This section covers controls that are mandatory for all system types, including:

•Heat pump controls for the auxiliary heaters,

•Zone thermostatic control including special requirements for hotel/motel guest rooms and perimeter systems,

•Shut-off and setback/setup controls,

•Infiltration control,

•Off-hours space isolation

•Economizer fault detection and diagnostics (FDD.

•Control equipment certification.

•Direct Digital Controls (DDC).

•Optimum start/stop controls.

4.5.1.1 Zone Thermostatic Controls

Thermostatic controls must be provided for each space-conditioning zone or dwelling unit to control the supply of heating and cooling energy within that zone. The controls must have the following characteristics:

1. When used to control heating, the thermostatic control must be adjustable down to 55°F or lower.

2. When used to control cooling, the thermostatic control must be adjustable up to 85°F or higher.

3. When used to control both heating and cooling, the thermostatic control must be adjustable from 55°F to 85°F and also provide a temperature range or dead band of at least 5°F. When the space temperature is within the dead band, heating and cooling energy must be shut off or reduced to a minimum. A dead band is not required if the thermostat requires a manual changeover between the heating and cooling modes Exception to §120.2(b)3.

4. For all single zone, air conditioners and heat pumps all thermostats shall have setback capabilities with a minimum of four separate setpoints per 24 hour period. Also the thermostat must comply with the Occupant Controlled Smart Thermostat requirements of Reference Joint Appendix JA5, which is capable of responding to demand response signals in the event of grid congestion and shortages during high electrical demand periods.

5. Systems equipped with DDC to the zone level, rather than zone thermostats, must be equipped with automatic demand shed controls as described later in Section 4.5.1.7.

The setpoint may be adjustable either locally or remotely, by continuous adjustment or by selection of sensors.

Supplemental perimeter heating or cooling systems are sometimes used to augment a space-conditioning system serving both interior and perimeter zones. This is allowed provided controls are incorporated to prevent the two systems from conflicting with each other. If that were the case, then the Energy Standards require that:

1. The perimeter system must be designed solely to offset envelope heat losses or gains; and

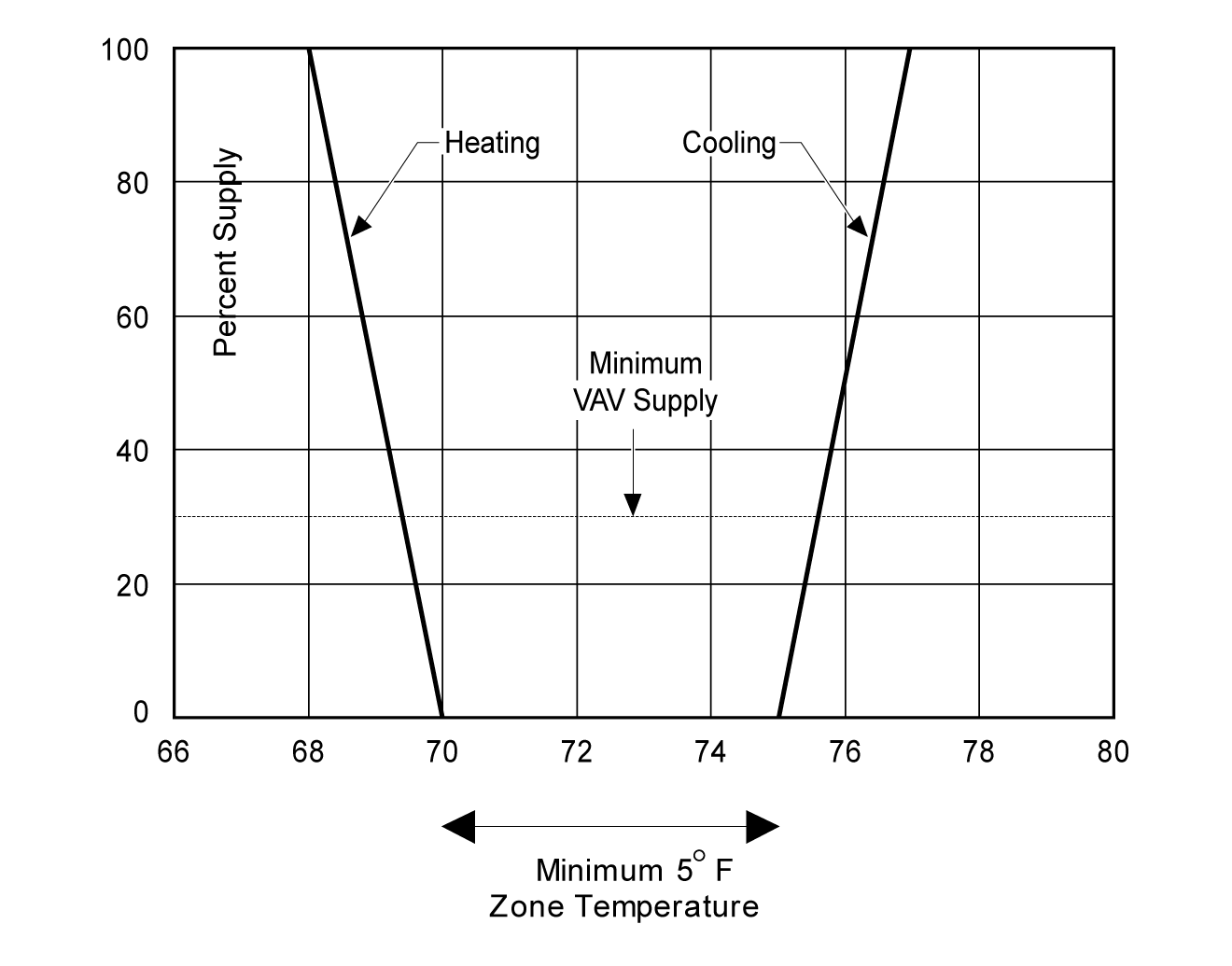

2. The perimeter system must have at least one thermostatic control for each building orientation of 50 ft. or more; and

3. The perimeter system is controlled by at least one thermostat located in one of the zones served by the system.

The intent is that all major exposures be controlled by their own thermostat, and that the thermostat be located within the conditioned perimeter zone. Other temperature controls, such as outdoor temperature reset or solar compensated outdoor reset, do not meet these requirements of the Energy Standards.

Example 4-23

Question

Can an energy management system be used to control the space temperatures?

Answer

Yes, provided the space temperature setpoints can be adjusted, either locally or remotely. This section sets requirements for “thermostatic controls” which need not be a single device like a thermostat; the control system can be a broader system like a direct digital control (DDC) system. Note that some DDC systems employ a single cooling setpoint and a fixed or adjustable deadband. These systems comply if the deadband is adjustable or fixed at 5°F or greater.

Thermostats with adjustable setpoints and deadband capability are not required for zones that must have constant temperatures to prevent the degradation of materials, an exempt process, or plants or animals (Exception 1 to §120.2(b)4). Included in this category are manufacturing facilities, hospital patient rooms, museums, computer rooms, etc. Chapter 13 describes mandated acceptance test requirements for thermostat control for packaged HVAC systems.

4.5.1.2 Hotel/Motel Guest Rooms and High-Rise Residential Dwellings Thermostats

The Energy Standards require that thermostats in hotel and motel guest rooms have:

1. Numeric temperature setpoints in °F, and

2. Setpoint stops that prevent the thermostat from being adjusted outside the normal comfort range (± 5oF). These stops must be concealed so that they are accessible only to authorized personnel, and

3. Setback capabilities with a minimum of four separate setpoints per 24 hour period; in additions, for nonresidential buildings, The Energy Standards effectively prohibit thermostats.

The Energy Standards require that thermostats in high-rise residential dwelling units have setback capabilities with a minimum of four separate setpoints per 24 hour period; in additions, for nonresidential buildings, the Energy Standards effectively prohibit thermostats.

Example 4-24

Question

What is the perimeter zoning required for the building shown here?

Answer

The southeast and northwest exposures must each have at least one perimeter system control zone, since they are more than 50 ft. in length. The southwest exposure and the serrated east exposure do not face one direction for more than 50 continuous ft. in length. They are therefore “minor” exposures and need not be served by separate perimeter system zones, but may be served from either of the adjacent zones.

Example 4-25

Question

Pneumatic thermostats are proposed to be used for zone control. However, the model specified cannot be adjusted to meet the range required by §120.2(a) to (c). How can this system comply?

Answer

§120.2(a) to (c) applies to “thermostatic controls” which can be a system of thermostats or control devices, not necessarily a single device. In this case, the requirement could be met by using multiple thermostats. The pneumatic thermostats could be used for zone control during occupied hours and need only have a range consistent with occupied temperatures (e.g. 68°F to 78°F), while two additional electric thermostats could be provided, one for setback control (adjustable down to 55°F) and one for set-up (adjustable up to 85°F). These auxiliary thermostats would be wired to temporarily override the system to maintain the setback/setup setpoints during off-hours.

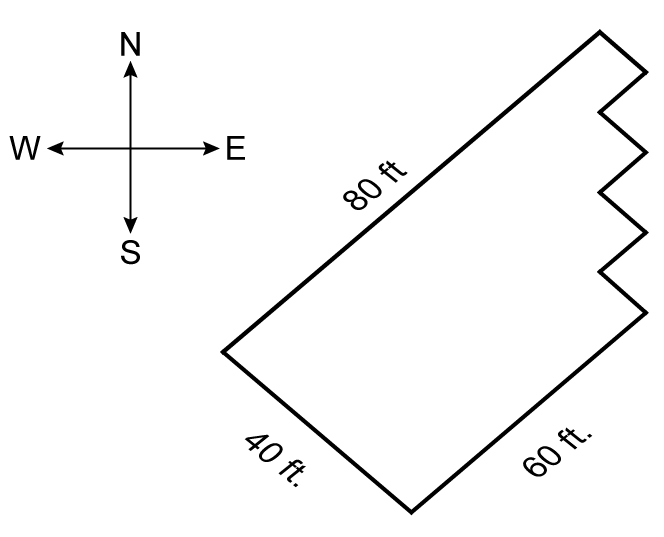

4.5.1.3 Heat Pump Controls

Heat pumps with electric resistance supplemental heaters must have controls that limit the operation of the supplemental heater to defrost and as a second stage of heating when the heat pump alone cannot satisfy the load. The most effective solution is to specify an electronic thermostat designed specifically for use with heat pumps. This “anticipatory” thermostat can detect if the heat pump is raising the space temperature during warm-up fast enough to warrant locking out the auxiliary electric resistance heater.

This requirement can also be met using conventional electronic controls with a two-stage thermostat and an outdoor lockout thermostat wired in series with the auxiliary heater. The outdoor thermostat must be set to a temperature where the heat pump capacity is sufficient to warm up the space in a reasonable time (e.g., above 40°F). This conventional control system is depicted schematically below in Figure 4-11.

