From simple thermostats and manual light switches to complex building automation systems, controls are integral to building health, safety, comfort, and energy efficiency. However, building owners disable many building control and equipment components after occupancy due to lack of functionality from improper installation.

Acceptance test requirements specify targeted inspections and functional performance tests to demonstrate that the building components, equipment, systems, and interfaces conform to the 2016 Building Energy Efficiency Standards (Energy Standards), Reference Nonresidential Appendix NA7, and applicable construction documents (plans and specifications). Furthermore, acceptance testing helps to ensure that the building meets its energy efficiency goals based on the original design in compliance with the energy standards and that the specified equipment or controls are functioning properly. This testing helps to eliminate issues found in the field. This conclusion was noted in a Public Interest Energy Research Program (PIER) report titled Integrated Design of Small Commercial HVAC Systems, Element 4 that found a number of problems with package rooftop equipment. These problems include the following:

A. Economizers

Economizers reduce cooling energy use dramatically but often are inoperable. Economizers show a high rate of failure in the study. Of the units equipped with economizers, 64 percent were not operating correctly. Failure modes included dampers that were stuck or inoperable (38 percent), sensor or control failure (46 percent), and poor operation (16 percent). The average energy impact of inoperable economizers is about 37 percent of the annual cooling energy.

B. Cycling Fans

In 38 percent of the units tested, system fans cycled on and off with a call for heating or cooling. The supply of continuous fresh air during occupied hours relies on continuous operation of the HVAC unit supply fan.

C. Unoccupied Fan Operation

In 30 percent of the systems, fans ran continuously during unoccupied periods. While this practice improves space ventilation, a greater opportunity presents itself to save energy through thermostat setback and fan cycling when the space is unoccupied.

D. Simultaneous Heating and Cooling

Adjacent rooftop units controlled by independent thermostats provided simultaneous heating and cooling to a space in 8 percent of the units monitored in the study, largely due to occupant errors in the setup, thermostat misuse, or poor thermostat placement during construction.

E. No Outdoor Air

An inspection revealed that about 8 percent of the inspected units were not capable of supplying any outdoor air. In some cases, outdoor air intakes were not present or were sealed off at the unit. In other instances, outdoor air dampers were stuck shut, effectively preventing outdoor air intake.

Acceptance testing does not take the place of commissioning, or of test and balance procedures that may be required elsewhere in the Energy Standards, or that a building owner may incorporate voluntarily to assess his or her building. Instead, it serves as an adjunct process focusing only on demonstrating compliance with the Energy Standards and proper functionality as described by the approved building plans.

Acceptance testing is not required to be performed by a third party that is independent from the designer or the contractor. However, compliance with the duct sealing requirements specified in §140.4(l) must be verified by a certified, third-party HERS Rater or third party quality control program pursuant to the requirements in Nonresidential Appendix NA2.

Acceptance tests may be performed by one or more field technicians under the responsible charge of a licensed contractor or design professional responsible person eligible under Division 3 of the Business and Professions Code, in the applicable classification, to accept responsibility for the scope of work specified by the certificate of acceptance document. The responsible person must review the information on the certificate of acceptance document and sign it to certify compliance with the acceptance requirements.

Typically, individuals who participate in the acceptance testing/verification are contractors, engineers, or commissioning agents. The individuals who perform the field testing/verification and provide the information required for completion of the acceptance document (field technicians) are not required to be licensed contractors or licensed design professionals. Only the responsible person who signs the certificate of acceptance document must be licensed.

A certified acceptance test technician (ATT) is required to complete the lighting controls (NRCA-LTI-02-A), automatic daylighting (NRCA-LTI-03-A), demand responsive lighting controls (NRCA-LTI-03-A) and outdoor motion sensor and lighting shut-off controls (NRCA-LTO-02-A) acceptance tests and to sign the certificate of acceptance.

The acceptance tests related to mechanical systems are not required to be performed by a certified acceptance test technician. Although a certified acceptance test training provider has been approved by the Energy Commission, the industry certification threshold has not been surpassed. Once surpassed, then a certified acceptance test technician will be required to complete the associated mechanical acceptance tests and sign the certificate of acceptance.

The acceptance test procedures generally require the following:

•Review the bid documents to make sure that the building component (that is, equipment, sensors, devices and control sequences) are properly documented.

•Review the construction installation.

•Complete the required functional testing.

•Certify the acceptance test results on the certificate of acceptance.

•Submit the certificate to the enforcement agency prior to receiving a final occupancy permit.

If more than one person is responsible for the acceptance testing, each person shall sign and submit the certificate of acceptance documentation applicable to the portion of the construction or installation for which he or she is responsible. Alternatively, the person with chief responsibility for the system design, construction, or installation shall sign and submit the certificate of acceptance documentation for the entire construction or installation.

The owner is responsible for designating the responsible parties for acceptance test work. Applicable roles and responsibilities related to acceptance testing should be clearly called out by the owner early in the process to ensure accurate pricing and bids.

A. Field Technician

The field technician is responsible for performing and documenting the results of the acceptance procedures on the certificate of acceptance documents. The field technician must sign the certificate of acceptance to certify that the information provided on the certificate of acceptance is true and correct. The field technician does not require a contractor’s, architect's or engineer's license but may require certification as an acceptance test technician.

