10.5

Commercial Refrigeration

10.5.1

Overview

This section addresses §120.6(b)

of the Energy Standards, which covers mandatory requirements for commercial

refrigeration systems in retail food stores. This section explains the mandatory

requirements for condensers, compressor systems, refrigerated display cases,

refrigeration heat recovery. All buildings under the Energy Standards must also

comply with the General Provisions of the Energy Standards (§100.0 – §100.2,

§110.0

– §110.10,

§120.0 – §120.9, §130.0

– §130.5), and

additions and alterations requirements (§141.1).

10.5.1.1

Mandatory Measures and Compliance Approaches

The energy efficiency requirements for commercial

refrigeration are all mandatory. There are no prescriptive requirements or

performance compliance paths for commercial refrigeration. Since the provisions

are all mandatory, there are no tradeoffs allowed between the various

requirements. The application must demonstrate compliance with each of the

mandatory measures. Exceptions to each mandatory requirement where provided are

described in each of the mandatory measure sections below.

10.5.1.2

What’s New in the 2016 Energy Standards

In the 2016 Energy Standards, the exception to §120.6(b)3

is no longer available. This affects retail food stores with 8,000 square feet

or more of conditioned area that use either: refrigerated display cases, or

walk-in coolers or freezers connected to remote compressor units or condensing

units, which are normally open for business for less than 140 hours per week.

These stores must now comply with §120.6(b)3,

without exception.

10.5.1.3

Scope and Application

§120.6(b)

of the Energy Standards applies to retail food stores that have 8,000 square

feet or more of conditioned area, and utilize either refrigerated display cases

or walk-in coolers or freezers, which are connected to remote compressor units

or condensing units. The Energy Standards have minimum requirements for

the condensers, compressor systems, refrigerated display cases, and

refrigeration heat recovery systems associated with the refrigeration systems in

these facilities.

The Energy Standards do not have minimum efficiency

requirements for walk-ins, as these are deemed appliances and are covered by the

California Appliance Efficiency Regulations (Title 20) and Federal Energy

Independence and Security Act of 2007. Walk-ins are defined as refrigerated

spaces with less than 3,000 square feet of floor area that are designed to

operate below 55°F (13°C). Additionally, the Energy Standards do not have

minimum equipment efficiency requirements for refrigerated display cases, as the

minimum efficiency for these units is established by Federal law in the

Commercial Refrigeration Equipment Final Rule but there are requirements for

display cases that do result in reduced energy consumption.

Example

10-9

Question

The only refrigeration

equipment in a retail food store with 10,000 square feet of conditioned area is

self-contained refrigerated display cases. Does this store need to comply with

the requirements for Commercial Refrigeration?

Answer

No. Since the refrigerated display cases are not

connected to remote compressor units or condensing units, the store does not

need to comply with the Energy Standards.

Example 10-10

Question

A new retail store with 25,000 square feet conditioned area

has two self-contained display cases. The store also has several display case

line-ups and walk-in boxes connected to remote compressors systems. Do all the

refrigeration systems need to comply with the requirements for Commercial

Refrigeration?

Answer

There are no provisions in the

Energy Standards for the two self-contained display cases. The refrigeration

systems serving the other fixtures must comply with the Energy

Standards.

10.5.2

Condensers Mandatory Requirements

This section addresses the mandatory requirements for

condensers serving commercial refrigeration systems. These requirements only

apply to stand-alone refrigeration condensers and do not apply to condensers

that are part of a unitary condensing unit.

If the work includes a new condenser replacing an existing

condenser, the condenser requirements do not apply if all of the following

conditions apply:

1.

The Total Heat of Rejection of the compressor system attached to the condenser

or condenser system does not increase, and

2.

Less than 25% of the attached refrigeration system compressors (based on

compressor capacity at design conditions) are new, and

3.

Less than 25% of the display cases (based on display case design load at applied

conditions) that the condenser serves, are new. Since the compressor system

loads commonly include walk-ins (both for storage and point-of-sale boxes with

doors), the 25% “display case" should be calculated with walk-ins included.

Example 10-11

Question

A supermarket remodel includes a refrigeration system

modification where some of the compressors will be replaced, some of the

refrigerated display cases will be replaced, and the existing condenser will be

replaced. The project does not include any new load and the design

engineer has determined that the total system heat of rejection will not

increase. The replacement compressors comprise 20% of the suction group

capacity at design conditions, and the replacement display cases comprise 20% of

the portion of the design load that comes from display cases. There are no

changes in walk-ins. Does the condenser have to comply with the provisions

of the Energy Standards?

Answer

No. This project meets all three criteria of the exception

to the mandatory requirements for condensers:

1. The new condenser is replacing an existing condenser

2. The total heat of rejection of the subject refrigeration

system does not increase

3a. The replacement compressors comprise less than 25% of

the suction group design capacity at design conditions

3b. The replacement display

cases comprise less than 25% of the portion of the design load that comes from

display cases.

10.5.2.1

Condenser Fan Control

Condenser fans for new air-cooled or evaporative condensers,

or fans on air- or water-cooled fluid coolers or cooling towers used to reject

heat on new refrigeration systems, must be continuously variable speed. Variable

frequency drives are commonly used to provide continuously variable speed

control of condenser fans and controllers designed to vary the speed of

electronically commutated motors are increasingly being used for the same

purpose. All fans serving a common high side, or indirect condenser water loop,

shall be controlled in unison. Thus, in normal operation, the fan speed of all

fans within a single condenser or set of condensers serving a common high-side

should modulate together, rather than running fans at different speeds or

staging fans off. However, when fan speed is at the minimum practical level

minimum level, usually no higher than 10-20%, the fans may be staged off to

further reduce condenser capacity. As load increases, fans should be turned back

on prior to significantly increasing fan speed, recognizing a control band is

necessary to avoid without excessive fan cycling. Control of air-cooled

condensers may also keep fans running and use a holdback valve on the condenser

outlet to maintain the minimum condensing temperature once all fans have reached

minimum speed; with the holdback valve set below the fan control minimum

saturated condensing temperature setpoint.

To minimize overall system energy consumption, the condensing

temperature control setpoint must be continuously reset in response to ambient

temperatures, rather than using a fixed setpoint value. This strategy is also

termed ambient-following control, ambient-reset, wetbulb following and drybulb

following—all referring to control logic which changes the condensing

temperature control setpoint in response to ambient conditions at the condenser.

The control system calculates a control setpoint saturated condensing

temperature that is higher than the ambient temperature by a predetermined

temperature difference (i.e. the condenser control TD). Fan speed is then

modulated so that the measured SCT (saturated condensing temperature) matches

the calculated SCT control setpoint. The SCT control setpoint for evaporative

condensers or water-cooled condensers (via cooling towers or fluid coolers) must

be reset according to ambient wet bulb temperature, and the SCT control setpoint

for air-cooled condensers must be reset according to ambient dry bulb

temperature.

The condenser control TD is not specified in the

Standard. The nominal control value is often equal to the condenser design

TD; however the value for a particular system is left up to the system

designer. Since the intent is to utilize as much condenser capacity as

possible without excessive fan power, common practice is to optimize the control

TD over a period of time such that the fan speed is in a range of approximately

60-80% during normal operation (i.e. when not at minimum SCT and not in heat

recovery).

The minimum saturated condensing temperature setpoint must be

70°F (21°C) or less. For systems utilizing halocarbon refrigerants with

glide, the SCT setpoint shall correlate with a midpoint temperature (between the

refrigerant bubble-point and dew point temperatures) of 70°F (21°C) or

less. As a practical matter, a maximum SCT setpoint is also commonly

employed to set an upper bound on the control setpoint in the event of a sensor

failure and to force full condenser operation during peak ambient

conditions. This value should be set high enough that it does not

interfere with normal operation.

Split air-cooled condensers are sometimes used for separate

refrigeration systems, with two circuits and two rows of condenser fans. Each

condenser half would be controlled as a separate condenser. If a condenser has

multiple circuits served by a common fan or set of fans, the control strategy

may utilize the average condensing temperature or the highest condensing

temperature of the individual circuits as the control variable for controlling

fan speed.

Alternative control strategies are permitted to the

condensing temperature reset control required in §120.6(b)1C.

The alternative control strategy must be demonstrated to provide equal or better

performance, as approved by the Executive Director.

Hybrid condensers, manufactured with integral capability to

operate with either air-cooled or evaporative-cooled operation, are not

covered. Air-cooled condensers with separately installed evaporative

precoolers added to the condenser are not considered hybrid condensers for the

purpose of this Standard. Air cooled condensers with an added evaporative

precooling must meet the requirements for air cooled equipment, including

specific efficiency and ambient-following control.

Example

10-12

Question

A

new supermarket with an evaporative condenser is being commissioned. The

control system designer has utilized a wet bulb-following control strategy to

reset the system saturated condensing temperature (SCT) setpoint. The

refrigeration engineer has calculated that adding a TD of 15°F (8.3°C) above the

ambient wet bulb temperature should provide a saturated condensing temperature

setpoint that minimizes the combined compressor and condenser fan power usage

throughout the year. What might the system SCT and SCT setpoint trends

look like over an example day?

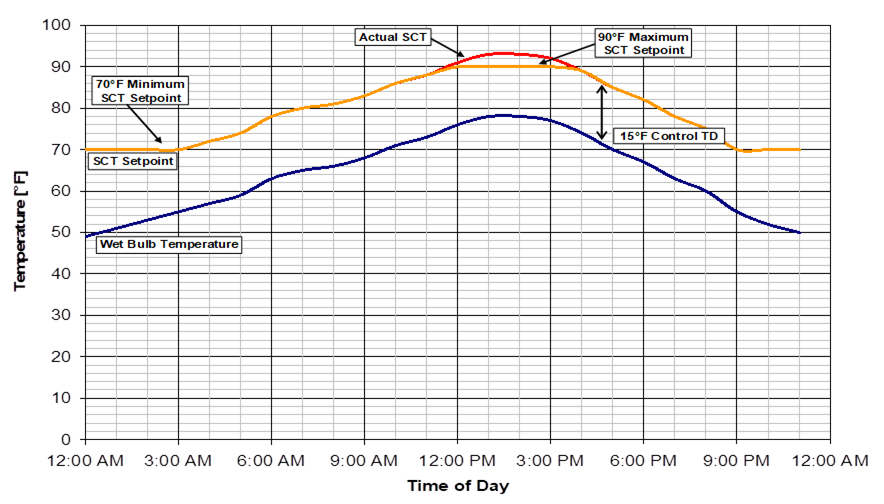

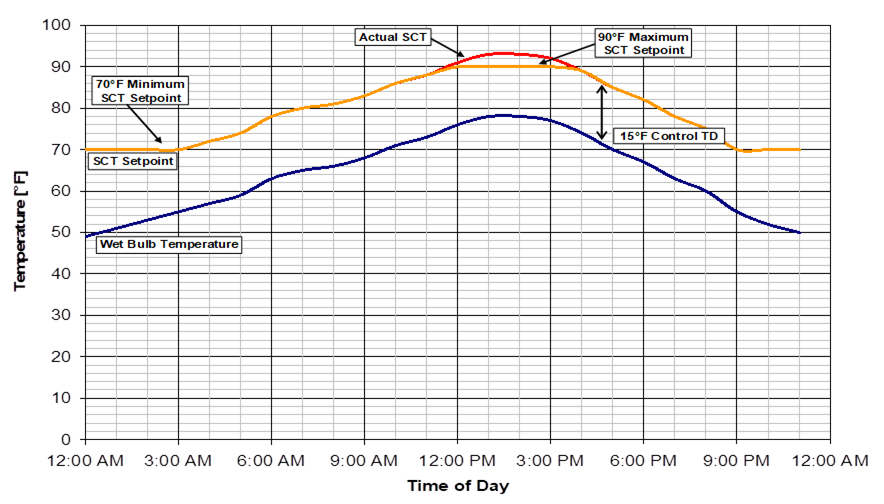

Answer

The

following figure illustrates what the actual saturated condensing temperature

and SCT setpoints could be over an example day using the wet bulb-following

control strategy with a 15°F (8.3°C) TD and also observing the 70°F (21°C)

minimum condensing temperature requirement. As the figure shows, the SCT

setpoint is continuously reset to 15°F (8.3°C) above the ambient wet bulb

temperature until the minimum SCT setpoint of 70°F is reached. The figure also

shows a maximum SCT setpoint (in this example, 90°F (32.2°C) which may be

utilized to limit the maximum control setpoint, regardless of the ambient

temperature value or TD parameter.