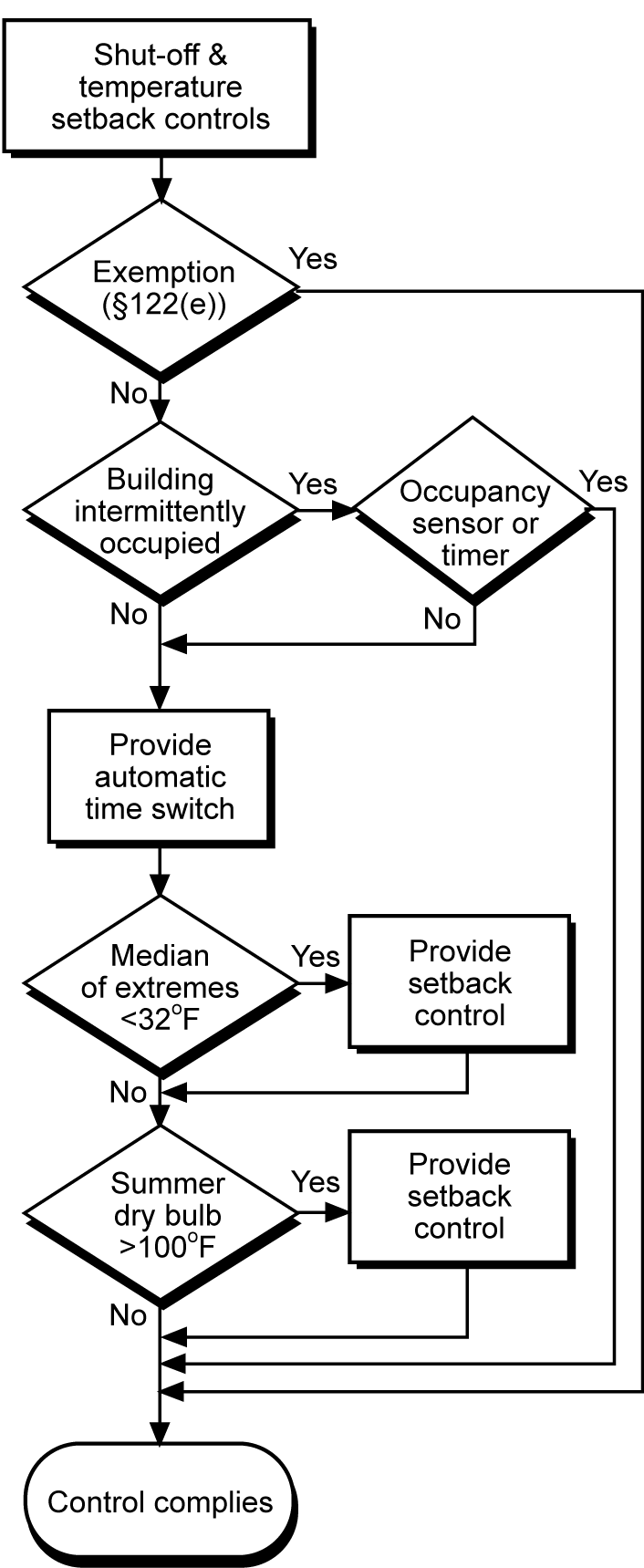

4.5.1.4 Shut-off and Temperature Setup/Setback

For specific occupancies and conditions, each space-conditioning system must be provided with controls that comply with the following requirements:

A. The control can automatically shut off the equipment during unoccupied hours and shall have one of the following:

An automatic time switch device must with the same characteristics that lighting devices must have, as described in Chapter 5

1. and a manual override accessible to the occupants that allows the system to operate up to four hours. The manual override can be included as a part of the control device, or as a separate override control.

2. An occupancy sensor. Since a building ventilation purge is required prior to normal occupancy, an occupancy sensor may be used to control the availability of heating and cooling, but should not be used to control the outdoor ventilation system.

3. A 4-hour timer that can be manually operated to start the system. As with occupancy sensors, the same restrictions apply to controlling outdoor air ventilation systems.

Exception to §120.2(e)1: The mechanical system serving retail stores and associated malls, restaurants, grocery stores, churches, or theaters equipped with 7-day programmable timers do not have to comply with the above requirements.

B. When shut down, the controls shall automatically restart the system to maintain:

1. A setback heating thermostat setpoint, if the system provides mechanical heating. Exception: Thermostat setback controls are not required in nonresidential buildings in areas where the Winter Median of Extremes outdoor air temperature is greater than 32°F.

2. A setup cooling thermostat setpoint, if the system provides mechanical cooling. Exception: Thermostat setup controls are not required in nonresidential buildings in areas where the Summer Design Dry Bulb 0.5 percent temperature is less than 100°F.

C. Occupant Sensor Ventilation Coil and Setback

Multipurpose room less than 1,000 ft2, classrooms greater than 750 ft2, conference, convention, auditorium and meeting center rooms greater than 750 ft2 that do not have processes or operations that generate dusts, fumes, vapors or gasses shall be equipped with occupant sensor(s) to accomplish the following when occupants are not present:

1. Slightly widen the thermal deadband: Automatically setup the operating cooling temperature set point by 2°F or more and setback the operating heating temperature set point by 2˚F or more; and

2. Automatically reset the minimum required ventilation rate with an occupant sensor ventilation control device according to Section 4.3.8.

This scenario requires an additional control sequence for built-up VAV systems or a thermostat that can accept an occupancy sensor input and has three scheduling modes (occupied, standby, and unoccupied) for packaged equipment. A thermostat with three scheduling modes works as follows.

•The unoccupied period is scheduled as usual for the normal unoccupied period, e.g. nighttime.

•The occupied period is scheduled as usual for the normal occupied period, e.g. daytime.

•When the morning warm-up occurs, the thermostat’s occupied schedule is used to establish the heating/cooling temperature setpoints.

•Upon completion of the morning warm-up, the standby setpoint schedule on the thermostat is enabled.

This schedule remains in effect until occupancy is sensed (then enabling the occupied setpoint schedule) or until the normally scheduled unoccupied period occurs. After the period of occupancy ends (e.g. a conference room is vacated) and the time delay expires as programmed into the occupancy sensor, the standby setpoint schedule on the thermostat is enabled.

The following chart shows an example of how the three scheduling modes might be programmed for a cooling setup of 4oF and a heating setback of 4oF.

Example Thermostat Setpoints for Three Modes

|

|

Cooling, °F |

Heating, °F |

|

Occupied |

75 |

70 |

|

Standby |

78 |

67 |

|

Unoccupied |

80 |

62 |

D. Exceptions for automatic shut-off, setback and setup and occupant sensor setback:

1. Exception to 1, 2 and 3: It can be demonstrated to the satisfaction of the enforcement agency that the system serves an area that must operate continuously

2. Exception to 1, 2 and 3: It can be demonstrated to the satisfaction of the enforcement agency that shutdown, setback, and setup will not result in a decrease in overall building source energy use

3. Exception to 1, 2 and 3: Systems have a full load demand less than 2 kW, or 6,826 Btu/h, if they have a readily accessible manual shut-off switch. Included is the energy consumed within all associated space-conditioning systems including compressors, as well as the energy consumed by any boilers or chillers that are part of the system.

4. Exception to 1 and 2: Systems serve hotel/motel guest rooms, if they have a readily accessible manual shut-off switch.

5. Exception to 3: If demand control ventilation is implemented as required by 4.3.7.

E. Hotel/Motel Guest Room Controls:

Hotel and motel guest rooms shall have captive card key controls, occupancy sensing controls, or automatic controls such that, no longer than 30 minutes after the guest room has been vacated, setpoints are setup at least +5°F (+3°C) in cooling mode and set-down at least -5°F (-3°C) in heating mode.

Example 4-26

Question

Can occupancy sensors be used in an office to shut off the VAV boxes during periods the spaces are unoccupied?

Answer

Yes, only if the ventilation is provided through operable openings. With a mechanical ventilation design the occupancy sensor could be used to reduce the VAV box airflow to the minimum allowed for ventilation. It should not shut the airflow off completely, ventilation must be supplied to each space at all times when the space is usually occupied.

Example 4-27

Question

Must a 48,000 ft² building with 35 fan coil units have 35 time switches?

Answer

No. More than one space-conditioning system may be grouped on a single time switch, subject to the area limitations required by the isolation requirements (see Isolation). In this case, the building would need two isolation zones, each no larger than 25,000 ft², and each having its own time switch.

Example 4-28

Question

Can a thermostat with setpoints determined by sensors (such as a bi-metal sensor encased in a bulb) be used to accomplish a night setback?

Answer

Yes. The thermostat must have two heating sensors, one each for the occupied and unoccupied temperatures. The controls must allow the setback sensor to override the system shutdown.

These provisions are required by the Energy Standards to reduce the likelihood that shut-off controls will be circumvented to cause equipment to operate continuously during unoccupied hours.

Example 4-29

Question

If a building has a system comprised of 30 fan coil units, each with a 300-watt fan, a 500,000 Btu/h boiler, and a 30-ton chiller, can an automatic time switch be used to control only the boiler and chiller (fan coils operate continuously)?

Answer

No. The 2 kW criteria applies to the system as a whole, and is not applied to each component independently. While each fan coil only draws 300 W, they are served by a boiler and chiller that draw much more. The consumption for the system is well in excess of 2 kW.

Assuming the units serve a total area of less than 25,000 ft² (see Isolation), one time switch may control the entire system.

4.5.1.5 Infiltration Control

Outdoor air supply and exhaust equipment must incorporate dampers that automatically close when fans shut down.

Fans shut down when ventilation or conditioned air is not necessary for the building, which only occurs when a normally scheduled unoccupied period begins (such as overnight or a weekend for office buildings. The dampers may either be motorized, or of the gravity type, however only motorized dampers that remain closed when the fan turns on would be capable of accomplishing the best practice below

|

Best Practice Though the Energy Standards only specify fan shut down, as a best practice outside air dampers should also remain completely closed during the unoccupied periods, even when the fan turns on to provide setback heating or cooling. However, to avoid instances of insufficient ventilation, or sick building syndrome, the designer should specify that the outside air dampers open and provide ventilation if: o The unoccupied period is a 1-hour pre-occupancy purge ventilation, as per §120.1(c)2. o The damper is enabled by an occupant sensor in the building as per §120.1(c)5, indicating that there are occupants that demand ventilation air. o The damper is enabled by an override signal as per §120.2(e)1, which includes an occupancy sensor but also an automatic time switch control device or manually operated 4-hour timer.

|

Exception 1: Damper control is not required where it can be demonstrated to the satisfaction of the enforcement agency that the space-conditioning system must operate continuously.

Exception 2: Nor is damper control required on gravity ventilators or other non-electrical equipment, provided that readily accessible manual controls are incorporated.

Exceptions 3 and 4: Damper control is also not required at combustion air intakes and shaft vents, or where prohibited by other provisions of law. If the designer elects to install dampers or shaft vents to help control stack-induced infiltration, the damper should be motorized and controlled to open in a fire in accordance with applicable fire codes.

4.5.1.6 Isolation Area Controls

Large space-conditioning systems serving multiple zones may waste considerable quantities of energy by conditioning all zones when only a few zones are occupied. Typically, this occurs during evenings or weekends when only a few people are working. When the total area served by a system exceeds 25,000 ft², the Energy Standards require that the system be designed, installed and controlled with area isolation devices to minimize energy consumption during these times. The requirements are:

1. The building shall be divided into isolation areas, the area of each not exceeding 25,000 ft². An isolation area may consist of one or more zones.

