Measurements for verification of refrigerant charge require two (2) pipe temperature sensors that pass the following qualifying test:

(a) Using test pipes in six sizes (1/4” dia., 3/16” dia., 3/8” dia., 3/4” dia., 7/8” dia., 1 1/8” dia.) that are maintained at a known temperature T1 in a test enclosure or test environment that is maintained at a known dry-bulb temperature T2,

(b) The absolute value of (T1 minus T2 ) is greater than 40ºF.

(c) The temperature sensor subjected to the qualifying test shall be placed in the test enclosure or test environment until its temperature has is stabilized at T2.

(d) The sensor shall have a response time that produces the accuracy specified in Section RA3.2.2.2.1.4 within 90 seconds of application of the sensor to one of the test pipes.

(e) A sensor may be used for more than one pipe size if it passes the above test for each pipe size for which it is used.

Refrigerant pressure measurements shall be made utilizing digital measurement instrumentation. Measurements made with digital refrigerant pressure measurement devices shall meet the following specifications

(a) accuracy: ± 7.0 psi liquid line pressure

(b) accuracy: ± 3.5 psi suction pressure

As an alternative, two saturation pressure measurement sensors (SPMS) may be permanently installed by the equipment manufacturer, or in a manner and location approved by the equipment manufacturer for use for measuring the saturation pressure of the refrigerant in the evaporator coil and in the condenser coil. Refer to Reference Joint Appendix JA6.2 for additional specification for SPMS.

RA3.2.2.3 Measurement Access Hole (MAH) Specification

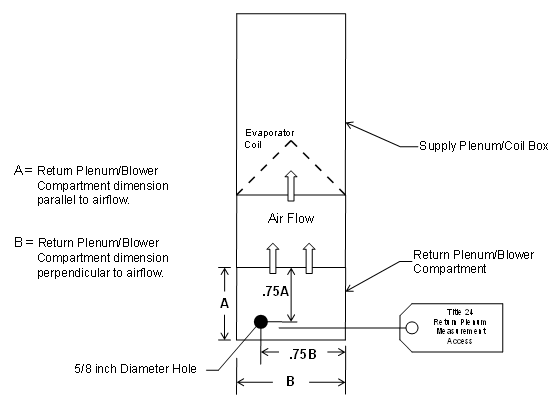

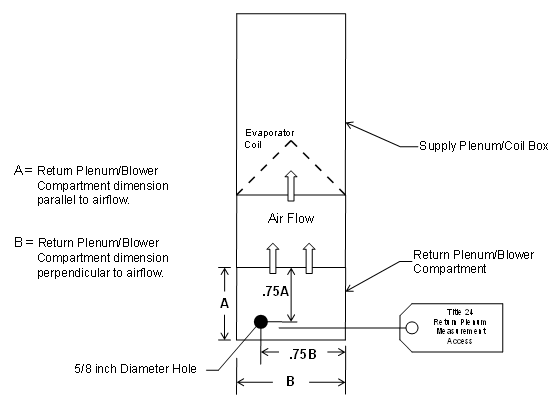

When required for compliance by Standards Section 150.1(c)7Aia, or when return plenum measurements are necessary for compliance with refrigerant charge verification requirements, a 5/8 inch (16 mm) diameter hole shall be provided as shown in Figure RA3.2-1.

Return plenum temperature measurements shall be taken at the location specified in Figure RA3.2-1 when performing the procedures in RA3.2. The measurement access shall be sealed to prevent leakage after the measurements have been completed.

The hole location shown in Figure RA3.2-1 can be applied to any one of the four sides of the return plenum. The hole location shall be labeled "Title 24 – Return Plenum Measurement Access" in at least 12-point type.

For air-handling units with the return located entirely within conditioned space (such as when an up-flow air handler is mounted on a pedestal in a closet in the dwelling, or when the return grille is an integral part of the air-handling unit), the return plenum measurement access hole is not required, and in this case the return air temperature measurements shall be taken at the return grill when performing the procedures in RA3.2.

