The objective of the Building Energy Efficiency Standards (Energy Code) for mechanical systems is to reduce energy consumption while maintaining occupant comfort by:

1. Maximizing equipment efficiency at design conditions and during part load operation

2. Minimizing distribution losses of heating and cooling energy

3. Optimizing system control to minimize unnecessary operation and simultaneous use of heating and cooling energy

An important function of the Energy Code is indoor air quality for occupant comfort and health. The 2022 Standards incorporate requirements for outdoor air ventilation that must be met during normally occupied hours.

This chapter summarizes the requirements for space conditioning, ventilation, and service water heating systems for non-process loads in nonresidential buildings. Chapter 10 covers process loads in nonresidential buildings and spaces.

This chapter is organized as follows:

•Section 4.1 overview of the chapter and the scope of the mechanical systems requirement in the Energy Code

•Section 4.2 requirements for heating, ventilation, and air conditioning (HVAC) and service water heating equipment efficiency and equipment mounted controls

•Section 4.3 mechanical ventilation, natural ventilation, occupant sensor ventilation control, and demand-controlled ventilation

•Section 4.4 construction and insulation of ducts and pipes and duct sealing to reduce leakage

•Section 4.5 control requirements for HVAC systems including zone controls and controls to limit reheating and recooling

•Section 4.6 remaining requirements for HVAC systems, including sizing and equipment selection, load calculations, economizers, electric resistance heating limitation, limitation on air-cooled chillers, fan power consumption, and fan and pump flow controls, dedicated outside air systems, and exhaust air heat recovery.

•Section 4.7 remaining requirements for service water heating

•Section 4.8 performance method of compliance

•Section 4.9 compliance requirements for additions and alterations.

•Section 4.10 glossary, reference, and definitions.

•Section 4.11 mechanical plan check documents, including information that must be provided in the building plans and specifications to show compliance with the Energy Code

Acceptance requirements apply to all covered systems regardless of whether the prescriptive or performance compliance approach is used.

Chapter 12 lays out the mandated acceptance test requirements, which are summarized at the end of each section.

•New prescriptive requirements for single zone space conditioning system types for certain space categories (Retail, grocery, school, office, financial institution, and library)

•New prescriptive requirements for heat pump water heating systems for small schools in climate zones 2 through 15

•Adjustments to the VAV airflow deadband controls

•Economizer Changes:

o Expanded airside economizer requirements

o New economizer exceptions:

§ Exception for certain dedicated outside air system configurations

§ Exception for controlled environment horticulture using carbon enrichment

•New requirements for Dedicated Outside Air Systems

•Expansion of scope of Occupant Sensor Ventilation Control (Occupied-Standby) to large office spaces

•New requirements for Exhaust Air Heat Recovery

•Changes to the fan power requirements

•Changes to duct leakage testing requirements

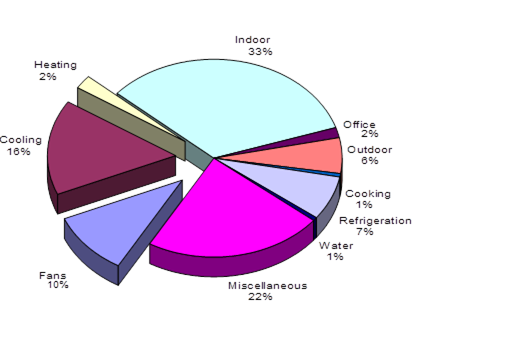

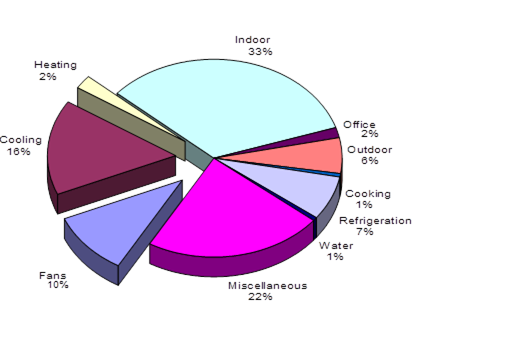

Mechanical and lighting systems are the largest consumers of energy in nonresidential buildings. The amount of energy consumed by various mechanical components varies according to system design and climate. Fans and cooling equipment are the largest components of energy consumed for HVAC purposes in most building in lower elevation climates. Energy consumed for heating is usually less than fans and cooling, followed by service water heating.

