRCC), Certificate(s) of Installation (NRCI), and Certificate(s) of Acceptance NRCA). The Registration Provider responsible for registering nonresidential compliance forms does not have to be an approved HERS provider and can be managed by any entity or organization meeting the nonresidential data registry requirements. However, an approved HERS provider may also manage a nonresidential data registry as an approved Registration Provider and register both residential and nonresidential compliance documentation.

The HERS rater is certified by an Energy Commission‐approved HERS provider to perform the field verification and diagnostic testing that may be required to demonstrate and document compliance with the Energy Standards. HERS raters receive special training in diagnostic techniques and building science as part of the HERS rater certification process administered by the HERS provider. Thus, HERS raters are to be considered special inspectors by enforcement agencies and shall demonstrate competence, to the satisfaction of the enforcement agency, to conduct the required visual inspections and diagnostic testing of the regulated energy efficiency features installed in the dwelling. HERS raters should be aware that some enforcement agencies charge a fee for special inspectors to operate within their jurisdictions, and because HERS raters are deemed to be special inspectors for the enforcement agency, a HERS rater may be prohibited from performing HERS verifications within a jurisdiction if the enforcement agency determines that a HERS rater willingly or negligently does not comply with the Energy Standards or the HERS Regulations’ requirements.

If the documentation author who produced the Certificate of Compliance documentation for the building is not an employee of the builder or subcontractor, the documentation author for the building may also act to perform the responsibilities of a HERS rater, provided the documentation author has met the requirements and has been certified as a HERS rater by one of the Energy Commission‐approved HERS providers.

The HERS rater is responsible for conducting the field verification and diagnostic testing of the air distribution ducts and for transmitting all required data describing the results to a HERS provider data registry. The HERS rater must confirm that the air distribution ducts conform to the design detailed on the building plans and specifications and the mechanical Certificate(s) of Compliance (NRCC-MCH-01-E) approved by the enforcement agency for the building. The HERS Rater is also responsible for verifying that the information on the Certificate(s) of Installation and Certificate(s) of Acceptance is consistent with the Certificate(s) of Compliance. The test results reported on the Certificate of Acceptance (NRCA-MCH-04-A) by the certified technician (see Chapter 12 of this manual) for the air distribution ducts must be consistent with the test results determined by the HERS rater's diagnostic verification and meet the criteria for compliance with the Standards. HERS testing shall be conducted in accordance with the HERS procedures in Nonresidential Reference Appendix NA2.

Results from the HERS rater's field verification and diagnostic testing must be reported to the HERS provider Data registry, including failures. If the results indicate compliance, the HERS provider data registry will make available a registered copy of the Certificate of Verification. A registered copy of the Certificate of Verification must be posted at the building site for review by the enforcement agency, and made available for all applicable inspections. A copy of the Certificate of Verification must be included with the documentation the builder provides to the building owner at occupancy as specified in §10-103(b).

A listing of Certificate of Verification forms is shown in Table 2-5. The Certificate of Verification forms submitted to the enforcement agency to demonstrate compliance shall conform to a format and informational order and content approved by the Energy Commission (see §10-103(a)1A for more details). Samples of the Energy Commission-approved forms are located in Appendix A of this manual

|

Component |

Form Name |

Standards Reference |

Reference Nonresidential Appendix |

|

Mechanical |

NRCV-MCH-04-H Air Distribution System Leakage Diagnostic |

§10-103(a)5; §140.4(l); §141.0(b)2C, D, and E |

At the builder’s option, HERS field verification and diagnostic testing shall be completed either for each constant volume, single zone, space conditioning unit in the building or for a sample from a designated group of units. Field verification and diagnostic testing for compliance credit for duct sealing shall use the diagnostic duct leakage from the fan pressurization of ducts procedure in Reference Nonresidential Appendix NA2. If the builder chooses the sampling option, the applicable procedures described in NA1.6.1, NA1.6.2 and NA1.6.3 shall be followed.

The builder or subcontractor shall provide to the HERS rater a copy of the Certificate(s) of Compliance approved/signed by the principal designer/owner and a copy of the Certificate(s) of Installation as required in NA1.4. Prior to completing field verification and diagnostic testing, the HERS rater shall confirm that the Certificate(s) of Installation and Certificate(s) of Acceptance has been completed as required, and that the information on those forms shows compliance consistent with the Certificate(s) of Compliance.

If field verification and diagnostic testing determines that the requirements for compliance are met, the HERS rater shall transmit the test results to the HERS provider data registry, whereupon the provider shall make available a copy of the registered Certificate of Verification to the HERS rater, the builder, the enforcement agency, and other authorized users of the HERS provider data registry. Printed copies, electronic or scanned copies, and photocopies of the completed, signed registered Certificate of Verification shall be allowed for document submittals, subject to verification that the information contained on the copy conforms to the registered document information currently on file in the provider data registry for the space conditioning unit.

The HERS rater shall provide copies of the registered Certificate of Verification to the builder, and post a completed signed registered copy of the Certificate of Verification at the building site for review by the enforcement agency in conjunction with requests for final inspection.

The HERS provider shall make available via phone or internet communications interface a way for enforcement agencies, builders, and HERS raters to verify that the information displayed on copies of the submitted Certificate of Verification conforms to the registered document information currently on file in the provider data registry.