Systems that cannot conform to the specifications for the hole location shown in Figure RA3.2-1 shall not be required to have holes as described in Figure RA3.2-1; however if return plenum measurements are required for compliance, an alternate location that provides access for making an accurate return plenum measurement shall be used.

RA3.2.2.4 Calibration

The accuracy of instrumentation shall be maintained using the following procedures. A sticker with the calibration check date shall be affixed to each instrument calibrated.

Thermometers with their temperature sensors shall be calibrated monthly to ensure that they are reading accurate temperatures.

The following procedure shall be used to check thermometer/temperature sensor calibration:

(a) Fill an insulated cup (foam) with crushed ice from distilled water. The ice shall completely fill the cup. Add distilled water to fill the cup.

(b) Insert two sensors into the center of the ice bath and attach them to the digital thermometer.

(c) Let the temperatures stabilize. The temperatures shall be 32°F (plus or minus 1°F). If the temperature is off by more than 1°F make corrections according to the manufacturer’s instructions. Any sensors that are off by more than 2°F shall be replaced.

(d) Switch the sensors and ensure that the temperatures read on both channels are still within plus or minus 1°F of 32°F.

(e) Affix sticker with calibration check date onto sensor.

(f) Repeat the process for all sensors.

Refrigerant gauges shall be checked monthly to ensure that the gauges are reading the correct pressures and corresponding temperatures. The following procedure shall be used to check gauge calibration:

(a) Place a refrigerant cylinder in a stable temperature environment and let it acclimate for 4 hours minimum to stabilize to the ambient conditions.

(b) Attach a calibrated temperature sensor to the refrigerant cylinder using tape so that there is good contact between the cylinder and the temperature sensor.

(c) Insulate over the temperature sensor connection to the cylinder.

(d) Zero the low side and high side refrigerant gauges with all ports open to atmospheric pressure (no hoses attached).

(e) Re-install the hoses, attach the high side gauge to the refrigerant cylinder, and open the valves to measure the pressure in the refrigerant cylinder.

(f) Read the temperature of the sensor on the refrigerant cylinder.

(g) Using a pressure/temperature chart for the refrigerant, look up the pressure that corresponds to the temperature measured.

(h) If gauge does not read the correct pressure corresponding to the temperature, the gauge is out of calibration and needs to be recalibrated.

(i) Close the valve to the refrigerant cylinder, and bleed off a small amount of refrigerant to lower the high side pressure to give a corresponding temperature to between 45°F and 55°F.

(j) Open the valves between the high side gauge and low side gauge.

(k) If the two gauges corresponding refrigerant temperatures do not read within 1°F of each other, the low side gauge is out of calibration and needs to be recalibrated.

(l) Affix sticker with calibration check date onto refrigerant gauge.

Digital hygrometers shall be calibrated according to the manufacturer's recommended procedures. When the manufacturer certifies the calibration for a limited time, the digital hygrometer shall be recalibrated according to the manufacturers required procedure when the calibration period expires.

RA3.2.2.5 Charge Verification Measurements

The following procedure shall be used to obtain measurements necessary to verify the required refrigerant charge.

(a) Follow the manufacturer’s directions and adhere to the manufacturer's limitations on indoor ambient air temperature (Tindoor air) and outdoor ambient air temperature (Toutdoor air) applicable to this procedure. Ensure that the return air dry bulb temperature remains equal to or greater than 70°F prior to and while performing the measurements.

(b) Connect the refrigerant gauges to the service ports, taking normal precautions to not introduce air into the system.

(c) Attach one pipe temperature sensor to the suction line near the suction line (low side) service valve and attach one pipe temperature sensor to the liquid line near the liquid line (high side) service valve. The sensors should be positioned to make good contact with the surface of the refrigerant line.

(d) Attach a temperature sensor to measure the condenser entering air dry-bulb temperature. The sensor shall be placed so that it records the average condenser air entering temperature and is shaded from direct sun.