Figure

4-1: Typical Nonresidential Building Electricity Us

Heating, cooling and ventilation account for about 28 percent of commercial building electricity use in California.

Source IEQ RFP, December 2002, California Energy Commission No. 500-02-501.

Mandatory measures, covered in §110.0-110.12 and §120.0-120.10, apply to all nonresidential buildings, whether the designer chooses the prescriptive or performance approach for compliance. The following sections are applicable to mechanical systems:

1. Equipment certification and equipment efficiency - §110.1 and §110.2

2. Service water heating systems and equipment - §110.3

3. Pool and spa heating systems and equipment - §110.4

4. Restrictions on pilot lights for natural gas appliances and equipment - §110.5

5. Demand responsive controls - §110.12

6. Ventilation and indoor air quality requirements - §120.1

7. Control requirements - §120.2

8. Pipe insulation - §120.3

9. Duct construction, sealing, insulation, and leakage testing - §120.4

10. Acceptance tests in §120.5 and the 2019 Reference Appendices NA7|topic=Appendix NA7 – Installation and Acceptance Requirements for Nonresidential Buildings and Covered Processes

11. Commissioning - §120.8

12. Commercial Boilers - §120.9

13. Fan Energy Index - §120.10

The Energy Code allows mechanical system compliance to be demonstrated by meeting the mandatory requirements and the requirements of either the prescriptive or performance compliance approaches.

•The measures in the prescriptive compliance approach, §140.4, and §140.5, cover specific requirements for individual components and systems that directly comply with the Energy Code, including:

•§140.4(a)1 – Sizing and equipment selection

•§140.4(a)2 – Single zone space conditioning system type

•§140.4(b) - Load calculations

•§140.4(c) - Fan power consumption

•§140.4(d)|topic=(d) Space-conditioning Zone Controls. - Controls to reduce reheating, recooling and mixing of conditioned air streams

•§140.4(e) - Economizers

•§140.4(f) - Supply temperature reset

•§140.4(g) - Restrictions on electric-resistance heating

•§140.4(h) - Fan speed controls for heat rejection equipment

•§140.4(h) - Limitation on centrifugal fan cooling towers

•§140.4(i) - Minimum chiller efficiency

•§140.4(j) - Limitation on air-cooled chillers

•§140.4(k) - Hydronic system design

•§140.4(m) - Supply fan control

•§140.4(n) - Mechanical system shut-off control

•§140.4(o) - Exhaust system transfer air

•§140.5 – Service Water Heating

The performance compliance approach, §140.1|topic=SECTION 140.1 – PERFORMANCE APPROACH\: ENERGY BUDGETS, allows the designer to trade off energy use between different building systems. This approach provides greater design flexibility but requires extra effort and a computer simulation of the building. The design must still meet all mandatory requirements.

1. Performance approach trade-offs can be applied to the following disciplines: mechanical, lighting, envelope, and covered processes. The performance approach requires creating a proposed energy model using approved Energy Commission compliance software. The software will automatically create a standard design model based on the features of the proposed model and compare the energy use of the two: Standard design energy model that meets mandatory and prescriptive requirements (per the Alternative Calculation Method Reference Manual).

2. Proposed design energy model that reflects the feature of the proposed building.

The proposed model complies if it results in lower time dependent valuation (TDV) energy use than the standard design model.

The performance approach may only be used to model the performance of mechanical systems that are covered under the building permit application (see Section 4.8 and Chapter 11 for more detail).