•Given that the industry certification threshold for certified lighting ATTs has been satisfied, a certified ATT is required to perform the acceptance test referenced by §130.4 and to sign the certificate(s) of acceptance.

•When the industry certification threshold has been satisfied for mechanical ATTs, a certified ATT will then be required to perform the acceptance test referenced by §120.5 and sign the certificate(s) of acceptance.

The acceptance tests listed in §120.5 and §130.4 may require that the field technician be a certified ATT. Other acceptance tests, such as those found in §120.6, do not require that the field technician be a certified ATT.

B. Responsible Person

A certificate of acceptance must be signed by a responsible person who is licensed and eligible under Division 3 of the Business and Professions code to take responsibility for the scope of work specified by the certificate of acceptance. The responsible person can also perform the field testing and verification, and if this is the case, the responsible person must complete and sign both the field technician's signature block and the responsible person's signature block on the certificate of acceptance document. The Responsible Person assumes responsibility for the acceptance testing work performed by his Field Technician agent or employee. Aside from being licensed, the responsible person that conducts his or her own testing may also need to be a certified ATT if he or she is performing an acceptance test that requires a certified ATT.

C. Enforcement Agency

The certificate of acceptance must be submitted to the enforcement agency to receive the final certificate of occupancy. Enforcement agencies shall not release a final certificate of occupancy unless the submitted certificate of acceptance demonstrates that the specified systems and equipment have been shown to be performing in accordance with the applicable acceptance requirements.

The enforcement agency has the authority to require the field technician or responsible person to demonstrate competence to its satisfaction. When a certified ATT is required to complete an acceptance test, the enforcement agency must verify the technician certification status through the acceptance test technician certification provider (ATTCP) before issuing a final certificate of occupancy.

The acceptance requirements require five major checkpoints to be conducted. They are:

1. Plan review.

2. Construction inspection.

3. Functional testing.

4. Signing of certification of acceptance.

5. Submission of certification of acceptance.

These are discussed in more detail below.

A. Plan Review

The responsible person must review the plans and specifications to ensure that they conform to the acceptance requirements, typically done prior to signing a certificate of compliance.

In reviewing the plans, the designer notes the appropriate certificate of compliance, all the respective acceptance tests that will be performed, as well as the parties responsible for performing the tests. An exhaustive list is required so that when the acceptance tests are bid, all parties are aware of the scope of acceptance testing on the project.

B. Construction Inspection

The construction inspection assures that installed equipment is capable of complying with the Energy Standards. Construction inspection also assures proper installation of equipment and current calibration.

The responsible person must perform a construction inspection prior to testing. Reviewing the acceptance requirements with the contractor before installation is very useful on several counts.

In some cases, performing tests immediately after installation is most economical, though this requires the complete installation of any associated systems and equipment necessary for proper system operation.

Awareness of the acceptance test requirements can allow the contractor to identify a design or construction practice that would not comply with the acceptance requirements prior to equipment installation.

Purchasing sensors and equipment with calibration certificates often reduces the amount of time required for site calibration, which can lower overall costs.

C. Functional Testing

A field technician assumes responsibility for performing the required acceptance requirements procedures. In some cases, the same field technician may not perform all the required acceptance tests for a project. However, for each acceptance test performed, the field technician who performs the test is responsible for identifying all performance deficiencies and, if necessary, repeating the test until the specified systems and equipment are performing in accordance with the acceptance requirements. The field technician who performs the testing signs the certificate of acceptance to certify the information recorded on the certificate is true and correct.

A responsible person ensures performance of the scope of work specified by the certificate of acceptance and reviews the test results provided by the field technician. The responsible person signs the certificate of acceptance to indicate his or her overall responsibility for the project.

The responsible person may also perform the field technician's responsibilities, and, if so, must also sign the field technician declaration on the certificate of acceptance. If the acceptance test requires a certified ATT and the responsible person performs the acceptance test, then he or she must be a certified ATT.

D. Certification of Acceptance

Acceptance test forms include a certificate of acceptance and worksheets to assist in field verification. Table 13-1 shows the certificate of acceptance documents and related references.

|

Component |

Document Name |

Energy Standards Reference |

Reference Nonresidential Appendix NA7 |

|

Envelope |

NRCA-ENV-02-F – Fenestration Acceptance |

||

|

NRCA-MCH-02-A – Outdoor Air Acceptance |

|||

|

NRCA-MCH-03-A – Constant Volume, Single Zone, Unitary Air Conditioner and Heat Pump Systems |

|||

|

NRCA-MCH-04-A – Air Distribution Systems Acceptance |

|||

|

Mechanical |

NRCA-MCH-05-A – Air Economizer Controls Acceptance |

||

|

NRCA-MCH-06-A – Demand Control Ventilation Systems Acceptance |

|||

|

NRCA-MCH-07-A – Supply Fan VFD Acceptance |

|||

|

NRCA-MCH-08-A – Valve Leakage Test |

|||

|

NRCA-MCH-09-A – Supply Water Temperature Reset Controls Acceptance |

|||

|

NRCA-MCH-10-A – Hydronic System Variable Flow Control Acceptance |

|||

|

NRCA-MCH-11-A – Automatic Demand Shed Control Acceptance |

|||

|

NRCA-MCH-12-A – Fault Detection & Diagnostics (FDD) for Packaged Direct Expansion Units |

