This chapter is organized by related topics as follows:

3.1.5 Prescriptive Component Envelope Approach

3.1.7 Envelope Definitions and Features

3.4 Relocatable Public School Buildings

3.7 Roofing Products (Cool Roofs)

3.8 Compliance Documentation

The standards have both mandatory measures and prescriptive requirements that affect the design and operation of the building. The mandatory measures, prescriptive requirements and operational schedules establish a minimum performance level which can be exceeded by other design measures and construction practices resulting in greater energy savings.

Public Resources Code, Section 25402.1 (b) requires the California Energy Commission to establish a formal process for certification of compliance options of new products, materials, designs or procedures that can improve building efficiency levels established by the Building Energy Efficiency Standards. §10-109 of the standards allows for the introduction of new calculation methods and measures which cannot be properly accounted for in the current approved compliance approaches.

The Energy Commission encourages the use of energy-saving techniques and designs for showing compliance with the standards. The compliance options process allows the Energy Commission to review and gather public input regarding the merits of new compliance techniques, products, materials, designs or procedures to demonstrate compliance for newly constructed buildings and additions and alterations to existing buildings.

Approved compliance options encourage market innovation and allow the Energy Commission to respond to changes in building design, construction, installation, and enforcement.

When the Energy Commission approves a new compliance option it is 'listed in the Special Cases section of the Energy Commission’s website: (www.energy.ca.gov). Approved compliance options are 'listed by their respective technology, compliance procedure, product or equipment type and often represent advanced methods for achieving high performance buildings.

The 2013 Standards include several important changes to the building envelope component requirements, as described below:

A. An updated equation to calculate the aged solar reflectance for field-applied coatings (cool roof), §110.8(i)2.

B. Minimum mandatory requirements for insulation, §120.7 that apply to:

a. Roof/ceiling insulation

ii. Wood framed and others

b. Wall insulation

i. Metal building

ii. Metal framed

iii. Light mass wall

iv. Heavy mass wall

v. Wood framed and others

vi. Spandrel panels and glass curtain walls

c. Floor and soffit insulation

i. Raised mass floors

ii. Other floors

iii. Heated slab floor

C. Building commissioning, §120.8.

D. Prescriptive requirements of §140.3 that apply to:

a. Cool roofs of low sloped roofs:

i. A minimum aged solar reflectance of 0.63 and thermal emittance of 0.75 in all climate zones, or solar reflectance index (SRI) of 75 in all climate zones

ii. Roof/ceiling insulation tradeoff for aged solar reflectance

E. Fenestration

a. Dynamic Glazing

b. Visible light transmittance (VT)

c. Skylights

d. Window Films

F. Requirements for additions, alterations, and repairs, §141.0 that apply to:

a. Mandatory insulation requirements for alterations

b. Maximum U-factor and shading requirements for fenestration in alterations

c. Roof/ceiling insulation tradeoff for aged solar reflectance of roofing being replaced, recovered or recoated

d. Requirements applying to altered duct systems

e. Requirements apply to lighting systems

f. Window Films

G. Requirements for additions, alterations applying to covered processes, §141.1.

The Standards have mandatory requirements, and prescriptive or performance methods for compliance. The standards establish a minimum level of performance which can be exceeded by advanced design and construction practices.

When compliance is being demonstrated with either the prescriptive or performance compliance paths, there are mandatory measures that must be installed. The minimum mandatory levels are sometimes superseded by more stringent prescriptive or performance approach requirements. For example, the mandatory measures specify a weighted average U-factor of a metal framed wall insulation to be U-0.105, but if compliance is being demonstrated with the prescriptive approach for a nonresidential building, Table 140.3-B of the standards is used to establish the minimum wall thermal compliance level. In this case, a U-0.098 or U-0.062 metal framed wall assembly insulation (depending on climate zone) must be installed. Conversely, the mandatory measures may be of a higher efficiency than permitted under the performance approach. In these instances, the higher mandatory levels must be installed. For example, a building may comply using the performance computer modeling with only a U-factor of U-0.121 insulation in a metal framed rafter roof, but a U-factor of at least U-0.098 must be installed because that is the mandatory minimum.