2. An isolation area cannot include spaces on different floors.

3. Each isolation area shall be provided with isolations devices such as valves or dampers that allow the supply of heating or cooling to be setback or shut off independently of other isolation areas.

4. Each isolation area shall be controlled with an automatic time switch, occupancy sensor, or manual timer. The requirements for these shut-off devices are the same as described previously in 4.5.1.4 As discussed previously for occupancy sensors, a building purge must be incorporated into the control sequences for normally occupied spaces, so occupancy sensors and manual timers are best limited to use in those areas that are intermittently occupied.

Any zones requiring continuous operation do not have to be included in an isolation area.

Example 4-30

Question

How many isolation zones does a 55,000-ft² building require?

Answer

At least three. Each isolation zone may not exceed 25,000-ft².

A. Isolation of Zonal Systems

Small zonal type systems such as water loop heat pumps or fan coils may be grouped on automatic time switch devices, with control interlocks that start the central plant equipment whenever any isolation area is occupied. The isolation requirements apply to equipment supplying heating and cooling only; central ventilation systems serving zonal type systems do not require these devices.

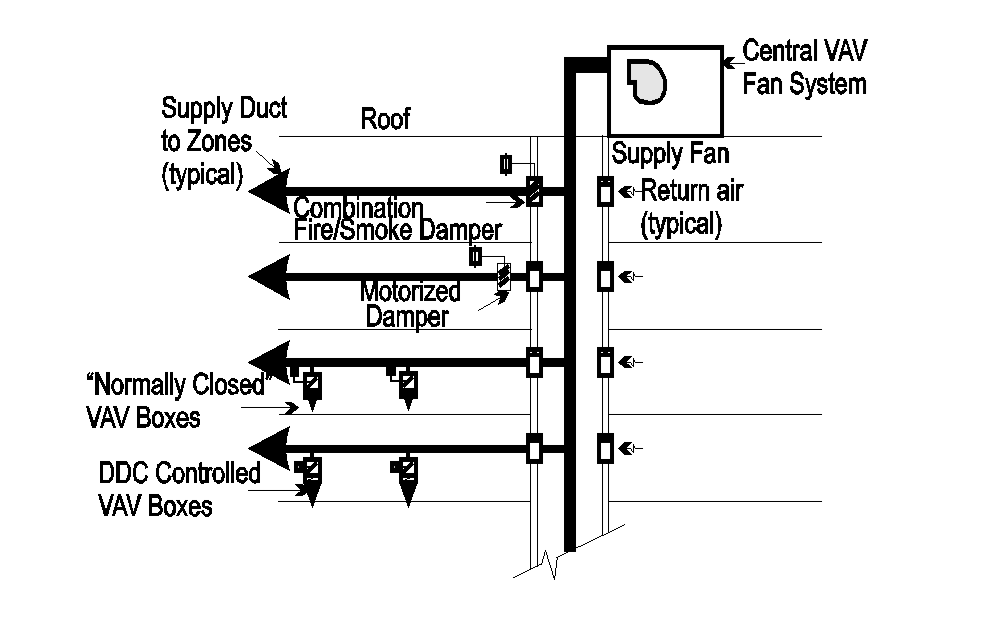

B. Isolation of Central Air Systems

Figure 4-13 below depicts four methods of area isolation with a central variable air volume system:

1. On the lowest floor, programmable DDC boxes can be switched on a separate time schedule for each zone or blocks of zones. When unoccupied, the boxes can be programmed to have zero minimum volume setpoints and unoccupied setback/setup setpoints. Note this form of isolation can be used for sections of a single floor distribution system.

2. On the second floor, normally closed pneumatic or electric VAV boxes are used to isolate zones or groups of zones. In this scheme the control source (pneumatic air or control power) for each group is switched on a separate control signal from an individual time schedule. Again this form of isolation can be used for sections of a single floor distribution system.

3. On the third floor isolation is achieved by inserting a single motorized damper on the trunk of the distribution ductwork. With the code requirement for fire/smoke dampers (see next bullet) this method is somewhat obsolete. When applied this method can only control a single trunk duct as a whole. Care must be taken to integrate the motorized damper controls into the fire/life safety system.

4. On the top floor a combination fire smoke damper is controlled to provide the isolation. Again this control can only be used on a single trunk duct as a whole. Fire/smoke dampers required by code can be used for isolation at virtually no cost provided that they are wired so that the fire life-safety controls take precedence over off-hour controls. (Local fire officials generally allow this dual usage of smoke dampers since it increases the likelihood that the dampers will be in good working order in the event of a fire.) Note that no isolation devices are required on the return.

Example 4-31

Question

Does each isolation area require a ventilation purge?

Answer

Yes. Consider each isolation area as if it were a separate air handling system, each with its own time schedule, setback and setup control, etc.

C. Turndown of Central Equipment

Where isolation areas are provided it is critical that the designer design the central systems (fans, pumps, boilers and chillers) to have sufficient stages of capacity or turndown controls to operate stably as required to serve the smallest isolation area on the system. Failure to do so may cause fans to operate in surge, excessive equipment cycling and loss of temperature control. Schemes include:

1. Application of demand based supply pressure reset for VAV fan systems. This will generally keep variable speed driven fans out of surge and can provide 10:1 turndown.

2. Use of pony chillers, an additional small chiller to be used at partial load conditions, or unevenly split capacities in chilled water plants. This may be required anyway to serve 24/7 loads.

3. Unevenly split boiler plants.

4.5.1.7 Automatic Demand Shed Controls

HVAC systems with DDC to the zone level must be programmed to allow centralized demand shed for non-critical zones as follows:

1. The controls shall have a capability to remotely setup the operating cooling temperature set points by four degrees or more in all non-critical zones on signal from a centralized contact or software point within an Energy Management Control System (EMCS).

2. The controls shall be capable of remotely setdown the operating heating temperature set points by four degrees or more in all non-critical zones on signal from a centralized contact or software point within an EMCS.

3. The controls shall have capabilities to remotely reset the temperatures in all non- critical zones to original operating levels on signal from a centralized contact or software point within an EMCS.

4. The controls shall be programmed to provide an adjustable rate of change for the temperature setup and reset.

5. The controls shall have the following features:

a. Disabled. Disabled by authorized facility operators; and

b. Manual control. Manual control by authorized facility operators to allow adjustment of heating and cooling set points globally from a single point in the EMCS; and

c. Automatic Demand Shed Control. Upon receipt of a demand response signal, the space-conditioning systems shall conduct a centralized demand shed, as specified in 1 and 2 above, for non-critical zones during the demand response period.

The Energy Standards defines a critical zone as a zone serving a process where reset of the zone temperature setpoint during a demand shed event might disrupt the process, including but not limited to data centers, telecom/private branch exchange (PBX) rooms, and laboratories.

To comply with this requirement, each non-critical zone temperature control loop will need a switch that adds in an offset on the cooling temperature setpoint on call from a central demand shed signal. A rate of change limiter can either be built into the zone control or into the functional block for the central offset value. The central demand shed signal can be activated either through a global software point or a hardwired digital contact.

This requirement is enhanced with an acceptance test to ensure that the system was programmed as required.

4.5.1.8 Economizer Fault Detection and Diagnostics

Economizer Fault Detection and Diagnostics (FDD) is a mandatory requirement for all newly installed air-cooled packaged direct-expansion units, with the following:

•an air handler mechanical cooling capacity greater than or equal to 54,000 Btu/hr.

•an air economizer.

The FDD system can be either a stand-alone unit or integrated. A stand-alone FDD unit is added onto the air handler, while an integrated FDD system is included in the air handler system controller or is part of the EMCS.

Where required, the FDD system shall meet the following requirements:

1. The following temperature sensors shall be permanently installed to monitor system operation: outside air, supply air, and return air; and

2. Temperature sensors shall have an accuracy of ±2°F over the range of 40°F to 80°F; and

3. The controller shall have the capability of displaying the value of each sensor; and

4. The controller shall provide system status by indicating the following conditions:

a. Free cooling available.

b. Economizer enabled.

c. Compressor enabled.

d. Heating enabled, if the system is capable of heating.

e. Mixed air low limit cycle active.

5. The unit controller shall manually initiate each operating mode so that the operation of compressors, economizers, fans, and heating system can be independently tested and verified; and

6. Faults shall be reported using one of the following options:

a. An EMCS that is regularly monitored by facility personnel.

b. Displayed locally on one or more zone thermostats or a device within 5 feet of a zone thermostat, clearly visible, at eye level and meet the following requirements:

i. On the thermostat, device, or an adjacent written sign, there must be instructions displayed for how to contact the appropriate building personnel or an HVAC technician to service the fault.

ii. In buildings with multiple tenants, the fault notification shall either be within property management offices or in a common space accessible by the property or building manager.

c. Reported to a fault management application that automatically provides notification of the fault to a remote HVAC service provider. This allows the service provider to coordinate with an HVAC technician to service the fault.

7. The FDD system shall have the minimum capability of detecting the following faults:

a. Air temperature sensor failure/fault. This failure mode is a malfunctioning air temperature sensor, such as the outside air, discharge air, or return air temperature sensor. This could include mis-calibration, complete failure either through damage to the sensor or its wiring, or failure due to disconnected wiring.

b. Not economizing when it should. In this case, the economizer should be enabled, but for some reason it’s not providing free cooling. This leads to an unnecessary increase in mechanical cooling energy. Two examples are the economizer high limit setpoint is too low, say 55˚F, or the economizer is stuck closed.

c. Economizing when it should not. This is opposite to the previous case of not economizing when it should. In this case, conditions are such that the economizer should be at minimum ventilation position but for some reason it is open beyond the correct position. This leads to an unnecessary increase in heating and cooling energy. Two examples are the economizer high limit setpoint is too high, say 82˚F, or the economizer is stuck open.

d. Damper not modulating. This issue represents a stuck, disconnected, or otherwise inoperable damper that does not modulate open and closed. It is a combination of the previous two faults: not economizing when it should, and economizing when it should not.

e. Excess outdoor air. This failure mode is the economizer provides an excessive level of ventilation, usually much higher than is needed for design minimum ventilation. It causes an energy penalty during periods when the economizer should not be enabled, that is, during cooling mode when outdoor conditions are higher than the economizer high limit setpoint. During heating mode, excess outdoor air will increase heating energy.

8. The FDD system shall be certified to the Energy Commission, by the manufacturer of the FDD system, to meet the requirements 1 through 7 above. The manufacturer submittal package is available in Joint Appendices JA6.3 Economizer Fault Detection and Diagnostics Certification Submittal Requirements.