10.5.2.2

Condenser Specific Efficiency

All newly installed evaporative condensers and air-cooled

condensers with capacities greater than 150,000 Btuh (at the specific efficiency

rating conditions) shall meet the minimum specific efficiency requirements shown

in Table 10-2.

Table 10-2: Fan-powered Condensers – Minimum Specific Efficiency

Requirements

|

Condenser Type |

Minimum Specific Efficiency |

Rating Condition |

|

Evaporative-Cooled |

160

Btuh/Watt |

100°F Saturated Condensing

Temperature (SCT),

70°F Entering Wetbulb

Temperature |

|

Air-Cooled |

65 Btuh/Watt |

105°F Saturated Condensing

Temperature (SCT),

95°F Entering Drybulb

Temperature |

Condenser specific efficiency is defined as:

Condenser Specific Efficiency = Total Heat Rejection (THR)

Capacity / Input Power

The total heat rejection capacity is defined at the rating

conditions of 100°F Saturated Condensing Temperature (SCT) and 70°F outdoor

wetbulb temperature for evaporative condensers, and 105°F SCT and 95°F outdoor

drybulb temperature for air-cooled condensers. Input power is the electric

input power draw of the condenser fan motors (at full speed), plus the electric

input power of the spray pumps for evaporative condensers. The motor power is

the manufacturer’s published applied power for the subject equipment, which is

not necessarily equal to the motor nameplate rating. Power input for secondary

devices such as sump heaters shall not be included in the specific efficiency

calculation.

The data published in the condenser manufacturer’s published

rating for capacity and power shall be used to calculate specific efficiency.

For evaporative condensers, manufacturers typically provide nominal condenser

capacity, and tables of correction factors that are used to convert the nominal

condenser capacity to the capacity at various applied condensing temperatures

and wetbulb temperatures. Usually the manufacturer publishes two sets of

correction factors: one is a set of “heat rejection” capacity factors, while the

others are “evaporator ton” capacity factors. Only the “heat rejection” capacity

factors shall be used to calculate the condenser capacity at the efficiency

rating conditions for the purpose of determining compliance with this

section.

For air-cooled condensers, manufacturers typically provide

the capacity at a given temperature difference (TD) between SCT and drybulb

temperature. Manufacturers typically assume that air-cooled condenser

capacity is linearly proportional to TD; the catalog capacity at 20°F TD is

typically twice as much as at 10°F TD. The condenser capacity for

air-cooled condensers at a TD of 10°F shall be used to calculate efficiency. If

the capacity at 10°F TD is not provided, the capacity shall be scaled

linearly.

Depending on the type of condenser, the actual manufacturer’s

rated motor power may vary from motor nameplate in different ways. Air cooled

condensers with direct-drive OEM motors may use far greater input power than the

nominal motor horsepower would indicate. On the other hand, evaporative

condenser fans may have a degree of safety factor to allow for higher motor load

in cold weather conditions (vs. the 100°F SCT/70°F WBT specific efficiency

rating conditions). Thus, actual motor input power from the manufacturer must be

used for direct-drive air-cooled condensers. For evaporative condensers

and fluid coolers, the full load motor power, using the minimum allowable motor

efficiencies published in the Nonresidential Appendix NA3: Fan Motor

Efficiencies, is generally conservative but manufacturer’s applied power should

be used whenever possible to more accurately determine specific efficiency.

There are three exceptions to the condenser specific

efficiency requirements.

1.

If the store is located in Climate Zone 1 (the cool coastal region in northern

California).

2.

If an existing condenser is reused for an addition of alteration.

3.

If the condenser capacity is less than 150 MBH at the specific efficiency rating

conditions.

Example

10-13

Question

An

air-cooled condenser is being designed for a new supermarket. The refrigerant is

R-507. The condenser manufacturer’s catalogue states that the subject

condenser has a capacity of 500 MBH at 10°F TD between entering air and

saturated condensing temperatures with R-507 refrigerant. Elsewhere in the

catalog, it states that the condenser has ten ½ hp fan motors that draw 450

Watts each. Does this condenser meet the minimum efficiency requirements?

Answer

First,

the condenser capacity must be calculated at the specific efficiency rating

condition. From Table 10-6, we see that the rating conditions for an

air-cooled condenser are 95°F entering drybulb temperature and 105°F SCT. The

catalog capacity is at a 10°F temperature difference, which is deemed suitable

for calculating the specific efficiency (105°F SCT - 95°F entering Drybulb =

10°F TD). Input power is equal to the number of motors multiplied by the input

power per motor:

10

fan motors x 450 Watts = 4,500

Watts

fan motor

The

specific efficiency of the condenser is therefore:

500MBH

x 1,000 Btu/hr / 4,500Watts = 111Btu/hr/

Watts

4,500 Watts

This

condenser has a specific efficiency of 111 Btuh per Watt, which is higher than

the 65 Btuh per Watt minimum requirement. This condenser meets the minimum

specific efficiency requirements.

Example

10-14

Question

An

evaporative condenser is being designed for a new supermarket. The

manufacturer’s catalog provides a capacity of 2,000 MBH at standard conditions

of 105°F SCT and 78°F wetbulb temperature. The condenser manufacturer’s catalog

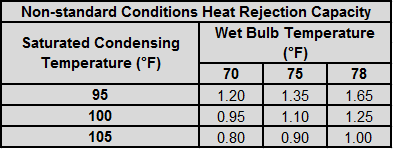

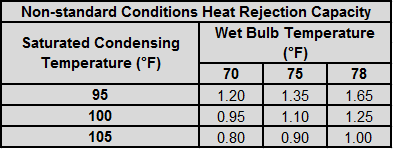

provides the following heat rejection capacity factors:

Elsewhere

in the catalog, it states that the condenser model has one 10 HP fan motor and

one 2 HP pump motor. Fan motor efficiencies and motor loading factors are

not provided by the manufacturer. Does this condenser meet the minimum

efficiency requirements?

Answer

First,

the condenser capacity must be calculated at the specific efficiency rating

condition. From Table 10-6, we see that the rating conditions for an

evaporative condenser are 100°F SCT, 70°F WBT and a minimum specific efficiency

requirement is 160 Btuh/Watt. From the Heat Rejection Capacity Factors

table, we see that the correction factor at 100°F SCT and 70°F WBT is

0.95. The capacity of this model at the specific efficiency rating

conditions is:

2,000

MBH / 0.95 = 2,105 MBH

To

calculate input power, we will assume 100% fan and pump motor loading and

minimum motor efficiencies since the manufacturer has not yet published actual

motor specific efficiency at the specific efficiency rating conditions. We

look up the minimum motor efficiency from Nonresidential Appendix NA3: Fan Motor

Efficiencies. For a 10 HP 6-pole open fan motor, the minimum efficiency is

91.7%. For a 2 HP 6-pole open pump motor, the minimum efficiency is 88.5%.

The fan motor input power is calculated to be:

1

Motor x 10 HP x 746 Watts x 100% assumed loading = 8,135

Watts

Motor

HP 91.7%

efficiency

The

pump motor input power is calculated to be:

1

Motor x 2 HP x 746 Watts x 100% assumed loading = 1,686

Watts

Motor

HP 88.5%

efficiency

The

combined input power is therefore:

8,135

Watts + 1,686 Watts = 9,821 Watts

Note:

Actual motor power should be used when available (see note in text).

Finally,

the efficiency of the condenser is:

(2,105

MBH x 1,000 Btuh) / 9,821 Watts = 214

Btuh/Watt

MBH

214

Btuh per Watt is higher than the 160 Btuh per Watt requirement; this condenser

meets the minimum efficiency requirements.

Air-cooled condensers shall have a fin density no greater

than 10 fins per inch. Condensers with higher fin densities have a higher risk

of fouling with airborne debris. This requirement does not apply for air-cooled

condensers that utilize a micro-channel heat exchange surface, since this type

of surface is not as susceptible to permanent fouling in the same manner as

traditional tube-and-fin condensers with tight fin spacing.

The fin spacing requirement does not apply to condensers that

are reused for an addition or alteration.

10.5.3

Compressor System Mandatory Requirements

This section addresses mandatory requirements for remote

compressor systems and condensing units used for refrigeration. In addition to

the requirements described below, all the compressors and all associated

components must be designed to operate at a minimum condensing temperature of

70°F (21°C) or less.

10.5.3.1

Floating Suction Pressure Controls

Compressors and multiple-compressor suction groups must have

floating suction pressure control to reset the saturated suction pressure

control setpoint based on the temperature requirements of the attached

refrigeration display cases or walk-ins.

Exceptions to the floating suction pressure requirements

are:

1.

Single compressor systems that do not have continuously variable capacity

capability

2.

Suction groups that have a design saturated suction temperature of 30°F or

higher

3.

Suction groups that comprise the high side of a two-stage or cascade system

4.

Suction groups that primarily serve chillers for secondary cooling fluids

5.

Existing compressor systems that are reused for an addition or alteration.

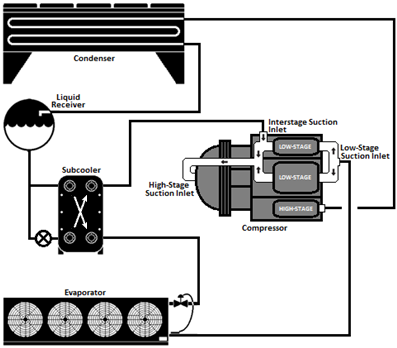

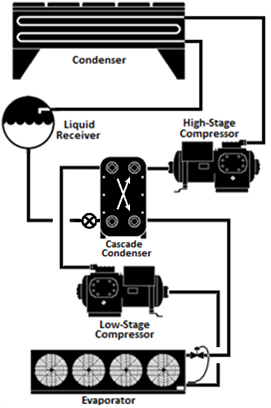

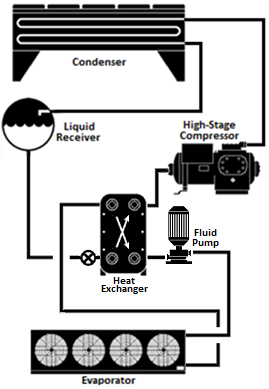

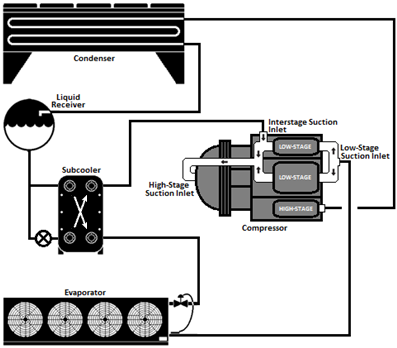

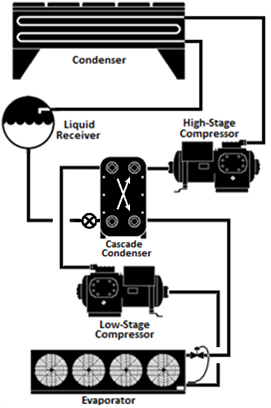

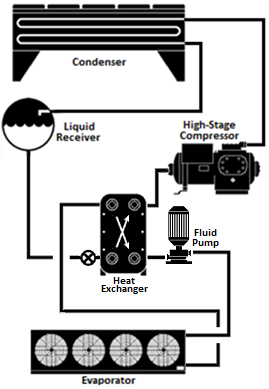

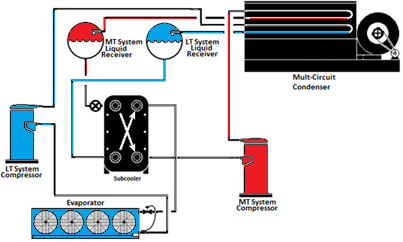

The examples of a two-stage system and a cascade system are

shown in Figure

10-7 and Figure

10-8, respectively. Figure

10-9 shows a secondary fluid system.

Figure 10-7: Two-stage System using a Two-Stage Compressor

Figure 10-8: Cascade System

Figure 10-9: Secondary Fluid System

Example 10-15

Question

A retail food store has four suction groups, A, B1, B2 and

C, with design saturated suction temperatures (SST) of -22°F, -13°F, 28°F and

35°F, respectively. System A is a condensing unit. The compressor in the

condensing unit is equipped with two unloaders. Suction group B1 consists

of a single compressor with no variable capacity capability. Suction group B2

has four compressors with no variable capacity capability and suction group C

has three compressors with no variable capacity capability. Which of these

suction groups are required to have floating suction pressure control?

Answer

Suction Groups A and B2 are required to have floating

suction pressure control. The rationale is explained below.