Standards Table 140.3-B, C and D

The prescriptive requirements are the simplest way to comply with the building envelope requirements but offer little flexibility. If each and every prescriptive requirement is met, the building envelope complies with the standards.

This prescriptive compliance approach consists of meeting specific requirements for each envelope component, and minimum mandatory levels of insulation. Prescriptive requirements apply to:

•roofs and ceilings,

•exterior roofing products

•exterior walls

•demising walls

•floors and soffits

•fenestration and skylights

Fenestration must meet prescriptive minimum thermal performance values and have a maximum of 40% window-to-wall ratio. Vertical fenestration has a maximum building, and maximum west-facing, area allowance as well as skylights have maximum area limits. Thermal performance values are specified for the maximum U-factor, Solar Heat Gain Coefficient (SHGC) and visible transmittance (VT). The prescriptive envelope requirements are prescribed in §140.3 which includes; Table 140.3-B for nonresidential buildings; Table 140.3-C for high-rise residential buildings and hotel/motel buildings; and Table 140.3-D for relocatable public school buildings.

Under the Envelope Component Approach, each of the envelope assemblies (walls, roofs, floors, windows, and skylights) must comply individually with its requirement. If one component of the envelope does not comply, the Envelope Component Approach cannot be used and another compliance method must be chosen. When using the Envelope Component Approach there can be no trade-offs between components. If one or more of the envelope components cannot meet its requirement, the alternative is to use either the Simplified Performance Tradeoff Approach or the Performance Approach, which allows tradeoffs between building features, 'in 'addition to the mandatory requirements.

The performance approach is a more sophisticated compliance method and it offers design flexibility. The performance approach may be used for:

•Envelope-only compliance

•Envelope and lighting compliance

•Envelope and mechanical compliance

•Envelope, lighting and mechanical compliance

The performance approach allows for more energy tradeoffs between building features, such as increasing envelope efficiency in order to allow more lighting power or a less efficient space-conditioning system. See Section 3.5 and Chapter 9 more complete discussion of the performance approach.

Elements of the building envelope significantly contribute to the energy efficiency of the building and its design intent. Several features are important to note when a method is chosen to demonstrate compliance. Components of the building shell include the walls, floor, the roof or ceiling, and fenestration. Details for fenestration compliance for windows, skylights and doors are addressed in Section 3.2, Fenestration.

A. Walls and Space(s) Surrounding Occupancy Uses

Envelope and other building component definitions are 'listed in §100.1.

•Envelope requirements vary by envelope component and are a function of their type of construction, and the space conditions on either side of the envelope surface.

•An exterior partition is an envelope component (roof, wall, floor, window etc.) that separates conditioned space from ambient (outdoor) conditions. A demising partition is an envelope component that separates conditioned space from an unconditioned enclosed space.

•A conditioned space is either directly conditioned or indirectly conditioned (see Section 100.1 for full definition). Indirectly conditioned space is thermally influenced more by adjacent directly conditioned space than it is by ambient (outdoor) conditions. An unconditioned space is enclosed space within a building that is not directly conditioned, or indirectly conditioned.

•A plenum space below an insulated roof and above an uninsulated ceiling is an indirectly conditioned space as there is less thermal resistance to the directly conditioned space below than to the ambient air outside. In comparison, an attic below an uninsulated roof and having insulation on the attic floor is an unconditioned space because there is less thermal resistance to the outside than across the insulated ceiling to the conditioned space below.

•An exterior wall is considered separately from a demising wall or demising partition and has more stringent thermal requirements.

