The conventional approach to meeting the prescriptive requirements of Package A for systems serving individual dwelling units the system would be to use either a small storage or instantaneous gas water heater as prescribed in the water heater Section 5.1. The distribution type options for a complying system would include either a conventional trunk and branch system or an on-demand recirculation system with manual controls. Both distribution systems must meet all of the mandatory requirements previously mentioned in this chapter. Other distribution system types do not meet the prescriptive requirement.

The other option under the prescriptive compliance method is to use the performance method for water heating only as defined in §150.1(b)1 and which is discussed in full in the performance compliance section later in this chapter. This path requires inputting the building square footage and detailing the water heater and distribution system information into the building performance compliance tool.

With the changes in the 2013 standards there are actually three prescriptive options for domestic hot water heating in single family residences depending upon whether natural gas service is available at the site.

1. A system with a single gas or propane storage type water heater must have:

a) A gas input rating < 75,000 Btu/h,

b) If the water heater’s efficiency only meets the minimum federal efficiency standards, the tank must be wrapped with an R-12 water heating blanket [a mandatory requirement in §150.0(j)1Water System Piping and Insulation for Piping\, Tanks\, and Cooling System Lines.].

c) If the system uses a trunk and branch distribution system then all pipes from the water heater to the kitchen must be insulated and all pipe with a diameter equal to or greater than ¾ of an inch must be insulated.

d) If this system has a recirculation pump then the control must be demand based with manual controls (pump only runs upon user direct activation until water temperature equals temperature setpoint). All portions of the distribution system that recirculate water must be insulated.

e) All applicable mandatory requirements in Section 110.3 and 150.0(j,n) must be met

2. A system with a single gas or propane instantaneous water heater without a storage tank must have:

a) A gas input rating < 200,000 Btu/h,

b) No supplemental storage tank is installed,

c) Uses a trunk and branch distribution system then all pipes from the water heater to the kitchen must be insulated and all pipe with a diameter equal to or greater than ¾ of a inch must be insulated.

d) All applicable mandatory requirements in Section 110.3 and 150.0(j,n) must be met

e) No recirculation systems can be installed.

3. An electric resistance storage or instantaneous water heater can be used if all of the following conditions are met:

a) Natural gas is unavailable at the site

b) The water heater is located within the building envelope

c) For storage electric and instantaneous a trunk and branch distribution system must have all pipes from the water heater to the kitchen and must be insulated and all pipe with a diameter equal to or greater than ¾ of an inch must be insulated.

d) All applicable mandatory requirements in Section 110.3 and 150.0 must be met

e) A solar water heater is installed which is designed to provide a solar fraction of 50% (provides 50% of the heating load) and is installed as specified in the Reference Residential Appendix RA4. The details of the solar water heating prescriptive requirements are in described in more detail in Section 5.6.1 later on in this chapter.

f) No supplemental storage tank is installed

g) No recirculation system can be installed with electric instantaneous water heaters.

If a water heater is installed in combination with a booster heater used to either eliminate cold surges when an instantaneous water heater is the primary system, or used to reheat water in a portion of the system the booster heater must be included in compliance. All booster heaters must be treated a separate electric instantaneous water heaters. To comply, performance compliance must be used to demonstrate the installed system uses no more energy than what is allowed under the standards.

Questions and Answers – Single Family Systems

Example 5-4 - Single family with multiple water heaters

Question

A 6,000-ft² single family residence has 3 storage gas water heaters (40 gallon, 30 gallon and a 100-gallon unit with 80,000 Btu/h input). Does it comply?

Answer

A performance calculation is required since the system does not meet the standard requirements and must be shown to meet the water heating budget of §150.1(b)1. In most cases, adding a second storage water heater will result in greater energy consumption than the standard design case.

Example 5-5 - Single family with large storage gas water heater

Question

A single family residence has a 76,000 Btu/hr input 50-gallon gas water heater with an on-demand recirculating distribution system (with manual push button control).Does it comply with the prescriptive requirements?

Answer

Since the input rating is greater than 75,000 Btu/hr the unit is considered a large storage gas water heater. Compliance will have to be determined using the performance approach. If the water heater had an input rating less than 75,000 Btu/ hr it would qualify, since the proposed distribution system. Qualifies as long as all mandatory measures are met.