The HERS rater shall diagnostically test and field verify the first constant, single zone, space conditioning unit of each building. This initial testing allows the builder to identify and correct any potential duct installation and sealing flaws or practices before other units are installed. If field verification and diagnostic testing determines that the requirements for compliance are met, the HERS rater shall transmit the test results to the HERS provider registry, whereupon the provider shall make available a copy of the registered Certificate of Verification to the HERS rater, the builder, and the enforcement agency.

“Re-sampling” refers to the procedure that requires testing of additional units within a sample group when the selected sample unit within a group fails to comply with the HERS verification requirements. When a failure is encountered during sample testing, the failure shall be entered into the provider’s data registry. Corrective action shall be taken and the unit shall be retested to verify that corrective action was successful. Corrective action and retesting on the unit shall be repeated until the testing indicates compliance and the results have been entered into the HERS provider data registry. Whereupon, a registered Certificate of Verification for the unit shall be made available to the HERS rater, the builder, the enforcement agency, and other authorized users of the HERS provider data registry.

'In addition, the HERS rater shall conduct re-sampling to assess whether the first failure in the group is unique or if the rest of the units in the group are likely to have similar failings. The HERS rater shall randomly select for re-sampling one of the remaining untested units in the group for testing of the feature that failed. If testing in the re-sample confirms that the requirements for compliance credit are met, then the unit with the failure shall not be considered an indication of failure in the other units in the group. The HERS rater shall transmit the re-sample test results to the HERS provider data registry, whereupon the provider shall make available to the HERS rater, the builder, the enforcement agency, and other authorized users of the HERS provider data registry, a copy of the registered Certificate of Verification for each of the remaining units in the group including the dwelling unit that was re-sampled.

If field verification and diagnostic testing in the re-sample results in a second failure, the HERS rater shall enter the second failure into the HERS provider data registry, and report the second failure to the builder and the enforcement agency. All dwelling units in the group must thereafter be individually field verified and diagnostically tested. The builder shall take corrective action in all space conditioning units in the group that have not been tested. In cases where corrective action would require destruction of building components, the builder may choose to reanalyze compliance and choose different measures that will achieve compliance. In this case a new Certificate(s) of Compliance shall be registered to the HERS provider data registry and a copy shall be submitted the enforcement agency and provided to the HERS rater. The HERS rater shall conduct field verification and diagnostic testing for each of these space conditioning units to verify that problems have been corrected and that the requirements for compliance have been met. Upon verification of compliance, the HERS rater shall enter the test results into the HERS provider data registry. Whereupon, the provider shall make available to the HERS rater, the builder, the enforcement agency, and other authorized users of the HERS provider data registry a copy of the registered Certificate of Verification for each individual unit in the group.

The HERS provider shall file a report with the enforcement agency explaining all action taken (including field verification, diagnostic testing, and corrective action,) to bring into compliance units for which full testing has been required. If corrective action requires work not specifically exempted by the California Mechanical Code (CMC) or the California Building Code (CBC), the builder shall obtain a permit from the enforcement agency prior to commencement of any of the work.

The Energy Commission may approve Third Party Quality Control Programs (TPQCP) that serve some of the functions of HERS raters for field verification purposes, but do not have the authority to sign compliance documentation as a HERS rater. Third Party Quality Control Programs:

A. Provide training to installers, participating program installing contractors, installing technicians and specialty TPQCP subcontractors regarding compliance requirements for measures for which diagnostic testing and field verification is required.

B. Collect data from participating installers for each installation completed for compliance credit.

C. Perform data checking analysis of information from diagnostic testing performed on participating TPQCP contractor installation work to evaluate the validity and accuracy of the data and to independently determine whether compliance has been achieved.

D. Provide direction to the installer to retest and correct problems when data checking determines that compliance has not been achieved.

E. Require resubmission of data when retesting and correction is directed.

F. Maintain a database of all data submitted by the participating TPQCP contractor in a format that is acceptable and made available to the Energy Commission upon request.

The HERS provider must arrange for the services of an independent HERS rater to conduct field verification and diagnostic testing of the installation work performed by the participating TPQCP contractor under the Third Party Quality Control Program. If group sampling is utilized for HERS verification compliance for jobs completed by a participating TPQCP contractor, the sample from the group that is tested for compliance by the HERS rater may be selected from a group composed of up to 30 units for which the same participating TPQCP contractor has performed the installation work. For alterations, the installation work performed by TPQCP contractors may be approved at the enforcement agency's discretion, based upon a properly completed Certificate(s) of Installation (NRCI-MCH-01) and Certificate(s) of Acceptance (NRCA-MCH-04-A) on the condition that if subsequent HERS compliance verification procedures determine that re-sampling, full testing or corrective action is necessary for such conditionally-approved dwellings in the group, the corrective work must be completed. If the Energy Standards require registration of the compliance forms, the Certificate(s) of Installation and Certificate(s) of Acceptance must be a registered copies from a nonresidential data registry and a HERS provider data registry, respectively.

Refer to Reference Nonresidential Appendix NA1 for additional information about the Third Party Quality Control Program and for additional information about document registration.

More details on field verification and diagnostic testing and the HERS provider data registry are provided in the 2016 Reference Nonresidential Appendices and 2016 Reference Joint Appendices, as described below:

A. Reference Nonresidential Appendix NA1 – Nonresidential HERS Verification, Testing, and Documentation Procedures

B. Reference Nonresidential Appendix NA2 – Nonresidential Field Verification and Diagnostic Test Procedures

C. Reference Joint Appendix JA7 – Data Registry Requirements