(e) Insert a dry-bulb temperature sensor into the return plenum at the "Title 24 – Return Plenum Measurement Access" detailed in Section RA3.2.2.3.

(f) Be sure that all cabinet panels that affect airflow are in place before making measurements. The temperature sensors shall remain attached to the system until the final charge is determined.

(g) Operate the air conditioner in cooling mode for 15 minutes to allow the temperatures and pressures to stabilize before taking any measurements. While the system is stabilizing, proceed with setting up the remaining temperature sensors if used.

(h) If used, place the cotton wick wet-bulb temperature sensor in distilled water, and ensure it is saturated. Do not get the dry-bulb temperature sensors wet.

(i) If the system has a fixed metering device, at 12 minutes, insert a wet-bulb temperature sensor into the return plenum at the "Title 24 – Return Plenum Measurement Access" detailed in Section RA3.2.2.3.

(j) If the system has a fixed metering device, after the system has operated for 15 minutes, and when the return plenum wet-bulb temperature has stabilized, using the temperature sensor already in place, measure and record the return (evaporator entering) air wet-bulb temperature (Treturn, wb).

(k) Using the temperature sensor already in place, measure and record the return (evaporator entering) air dry-bulb temperature (Treturn, db).

(l) Using the refrigerant gauge or saturation pressure measurement sensor already attached, measure and record the suction line (low side) pressure, and record the refrigerant saturation temperature corresponding to the measured low side pressure (Tevaporator, sat).

(m) Using the refrigerant gauge or saturation pressure measurement sensor already attached, measure and record the liquid line (high side) pressure, and record the refrigerant saturation temperature corresponding to the measured high side pressure (Tcondenser, sat).

(n) Using the pipe temperature sensor already in place, measure and record the suction line temperature (Tsuction,).

(o) Using the pipe temperature sensor already in place, measure and record the liquid line temperature (Tliquid).

(p) Using the dry-bulb temperature sensor already in place, measure and record the condenser (entering) air dry-bulb temperature (Tcondenser, db).

The above measurements shall be used to verify the refrigerant charge as described in following sections.

RA3.2.2.6 Refrigerant Charge and Metering Device Calculations

The following steps describe the calculations to determine if the system meets the required refrigerant charge and metering device function using the measurements determined in Section RA3.2.2.5. If a system fails, then remedial actions must be taken by the HVAC system installer. Be sure to run the air conditioner for 15 minutes after the final adjustments before taking any measurements.

The Superheat Charging Method is used only for systems equipped with fixed metering devices. These include capillary tubes and piston-type metering devices.

(a) Calculate Actual Superheat as the suction line temperature minus the evaporator saturation temperature.

Actual Superheat = Tsuction, – Tevaporator, sat.

(b) Determine and record the Target Superheat using Table RA3.2-2 or the manufacturer's superheat chart using the return air wet-bulb temperature (Treturn, wb) and condenser air dry-bulb temperature (Tcondenser, db).

(c) If a dash mark is read from Table RA3.2-2, the target superheat is less than 5°F. Note that a valid refrigerant charge verification test cannot be performed under these conditions. A severely undercharged unit will show over 9°F of superheat. However overcharged units cannot be detected from the superheat method under these conditions. The usual reason for a target superheat determination of less than 5°F is that outdoor conditions are too hot and the indoor conditions are too cool. One of the following is needed so a target superheat value can be obtained from Table RA3.2-2 either 1) turn on the space heating system and/or open the windows to warm up indoor temperature; or 2) retest at another time when conditions are different.

(d) Calculate the difference between actual superheat and target superheat (Actual Superheat - Target Superheat).

(e) In order to allow for inevitable differences in measurements, the Pass/Fail criteria are different for the Installer and the HERS Rater.

(f) For the Installer, if the difference is within the tolerance given as compliance criteria in Table RA3.2-1, then the system passes the required refrigerant charge criterion.