|||

|

NRCA-MCH-13-A – Automatic Fault Detection & Diagnostics (FDD) for Air Handling Units & Zone Terminal Units Acceptance |

|||

|

Mechanical |

NRCA-MCH-14-A – Distributed Energy Storage DX AC Systems Acceptance |

||

|

NRCA-MCH-15-A – Thermal Energy Storage (TES) System Acceptance |

|||

|

NRCA-MCH-16-A – Supply Air Temperature Reset Controls Acceptance |

|||

|

NRCA-MCH-17-A – Condenser Water Supply Temperature Reset Controls Acceptance |

Not required per Energy Standards. However, this test is required if this control strategy is implemented. |

||

|

NRCA-MCH-18-A – Energy Management Control System Acceptance |

§110.2(e), §120.2(h), §120.5(a)17, §130.4(b), §130.5(f), §150.0(k) |

-------- | |

|

Indoor ighting |

NRCA-LTI-02-A Lighting Controls |

||

|

NRCA-LTI-03-A Automatic Daylighting Controls |

|||

|

NRCA-LTI-04-A Demand Responsive Lighting Controls |

|||

|

NRCA-LTI-05-A Institutional Tuning Power Adjustment Factor |

|||

|

Outdoor Lighting |

NRCA-LTO-02-A – Outdoor Lighting Acceptance Tests |

||

|

Process |

NRCA-PRC-01-F – Compressed Air System Acceptance |

||

|

NRCA-PRC-02-F – Commercial Kitchen Exhaust |

|||

|

NRCA-PRC-03-F – Parking Garage Exhaust |

|||

|

NRCA-PRC-04-F – Refrigerated Warehouse – Evaporator Fan Motor Controls Acceptance |

|||

|

NRCA-PRC-05-F – Refrigerated Warehouse – Evaporative Condenser Controls Acceptance |

|||

|

NRCA-PRC-06-F – Refrigerated Warehouse – Air-Cooled Condenser Controls Acceptance |

|||

|

NRCA-PRC-07-F – Refrigerated Warehouse – Compressor Variable Speed Acceptance |

|||

|

NRCA-PRC-08-F – Refrigerated Warehouse – Electric Resistance Underslab Heating System Acceptance |

|||

|

NRCA-PRC-12-F – Elevator Lighting and Ventilation Controls |

|||

|

NRCA-PRC-13-F – Escalator and Moving Walkways Speed Control |

E. Submission of Certification of Acceptance

The completed and signed certificate of acceptance must be submitted to the local enforcement agency in accordance with the local laws, ordinances, regulations, or customs. There is no general requirement for a certificate of acceptance to be submitted to any other regulatory agency or to an ATTCP, though specific contractual agreements may require such submissions. For example, in many cases ATTCP will require that certified acceptance test technicians electronically submit all completed certificates of acceptance as a condition of maintaining their certification status.

The administrative requirements contained in the Energy Standards (§10-103(b).) require the envelope and mechanical plans and specifications to contain:

•Completed acceptance testing documents for mechanical systems and equipment shown in Table 13-1; submission of record drawings to the building owners within 90 days of receiving a final occupancy permit.

•Submission of operating and maintenance information to the building owner.

•Installation certificates for mechanical equipment (for example, factory-installed economizers).

13.2.4.1. Envelope and Mechanical Acceptance Test Issues

Acceptance testing must be tailored for each specific design, job site, and climatic condition. While the steps for conducting each test and the acceptance criteria remain consistent, the application of the tests to a particular site may vary. The following section discusses some of the known issues that occur when applying acceptance tests on-site.

A. General Issues − Envelope

Important aspects to the fenestration acceptance requirements are:

•Verification of thermal performance (U-factor, SHGC, and VT) for each specified fenestration product to ensure that it matches the fenestration certificate, building plans, energy compliance documentation, and the purchase order or receipt.

•When installed fenestration thermal performance is equal or better than the specified or listed on the energy documentation, then no further recompliance is required.

•When installed fenestration is less than the energy documentation, then recompliance is required. Installation of less efficient fenestration can increase the cooling load of the building and adversely affect the overall energy use of the building.

•When using the performance approach, the weighted average thermal performance per orientation is applicable if it is equal or better than the specified values as noted above; otherwise, recompliance is required.

B. General Issues – Mechanical Combining Tests to Reduce Testing Costs

Many of the acceptance tests overlap in terms of activities. For example, both Reference Nonresidential Appendix NA7.5.1.1 Ventilation Systems for Variable Air and Constant Volume Systems Acceptance and NA7.5.6 Supply Fan Variable Flow Controls (FVC) Acceptance require zone controls be overridden to force the system into full design flow and low flow conditions. Since the bulk of the time for either test is driving the zone controls (for example, variable air volume [VAV] boxes) into a set position, one may combine these two tests: performing the superset of activities with the boxes at both design and part-load conditions. There are several places where combining tests will save time. These opportunities are summarized below and described again in the test descriptions.