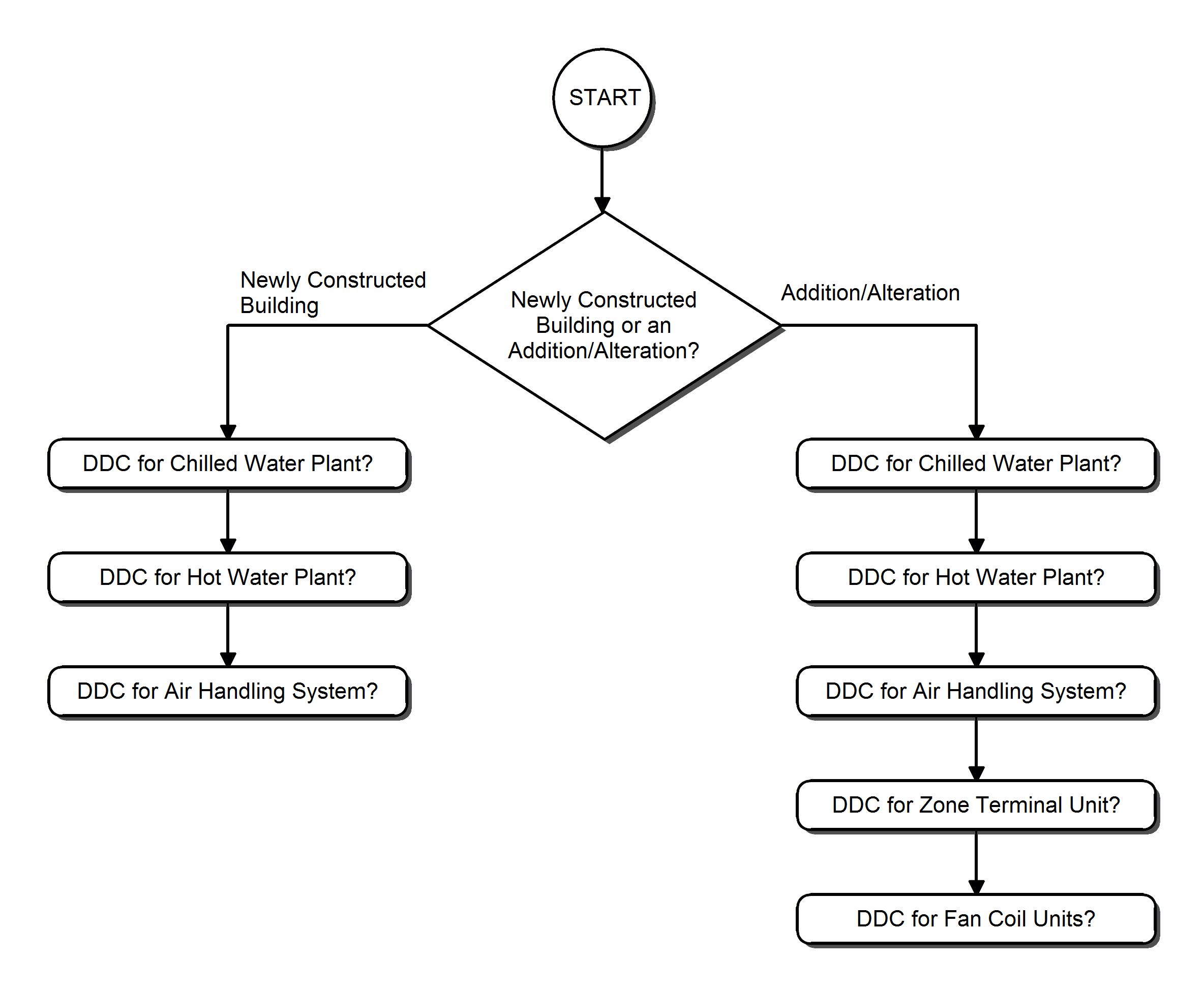

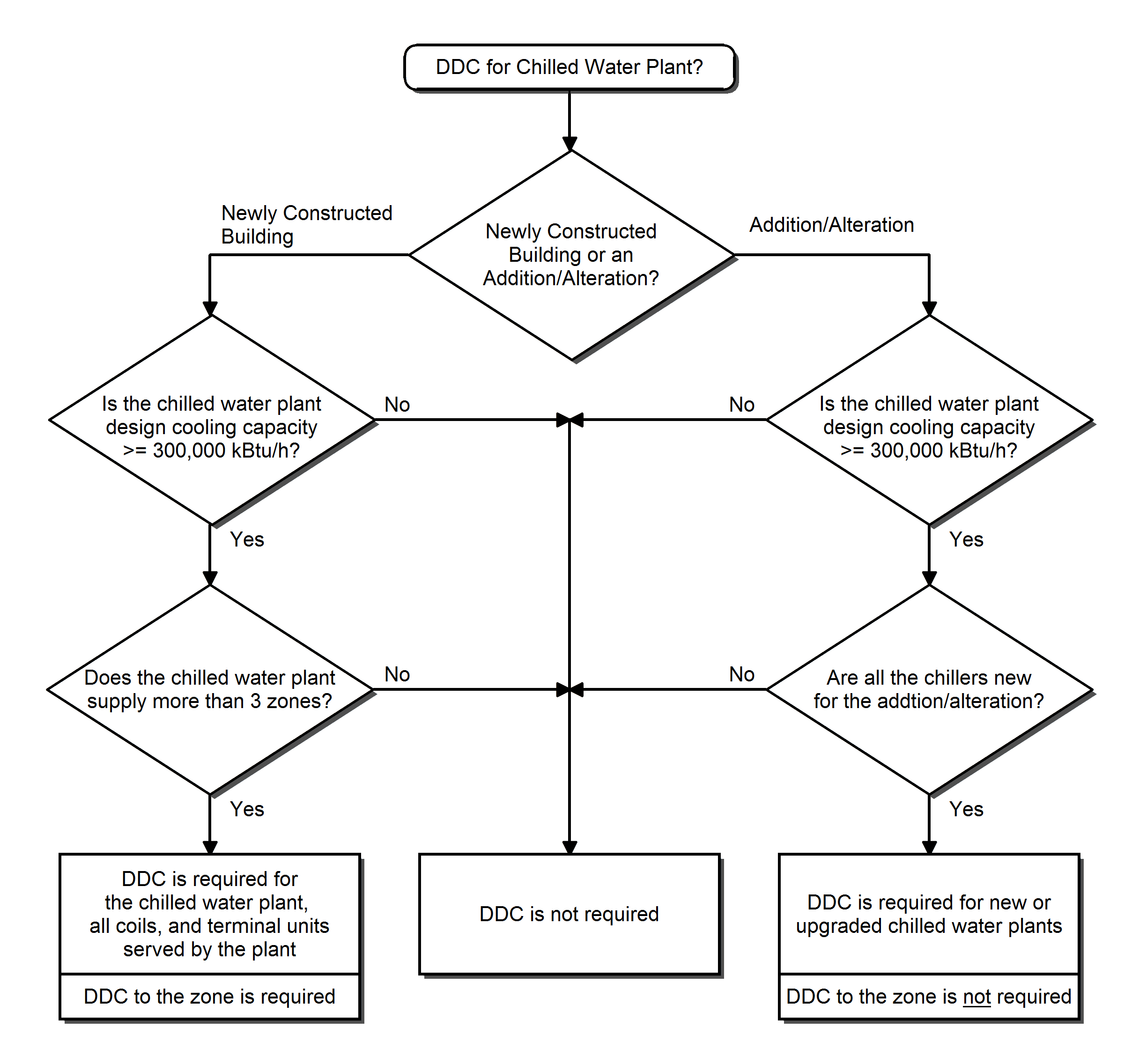

4.5.1.9 Direct Digital Controls

New to the 2016 Energy Standards is the requirement to include Direct Digital Controls in buildings for new construction, additions or alterations. Previously, the Energy Standards did not require the installation of DDC, however if a builder did install DDC it would trigger code sections of Title 24 requiring specific energy saving measures that can be effectively implemented with DDC. This new requirement (for DDC systems in building applications, where appropriate) will increase building energy savings that were not previously captured.

The requirement for DDC will mostly impact smaller buildings, since it is already common practice to install DDC in medium and large buildings; primarily due to the size and complexity of HVAC systems of medium and large buildings, which DDC is well suited to operate. Small buildings in the past did not require DDC and therefore could not take advantage of basic energy savings strategies.

DDC systems facilitate energy saving measures through monitoring and regulating the HVAC systems and optimizing their efficient operation. With most buildings requiring DDC, the following energy saving measures will be triggered if DDC is to the zone level:

1. Demand Control Ventilation (mandatory) - Section 4.3.7

2. Automatic Demand Shed Controls (mandatory) - Section 4

3. Optimum Start/Stop Controls (mandatory) - Section 4.5.1.10

4. Setpoint Reset Controls for Variable Air Volume Systems (prescriptive) - Section 4.5.2.3

For further explanation, see the appropriate compliance manual sections for the measures listed above.