Example 5-6 - Single family with point of use distribution system

Question

A 1,800 ft² single family residence has two identical 30-gallon gas storage tank water heaters and a distribution system that meets the point of use criteria. Does this comply?

Answer

Because there are two water heaters, this system does not meet the standard prescriptive water heating systems requirements of §150.1(f)8, regardless of the distribution system. To evaluate this design, it must be modeled using the performance approach.

Example 5-7 - Home Using Electric Water Heaters

Question

We plan to install a heat pump water heater in a single family home. Since heat pump water heaters have electric-resistance heating elements, are they considered as electric-resistance water heaters and subject to solar water heating requirements? How about for systems using a gas water heater as the primary water heater, but using under-sink electric heaters as booster heaters?

Answer

Heat pump water heaters are considered electric water heaters, but have different requirements for new construction and alterations when using the prescriptive approach New construction homes following prescriptive compliance method can install a heat pump water heater as the primary water heater if natural gas is not available to the home. A solar water heater with a minimum solar fraction of 0.5 must also be installed for prescriptive compliance. Upgrading an existing electric water heater to a heat pump water heater is not subject to the solar water heating requirement. Alternatively, one can model the heat pump water heater using the performance approach and likely not require the solar water heater.

When the primary water heater is a gas water heater, installing a solar water heater is not required for compliance purposes, even when small point-of-use electric water heaters are installed.

When using the prescriptive approach on multi-family buildings two options exist. Either individual water heaters must be installed in each unit that meet the requirements for single family building or a central gas or propane fired water heater or boiler is required. The water heater must have an efficiency that meets the requirements in Sections 110.1 and 110.3 in the standards (as 'listed in Table 5-1 or Table 5-2 earlier in this chapter). In 'addition if a central recirculation system is installed it shall be installed with controls and a distribution layout that will include demand recirculation controls and at least two recirculation loops. These new prescriptive rules were added based on studies that found that recirculation pipe heat loss is a major component of energy loss within a central hot water system. Pipe heat loss is affected by the temperature difference between the hot water and ambient, pipe insulation level, and pipe surface area. The motivation behind having two loops is to reduce recirculation pipe sizes, thus pipe surface areas. This measure reduces energy uses and piping materials associated with recirculation systems. Central water heating systems with eight or fewer dwelling units are exempted from needing two recirculation loops.

1. Solar Water Heating Requirements

A new requirement for multi-family buildings with a central distribution system is that a solar water heating system be installed. Section 5.6 is entirely dedicated to solar water heating, and it includes detailed descriptions on associated mandatory and prescriptive requirements. The installed solar heating collectors must be certified by the Solar Rating and Certification Corporation (SRCC). Minimum solar fractions for each climate zone are listed below in Table 5-6, and documented on the corresponding compliance form.

|

Climate Zone |

Minimum Solar Fraction |

|

1-9 |

0.20 |

|

10-162 |

0.35 |

2. Dual Loop Recirculation System Design

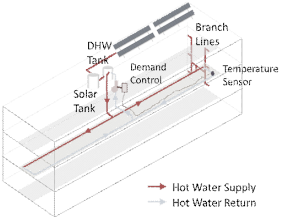

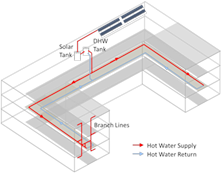

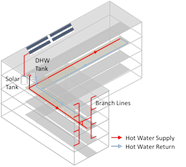

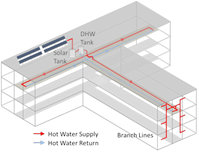

A dual-loop design is illustrated in Figure 5-11. In a dual-loop design, each loop serves half of the dwelling units. According to plumbing code requirements, the pipe diameters can be downsized compared to a loop serving all dwelling units. The total pipe surface area is effectively reduced, even though total pipe length is about the same as that of a single-loop design. For appropriate pipe sizing guidelines, please refer to the Universal Plumbing Code.

Figure 5-12 provides an example of how to implement duel-loop design in a low-rise multi-family building with a simple layout. In this example, the water heating equipment is located in the middle of top floor with each recirculation loop serve exactly half of the building. The recirculation loops are located in the middle floor to minimize branch pipe length to each dwelling units. The figure also illustrates how the solar water heating system and demand control are integrated.

For buildings with complicated layouts, how to create and locate recirculation loops heavily depends on building geometry. In general, the system should be designed to have each loop serve the equal number of dwelling units in order to minimize pipe sizes. For systems serving buildings with distinct sections, e.g. two wings in an “L” shaped building, it is better to dedicate a separate recirculation loop to each of the sections. Very large buildings and buildings with more than two sections should consider using separate central water heating systems for each section. In all cases, simple routing of recirculation loops should be used to keep recirculation pipes as short as possible. Figure 5-12 provides dual-loop recirculation system designs in buildings with complicated shapes.

Location of water heating equipment in the building also needs to be carefully considered to properly implement the dual-loop design. The goal is to keep overall pipe length as short as possible. As an example, for building in regular shapes, locating the water heating equipment at the center of the building footprint rather than at one end of the building helps to minimize the pipe length needed to connect the water heating equipment to the two loops. If a water heating system serves several distinct building sections, the water heating equipment would preferably nest in between these sections.

With the new prescriptive solar water heating requirement this cycle, it is especially important to consider the integration between the hot water recirculation system and the solar water heating system. Based on feedbacks from industry stakeholders, most solar water heating systems are only configured as a pre-heater of the primary gas water heating equipment. In other words, recirculation hot water returns are usually plumbed back to the gas water heating storage tanks, not directly into the solar tank. This means recirculation loop designs should be mostly based on the building layout and are relatively independent of the solar water heating system. On the other hand, gas water heating equipment and solar tanks should be located closed to each other to avoid heat loss from pipes connecting the two systems. The preferred configuration is to place both the gas water heating equipment and solar tanks on the top floor near the solar collector so that the total system pipe length can be reduced. As noted before, minimizing pipe length helps reduced DHW system energy use as well as system plumbing cost.

3. Demand Recirculation Control

The prescriptive requirement for DHW systems serving multiple dwelling units requires the installation of a demand recirculation control to minimize pump operation. Please note that they are different from the demand control used in single dwelling unit, as described in the section 0. Demand controls for central recirculation systems are based on hot water demand and recirculation return temperatures. The temperature sensor should be installed at the last branch pipe along the recirculation loop.

Any system not meeting these prescriptive requirements must instead meet the Standard Design Building energy budget as described in §150.1(b)1, or must follow the performance compliance method for the building as a whole.

Example 5-8 - Multi-family with individual water heater

Question

A 10-unit multi-family building has separate gas water heaters for each dwelling unit. Five units have 30-gallon water heaters, and 5 units have 50-gallon water heaters. Does this comply?

Answer

The Standard provides two prescriptive compliance paths for domestic hot water heating systems in multi-family buildings. One is to use a central water heating system. The other is to use separate gas waters for each dwelling unit, as in this example. In order to use this compliance method, all dwelling units must use residential water heaters (heat input of less than 75,000 Btu/hr) with EF ratings equal or higher than corresponding Title 20 appliance standard requirements. .

Example 5-9 - Multi-family recirculation system

Question

We are building an 8-unit, 7,800 ft² multi-family building with a 200 gallon storage gas water heater with a time and temperature controlled recirculation system that has R-4 insulation on all the piping. The system serves all the units. Do I have to perform calculations to show compliance?

Answer

Water heating calculations are required since the standard design assumption uses demand recirculation for the control strategy for central recirculation. There is also the concern that solar water heating is required for all multi-family building with central recirculation systems.

Example 5-10 - Multi-family large water heater

Question

We

are building a 10-unit apartment building with a single large water heater. We

do not plan to install a recirculation pump and loop. Does this meet the

Prescriptive requirements?

Answer

No. Since it is unlikely that a non-recirculating system will satisfactorily supply hot water to meet the tenants’ needs, either a recirculating system or individual water heaters must be installed to meet the Prescriptive requirements. There is an exception for multi-family buildings of eight units or less. using the performance approach