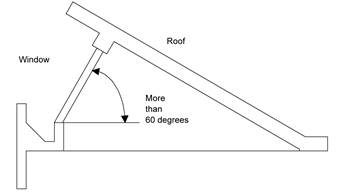

•Sloping surfaces are considered either a wall or a roof, depending on their slope (see Figure 3-1). If the surface has a slope of less than 60° from horizontal, it is considered a roof; a slope of 60° or more is a wall. This definition extends to fenestration products, including windows in walls and any skylights in roofs.

•Floors and roof/ceilings do not differentiate between demising and exterior. Thus an exterior roof/ceiling ”is an exterior partition, or a demising partition, that has a slope less than 60 degrees from horizontal, that has conditioned space below,” ambient conditions or unconditioned space above “and that is not an exterior door or skylight.”

•Similarly an “exterior floor/soffit is a horizontal exterior partition, or a horizontal demising partition, under conditioned space” and above an unconditioned space or above ambient (outdoor) conditions.

•Windows are considered part of the wall because the slope is over 60°. Where the slope is less than 60°, the glazing indicated as a window is considered a skylight.

A.

B. Roofing Products (Cool Roof)

Roofing products with a high solar reflectance and thermal emittance are referred to as “cool roofs.” These roofing types absorb less solar heat and give off more heat to their surroundings than traditional roofing material. These roofs are cooler and thus help reduce air conditioning loads by reflecting and emitting energy from the sun. Roof radiative properties are rated and 'listed by the Cool Roof Rating Council (CRRC) (www.coolroofs.org)

Light-colored high reflectance surfaces reflect solar energy (visible light, invisible infrared and ultraviolet radiation) and stay cooler than darker surfaces that absorb the sun’s energy and become hot. Thermal emittance refers to the ability of heat to escape from a surface once heat energy is absorbed. Both solar reflectance and thermal emittance are measured from 0 to 1; the higher the value, the "cooler" the roof. There are numerous roofing materials in a wide range of colors that have relatively good cool roof properties. Surfaces with low emittance (usually shiny metallic surfaces) contribute to the transmission of heat into components under the roof surface. Excess heat can increase the building’s air conditioning load resulting in increased air conditioning energy needed for maintaining occupant comfort. High-emitting roof surfaces reject absorbed heat quickly (upward and out of the building) than darker roof surfaces with low-emitting properties.

The standards prescribe cool roof radiative properties differently for low-sloped and steep-sloped roofs (§140.3(a)1A). A low-sloped roof is defined as a surface with a pitch less than or equal to 2:12 (9.5 degrees from the horizon), while a steep-sloped roof is a surface with a pitch greater than 2:12 (9.5 degrees from the horizon). Because heat solar gain is based on the sun’s angle of incidence on a surface, low-sloped roofs receive more solar radiation than steep-sloped roofs in the summer when the sun is high in the sky.

The standards specify radiative properties that represent minimum “cool roof performance” qualities of roofing products. Performance values are established based on “initial” testing of the roofing product and for their “aged” value which accounts for the effects of weathering due to different climate conditions over time:

•Solar reflectance: The fraction of solar energy that is reflected by the roof surface.

•Thermal emittance: The fraction of thermal energy that is emitted from the roof surface

•Solar Reflectance Index (SRI): The relative surface temperature of a surface with respect to standard white (SRI=100) and standard black (SRI=0) under the standard solar and ambient condition. This combined metric is a function of both solar reflectance and thermal emittance. One can achieve the same SRI if the roofing product has a higher solar transmittance but a lower thermal reflectance.

A.

B.

C. Infiltration and Air Leakage

Infiltration is the unintentional replacement of conditioned air with unconditioned air through leaks or cracks in the building envelope. Poor construction detailing at interfacing points of different construction materials, particularly in extreme climates, can have a significant impact on heating and cooling loads. Air leakage can occur through holes and cracks in the building envelope and around doors and fenestration areas. Ventilation is the intentional replacement of conditioned air with unconditioned air through open windows or mechanical ventilation.

Reducing air leakage in the building envelope can result in significant energy savings, especially in climates with more severe winter and summer conditions. It also can result in improved building comfort, reduced moisture intrusion, and fewer air pollutants.

An air barrier that inhibits air leakage is critical to good building design and is a prescriptive requirement for some climate zones (see Section 3.3.2, Prescriptive Envelope Requirements, G. Air Barrier).

D. Thermal Properties of Opaque Envelope Components

Typical opaque envelope assemblies are made up of a variety of components, such as wood or metal framing, masonry or concrete, insulation, various membranes for moisture and/or fire protection, and may have a variety of interior and exterior sheathings even before the final exterior façade is placed. Correctly calculating assembly U-factors is critical to the selection of equipment to meet the building’s heating and cooling loads. Performance compliance software automatically calculates the thermal effects of component layers making up the overall envelope assembly, but software programs may utilize different user input hierarchies. The Reference Appendices, Joint Appendix JA4, “U-factor, C-factor, and Thermal Mass Data”, provides detailed thermal data for many wall, roof/ceiling, and floor assemblies. However, this reference cannot cover every possible permutation of materials, thickness, etc. that might be used in a building; thus, the Energy Commission has developed the EZ-FRAME2013 program for calculating material properties of a typical envelope assemblies that may not be found from the JA4 reference data.

Key terms of assembly thermal performance are:

•Btu (British thermal unit): The amount of heat required to raise the temperature of 1 lb. of water 1 oF.

•Btuh or Btu/hr (British thermal unit per hour): The rate of heat flow during an hour’s time. The term is used to rate the output of heating or cooling equipment or the load that equipment must be capable of handling; that is, the capacity needed for satisfactory operation under stated conditions.

•R or R-value (Thermal resistance): the ability of a material or combination of materials to retard heat flow. As the resistance increases, the heat flow is reduced. The higher the ‘R’, the greater the insulating value. R-value is the reciprocal of the conductance, ‘C’.

R-value = hr x ft2 x oF/Btu

R = inches of thickness/k

•U or U-factor (Thermal transmittance or coefficient of heat transmission): The rate of heat transfer across an envelope assembly per degree of temperature difference on either side of the envelope component. U-factor is a function of the materials and their thickness. U-factor includes air film resistances on inside and outside surfaces. U-factor applies to heat flow through an assembly or system, whereas ‘C’, having the same dimensional units applies to individual materials. The lower the ‘U’, the higher the insulating value.

U-factor = Btu/(hr x ft² x ºF)

•k or k-value (Thermal conductivity): The property of a material to conduct heat in The number of Btu that pass through a homogeneous material 1 inch thick and 1 sf. in area in an hour with a temperature difference of 1 oF between the two surfaces. The lower the ‘k’, the greater the insulating value.

•C or C-value (Thermal conductance): The number of Btu that pass through a material of any thickness and 1 sf. in area in an hour with a temperature difference of 1 oF between the two surfaces. The time rate of heat flow through unit area of a body induced by a unit temperature difference between the body surfaces. The C-value does not include the air film resistances on each side of the assembly. The term is usually applied to homogeneous materials but may be used with heterogeneous materials such as concrete block. If ‘k’ is known, the ‘C’ can be determined by dividing ‘k’ by inches of thickness. The lower the ‘C’, the greater the insulating value.

C = Btu/(hr. x ft2 x °F) or C = k/inches of thickness

•HC (Heat capacity – thermal mass): The ability to store heat in units of Btu/ft2 and is a property of a given envelope component’s specific heat, density and thickness. High thermal mass building components, such as tilt-up concrete walls, can store heat gains and release stored heat later in the day or night. The thermal storage capability of high mass walls, floors, and roof/ceilings can slow heat transfer and shift heating and cooling energy affecting building loads throughout a 24-hour period depending on the building’s design, location and occupancy use.