Tests requiring override of zone controls:

•NA7.5.1.1 Ventilation Systems for Variable Air Volume Systems Acceptance

•NA7.5.6 Supply Fan Variable Flow Controls Acceptance

Tests requiring override of the OSA damper:

•NA7.5.1.1 Variable Air Volume Systems Outdoor Air Acceptance (or NA7.5.1.2 Constant Volume Systems Outdoor Air Acceptance)

•NA7.5.4 Air Economizer Controls Acceptance

•NA7.5.5 Demand Controlled Ventilation Systems Acceptance

•NA7.5.11 Fault Detection and Diagnostics (FDD) for Packaged Direct-Expansion Units

Tests requiring a change in the unit mode of operation:

•NA7.5.2 Constant Volume, Single-Zone, Unitary Air Conditioner and Heat Pumps Systems Acceptance

•NA7.5.4 Air Economizer Controls Acceptance

Tests requiring dead head of the circulation pump and overriding control valves:

•NA7.5.9 Hydronic System Variable Flow Controls Acceptance.

C. Internal Control Delays

Be aware of the potential for delays programmed into many control sequences. Delays prevent the system from instability. With delays between 5 to 30 minutes, the acceptance testing can be prolonged considerably.

Examples include the normal time that a damper uses to stroke (typically several minutes end to end) and antirecycle timers on refrigerant compressors (typically 5 to 15 minutes).

1. Initial Conditions

Each test instructs the contractor to return the systems to normal operating condition based on the initial schedules, set points, and control parameters. These initial settings shall be recorded prior to initiating testing.

2. Obtain Correct Control Sequences Before Testing

Before testing begins, be familiar with the control sequences. Otherwise, the contractor will not be able to customize the test to the particular systems or verify that the systems work as intended. In many cases, the testing will be performed in conjunction with the controls contractor. In addition, many of these tests can be performed as part of the equipment/system start-up process.

The equipment operations and maintenance (O&M) manual usually documents the internal electronic controls.

With pneumatic controls, the control drawings are the best resource to ascertain how the system controls function.

With DDC controls, review the existing control programming loaded in the controllers. An important note is that the actual control logic is often different from the sequences on the design plans and specifications due to a number of reasons including:

•Poorly written or incomplete sequences on the design drawings.

•Standard practices by the installing EMCS contractor.

•Issues that arose in the field during control system start-up and commissioning.

Functional testing based on incorrect sequences will not necessarily yield a valid result.

3. Estimated Time to Complete

To give the full picture to contractors, the test summaries below (“At-A-Glance”) include estimates of the time to complete construction observation, as well as functional testing on each system. These estimates are made for a specific test on a specific system and need to be combined to estimate the total time for completion on all systems associated with the entire building. Use these estimates with caution; times will vary depending on several factors, including the complexity of the controls, the number of control zones, the number of similar tests, and other issues. Expect delays during the first test. Subsequent tests take less time as the tester becomes more experienced and familiar with the test.

4. Sensor Calibration

A variety of sensors control many facets of heating, ventilating, and air conditioning systems. Confirming each sensor measures the respective parameter accurately is crucial to proper system operation and energy performance. For example, if a supply fan variable frequency drive is controlled based on duct static pressure, then an accurate pressure sensor is understandably imperative.

The requirement found in a few test procedures for sensor calibration can be met by either having a calibration certificate provided with the sensor from the manufacturer or through field verification. A calibration certificate from the manufacturer verifies testing of a particular sensor per a traceable standard (typically National Institute of Standards and Technology [NIST]) and confirms the sensor measures accurately. Common practice assumes a factory-calibrated sensor accurate and needs no further testing. Field verification generally requires checking the measured value from the sensor installed in the system against a calibrated instrument. Typically most sensors can be checked at a single operating point if the expected measurement range does not vary significantly. Any adjustments needed to make the field-installed sensor correspond to the value measured by the calibrated instrument can be made at either the transmitter itself or within the control system database.

The following sensors require checking for calibration:

•Pressure sensors used in variable flow applications (that is, supply fan or pump variable frequency drive is controlled to maintain a specific pressure set point). The following test procedure(s) apply: NA7.5.6 Supply Fan Variable Flow Controls and NA7.5.9 Hydronic System Variable Flow Controls.

•Temperature sensors used to control field-installed economizers and supply water temperature reset. The following test procedure(s) apply: NA7.5.4 Air Economizer Controls Acceptance and NA7.5.8 Supply Water Temperature Reset Controls.

•Carbon dioxide sensors used to implement a demand-controlled ventilation control strategy. The following test procedure(s) apply: NA7.5.5 Demand-Controlled Ventilation Systems Acceptance.

D. VAV Control Systems

There are many ways to control minimum ventilation in a VAV system, including, but not limited to:

•Supply/return flow tracking.

•Direct outdoor air flow measurement.

•Constant differential pressure across dedicated ventilation air damper.

•Constant mixed air plenum pressure.