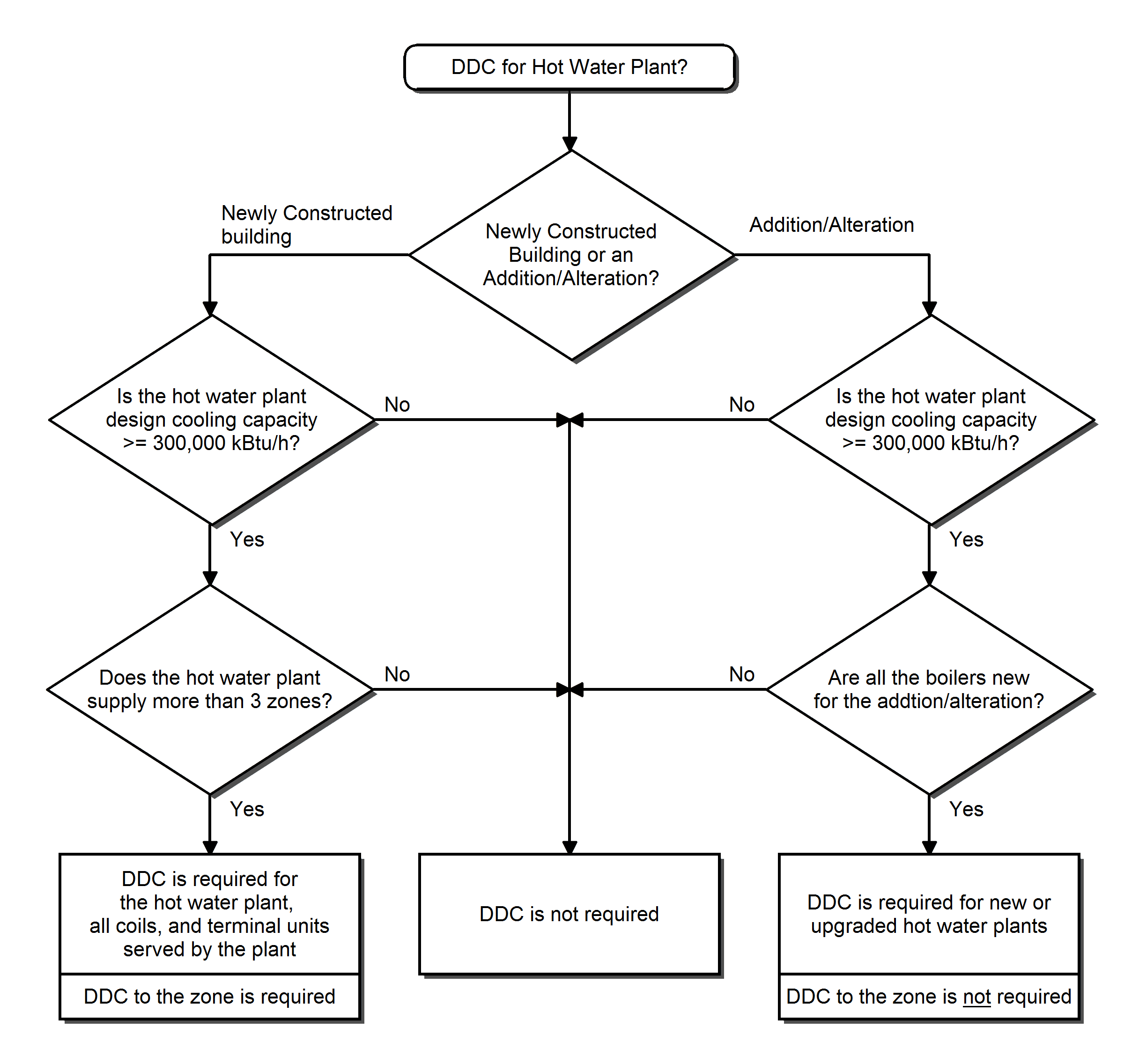

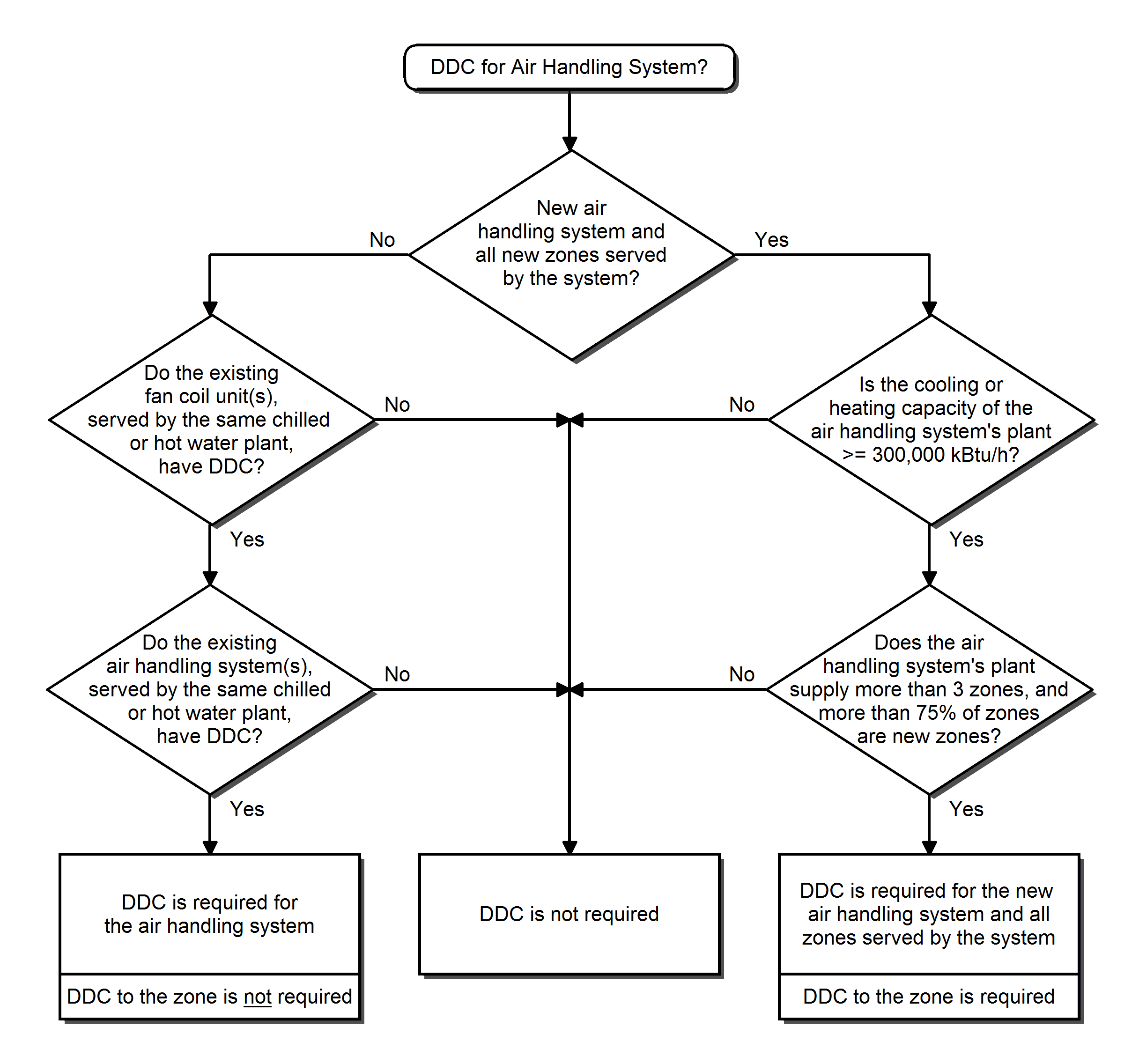

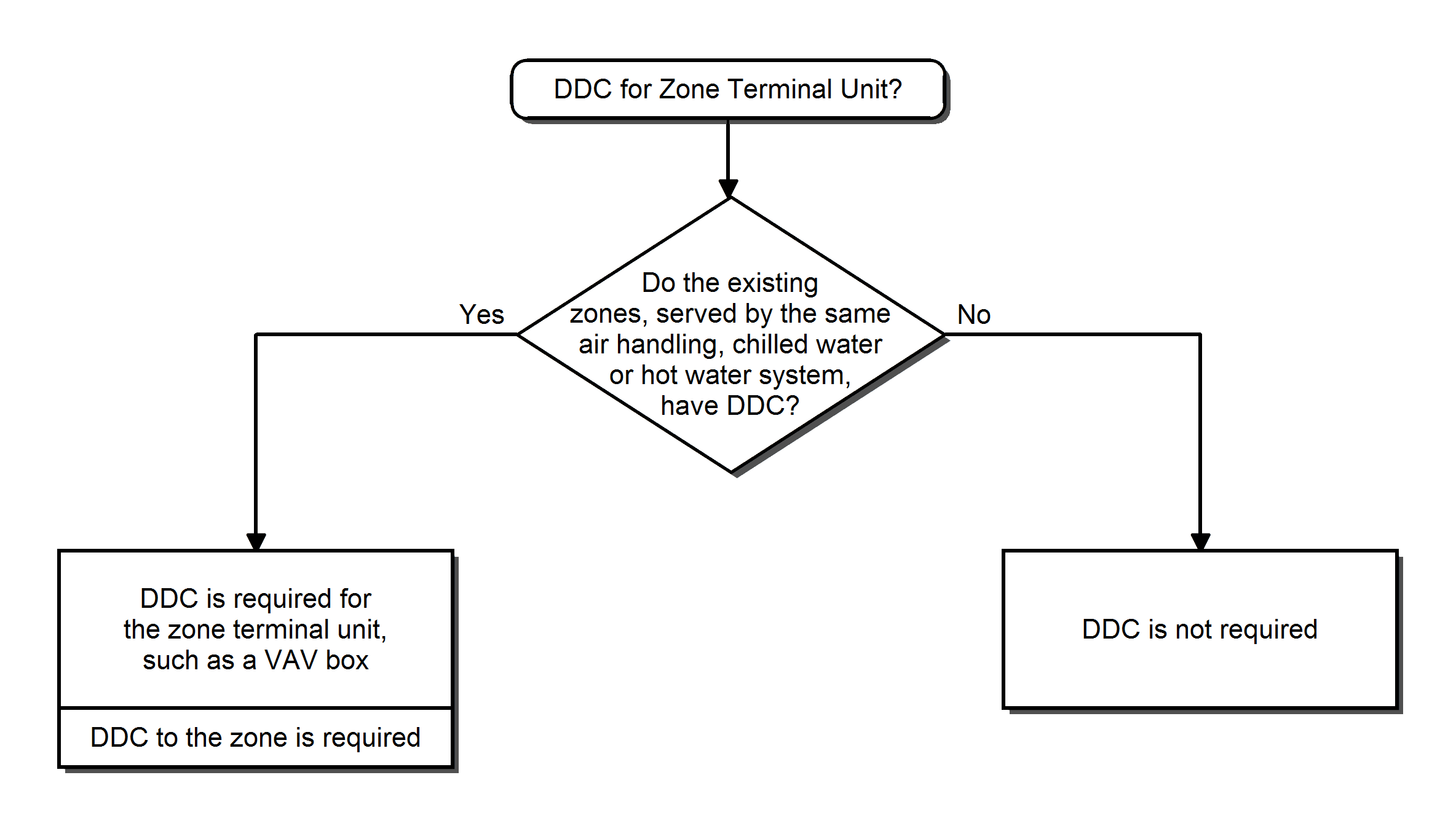

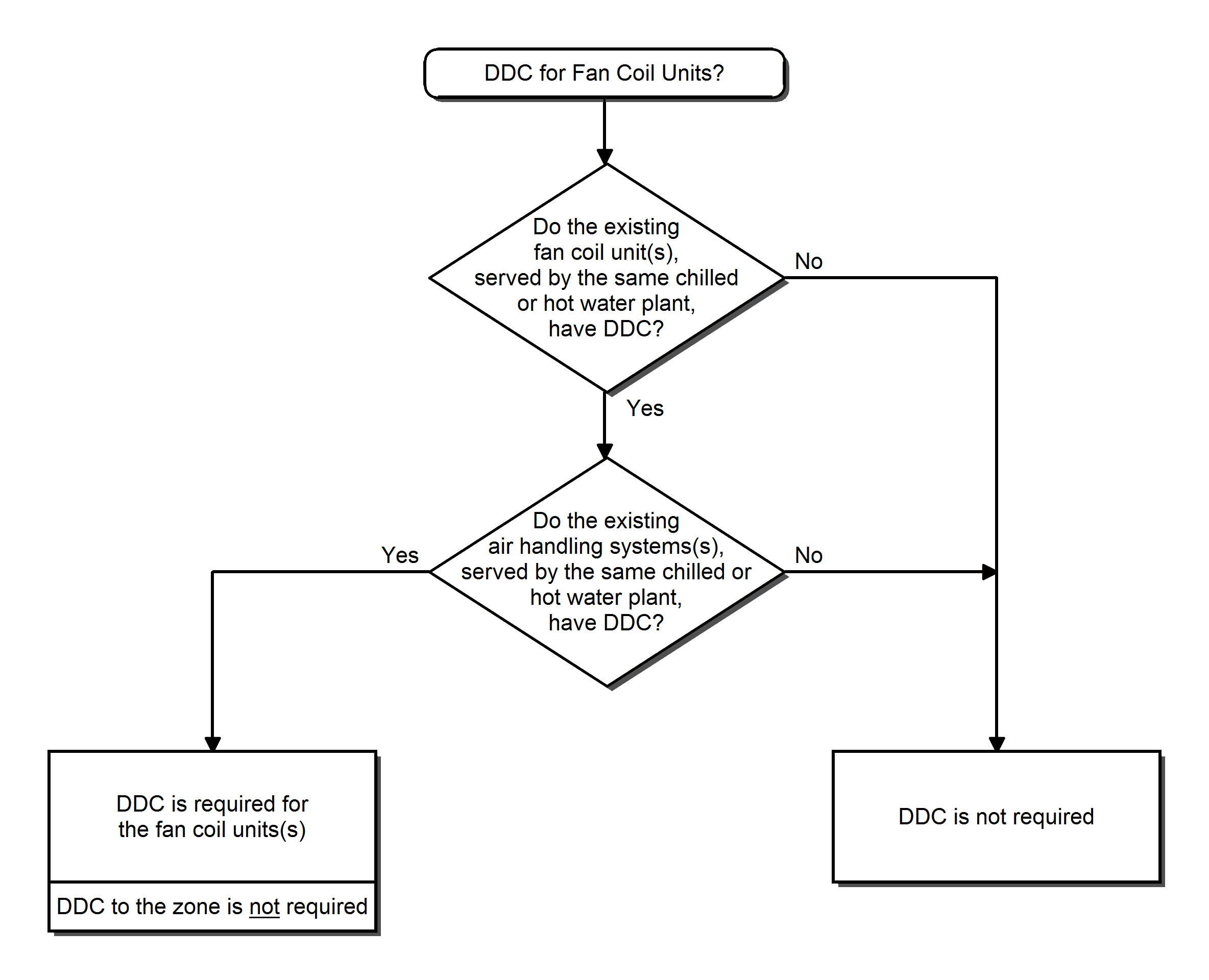

The Energy Standards mandate DDC for only certain building applications with minimum qualifications or equipment capacities, as specified in Table 120.2-A of the Energy Standards, see Table 4-17 below for a duplicate of this table.

|

BUILDING STATUS |

APPLICATIONS |

QUALIFICATIONS |

|

Newly Constructed Buildings |

Air handling system and all zones served by the system |

Individual systems supplying more than three zones and with design heating or cooling capacity of 300 kBtu/h and larger |

|

Newly Constructed Buildings |

Chilled water plant and all coils and terminal units served by the system |

Individual plants supplying more than three zones and with design cooling capacity of 300 kBtu/h (87.9 kW) and larger |

|

Newly Constructed Buildings |

Hot water plant and all coils and terminal units served by the system |

Individual plants supplying more than three zones and with design heating capacity of 300 kBtu/h (87.9 kW) and larger |

|

Additions or Alterations |

Zone terminal unit such as VAV box |

Where existing zones served by the same air handling, chilled water, or hot water systems that have DDC |

|

Additions or Alterations |

Air handling system or fan coil |

Where existing air handling system(s) and fan coil(s) served by the same chilled or hot water plant have DDC |

|

Additions or Alterations |

New air handling system and all new zones served by the system |

Individual systems with with design heating or cooling capacity of 300 kBtu/h and larger and supplying more than three zones and more than 75 percent of zones are new |

|

Additions or Alterations |

New or upgraded chilled water plant |

Where all chillers are new and plant design cooling capacity is 300 kBtu/h (87.9 kW) and larger |

|

Additions or Alterations |

New or upgraded hot water plant |

Where all boilers are new and plant design heating capacity is 300 kBtu/h (87.9 kW) and larger |

Table 120.2-A of the Energy Standards

Buildings that do not meet the specified minimum qualifications are not required to install DDC.

Follow the logic flowchart in Figure 4-14 to determine if a DDC system is required for newly constructed buildings or for additions or alterations to buildings. The Building Status Flowchart will indicate which equipment flowchart (Figure 4-15 through Figure 4-19) should be used for each type of HVAC equipment that will be installed in the building.

The logic of the equipment flowcharts will indicate whether DDC is required for the building, how DDC should be applied to the equipment and whether DDC is required to be installed to the zone level.

For additions or alterations to buildings, zones that are not part of the addition or alteration are not required to be retrofitted with DDC. Pre-existing DDC systems in buildings are not required to be retrofitted so DDC is to the zone.

Example 4-32

Question

If a newly constructed building has a HVAC system comprised of an air handling system, serving 4 zones and a chilled water plant with a design cooling capacity of 250,000 Btu/h, is DDC required?

Answer

No. Although the HVAC system is serving more than 3 zones, the chilled water plant does not meet the minimum design cooling capacity of 300,000 Btu/h (300 kBtu/h). A DDC system would be required if the design cooling capacity was 300,000 Btu/h or larger.

Example 4-33

Question

If an addition to a building requires a new VAV box, is DDC required?

Answer

Yes or No. The answer is dependent upon whether there is already a DDC system for the zones served by the same air handling, chilled water or hot water system. Essentially this is to ensure that if a DDC system is already installed, than it must be continued throughout the building, including the addition.

Example 4-34

Question

If a building’s chilled water plant is upgraded with new chillers that have a design capacity of 500 kBtu/h and serves 3 zones, is DDC required?

Answer

Yes. The criteria that triggers the DDC requirement is that the plant upgrade is installing new chillers with a cooling capacity greater than 300 kBtu/h. In this case, the number of zones is irrelevant for determining if DDC is required.

The Energy Standards now require the mandated DDC system to have the following capabilities to ensure that the full energy saving benefits of DDC:

1. Monitor zone and system demand for fan pressure, pump pressure, heating and cooling

2. Transfer zone and system demand information from zones to air distribution system controllers and from air distribution systems to heating and cooling plant controllers

3. Automatically detect those zones and systems that may be excessively driving the reset logic and generate an alarm or other indication to the system operator

4. Readily allow operator removal of zone(s) from the reset algorithm

5. For new buildings, trending and graphically displaying input and output points, and

6. Resetting setpoints in non-critical zones upon a signal; from a centralized contract or software point as described in 4.5.1.7.

4.5.1.10 Optimum Start/Stop Controls

New to the 2016 Energy Standards are requirements for optimum start/stop controls when DDC is to the zone level.

Optimum start/stop controls are an energy saving technique where the HVAC system determines the optimum time to turn on or turn off the HVAC system so that the space reaches the appropriate temperature during occupied hours only, without wasting energy to condition the space during unoccupied hours; applies both to heating and cooling.

Optimum start controls are designed to automatically adjust the start time of a space conditioning system each day with the intent of bringing the space temperature to the desired occupied temperature levels at the beginning of scheduled occupancy. The controls shall take in to account the space temperature, outside ambient temperature, occupied temperature, amount of time prior to scheduled occupancy, and if present, the floor temperatures of a mass radiant floor slab systems.

Optimum stop controls are designed to automatically adjust the stop time of a space conditioning system each day with the intent of letting the space temperature coast to the unoccupied temperature levels after the end of scheduled occupancy. The controls shall take in to account the space temperature, outside ambient temperature, unoccupied temperature, and the amount of time prior to scheduled occupancy

4.5.2.1 Space Conditioning Zone Controls

Each space-conditioning zone shall have controls that prevent:

1. Reheating of air that has been previously cooled by mechanical cooling equipment or an economizer.

2. Recooling of air that has been previously heated. This does not apply to air returned from heated spaces.

3. Simultaneous heating and cooling in the same zone, such as mixing or simultaneous supply of air that has been previously mechanically heated and air that has been previously cooled, either by cooling equipment or by economizer systems.

Certain exceptions exist for space conditioned zones with one of the following:

1. Special pressurization relationships or cross contamination control needs. Laboratories are an example of spaces that might fall in this category.

2. Site-recovered or site-solar energy providing at least 75 percent of the energy for reheating, or providing warm air in mixing systems.

3. Specific humidity requirements to satisfy exempt process needs. Computer rooms are explicitly not covered by this exception.

4. Zones with a peak supply air quantity of 300 cfm or less.

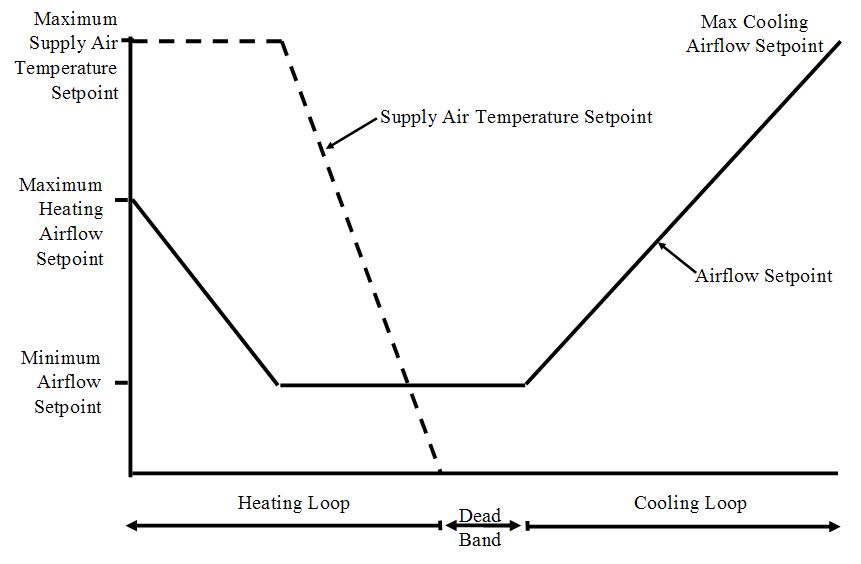

5. Zones served by variable air volume systems that are designed and controlled to reduce the volume of reheated, recooled or mixed air to a minimum. The controls must meet all of the following:

a. For each zone with direct digital controls (DDC):

i. The volume of primary air that is reheated, re-cooled, or mixed air supply shall not exceed the larger of:

1. 50 percent of the peak primary airflow; or

2. The design zone outdoor airflow rate per Section 4.3

ii. The volume of primary air in the dead band shall not exceed the larger of:

1. 20 percent of the peak primary airflow; or

2. The design zone outdoor airflow rate per Section 4.3

iii. The first stage of heating consists of modulating the zone supply air temperature setpoint up to a maximum setpoint no higher than 95ºF while the airflow is maintained at the deadband flow rate

iv. The second stage of heating consists of modulating the airflow rate from the deadband flow rate up to the heating maximum flow rate.

b. For each zone without DDC, the volume of primary air that is reheated, re-cooled, or mixed air supply shall not exceed the larger of the following:

i. 30 percent of the peak primary airflow; or

ii. The design zone outdoor airflow rate per Section 4.3.

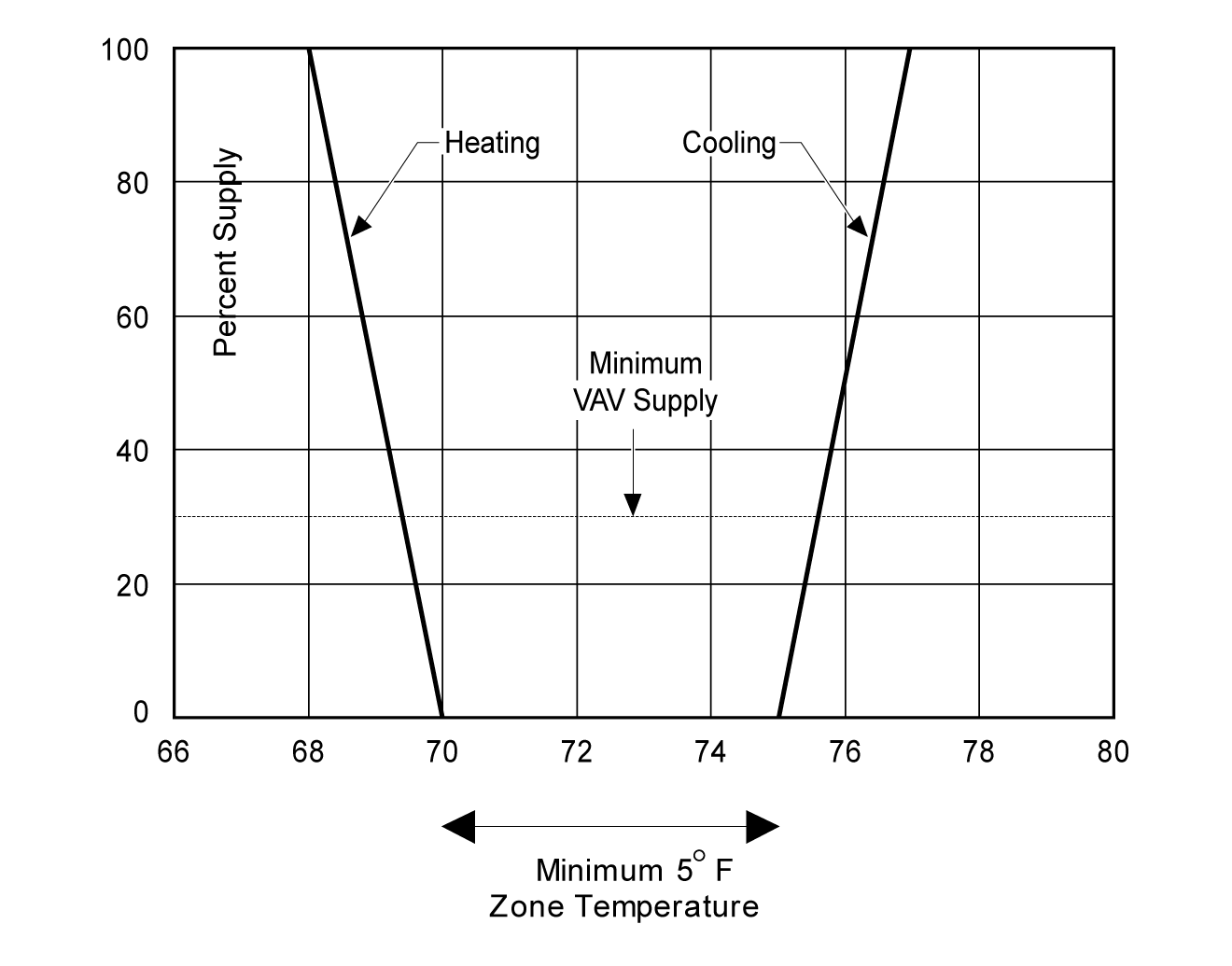

For systems with DDC to the zone level, the controls must be able to support two different maximums: one each for heating and cooling. This control is depicted in Figure 4-20 below. In cooling, this control scheme is similar to a traditional VAV reheat box control. The difference is what occurs in the deadband between heating and cooling and in the heating mode. With traditional VAV control logic, the minimum airflow rate is typically set to the largest rate allowed by code. This airflow rate is supplied to the space in the deadband and heating modes. With the "dual maximum" logic, the minimum rate is the lowest allowed by code (e.g. the minimum ventilation rate) or the minimum rate the controls system can be set to (which is a function of the VAV box velocity pressure sensor amplification factor and the accuracy of the controller to convert the velocity pressure into a digital signal). As the heating demand increases, the dual maximum control first resets the discharge air temperature (typically from the design cold deck temperature up to 85 or 90°F) as a first stage of heating then, if more heat is required, it increases airflow rate up to a “heating” maximum airflow setpoint, which is the same value as what traditional control logic uses as the minimum airflow setpoint. Using this control can save significant fan, reheat and cooling energy while maintaining better ventilation effectiveness as the discharge heating air is controlled to a temperature that will minimize stratification.

This control requires a discharge air sensor and may require a programmable VAV box controller. The discharge air sensor is very useful for diagnosing control and heating system problems even if they are not actively used for control.

For systems without DDC to the zone (such as electric or pneumatic thermostats), the airflow that is reheated is limited to a maximum of the larger either 30 percent of the peak primary airflow or the minimum airflow required to ventilate the space.

Example 4-35

Question

What are the limitations on VAV box minimum airflow setpoint for a 1,000 ft² office having a design supply of 1,100 cfm and 8 people?

Answer

For a zone with pneumatic thermostats, the minimum cfm cannot exceed the larger of:

a. 1,100 cfm x 30 percent = 330 cfm; or

b. The minimum ventilation rate which is the larger of

1) 1,000 ft² x 0.15 cfm/ft² = 150 cfm; and

2) 8 people x 15 cfm/person = 120 cfm

Thus the minimum airflow setpoint can be no larger than 330 cfm.

For a zone with DDC to the zone, the minimum cfm in the deadband cannot exceed the larger of:

a. 1,100 cfm x 20 percent = 220 cfm; or

b. The minimum ventilation rate which is the larger of

1) 1,000 ft² x 0.15 cfm/ft² = 150 cfm; and

2) 8 people x 15 cfm/person = 120 cfm

Thus the minimum airflow setpoint in the dead band can be no larger than 220 cfm. And this can rise to 1100 cfm X 50 percent or 550 cfm at peak heating.

For either control system, based on ventilation requirements, the lowest minimum airflow setpoint must be at least 150 cfm, or transfer air must be provided in this amount.

4.5.2.2 Economizers

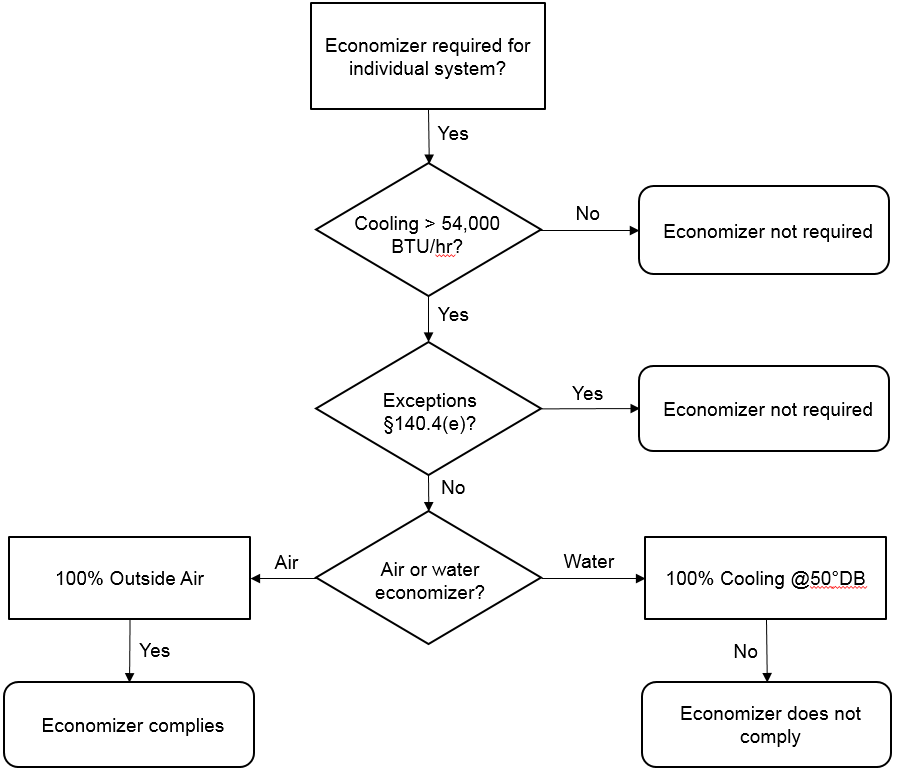

An economizer must be fully integrated and must be provided for each individual cooling air handler system that has a total mechanical cooling capacity over 54,000 Btu/h. The economizer may be either:

1. An air economizer capable of modulating outside air and return air dampers to supply 100 percent of the design supply air quantity as outside air; or

2. A water economizer capable of providing 100 percent of the expected system cooling load at outside air temperatures of 50°F dry-bulb and 45°F wet-bulb and below.

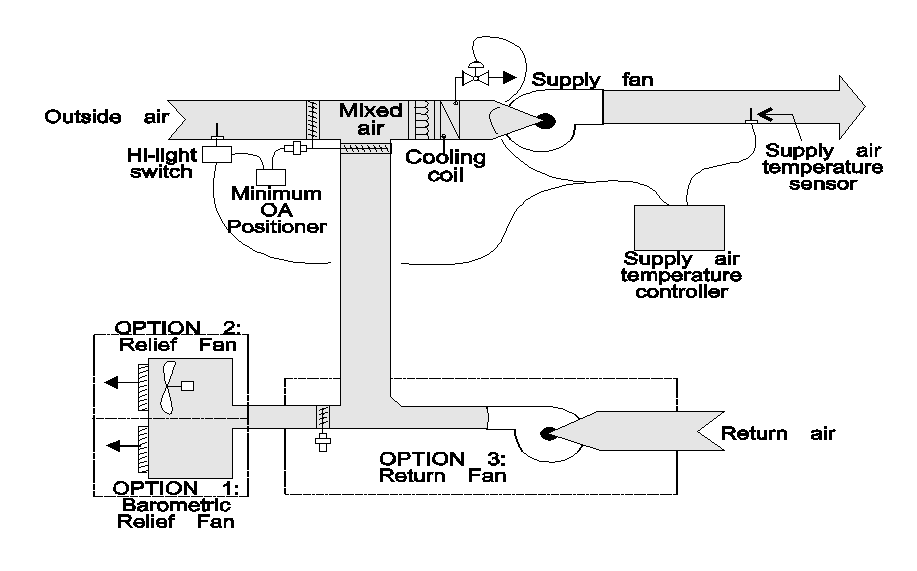

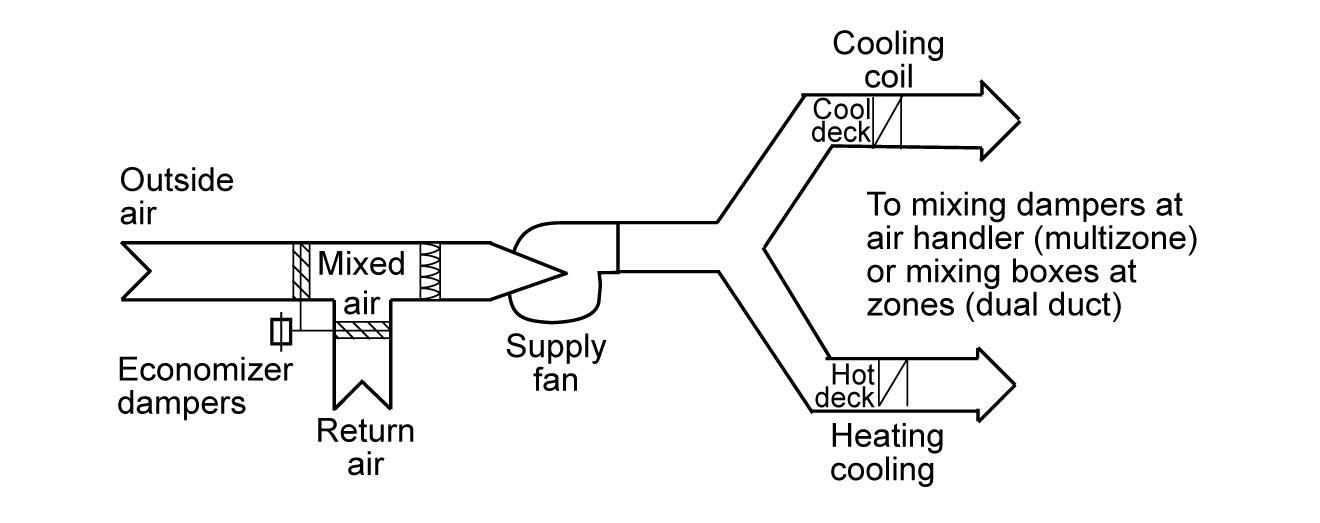

Depicted below in Figure 4-21 is a schematic of an air-side economizer. All air-side economizers have modulating dampers on the return and outdoor air streams.