Suction group A: Although the suction group has only one

compressor, the compressor has variable capacity capability in the form of

unloaders. Therefore, the suction group is required to have floating

suction pressure control.

Suction group B1: The suction group has only one compressor

with no variable capacity capability. Therefore, the suction group is not

required to have floating suction pressure control.

Suction group B2: Although the suction group has

compressors with no variable capacity capability, the suction group has multiple

compressors which can be sequenced to provide variable capacity

capability. Therefore, the suction group is required to have floating

suction pressure control.

Suction group C: The design SST of the suction group is

higher than 30°F. Therefore, the suction group is not required to have floating

suction pressure control.

Example 10-16

Question

A retail food store has two suction groups, a low

temperature suction group A (-22°F design SST) and medium temperature suction

group B (18°F design SST). Suction group A consists of three compressors.

Suction group B has four compressors that serve a glycol chiller working at

23°F. Which of these suction groups are required to have floating suction

pressure control?

Answer

Suction group A: The suction group has multiple

compressors. Therefore, the suction group is required to have floating suction

pressure control.

Suction group B: Although the suction group has multiple

compressors, it serves a chiller for secondary cooling fluid (glycol).

Therefore, the suction group is not required to have floating suction pressure

control.

Example 10-17

Question

A retail food store is undergoing an expansion and has two

refrigeration systems: an existing system and a new CO2 cascade

system. The existing system consists of four compressors and a design SST of

18°F. The cascade refrigeration system consists of four low temperature

compressors operating at -20°F SST and three medium temperature compressors

operating at 26°F SST. Which of these systems are required to have floating

suction pressure control?

Answer

Existing system: Although the system has multiple

compressors, the compressor system is being reused, and the existing rack

controller and sensors may not support floating suction pressure control.

Therefore, the system is not required to have floating suction pressure

control.

Cascade system: Only low

temperature suction group of the system is required to have floating suction

pressure control.

Evaporator coils are sized to maintain a design fixture

temperature under design load conditions. Design loads are high enough to

cover the highest expected load throughout the year, and inherently include

safety factors. The actual load on evaporator coils varies throughout the day,

month and year, and an evaporator coil operating at the design saturated

evaporating temperature (SET) has excess capacity at most times. The SET can be

safely raised during these times, reducing evaporator capacity and reducing the

required “lift” of the suction group, saving energy at the compressor while

maintaining proper fixture (and product) temperature.

In a floating suction pressure control strategy, the suction

group target saturated suction pressure (SST) setpoint is allowed to vary

depending on the actual requirements of the attached loads, rather than fixing

the SST setpoint low enough to satisfy the highest expected yearly load. The

target setpoint is adjusted so that it is just low enough to satisfy lowest

current SET requirement of any attached refrigeration load while still

maintaining target fixture temperatures, but not any higher. The controls

are typically bound by low and high setpoints limits. The maximum float value

should be established by the system designer, but a minimum value equal to the

design SST (that is no negative float) and a positive float range of 4-6°F of

saturation pressure equivalent have been used successfully.

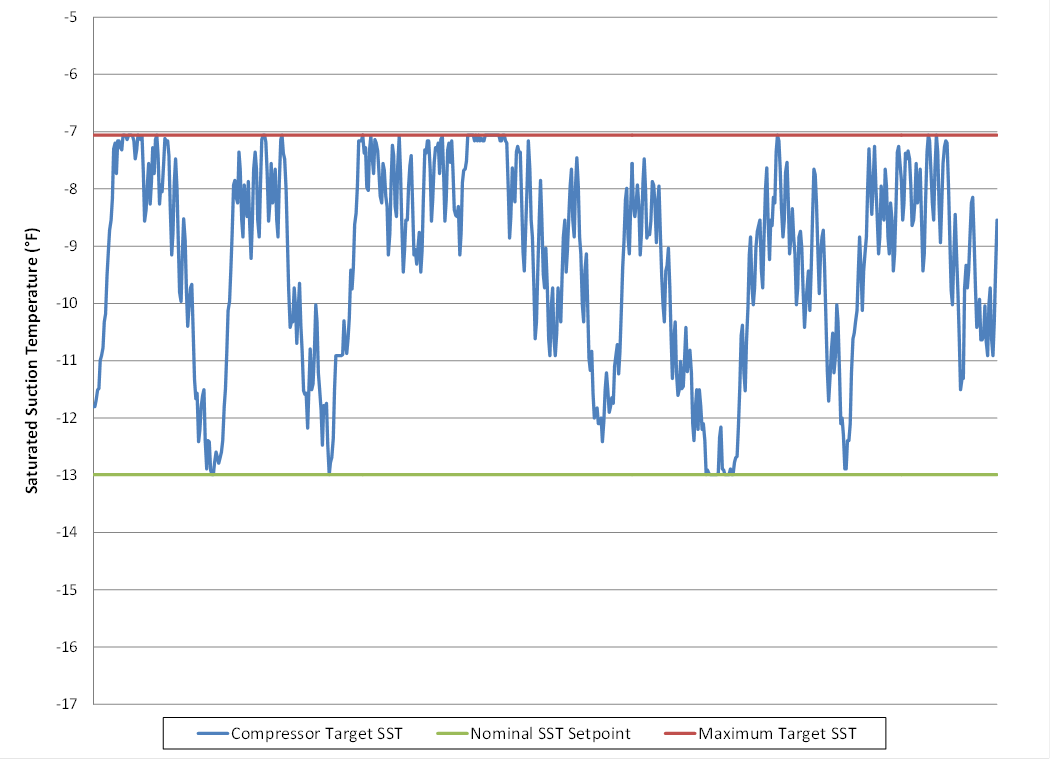

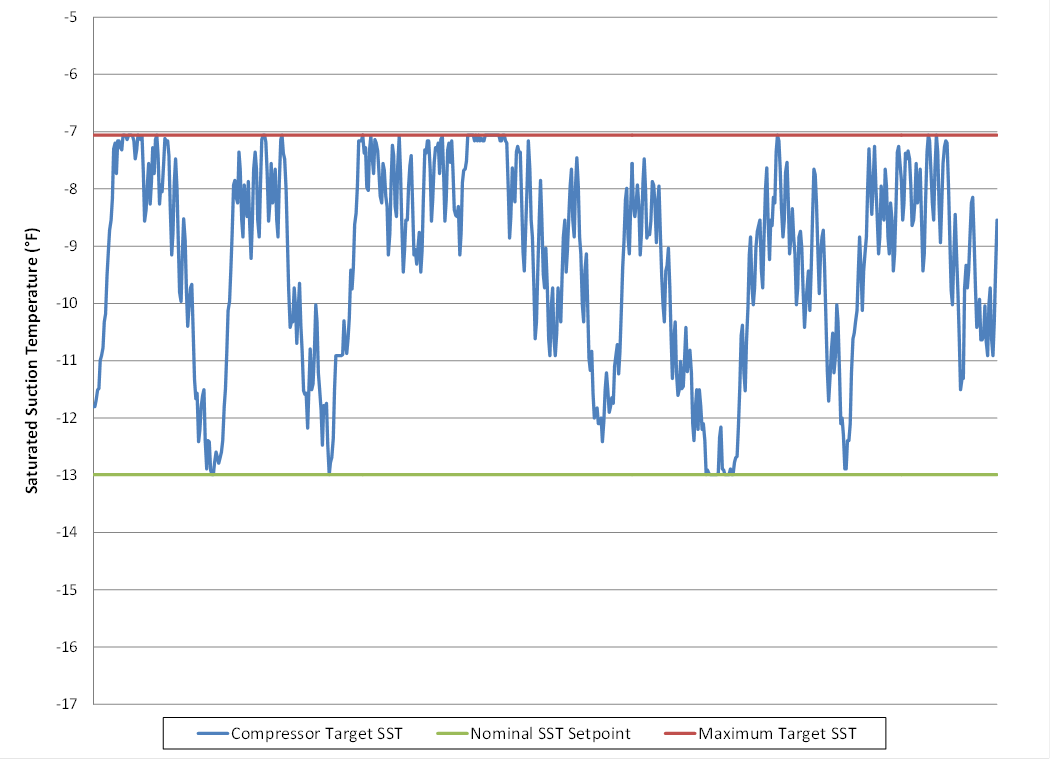

Figure 10-10 shows hourly values for floating suction

pressure control over a one week period, expressed in equivalent saturation

temperature. The suction pressure control setpoint is adjusted to meet the

temperature setpoint at the most demanding fixture or walk-in. The difference in

SST between the floating suction pressure control and fixed suction pressure

control translates into reduced compressor work and thus energy savings for the

floating suction control.

Figure 10-10: Example of Floating Suction Pressure Control

A. Floating Suction

Pressure Control with Mechanical Evaporator Pressure Regulators

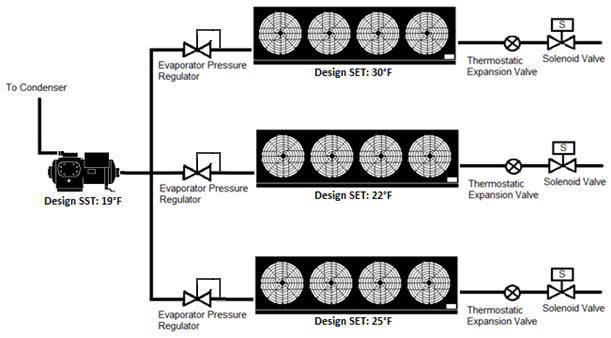

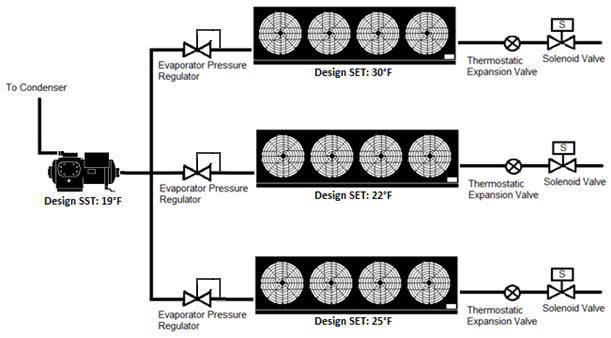

Mechanical evaporator pressure regulators (EPR valves) are

often used on multiplex systems to maintain temperature by regulating the SET at

each multiple evaporator connected to the common suction group, and often to

also function as a suction-stop valve during defrost. EPR valves throttle to

maintain the pressure at the valve inlet and thus indirectly control the

temperature at the case or walk-in. The valves are manually adjusted to the

pressure necessary to provide the desired fixture or walk-in air temperature.

The load (circuit) with the lowest EPR pressure governs the required compressor

suction pressure setpoint.

Floating suction pressure on a system with EPR valves

requires special attention to valve settings on the circuit(s) used for floating

suction pressure control. EPR valves on these circuit(s) must be adjusted

“out of range”, meaning the EPR pressure must be set lower than what would

otherwise be used to maintain temperature. This keeps the EPR valve from

interfering with the floating suction control logic. In some control systems,

two circuits are used to govern floating suction control; commonly designated as

primary and secondary float circuits. EPR valves may also be equipped with

electrically controlled wide-open solenoid pilots for more fully automatic

control if desired.

Similar logic is applied on systems using on/off liquid line

solenoid valves (LLSV) for temperature control, with the control of the solenoid

adjusted slightly out of range to avoid interference with floating suction

pressure.

These procedures have been employed to float suction on

supermarket control systems since the mid-80’s, however careful attention is

still required during design, start-up and commissioning to insure control is

effectively coordinated.

Figure 10-11: Evaporators with Evaporative Pressure Regulator Valves

B.

Floating Suction Pressure Control with Electronic Suction Regulators

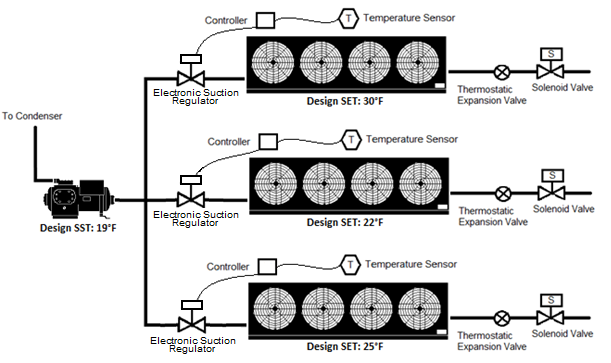

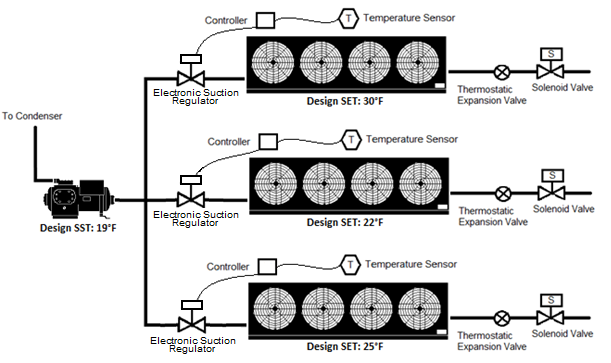

An electronic suction regulator (ESR) valve is an

electronically controlled valve used in the place of a mechanical evaporator

pressure regulator valve. ESRs are known in industry as electronic suction

regulator (ESR) or electronic evaporator pressure regulator (EEPR). It is

important to note that ESR valves are not pressure regulators; instead they

control the flow through the evaporator based on a setpoint air temperature at

the case or walk-in. ESR valves are modulated to maintain precise temperature.

This provides more accurate temperature compared to an EPR which controls

temperature indirectly through pressure and is subject to pressure drop in

piping and heat load (and thus TD) on the evaporator coil.

Floating suction pressure strategies with ESR valves vary

depending on the controls manufacturer, but will generally allow for more

flexibility than systems with EPR valves. In general, the control system

monitors how much each ESR valve is opened. If an ESR is fully open, indicating

that the evaporator connected to the ESR requires more capacity, the control

system will respond by decrementing the SST setpoint. If all ESR valves are less

than fully open, the control system increments the suction pressure up until an

ESR valve fully opens. At this point, the control system starts floating down

the suction pressure again. This allows suction pressure to be no lower than

necessary for the most demanding fixture.

Figure 10-12 shows multiple evaporators controlled by ESR

valves connected to a common suction group.

Figure 10-12: DX Evaporators with ESRs on a Multiplex System

10.5.3.2

Liquid Subcooling

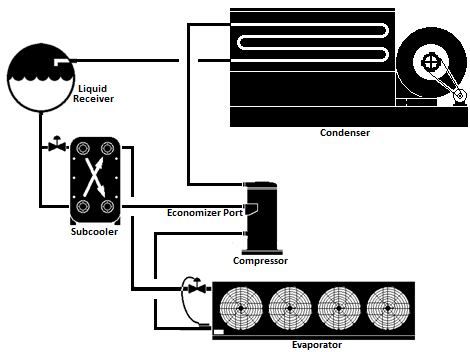

Liquid subcooling must be provided for all low temperature

compressor systems with a design cooling capacity of 100,000 Btuh or greater and

with a design saturated suction temperature of -10°F or lower. The

subcooled liquid temperature of 50°F or less must be maintained continuously at

the exit of the subcooler. Subcooling load may be handled by compressor

economizer ports, or by using a suction group operating at a saturated suction

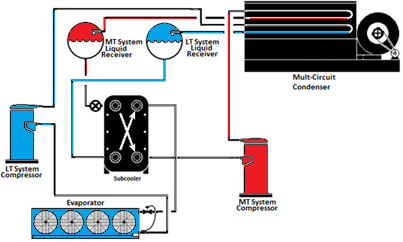

temperature of 18°F or higher. Figure

10-13 and Figure

10-14 show example subcooling configurations.

Exceptions to the liquid subcooling requirements are:

1.

Low temperature cascade systems that condense into another refrigeration system

rather than condensing to ambient temperature.

2.

Existing compressor systems that are reused for an addition or

alteration.

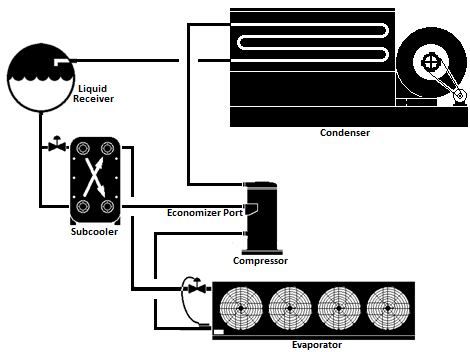

Figure 10-13: Liquid Subcooling Provided by Scroll Compressor Economizer

Ports

Figure 10-14: Liquid Subcooling Provided By a Separate Medium-Temperature

System

10.5.4

Refrigerated Display Case Lighting Control Requirements

All lighting in refrigerated display cases, and lights

installed on glass doors of walk-in coolers and freezers shall be controlled by

either automatic time switch controls and/or motion sensor control.

A. Automatic Time

Switch Control

Automatic time switch controls shall turn off the lights

during non-business hours.

Timed overrides for a display case line-up or walk-in case

may be used to turn on the lights for stocking or non-standard business hours.

The override must time-out and automatically turn the lights off again in one

hour or less. The override control may be enabled manually (e.g. a push button

input to the control system) or may be scheduled by the lighting control or

energy management system.

B.

Motion Sensor

Motion sensor control can be used to meet this requirement by

either dimming or turning off the display case lights when space near the case

is vacated. The lighting must dim so that the lighting power reduces to 50% or

less. The maximum time delay for the motion sensor must be 30 minutes or

less.

10.5.5

Refrigeration Heat Recovery

This section addresses mandatory requirements for the use of

heat recovery from refrigeration system(s) to HVAC system(s) for space heating

and the charge limitations when implementing heat recovery, including an

overview of configurations and design considerations for heat recovery systems.

Heat rejected from a refrigeration system is the total of the cooling load taken

from display cases and walk-ins in the store plus the electric energy used by

the refrigeration compressors. Consequently, there is a natural relationship

between the heat available and the heating needed; a store with greater

refrigeration loads needs more heat to make up for the cases and walk-ins and

also has more heat available.

The heat recovery requirements apply only to space

heating.

There are many possible heat recovery design configurations

due to the variety of refrigeration systems, HVAC systems and potential

arrangement and locations of these systems. A number of examples are

presented here but the Energy Standards do not require these configurations to

be used. The heat recovery design must be consistent with the other requirements

in the Energy Standards such as condenser floating head pressure.

At least 25 percent of the sum of the design Total Heat of

Rejection (THR) of all refrigeration systems with individual design Total Heat

of Rejection of 150,000 Btu/h or greater must be utilized for space heat

recovery.

Exceptions to the above requirements for heat recovery

are:

1.

Stores located in Climate Zone 15, which is the area around Palm Springs,

California. Weather and climate data are available in Joint Appendix

JA2 – Reference Weather/Climate Data

2.

The above requirements for heat recovery do not apply to the HVAC and

refrigeration systems that are reused for an addition or alteration

The Energy Standards also limit the increase in

hydrofluorocarbon (HFC) refrigerant charge associated with refrigeration heat

recovery. The increase in HFC refrigerant charge associated with

refrigeration heat recovery equipment and piping must not be greater than 0.35

lbs. per 1,000 Btuh of heat recovery heating capacity.

Example

10-18

Question

A

store has three new distributed refrigeration systems, A, B and C, with design

Total Heat of Rejection (THR) of 140,000 Btuh, 230,000 Btu/h and 410,000 Btuh,

respectively. What is the minimum required amount of refrigeration heat

recovery?

Answer

Refrigeration

systems B and C have individual design THR of greater than 150,000 Btu/h,

whereas refrigeration system A has design THR of less than 150,000 Btuh.

Therefore, the store must have the minimum refrigeration heat recovery equal to

25% of the sum of THR of refrigeration systems B and C only. The minimum

required heat recovery is therefore:

25% x (230,000 Btuh + 410,000

Btuh) = 160,000 Btuh

Example

10-19

Question

How

should the Total Heat of Rejection be calculated for the purpose of this

Section?

Answer

The

THR value is equal to the total compressor capacity plus the compressor heat of

compression.

Example

10-20

Question

A

35,000 ft2 food store is undergoing an expansion to add 20,000 square feet area.

The store refrigeration designer plans to use two existing refrigeration systems

with 600,000 Btu/h of design total heat rejection capacity and add a new

refrigeration system with a design total heat rejection capacity of 320,000

Btu/h. The store mechanical engineer plans on replacing all the existing HVAC

units. Is the store required to have refrigeration heat recovery for space

heating?

Answer

Yes.

The store must have the minimum required refrigeration heat recovery from the

new refrigeration system. The new refrigeration system has a design THR of

greater than 150,000 Btu/h threshold. The minimum amount of the refrigeration

heat recovery is 25% of the new system THR. The existing refrigeration systems

are not required to have the refrigeration heat recovery.

10.5.5.1

Refrigeration Heat Recovery Design Configurations

The designer of heat recovery systems must consider the

arrangement of piping, valves, coils, and heat exchangers as applicable to

comply with the Energy Standards. Numerous refrigeration heat recovery systems

configurations are possible depending upon the refrigeration system type, HVAC

system type and the store size. Some possible configurations are:

1.

Direct heat recovery

2.

Indirect heat recovery

3.

Water loop heat pump system

These configurations are described in more detail with the

following sections.

A. Direct Heat

Recovery

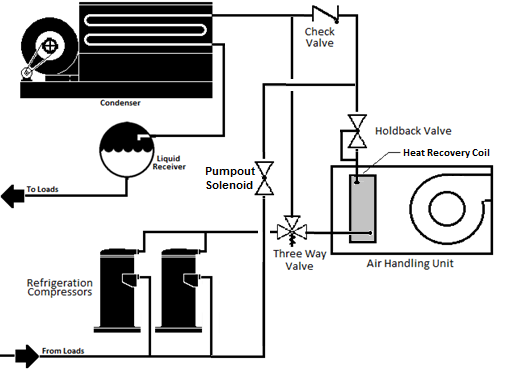

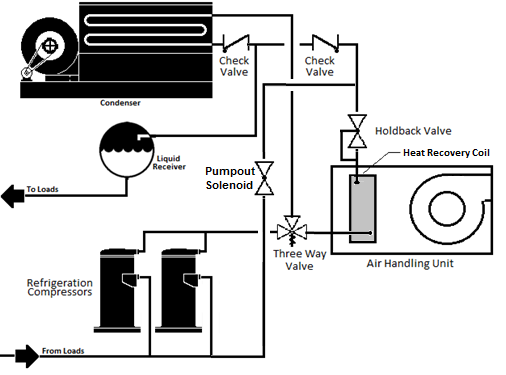

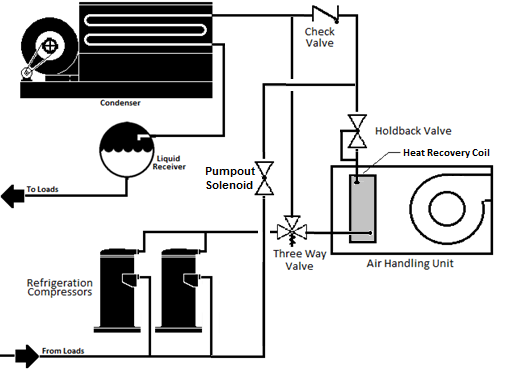

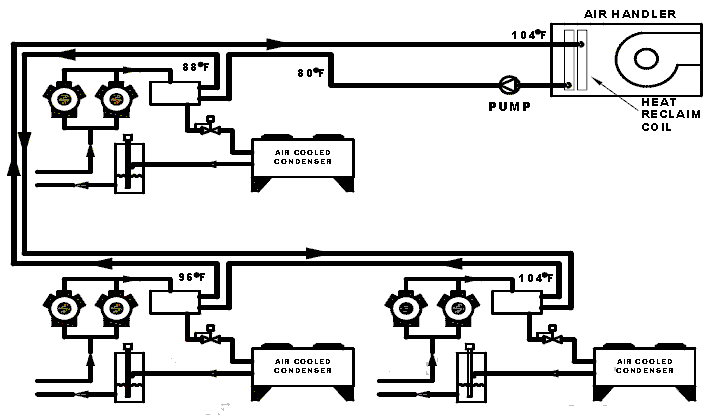

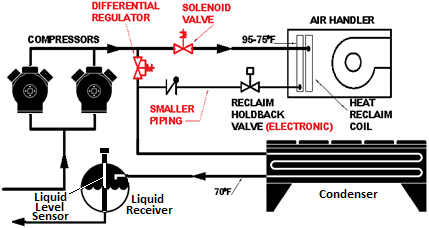

Figure 10-15 shows a series-connected direct condensing heat

recovery configuration. In this configuration, the heat recovery coil is

placed directly within the HVAC unit airstream (generally the unit serving the

main sales area), and the discharge refrigerant vapor from the compressors is

routed through the recovery coil and then to the outdoor refrigerant condenser

when in heating mode. If two or more refrigeration systems are used for heat

recovery, a multi-circuit heat recovery coil could be used.

This configuration is very suitable when the compressor racks

are close to the air handling units used for heat recovery. If the

distance is too far, an alternative design should be considered; the long piping

runs may result in a refrigerant charge increase that exceeds the maximum

defined in the Energy Standards, or there may be excessive pressure losses in

the piping that could negatively affect compressor energy.

Figure 10-15: Series Direct Heat Recovery Configuration

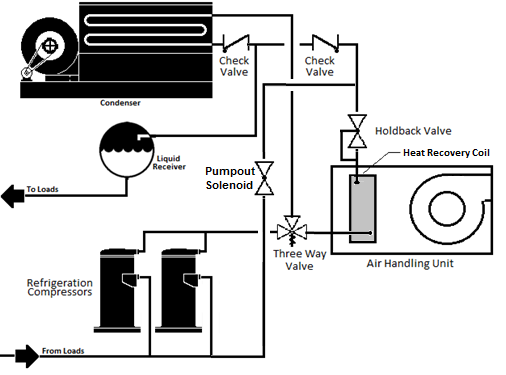

Figure 10-16 shows a parallel-connected

direct-condensing configuration. In this configuration, the heat recovery coil

handles the entire condensing load for the connected refrigeration system(s)

when the air handling unit is in heating mode. Reduced refrigerant charge

is the primary advantage of this configuration. Since the unused condenser

(either the heat recovery condenser or the outdoor condenser) can be pumped out,

there is no increase in refrigerant charge. A high degree of design expertise is

required with this configuration in that the heat recovery condenser and

associated HVAC system must take the entire heating load while operating at

reasonable condensing temperatures—in any event, no higher than the system

design SCT and in most instances with reasonable design no higher than

95°F-100°F condensing temperature in the heat recovery condenser. Ducting with

under case or low return air design is essential in this type of system, in

order to obtain cooler entering air and maintain reasonable condensing

temperatures. Provision is required for practical factors such as dirty air

filters.

Since the main condenser is not in use during heat recovery,

the condenser floating head pressure requirements do not apply.

Figure 10-16: Parallel Direct Condensing Heat Recovery Configuration

B.

Indirect Heat Recovery

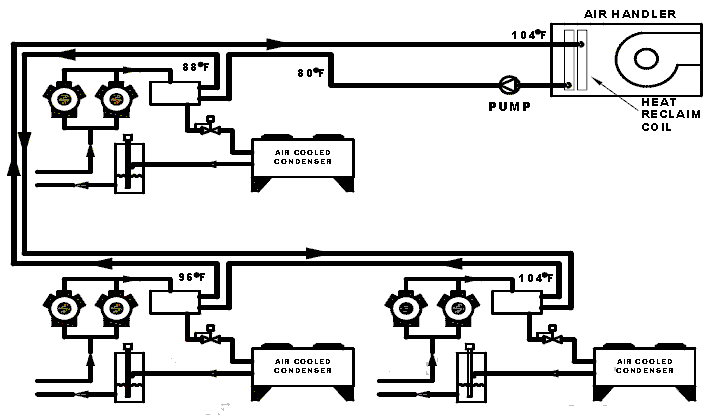

Figure 10-17 shows an indirect heat recovery configuration

with a fluid loop. In this configuration, the recovered heat is transferred from

the refrigerant to an intermediate fluid, normally water or water-glycol, which

is circulated through a fluid-to-air heat exchanger located in the air handling

unit airstream. Like the direct condensing configuration, discharge refrigerant

gas from the compressors is routed through the refrigerant-to-fluid heat

exchanger and then to the outdoor refrigerant condenser when in heating

mode.

The refrigerant-to-fluid heat exchanger can be located close

to the refrigeration system compressors, maximizing the available heat for

recover while keeping the overall refrigerant charge increase low. This

configuration is also suitable when multiple HVAC units are employed for the

refrigeration heat recovery. Indirect systems must utilize a circulation pump to

circulate the fluid between the HVAC unit and the recovery heat

exchanger.

Figure 10-17: Indirect Heat Recovery with an Indirect Loop

Multiple refrigeration systems can also be connected in

parallel or in series, using a common indirect fluid loop. Figure 10-18 shows

three refrigeration systems connected in series by a common fluid loop. The

temperatures shown are only examples.

Figure 10-18: Series-Piped Indirect Water Recovery

This configuration allows the refrigerant-to-water condenser

temperature difference (TD) to be kept low at each refrigeration system (e.g.

8°-10°F is possible) while maintaining a sufficiently high water-side TD at the

air handling unit (e.g. 20°-25°F depending on specifics) to allow an effective

selection of the water-to-air heating coil vs. the available airflow. This

method also minimizes both the required fluid flow and pump power.

C.

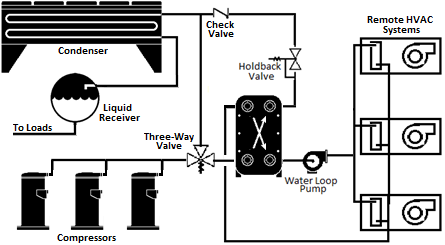

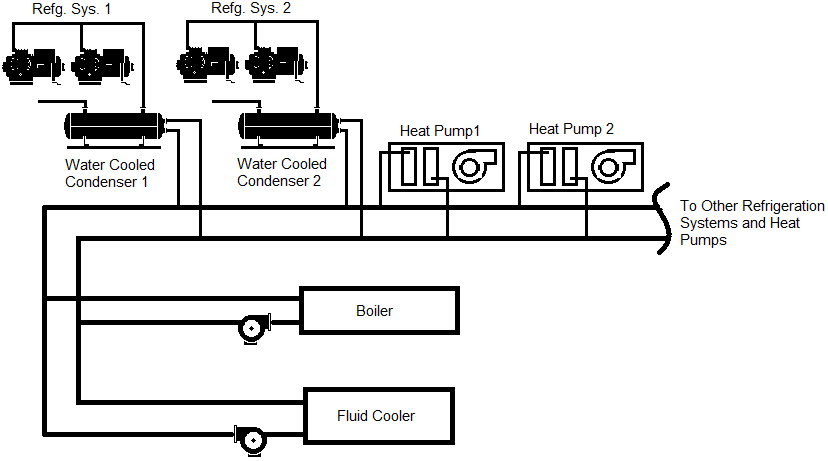

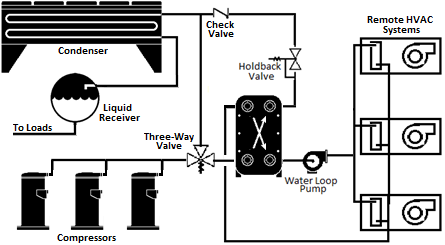

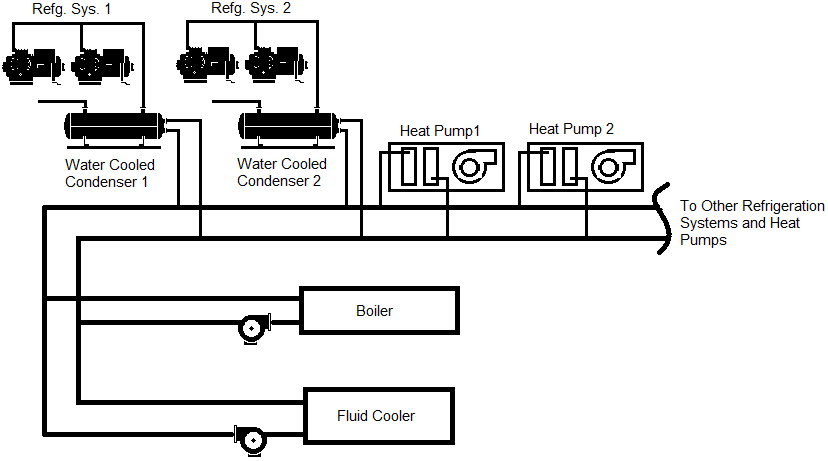

Water Loop Heat Pump Heat Recovery

Water-source heat pumps (WLHP) can be used for in conjunction

with water cooled refrigeration systems, connected to a common water loop as

shown in Figure 10-19. Refrigeration systems heat pumps serving various zones of

the store reject heat into a water loop, which in turn is rejected to ambient by

an evaporative fluid cooler. When the heat pumps are in heating mode, they

extract the heat rejected by the refrigeration systems from the water loop.

Additional heat, if required, is provided by a boiler connected to the water

loop. A significant advantage of this design is low refrigerant charge, since

the refrigeration systems use a compact water-cooled condenser, typically with

less charge than an air-cooled condenser and no heat recovery condenser is

required. Compared with other methods, however, the electric penalty is somewhat

higher to utilize the available heat.

The floating pressure requirements in the standard would

apply to the fluid coolers, i.e. controls to allow refrigeration systems to

float to 70°F SCT and use of wetbulb following control logic.

Figure 10-19: Water Loop Heat Pump Example

10.5.5.2

Control Considerations

A. Holdback

Considerations

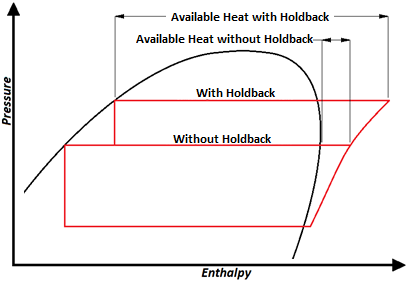

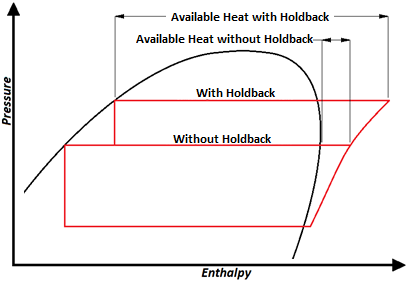

For direct and indirect systems, a holdback valve is required

to control the refrigerant condensing temperature in the heat recovery coil (for

direct systems) or the refrigerant-to-water condenser (for indirect systems)

during heat recovery operation. Regulating the refrigerant pressure to achieve

condensing recovers the latent heat from the refrigerant. Without condensing,

only the sensible heat (i.e. superheat) is obtained, which is only a small

fraction of the available heat. Figure 10-20 is a pressure-enthalpy diagram

showing the difference in available recovery heat from a refrigeration system

with and without a holdback valve.

Figure 10-20: Pressure-Enthalpy Diagram with and without a Holdback

Valve

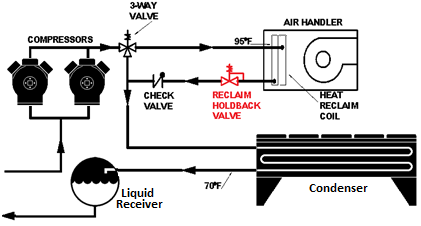

The holdback valve regulates pressure at its inlet, and is

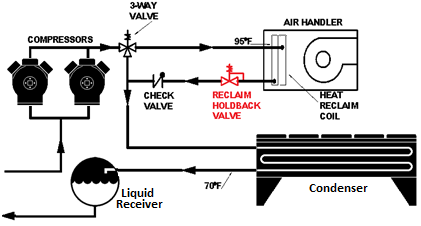

located at the exit of the recovery heat exchanger. Figure 10-21 shows a

direct-condensing configuration with the proper location of the holdback

valve.

Figure 10-21: Direct-condensing configuration showing location of holdback

valve

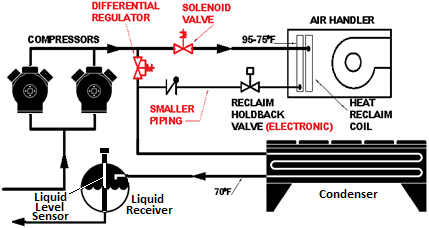

A more advanced

design uses an electronic holdback valve controlled based on the temperature of

the air entering the heat recovery coil. The electronic heat recovery holdback

valve controls the valve inlet pressure and thus the heat recovery coil

condensing temperature to maintain only the pressure necessary to achieve the

required condensing TD (heat recovery SCT less entering air temperature) thereby

minimizing compressor efficiency penalty. This is particularly useful when

the volume outside air can significantly change the mixed air temperature

entering the heat recovery coil. In colder climates, reducing the heat recovery

holdback pressure can be important as a means to avoid over-condensing (i.e.

subcooling). As shown in the pressure-enthalpy diagram above, there is

additional flash gas handled by the condenser (even if the refrigerant fully

condenses in the heat recovery coil) which is necessary to maintain piping and

condenser velocity and thus minimize the charge in the outdoor condenser.

Other designs can replace the three-way valve with a

differential pressure regulator and solenoid valve. Figure 10-21 shows a

direct-condensing configuration with an electronic heat recovery holdback valve,

solenoid valve, and differential pressure regulator.

Figure 10-22: Direct-condensing configuration showing differential

regulator, solenoid valve, electronic holdback valve

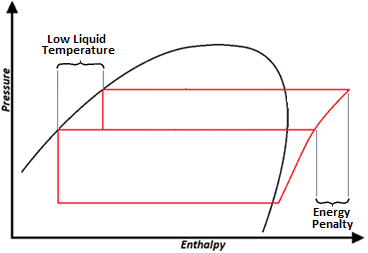

B. Heat Recovery

and Floating Head Pressure

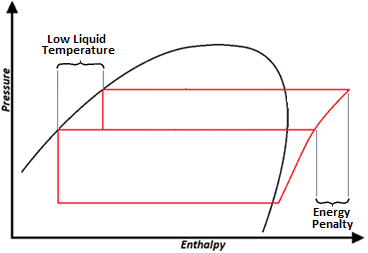

There is typically a tradeoff between heat recovery and

refrigeration system efficiency, in that compressor discharge pressure must be

increased to provide condensing for heat recovery. If implemented

properly, the electric penalty at the refrigeration system compressors is small

compared to the heating energy savings.

The Standards require that the minimum condensing temperature

at the refrigeration condenser shall be 70°F or less. That means that (in

the typical case of series-connected heat recovery) the refrigeration “cycle”

still benefits from lower refrigerant liquid temperature, even if the compressor

power is somewhat increased during heat recovery. The pressure-enthalpy diagram

shown in Figure 10-22 shows the incremental energy penalty at the

refrigeration compressors due to the higher discharge pressure required for heat

recovery, as well as the lower liquid temperature (and thus improved refrigerant

cooling capacity) by floating head pressure at the outdoor condenser.

Figure 10-23: Pressure-enthalpy diagram for heat recovery

10.5.5.3

Recovery Coil Design Considerations

A. Recovery Coil

Sizing Example

Selecting an appropriately-sized heat recovery coil is

essential to proper heat recovery system operation. The following example

details the process of selecting a right-sized heat recovery coil.

Example

10-21

Question

A

supermarket is being constructed that will utilize heat recovery. The

refrigeration system selected for recovery has the following parameters:

Design

Refrigeration Load: 455.8 MBH

System

design SST: 24°F

Representative

Compressor Capacity at Design Conditions: 54.2 MBH

Representative

Compressor Power at Design Conditions: 5.59 kW

The

HVAC system serving the supermarket sales area is a central air handling unit.

Heat recovery will be accomplished with a direct-condensing recovery coil inside

the air handling unit, downstream of both the return air duct and the outside

air damper. The air handling unit has the following design parameters:

Design

Air Volume: 25,000 cfm

Design

Coil Face Area: 41.7 sq.ft.

To

avoid excessive pressure drop across the recovery coil, the designer will select

a coil with a fin density of 10 fins per inch. The heat recovery circuit will

use a holdback valve set at 95°F SCT.

What

is the procedure for selecting a heat recovery coil?

Answer

To

size a heat recovery system, the designer should first establish a design

recovery coil capacity by analyzing the refrigeration system from which heat

will be recovered. Best practice dictates that the recovery system should be

sized to recovery most of the available system total heat of rejection at

typical operating conditions, not peak conditions. Since we are designing for

average operating conditions, the designer assumes the average refrigeration

load is 70% of the design load. Therefore, the average system THR for heating

design is:

Average

System THR = 70% x Design Refrigeration Load x THR Adjustment Factor

where:

THR

Adjustments Factor = Representative Compressor

THR

Representative Compressor Capacity

and:

Rep.

Compressor THR = Rep. Compressor Capacity + Rep. Compressor Heat of

Compression

Using

values from the example:

Representative Compressor THR = 54.2MBH + (5.50

kW x 3.415

MBH)

kW

Representative Compressor THR = 73.3 MBH

Therefore,

THR

Adjustment Factor = 73.3

MBH

54.2 MBH

THR Adjustment Factor = 1.35

Using

the values in this example and the calculated THR Adjustment Factor, the average

system THR is:

Average

system THR = 70% x 455.8 MBH x1.35

Average

system THR = 430.1 MBH

It

is important to note that the recovery system will not be capable of extracting

100% of the total heat of rejection since the condenser operates at a lower

pressure and will reject additional heat, even if the heat recovery coil

achieves full condensing. In addition, the heat recovery coil performance may

often be limited by the available airflow across the coil and the consequent

temperature rise vs. the heat being transferred. This performance is determined

through evaluation of coil performance, considering entering air temperature,

and condensing temperature, as well as the coil design (e.g. rows, fins, air

velocity and other factors). Airside pressure drop can be minimized by using a

larger face area, requiring lower face velocity and fewer rows.

For

in this example, it was assumed that after evaluating coil performance, 85% of

the average THR could be recovered with a reasonable coil velocity and coil

depth.

Available

Heat for Reclaim = 85% x Average System THR

Available

Heat for Reclaim = 85% x 430.1 MBH

Available

heat for Reclaim = 365.6 MBH

The

available heat for recovery is the design capacity of the recovery coil we will

select for our air handling unit.

Next,

the designer needs to know the face velocity of the airstream in the air

handling unit. The face velocity is:

F.V.

= Design cfm

AHU Face Area

F.V.

= 25,000

cfm

41.7 ft2

F.V.

= 600 ft/min

Finally,

the designer needs to know the temperature difference between the condensing

temperature (inside the recovery coil) and the temperature of the air entering

the recovery coil. Since the coil will be installed in an air handling unit

downstream of the outside air damper, the designer assumes that the air entering

the coil is a mix of return air from the store and outside air. The designer

must determine an appropriate design temperature for the air entering the

recovery coil (Entering Air Temperature or EAT) during average heating hours,

which is this instance was determined to be 65°F. From the example, the heat

recovery system will have a holdback valve setting of 95°F SCT. Therefore, the

temperature difference is:

TD

= SCT – EAT

TD

= 95oF - 65 oF

TD

= 30 oF

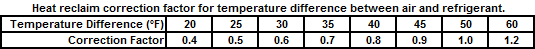

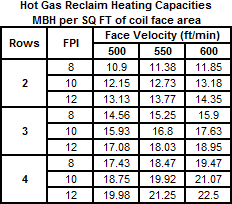

Using

the face velocity, design coil capacity, and temperature difference between

condensing temperature and entering air temperature, the designer then refers to

the air handling unit catalog to select a recovery coil. Then the designer uses

the following two tables:

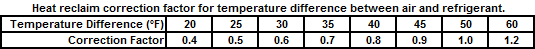

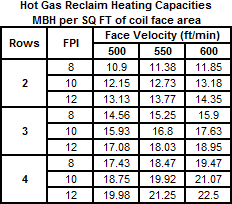

The

designer enters the first table with the calculated TD of 30°F, finding a

correction factor of 0.6. We enter the second table with the value:

MBH

per SQ FT = (Design Coil Capacity) / Correction

Factor

Coil Face Area

MBH

per SQ FT = (4184 MBH) /

0.6

41.7 ft2

MBH

per SQ FT = 16.72

Per

design requirements, the designer will select a 10 fin-per-inch coil. From the

second table, the designer selects the 3-row, 10 fin-per-inch coil for this

application.

More

commonly, computerized selection tools are used to select heat recovery coils,

allowing vendors to provide multiple selections for comparison.

B. Air-side

Integration Considerations

1.

Return Air Location

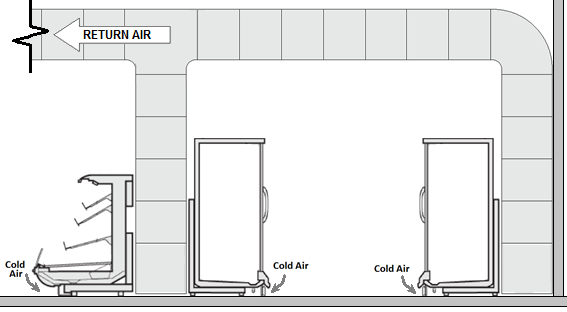

In supermarkets, ducting return air from behind display cases

or near the floor is beneficial in improving comfort by removing the stagnant

cool air that naturally occurs due to product refrigeration cases. This approach

also increases the effectiveness of refrigeration heat recovery by increasing

the temperature difference between the return air temperature and the

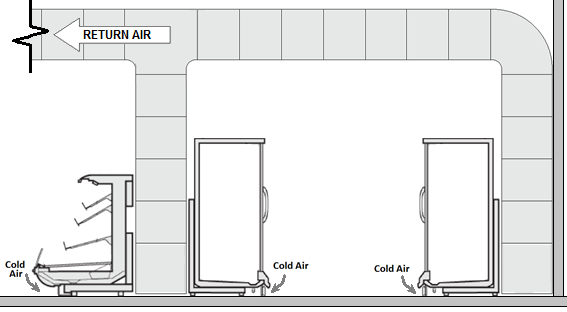

refrigerant condensing temperature in the heat recovery coil. Figure 10-23 shows

the location of an HVAC return air duct positioned to scavenge cool air from the

floor level near refrigerated display cases.

Figure 10-24: Low Return Air Example

2. Return Air

Duct Configuration

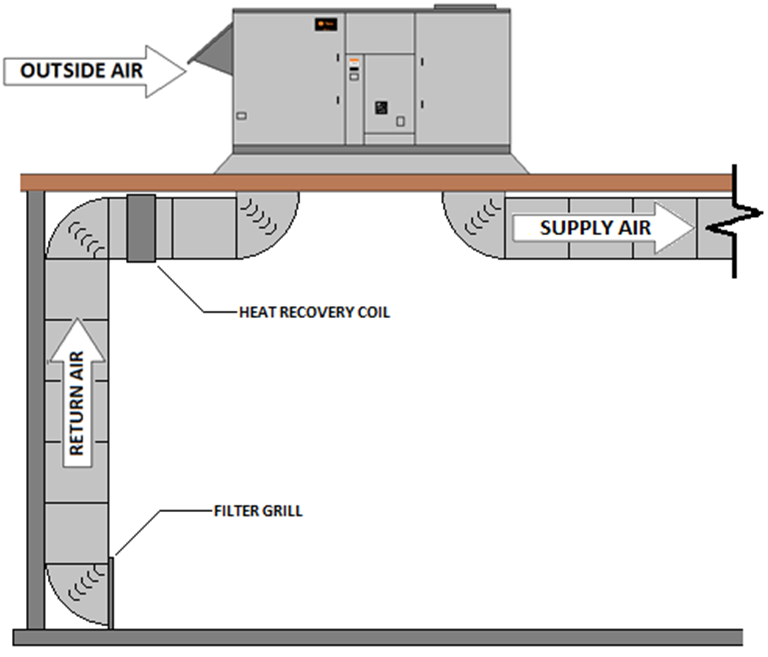

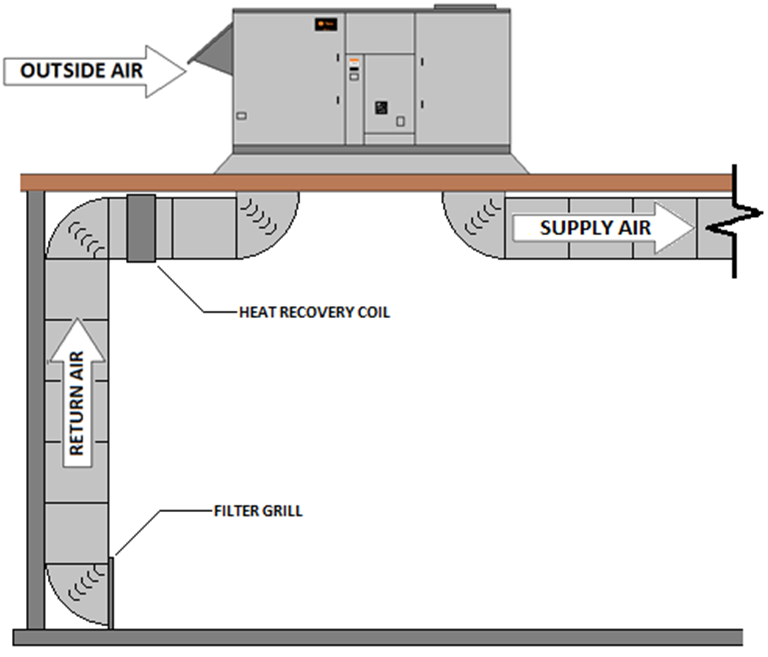

Heat recovery can be incorporated into rooftop HVAC units

(RTU) by installing the heat recovery coil inside the RTU cabinet or by

installing in the return air duct upstream of the RTU, as shown in Figure 10-25.

Location inside the RTU is preferable when outside air is a substantial part of

the heating load, but location in the return air duct is reasonable and can

provide greater flexibility in selecting the heat recovery coil (e.g. for low

face velocity and pressure drop), particularly when coupled with low return air

on units located in the refrigerated space, which predominantly provide heating.

The fan design must allow for the additional ductwork and coil pressure

drop.

Figure 10-25: Heat Recovery Coil in Return Air Duct

3. Transfer

Fan Configuration

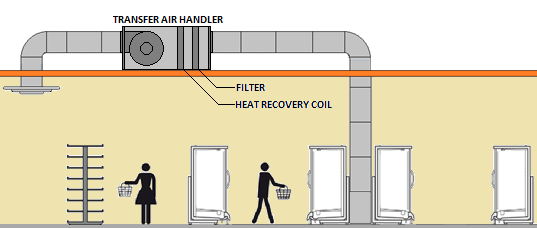

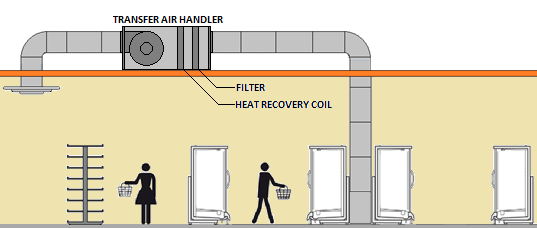

A ducted transfer system is sometimes employed to remove cold

air from aisles with refrigerated display cases (rather than blowing warm air

into the refrigerated areas) and can be an easy and appropriate way to utilize

heat recovery, particularly from smaller distributed systems. Figure 10- 25

depicts a ducted transfer system.

Figure 10-26: Ducted Transfer System

4.

Calculating Charge Increase

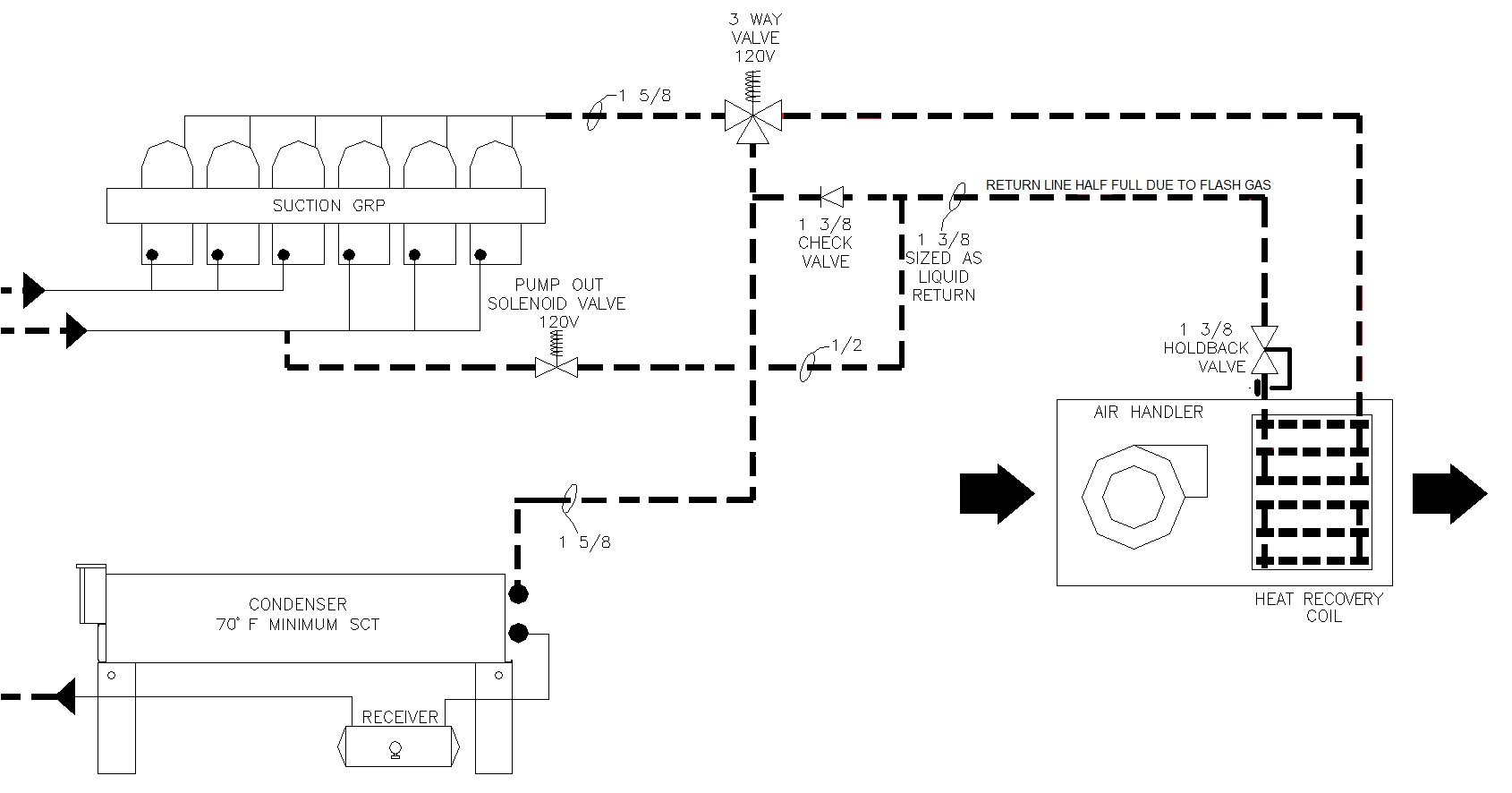

The Energy Standards require that the increase in HFC

refrigerant charge from all equipment related to heat recovery for space heating

shall be less than 0.35 lbs. for every 1,000 Btuh of heat recovery capacity at

design conditions. Refrigerant charge may increase due to the addition of the

recovery coil itself (either the refrigerant-to-air heat exchanger for direct

configurations, or the refrigerant-to-water heat exchanger for indirect

configurations), and the additional piping between the compressor group and the

recovery coil. 'In addition, the refrigerant leaving the

recovery coil and entering the refrigerant condenser will be mostly condensed,

which increases the charge in the outdoor condenser compared with normal

operation. Operating the outdoor condenser at lower pressure (i.e. the required

floating heat pressure control) vs. the higher setting at the heat recovery coil

holdback valve creates pressure drop, flashing of some liquid to vapor and an

increase in velocity due to the much larger volume of a pound of vapor vs. a

point of liquid refrigerant. Split condenser control, which is very common in

cooler climates, can also be used to close-off and pump out half of the outdoor

condenser.

It is the responsibility of the system designer to fully

understand how the heat recovery system affects overall refrigerant charge.

Example

10-22

Question

A

heat recovery system is being designed for a new supermarket. The

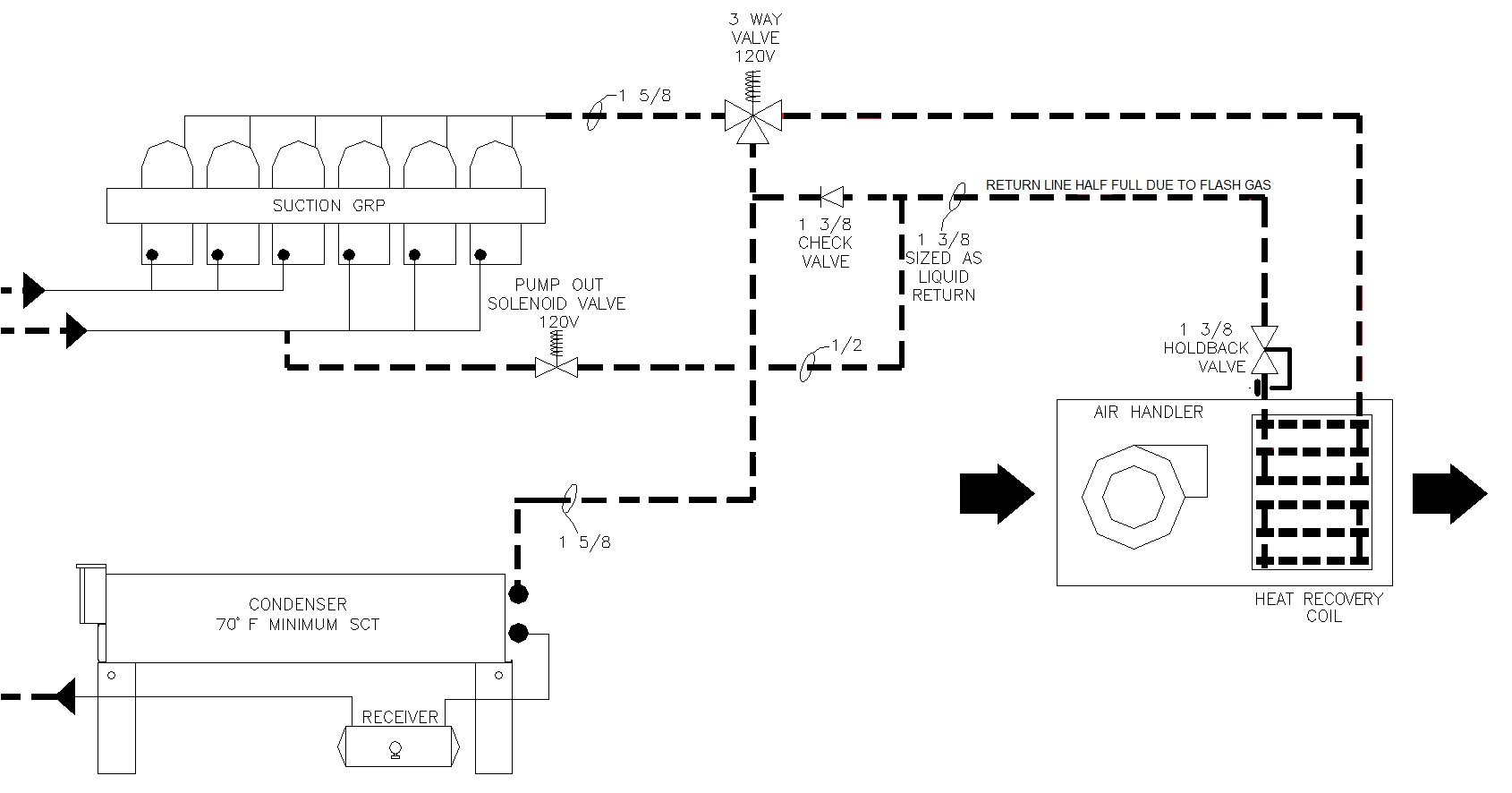

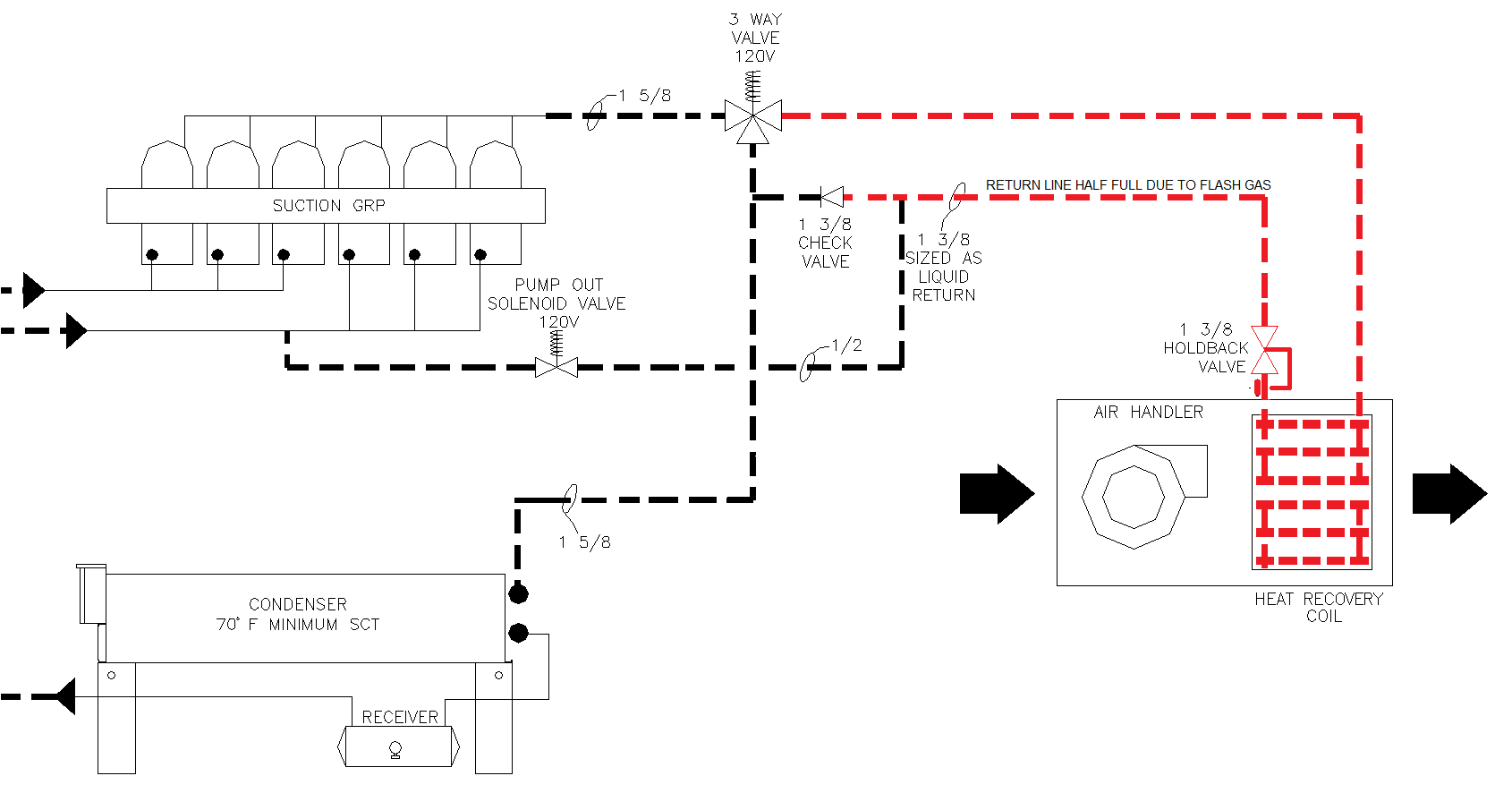

refrigerant is R-404A. The proposed design is shown below:

Which

piping runs should be included in the calculation of refrigerant charge increase

in the proposed design?

Answer

Only

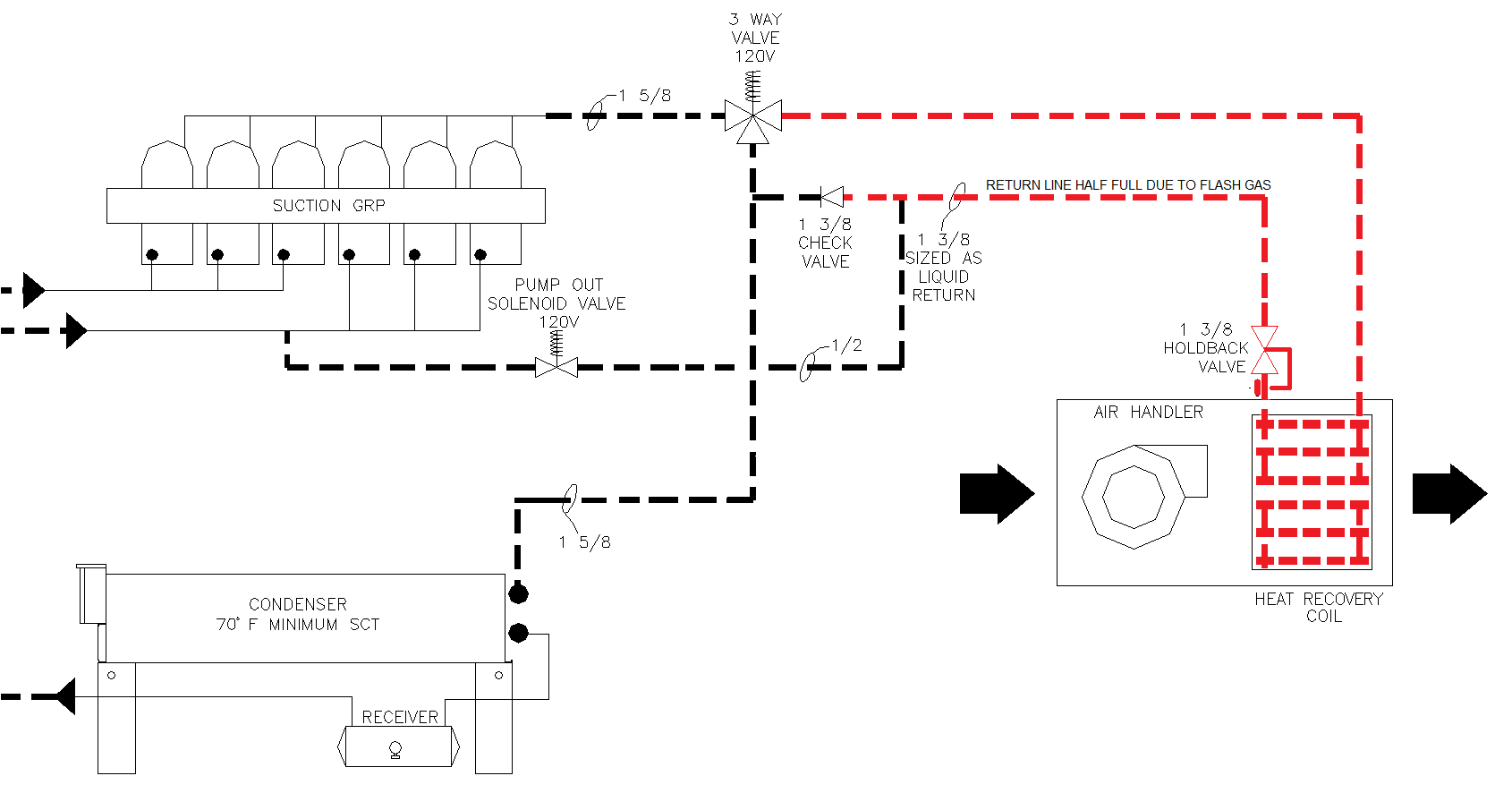

the additional piping required to route the refrigerant to the heat recovery

coil needs to be considered in this calculation. The piping runs shown in

red in the following figure should be included in the calculation of refrigerant

charge increase from heat recovery.

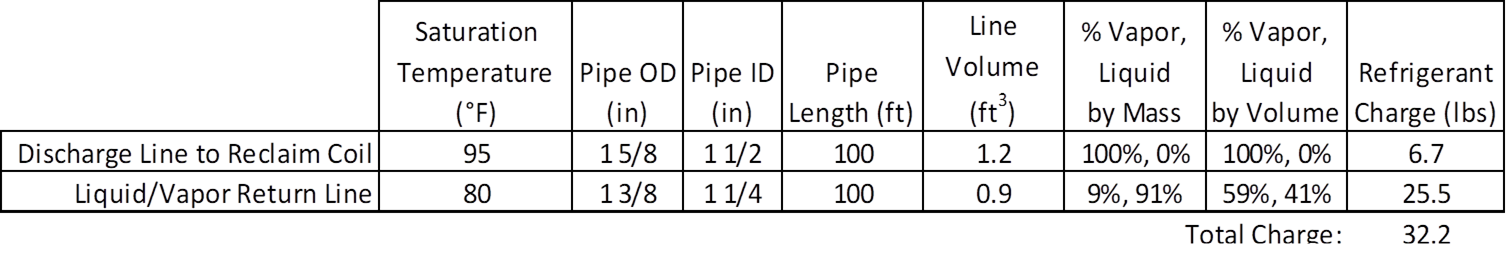

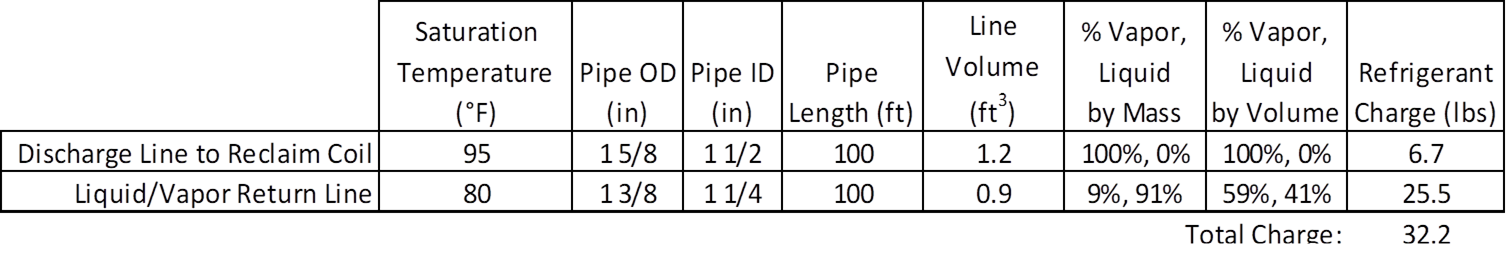

Example

10-23

Question

What

is the refrigerant charge size increase in the example described above?

Answer

The

system designer prepares the following analysis to calculate the charge size in

the refrigerant piping

The

outdoor condenser has a capacity of 350 MBH at a TD of 10°F. Using

manufacturers published data, the designer determines that the condenser normal

operating charge (without heat recovery) is 26.9 lbs. To calculate the charge

increase in the condenser due to heat reclaim, the designer estimates the

condenser could be as much as 75% full of liquid, resulting in a condenser

charge of 68.8 lbs. with heat recovery.

The

heat recovery coil has a capacity of 320 MBH at a design TD of 20°F. he

system designer uses manufacturer’s documentation to determine that the heat

recovery coil refrigerant charge is 14.1 lbs.

The

total refrigerant charge with heat recovery is:

32.2

lbs ) piping + 68.8 lbs (system condenser) + 14.1 lbs (recovery coil) = 115.1

lbs

Therefore,

the refrigerant charge increase with heat recovery is:

115.1

lbs – 26.9 lbs = 88.2 lbs

Example

10-24

Question

In

the example above, does the recovery design comply with the requirement in the

Energy Standards that the recovery design shall utilize at least 25% of the

design Total Heat of Rejection (THR) of the refrigeration system?

Answer

The

system designer determines that the total THR of all the refrigeration systems

in the new supermarket is 800 MBH. From the previous example, the heat

recovery capacity is 320 MBH.

100

% x 320 MBH =

40%

800 MBH

Therefore,

the design is in compliance with the Energy Standards.

Example

10-25

Question

In

the example above, does the recovery design comply with the requirement in the

Energy Standards that the recovery design shall not increase the refrigerant

charge size by more than 0.35 lbs. of refrigerant per 1,000 Btuh of recovery

capacity?

Answer

From

the previous example, the recovery capacity is 320 MBH at design conditions, and

the total refrigerant charge size increase is 88.2 lbs.

88.2

lbs = 0.28 lbs/Btuh

320 MBH

Since

the refrigerant charge increases by less than 0.35 lbs./MBH, this design is in

compliance with the Energy Standards.

10.5.6

Additions and Alterations

Requirements related to commercial refrigeration additions

and alterations to existing buildings are covered by the Energy Standards in §141.1(b).

The specific requirements for additions and alterations for Commercial

Refrigeration are included in §120.6(b).

10.5.7

Compliance Documentation

Compliance documentation includes the forms, reports and

other information that are submitted to the enforcement agency with an

application for a building permit (Certificate of Compliance). Compliance

documentation also includes documentation completed by the installing

contractor, engineer/architect of record, or owner’s agent to verify that

certain systems and equipment have been correctly installed and commissioned

(Installation Certificate).

Form NRCC-PRC-05-E for Commercial Refrigeration -

Certificate of Compliance

NRCC-PRC-05-E is the primary form for commercial

refrigeration in retail food stores, which provides compliance information for

the use of the enforcement agency’s field inspectors. This form must be included

on the plans. A copy of this form should also be submitted to the enforcement

agency along with the rest of the compliance submittal at the time of building

permit application. With enforcement agency approval, the applicant may use

alternative formats of these forms (rather than the Energy Commission’s forms),

provided the information is the same and in similar format.