The term “system” refers to whatever type of control strategy employed to control minimum ventilation air flow. The following test procedure(s) apply: NA7.5.1.1 Variable Air Volume Systems Outdoor Air Acceptance. Overall, the system must be able to control flow to within 10 percent of the design outdoor air ventilation value.

E. Air and Water Measurements

Before granting an occupancy permit for a new building or space, or a new space conditioning system serving a building or space, balance the system in accordance with the procedures defined by the Testing Adjusting and Balancing Bureau (TABB) National Standards (2003); the National Environmental Balancing Bureau (NEBB) Procedural Standards (1983); or Associated Air Balance Council (AABC) National Standards (1989).

F. Factory Air Economizer Certification Procedure

§120.5(a)4 requires air economizer acceptance testing in accordance with NA7.5.4, Air Economizer Controls. This test assures economizers work per the intent of the Energy Standards §140.4(e) Economizers. NA7.5.4, Air Economizer Controls describes the requirements for the acceptance test, as well as provides a detailed test description.

Air economizers installed by the HVAC system manufacturer and certified to the California Energy Commission as being factory installed, calibrated, and tested are exempted from the Air Economizer Controls acceptance test as described in the Nonresidential Reference Appendix NA7.5.4. The following sections describe the requirements of a “factory installed and calibrated economizer” certification and how to apply for Energy Commission approval of a certification program.

Inspection:

•Verify minimum outside air damper position can be adjusted. Verify outside and return air dampers modulate as necessary to achieve the desired position.

•Verify outside air dampers completely close when the unit is off.

•Verify outside air dampers move freely without binding.

•Provide a 5-year manufacturer warranty of economizer assembly.

•Provide an economizer specification sheet proving capability of at least 60,000 actuations

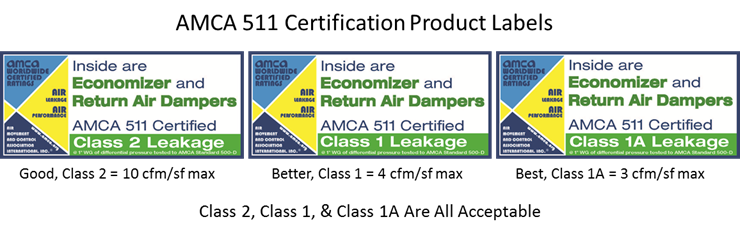

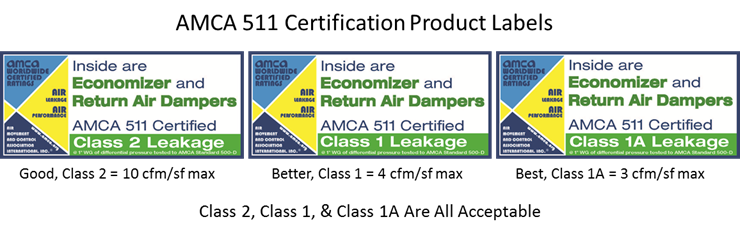

•Provide a product specification sheet proving compliance with Air Movement and Control Association (AMCA) Standard 500 damper leakage at 10 cfm/sf at 1.0 in. w.g. Provide a product specification sheet showing the manufacturer’s results after following the testing procedures of AMCA Standard 500 or AMCA certification by a third-party reviewer under AMCA Publication 511 may also be used to satisfy this requirement (Class 1A, 1, and 2 are acceptable). (See figure below)

•Verify system has return fan speed control, relief dampers, or dedicated exhaust fans to prevent building over pressurization in full economizer model

•Verify calibration of outdoor air, return air, mixed air, and supply air sensors to known references within the following measurement tolerances:

o Dry bulb and wet bulb temperatures accurate to ± 2°F over the range of 40°F to 80°F

o Enthalpy accurate to ± 3 Btu/lb over the range of 20 Btu/lb to 36 Btu/lb

o Relative humidity (RH) accurate to ± 5 percent over the range of 20 percent to 80 percent RH

•Verify the economizer instruction material provides the sensor performance curve. In addition, confirm the sensor output value measured during sensor calibration is plotted on the performance curve.

•Verify whether the high limit set point is fixed dry-bulb or fixed enthalpy + fixed dry-bulb; in either case, the control shall have an adjustable set point.

•Verify the location of sensors used for the high limit control to prevent false readings, for example, properly shielded from direct sunlight

•Verify that the high-limit shutoff set point is set to these default limit settings per Table 140.4-B, as referenced in §140.4(e)3:

No climate zones allow fixed enthalpy, differential enthalpy, and electronic enthalpy.

1. Functional Testing

Factory-installed and calibrated economizer certification shall document that the following conditions are met:

•During a call for heating, outside air dampers close to minimum ventilation position and return air dampers open.

•Demonstrate proper integration between economizer and compressor using the steps in Table 13-2.

•Demonstrate economizer high-limit control and dead band using the process in Table 13-3.

|

Step |

Description |

Purpose |

|

1 |

Simulate OAT to 45°F and RAT to 75°F |

------- |

|

2 |

Generate call for cooling and increase OAT such that economizer damper modulates to position between minimum and 50 percent open with no mechanical cooling. |

Test partial economizing at low OAT. |

|

3 |

Verify economizer position is correct (between minimum and 50 percent) and stable with no hunting, compressor is not enabled, and heating is disabled. Record the OAT and economizer damper position. |

------ |

|

4 |

Increase the OAT such that economizer damper modulates to any position within 50 percent to 100 percent open with no mechanical cooling. |

Test partial economizing. |

|

5 |

Verify economizer modulates open to a larger degree, is stable with no hunting, the return air damper modulates more closed, and the compressor is not enabled. Record the OAT and economizer damper position. |

------- |

|

6 |

Increase the OAT such that the compressor turns on and the economizer damper modulates more closed. |

Test partial economizing and compressor integration. |

|

7 |

Verify the compressor is enabled. Record the OAT at high limit and the economizer damper position. |

|

|

8 |

Verify the compressor turns off and the economizer damper modulates to 100 percent open. |

Test full economizing. |

|

9 |

Record the compressor run time (minutes) |

------ |

|

10 |

Repeat Steps 7-8 when the compressor turns on again. Also verify the economizer damper modulates to close. |

Test partial economizing and compressor integration. |

|

11 |

Record the compressor off time between cycles (minutes) |

------- |

|

12 |

Slowly increase the OAT such that mechanical cooling is enabled and the economizer damper modulates to minimum position |

Test minimum ventilation and compressor integration. |

|

13 |

Verify economizer and return air damper positions are correct and stable with no hunting, compressor is enabled, and heating is disabled. |

------- |

|

Step |

Description |

Purpose |

|

1 |

Simulate RAT to 80˚F; OAT to 72˚F |

|

|

2 |

Generate a call for cooling |

|

|

3 |

Verify that economizer is at minimum position |

Test minimum ventilation above the high limit setpoint. |

|

4 |

Incrementally lower the OAT |

|

|

5 |

Verify that economizer stays at minimum position until ambient air conditions are less than high limit setpoint then opens to 100 percent |

Test the high limit setpoint from above. |

|

6 |

Incrementally raise the OAT |

Test the dead band. |

|

7 |

Verify that economizer stays at maximum position until ambient air conditions are higher than high limit setpoint then closes to minimum position |

Test the high limit setpoint from below. |

|

8 |

Test passes if both

conditions are met: |

|

2. Documents to Accompany Factory-Installed and Calibrated Economizer Certificate

•Installation instructions. For systems with cooling capacities greater than 54,000 Btu/hr, instructions shall include methods to assure economizer control is integrated and is cooling, even when economizer cannot serve the entire cooling load.

•Sensor performance curve for high-limit shutoff sensors and instructions for measuring sensor output. Performance curve shall also contain test points during calibration plotted on the curve. Curve details shall show measurement resolution in increments of 1°F and 1 Btu/lb.

•Economizer specification sheet proving capability of at least 60,000 actuations.

•Provide a product specification sheet proving compliance with AMCA Standard 500 damper leakage at 10 cfm/sf at 1.0 in. w.g. A product specification sheet showing the manufacturer’s results after following the testing procedures of AMCA Standard 500 or AMCA certification by a third party under AMCA Publication 511 can be used to satisfy this requirement (Class 1A, 1, and 2 are acceptable).

3. Application for Factory-Installed and Calibrated Economizer Certification

Manufacturers who wish to label their economizers as factory-installed and calibrated must provide the following information to the California Energy Commission:

•Brief description of test method, including:

o Method of placing equipment in heating and cooling mode.

o Method of calibrating high limit sensor.

o Method of testing control and damper.

•Model numbers of products to be certified.

•Sample of factory-installed and calibrated economizer documentation that would accompany each qualifying economizer.

•Name and contact information of lead staff in charge of certification

Send the application materials to:

Building Standards Development Office

California Energy Commission

1516 Ninth St., MS 37

Sacramento, CA 95814

4. Sample Certificate of Factory-Installed and Calibrated Economizers

“This document certifies that this economizer has been factory installed and calibrated according to the requirements of the California Energy Commission. As a result, this economizer is exempted from the functional testing requirements (but not the construction inspection requirements) as described in Appendix NA7.5.4 Air Economizer Controls’ and on the MECH-5 acceptance testing document.”

|

Date of economizer testing: |

Model Number: |

|

Supervisor: |

Serial Number: |

|

Technician: |

Rated Cooling Capacity: |

|

Economizer fully integrated? YES NO | |

|

Device Type |

Control Type & Setpoint |

Climate Zones |

Required High Limit (Economizer Off When): | |

|

Equation |

Description | |||

|

Fixed Dry Bulb |

□ |

1, 3, 5,

11-16 |

TOA > 75°F |

Outdoor air temperature exceeds 75°F |

|

□ |

2, 4, 10 |

TOA > 73°F |

Outdoor air temperature exceeds 73°F | |

|

□ |

6, 8, 9 |

TOA > 71°F |

Outdoor air temperature exceeds 71°F | |

|

□ |

7 |

TOA > 69°F |

Outdoor air temperature exceeds 69°F | |

|

Differential Dry Bulb |

□ |

1, 3, 5, 11-16 |

TOA > TRA |

Outdoor air temperature exceeds return air temperature |

|

□ |

2, 4, 10 |

TOA > TRA – 2°F |

Outdoor air temperature exceeds return air temperature minus 2°F | |

|

□ |

6, 8,

9 |

TOA > TRA – 4°F |

Outdoor air temperature exceeds return air temperature minus 4°F | |

|

□ |

7 |

TOA > TRA – 6°F |

Outdoor air temperature exceeds return air temperature minus 6°F | |

|

Fixed Enthalpy + Fixed Drybulb |

□ |

All |

hOA > 28 Btu/lb or TOA > 75°F |

Outdoor air enthalpy exceeds 28 Btu/lb of dry air or Outdoor air temperature exceeds 75°F |

Note to installer: Economizer high-limit setpoint must be reset when needed based upon climate zone and/or device type.

Outside Air Calibration

a. Outside air conditions during calibration test from reference measurement: TOA = _______ hOA = _______

b. Outside air sensor output during calibration test: TOA = _______ hOA = _______ Units (V, mA etc) ______

c. Sensor measured value from sensor performance curve: TOA = _______ hOA = _______

d. Are sensor measurements within 2°F or 3 Btu/lb of reference measurement?

(Yes, No, N/A) TOA = _______ hOA = _______

ð Sensor output plotted on sensor performance curve

ð Sensors used for the high limit control are properly shielded from direct sunlight

e. Return air calibration (for differential dry bulb controls only)

f.

Return air temperature during calibration test from reference measurement:

Treturn = _______

g. Return air sensor output during calibration test: Units (V, mV, etc) _______

h.

Sensor measured value from sensor performance curve

Treturn =

_______

i. Are sensor measurements within 2°F of reference measurement?

(Yes, No, N/A) TOA = _______

ð Sensor output plotted on sensor performance curve

Functional Tests Under Simulated Temperature Conditions

•During a call for heating, outside air dampers are closed to a minimum outside air setting and air dampers are opened.

•During a call for full cooling and ambient conditions below the high-limit shutoff set point, before mechanical cooling is enabled, the outside air dampers must be 100 percent open and the return dampers fully closed.

•For systems with cooling capacities greater than 54,000 Btu/h, during a call for full cooling, if the ambient conditions are below the high limit shutoff set point and economizer cannot provide full cooling, then mechanical cooling is modulated to maximize economizer cooling, N/A system cooling capacity ≤ 54,000 Btu/h

•During a call for cooling, if the measured ambient air condition is greater than the high-limit shutoff set point, the outside air dampers are closed to a minimum outside air damper position and the return air dampers are opened.

•Minimum outside air can be adjusted.

•The outside air dampers are closed when the unit is off.

•The outside air dampers move freely without binding.

Accompanying Documents

•Installation instructions.

•For systems with cooling capacities greater than 54,000 Btu/hr, instructions shall include methods to assure economizer control is integrated and is cooling even when economizer cannot serve the entire cooling load. N/A system cooling capacity ≤ 54,000 Btu/h.

•Economizer specification sheet proving capability of at least 60,000 actuations.

•Provide a product specification sheet proving compliance with AMCA Standard 500 damper leakage at 10 cfm/sf at 1.0 in. w.g. A product specification sheet showing the manufacturer’s results after following the testing procedures of AMCA Standard 500 or AMCA certification by a third party under AMCA Publication 511 can be used to satisfy this requirement (Class 1A, 1, and 2 are acceptable)

•Performance curve for high-limit shutoff sensors and instructions for measuring sensor output.

The (Manufacturing Company Name) certifies that all the information on this certificate for factory installed and calibrated economizers is true and that this economizer complies with all of the California Energy Commission requirements for factory-installed and calibrated economizers.

Acceptance requirements can effectively improve code compliance and help determine whether lighting equipment meets operational goals and if efficiency and effectiveness need to increase.

The administrative requirements contained in the Energy Standards (§10-103(b)) require:

•Completed certificate of compliance, installation, verification and acceptance documents for lighting controls, automatic daylighting controls, demand responsive lighting controls, and outdoor motion sensors and lighting shutoff controls.

•Record drawings are provided to the building owners within 90 days of receiving a final occupancy permit.

•Operating and maintenance information be provided to the building owner.

•Completed installation certificates for daylighting controls, occupant sensing devices, and automatic shut-off controls.

13.2.5.1. Lighting Acceptance Test Issues

Acceptance testing must be tailored for each specific design, job site, and/or climatic condition. While the steps for conducting each test remain consistent, the application of the tests to a particular site may vary. The following section discusses some of the known issues that occur when the acceptance tests are applied to a project.

A. Internal Control Delays

Be aware of the potential for delays programmed into many control sequences. Delays prevent the system from instability. With delays between 5 to 30 minutes, the acceptance testing can be prolonged considerably.

B. Initial Conditions

Each test instructs the contractor to return the systems to normal operating condition based on the initial schedules, set points, and control parameters. These should be recorded before initiating testing.

C. Obtain Correct Control Sequences Before Testing

Before testing begins, the contractor must be aware:

•How the control sequence are programmed.