(g) For the HERS Rater inspecting the system, if the difference is within the criteria in Table RA3.2-1, then the system passes the required refrigerant charge criterion.

(h) For the Installer, if the system fails to meet the criteria, refrigerant needs to be added if the superheat is too high and refrigerant needs to be removed if it is too low. The installer needs to remain aware of other potential system faults. Adjust refrigerant charge and check the measurements as many times as necessary to pass the test. After the final adjustment has been made, allow the system to run 15 minutes before completing the final measurement procedure.

The Subcooling Charging Method is used for systems equipped with variable metering devices. These include Thermostatic Expansion Valves (TXV) and Electronic Expansion Valves (EXV). The amount of refrigerant is set based on the measured subcooling value, and the measured superheat value determines whether the metering device is working properly.

(a) Calculate Actual Subcooling as the condenser saturation temperature minus the liquid line temperature. Actual Subcooling = Tcondenser, sat – Tliquid.

(b) Determine the Target Subcooling specified by the manufacturer

(c) Calculate the deviation of the actual subcooling value from the target subcooling value. Subcooling Deviation = Actual Subcooling - Target Subcooling.

In order to allow for inevitable differences in measurements, the Pass/Fail criteria are different for the Installer than for the HERS Rater.

(d) If the Subcooling Deviation is within the subcooling tolerance allowed by Table RA3.2-1, then the system complies with the subcooling criterion, otherwise the system does not comply.

(e) For the HVAC installer, if the system does not comply, and if the Actual Subcooling value is greater than the Target Subcooling value, the Installer shall remove refrigerant. If the Actual Subcooling value is less than the Target Subcooling value, the Installer shall add refrigerant. The Installer shall determine whether there are other system faults that may affect the validity of the refrigerant charge verification procedure, and make any needed system repairs or adjustments to clear system faults prior to completion of the refrigerant charge verification procedure. The Installer shall adjust the refrigerant charge and check the measurements as many times as necessary to pass the test. After the final adjustment has been made, the Installer shall allow the system to run 15 minutes before completing the final measurement procedure.

(f) Calculate Actual Superheat as the suction line temperature minus the evaporator saturation temperature. Actual Superheat = Tsuction, – Tevaporator, sat.

(g) If possible, determine the Superheat Range specified by the manufacturer.

(h) In order to allow for inevitable differences in measurements, the Pass/Fail criteria are different for the Installer than for the HERS Rater.

If the superheat is within the tolerance allowed by Table RA3.2-1, then the system complies with the metering device criterion, otherwise the system does not comply.

For the HVAC installer, if the system does not comply remedial actions must be undertaken to ensure the TXV or EXV is operating properly.

RA3.2.2.7 Minimum System Airflow Requirements

Compliance with the refrigerant charge verification procedures in Section RA3.2.2 requires that the system meet minimum system airflow criteria as specified in subsections RA3.2.2.7.1, RA3.2.2.7.2, or RA3.2.2.7.3.

For newly constructed buildings, space-conditioning systems shall comply with the minimum system airflow requirement by demonstrating compliance with Standards Section 150.0(m)13.

For altered space conditioning systems, the minimum system

airflow requirement shall be verified by use of one of the system airflow rate

measurements defined in Section

RA3.3 to demonstrate a measured airflow rate equal to or greater than 300

cfm per nominal ton of condensing unit cooling capacity. If a system fails to

meet this minimum airflow criterion, remedial actions shall be taken to ensure

the system conforms to the minimum 300 cfm per ton airflow requirement.

When an altered space conditioning system fails to demonstrate compliance with the required 300 cfm per nominal condensing unit ton minimum system airflow, the system shall perform the remedial actions 'listed in Section RA3.2.2.7.3.1. If these remedial actions fail to bring the system into compliance with the 300 cfm per nominal condensing unit ton airflow requirement, the installer shall complete the refrigerant charge verification utilizing the best airflow rate attainable. The system shall be considered in compliance if the installer certifies that the following corrective measures have been performed: