The objective of the Building Energy Efficiency Standards (Standards) requirements for mechanical systems is to reduce energy consumption while maintaining occupant comfort. These goals are achieved by:

1. Maximizing equipment efficiency, both at design conditions and during part load operation

2. Minimizing distribution losses of heating and cooling energy

3. Optimizing system control to minimize unnecessary operation and simultaneous use of heating and cooling energy

The Standards also recognize the importance of indoor air quality for occupant comfort and health. To this end, the Standards incorporate requirements for outdoor air ventilation that must be met during all operating conditions.

This chapter summarizes the requirements for space conditioning, ventilating, and service water heating systems for non-process loads in nonresidential buildings. Chapter 10 covers process buildings and process spaces in non-residential buildings. The chapter is organized as follows:

1. Section 4.1 provides an overview of compliance approaches including the mandatory measure, the prescriptive approach, and the performance approach.

2. Section 4.2 addresses the requirements for HVAC and service water heating equipment efficiency and equipment mounted controls.

3. Section 4.3 includes mechanical ventilation, natural ventilation and demand controlled ventilation.

4. Section 4.4 covers construction and insulation of ducts and pipes, and duct sealing to reduce leakage.

5. Section 4.5 covers control requirements for HVAC systems including zone controls, and controls to limit reheating and recooling.

6. Section 4.6 covers the remaining requirements for HVAC systems; including sizing and equipment selection, load calculations, economizers, electric resistance heating limitation, limitation on air-cooled chillers, fan power consumption and fan and pump flow controls.

7. Section 4.7 covers the remaining requirements for service water heating.

8. Section 4.8 covers the performance method of compliance.

9. Section 4.9 covers compliance requirements for additions and alterations.

10. Section 4.10 covers the glossary, reference, and definitions.

11. Section 4.11 describes the mechanical plan check documents, which includes information that must be included in the building plans and specifications to show compliance with the Standards, including a presentation and discussion of the mechanical compliance forms.

Acceptance requirements apply at all times to the systems covered regardless of the path of compliance (for example, an air side economizer, if provided, will always be tested whether the system complied with the prescriptive or performance compliance approach). Chapter 12 describes mandated acceptance test requirements, which are summarized at the end of each section. The full acceptance requirements are in §120.5 of the Standards and in 2013 Nonresidential Appendix NA7.

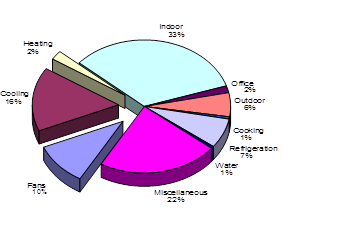

Mechanical systems and lighting systems are the largest consumers of energy in nonresidential buildings. The proportion of space-conditioning energy consumed by various mechanical components varies according to system design and climate. For most buildings in non-mountainous California climates, fans and cooling equipment are the largest components of HVAC energy use. Space heating energy is usually less than fans and cooling, followed by service water heating.

Heating, cooling and ventilation account for about 28% of commercial building electricity use in California. Source IEQ RFP, December 2002, California Energy Commission No. 500-02-501.

Mandatory measures §110.0-110.5 and §120.0-120.5 apply to all nonresidential buildings, whether the designer chooses the prescriptive or performance approach to compliance. Mandatory measures will be discussed further in the chapter and include:

1. Equipment certification and equipment efficiency §110.1 and §110.2.

2. Service water heating systems and equipment §110.3.

3. Spa and pool heating systems and equipment §110.4

4. Restrictions on pilot lights for natural gas appliances and equipment §110.5.

5. Ventilation requirements §120.1 including:

a. Natural ventilation

b. Mechanical ventilation, and

c. Demand controlled or occupant sensor controlled ventilation

6. Control requirements §120.2 including:

a. Zoning

b. Thermostats including Occupant Controlled Smart Thermostats (OCST)

c. Shut-off controls

d. Supply/Exhaust Damper Controls

e. Night setback/setup,

f. Area isolation

g. Demand shed controls, and

h. Automatic fault detection and diagnostics for air-side economizers.

7. Pipe insulation §120.3

8. Duct construction and insulation §120.4.

9. Acceptance tests §120.5 and 2013 Nonresidential Appendix NA7.

After the mandatory measures are met, the Standards allow mechanical system compliance to be demonstrated through prescriptive or performance requirements.

A. Prescriptive Requirements

Prescriptive measures cover items that can be used to qualify components and systems on an individual basis and are contained in §140.4. Prescriptive measures provide the basis of energy use for the Standards: You can comply with them directly in the prescriptive approach or provide an alternate design that meets a prescriptive Time Dependent Valuation (TDV) target in the performance approach. Prescriptive measures include:

1. Load calculations, sizing, system type and equipment selection §140.4(a) and (b).

2. Fan power consumption §140.4(c).

3. Controls to reduce reheating, recooling and mixing of conditioned air streams; §140.4(d).

4. Economizers §140.4(e).

5. Supply temperature reset §140.4(f).

6. Restrictions on electric-resistance heating §140.4(g).

7. Fan speed controls for heat rejection equipment §140.4(h).

8. Limitation on centrifugal fan cooling towers §140.4(h).

9. Minimum chiller efficiency §140.4(i)

10. Limitation on air-cooled chillers §140.4(j).

11. Hydronic system design §140.4(k).

12. Duct sealing §140.4(l).

13. Supply fan control §140.4(m).

B. Performance Approach

The Performance Approach §140.1 allows the designer to trade off energy use in different building systems. This approach provides greater design flexibility but requires extra effort to perform: a computer simulation of the building must be developed to show compliance. In this approach the design team must still meet all of the mandatory measures but they do not have to meet specific prescriptive measures. Performance approach trade-offs can be across all of the disciplines (mechanical, lighting, envelope, and Covered Processes). The performance approach creates two models: 1) a base-case building energy model which meets all of the mandatory and prescriptive requirements; and 2) a proposed building energy model that reflects the proposed building design. The design complies if the proposed design model has a lower TDV value than the base-case model. The performance approach requires the use of an Energy Commission-certified compliance software program, and may only be used to model the performance of mechanical systems that are covered under the building permit application (see Section 4.8 and Chapter 11 for more detail).