•That written control sequences often do not include enough detail to test the system (or they are found to be incorrect).

•How to operate the control system.

D. Estimated Time to Complete

To give the full picture to contractors, the at-a-glance includes the time to complete construction observation as well as functional testing. In addition, the At-A-Glance indicates the time shown is per system (not per building).

The administrative requirements contained in the Energy Standards require the refrigerated warehouse plans to contain:

•Applicable refrigerated warehouse compliance documents: NRCC-PRC-06-E, which includes the required acceptance tests, and documents NRCC-PRC-07-E and NRCC-PRC-08-E, as applicable.

•A note that specifies that the record drawings (“as-built” drawings) are provided to the building owners within 90 days of receiving a final occupancy permit.

Furthermore, the administrative requirements contained in the Energy Standards require:

•Installation certificates for refrigeration warehouses: NRCI-PRC-01-E.

•Refrigerated warehouse acceptance testing documents, NRCA-PRC-04-A, NRCA-PRC-05-A, NRCA-PRC-06-A, NRCA-PRC-07-A and NRCA-PRC-08-A.

•Operating and maintenance information in the building after occupancy.

13.2.6.1. Process Acceptance Test Issues

Acceptance testing must be tailored for each specific design, job site, and/or climatic conditions. While the steps for conducting each test and the acceptance criteria remain consistent, the application of the tests to a particular site may vary. The following section discusses some of the known issues when performing the acceptance tests.

A. Cooling Loads

Some acceptance tests require an accurate determination of an adequate cooling load. For performing the acceptance test, the system cooling load may be artificially increased (such as by lowering the space temperature set point).

B. Initial Conditions

Each acceptance test includes a final instruction stating that any schedules, set points, and/or control parameters changed during the acceptance test shall be restored to pretest values. Record these initial settings before performing the acceptance test.

C. Internal Control Features

The field technician should be aware that many control functions include internal control features such as start-up and shutdown delays, fail-safes, control dead bands, and automatic overrides. These features protect system equipment and increase system stability. These features are necessary for the safe and efficient operation of the refrigeration system and disregarded when determining if a component passes or fails an acceptance test.

Before doing any acceptance testing, the field technician shall fully understand the control logic for each component under test. Close coordination and communication with the controls engineer, contractor, or component vendor may be necessary.

D. Estimated Time to Complete

The “at-a-glance” summaries include estimates of the time to complete construction inspection, as well as functional testing for each system component. These estimates are made for a test on a single component; actual time to complete the tests will vary depending on the complexity of the controls and the refrigeration system, the number of control systems, and other factors. Expect delays during the first test.

E. Sensor Calibration

In refrigerated warehouses, sensors used for refrigeration system control include numerous field-installed sensors, such as evaporator zone temperatures, suction and discharge pressure transducers, and outdoor temperature and humidity sensors. Sensors may also be factory-installed on equipment such as a screw compressor package. To ensure efficient system operation, as well as meet the construction inspection requirements for the acceptance tests, all sensors used for operational control of the system must have current calibration.

Sensors used for information or other purposes that do not relate to maintaining pressures, temperatures, or routine equipment sequencing and operational control are not subject to these calibration requirements.

For field-installed sensors, on-site calibration must be completed, even if the sensor was provided with a calibration certificate. For field-installed sensors, there are multiple potential sources of error in the readings between the sensor and the operator interface. Errors may include, but are not limited to, sensor error, transmitter error, conversion error, thermal drift, or electrical noise. To provide accurate values to the control system, calibrate from end-to-end (in other words, sensor to the operator interface).

The instruments used to calibrate the field-installed sensors must be highly accurate to prevent bias errors. This calibrating instrument, also called the calibration “standard,” must be calibrated at least every two years using a NIST traceable reference. The refrigerated warehouse refrigeration system acceptance tests require calibrating instrument measurement tolerances as follows:

•Temperature: ±0.7°F between -30°F to 200°F

•Pressure: ±2.5 psi between 0 and 500 psig

•Relative humidity (RH): ±1 percent between 5 percent and 90 percent RH

The calibration includes checking the sensor reading (as read from the operators interface) versus the calibration instrument reading. The control system values shall be adjusted according to the control system procedures, which may include zero and span values or single offset values for calibration, so that the reading from the operator readout is within an acceptable deviation from the calibrating instrument reading. To ensure consistency with control system documentation and proper implementation of sensor function and signal conversion (for example, proper ranges and engineering units), perform calibration at more than one condition (such as temperature or pressure). Measurements taken for calibration values should be tested for repeatability in the event of a controller or computer power reset.

For factory-installed sensors on an equipment package that is used for system control, the package manufacturer may certify the sensor as calibrated using a NIST-traceable reference or using the preceding field calibration.

For refrigerated warehouses, the calibration requires documentation to be provided to the field technician completing the acceptance test and the building owner for documentation and use in ongoing system maintenance. Calibration documentation includes records showing the calibration date, instruments used in calibration, and any offsets or other calibration values adjusting sensor readings in the control system. This process requires both field-installed sensors and factory-installed sensors on equipment packages.