|

Best Practice: To provide 100 percent of the design supply air, designers will need to specify an economizer with a nominal capacity sufficient to deliver the design air flow rate when the supply air damper is in the full open position, and the return air damper is completely closed. An appropriately sized economizer can also be estimated by determining the face velocity passing through the economizer by using the design airflow and the area of the economizer damper/duct opening. The design airflow (cfm) should be available from the mechanical drawings or air handler cutsheet. The minimum area (ft2) through which air is flowing from the outside to the fan can be measured in the field, or it can be found on the economizer damper cutsheet if the economizer damper is the smallest area. Dividing the design airflow by the smallest area will give the velocity of the air in ft/min. Appropriately sized economizers that can supply 100% of the supply airflow without large pressure drops typically have face velocities of less than 2,000 ft/min. |

•Option 1 barometric relief,

•Option 2 a relief fan generally controlled by building static pressure,

•Option 3 a return fan often controlled by tracking the supply.

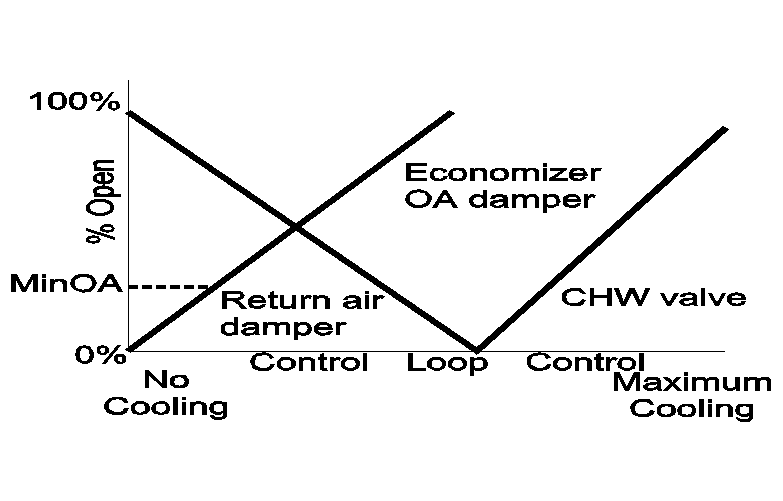

Figure 4-22 depicts an integrated air-side economizer control sequence. On first call for cooling the outdoor air damper is modulated from minimum position to 100 percent outdoor air. As more cooling is required, the damper remains at 100 percent outdoor air as the cooling coil is sequenced on.

Graphics of water-side economizers are presented in Section 4.10.7.2 at the end of this chapter.

A. Economizers are not required where:

Exceptions to §140.4(e)1

1. Outside air filtration and treatment for the reduction and treatment of unusual outdoor contaminants make compliance infeasible.

2. Increased overall building TDV energy use results. This may occur where economizers adversely impact other systems, such as humidification, dehumidification or supermarket refrigeration systems.

3. Systems serving high-rise residential living quarters and hotel/motel guest rooms.

4. If cooling capacity is less than or equal to 54,000 Btu/h

5. Where cooling systems have the cooling efficiency that meets or exceeds the cooling efficiency improvement requirements in Table 4-18.

6. Fan systems primarily serving computer room(s). See §140.9 (a) for computer room economizer requirements.

B. If an economizer is required, it must be:

Exceptions to §140.4(e)2

1. Designed and equipped with controls that do not increase the building heating energy use during normal operation. This prohibits the application of single-fan dual-duct systems and traditional multizone systems using the Prescriptive Approach of compliance. With these systems the operation of the economizer to pre-cool the air entering the cold deck also precools the air entering the hot deck and thereby increases the heating energy.

Exception: when at least 75 percent of the annual heating is provided by site-recovered or site-solar energy.

2. Fully integrated into the cooling system controls so that the economizer can provide partial cooling even when mechanical cooling is required to meet the remainder of the cooling load. On packaged units with stand-alone economizers, a two-stage thermostat is necessary to meet this requirement.

The requirement that economizers be designed for concurrent operation is not met by some popular water economizer systems, such as those that use the chilled water system to convey evaporatively-cooled condenser water for “free” cooling. Such systems can provide 100 percent of the cooling load, but when the point is reached where condenser water temperatures cannot be sufficiently cooled by evaporation; the system controls throw the entire load to the mechanical chillers. Because this design cannot allow simultaneous economizer and refrigeration system operation, it does not meet the requirements of this section. An integrated water-side economizer which uses condenser water to precool the CHWR before it reaches the chillers (typically using a plate-and-frame heat exchanger) can meet this integrated operation requirement.

|

Climate Zone |

Efficiency Improvementa |

|

1 |

70% |

|

2 |

65% |

|

3 |

65% |

|

4 |

65% |

|

5 |

70% |

|

6 |

30% |

|

7 |

30% |

|

8 |

30% |

|

9 |

30% |

|

10 |

30% |

|

11 |

30% |

|

12 |

30% |

|

13 |

30% |

|

14 |

30% |

|

15 |

30% |

|

16 |

70% |

Energy Standards Table 140.4-A

a If a unit is rated with an IPLV, IEER or SEER, then to eliminate the required air or water economizer, the applicable minimum cooling efficiency of the HVAC unit must be increased by the percentage shown. If the HVAC unit is only rated with a full load metric, such as EER or COP cooling, then that metric must be increased by the percentage shown.

C. Air-Side Economizer High Limit Switches

If an economizer is required by §140.4(e)1 and an air economizer is used to meet the requirement, the air side economizer is required to have high-limit shut-off controls that comply with Table 4-19.

1. The first column identifies the high limit control category. There are three categories allowed in this prescriptive requirement: Fixed Dry Bulb; Differential Dry Bulb; and Fixed Enthalpy + Fixed Dry Bulb.

2. The second column represents the California climate zone. “All” indicates that this control type complies in every California climate.

3. The third and fourth columns present the high-limit control setpoints required.

The Energy Standards eliminated the use of Fixed Enthalpy, Differential Enthalpy and Electronic Enthalpy controls. Research on the accuracy and stability of enthalpy controls led to their elimination (with the exception of use when combined with a fixed dry-bulb sensor). The enthalpy based controls can be employed if the project uses the performance approach however the performance model will show a penalty due to the inaccuracy of the enthalpy sensors.

|

Device Typea |

Climate Zones |

Required High Limit (Economizer Off When): | |

|

Equationb |

Description | ||

|

Fixed Dry Bulb |

1, 3, 5, 11-16 |

TOA > 75°F |

Outdoor air temperature exceeds 75°F |

|

2, 4, 10 |

TOA > 73°F |

Outdoor air temperature exceeds 73°F | |

|

6, 8, 9 |

TOA > 71°F |

Outdoor air temperature exceeds 71°F | |

|

7 |

TOA > 69°F |

Outdoor air temperature exceeds 69°F | |

|

Differential Dry Bulb |

1, 3, 5, 11-16 |

TOA > TRA°F |

Outdoor air temperature exceeds return air temperature |

|

2, 4, 10 |

TOA > TRA-2°F |

Outdoor air temperature exceeds return air temperature minus 2°F | |

|

6, 8, 9 |

TOA > TRA-4°F |

Outdoor air temperature exceeds return air temperature minus 4°F | |

|

7 |

TOA > TRA-6°F |

Outdoor air temperature exceeds return air temperature minus 6°F | |

|

Fixed Enthalpyc + Fixed Drybulb |

All |

hOA > 28 Btu/lbc or TOA > 75°F |

Outdoor air enthalpy exceeds 28 Btu/lb of dry airc orOutdoor air temperature exceeds 75°F |

|

a Only the high limit control devices 'listed are allowed to be used and at the setpoints 'listed. Others such as Dew Point, Fixed Enthalpy, Electronic Enthalpy, and Differential Enthalpy Controls, may not be used in any climate zone for compliance with §140.4(e)1. unless approval for use is provided by the Energy Commission Executive Director b Devices with selectable (rather than adjustable) setpoints shall be capable of being set to within 2°F and 2 Btu/lb of the setpoint 'listed. c At altitudes substantially different than sea level, the Fixed Enthalpy limit value shall be set to the enthalpy value at 75°F and 50percent relative humidity. As an example, at approximately 6,000 foot elevation, the fixed enthalpy limit is approximately 30.7 Btu/lb. | |||

|

Energy Standards Table 140.4-B | |||

D. Air Economizer Construction

If an economizer is required by §140.4(e)1, and an air economizer is used to meet the requirement, then the air economizer, and all air dampers shall have the following features:

1. A 5-year factory warranty for the economizer assembly.

2. Certification by the manufacturer that the that the economizer assembly, including but not limited to outdoor air damper, return air damper, drive linkage, and actuator, have been tested and are able to open and close against the rated airflow and pressure of the system for at least 60,000 damper opening and closing cycles.

3. Economizer outside air and return air dampers shall have a maximum leakage rate of 10 cfm/sf at 250 Pascals (1.0 in. w.g) when tested in accordance with AMCA Standard 500-D. The leakage rates for the outside and return dampers shall be certified to the Energy Commission in accordance with §110.0.

4. If the high-limit control uses either a fixed dry-bulb, or fixed enthalpy control, the control shall have an adjustable setpoint.

a. Economizer sensors shall be calibrated within the following accuracies.

a. Drybulb and wetbulb temperatures accurate to ±2°F over the range of 40°F to 80°F.

b. Enthalpy accurate to ±3 Btu/lb over the range of 20 Btu/lb to 36 Btu/lb.

c. Relative Humidity (RH) accurate to ± 5 percent over the range of 20 percent to 80 percent RH

5. Data of sensors used for control of the economizer shall be plotted on a sensor performance curve.

6. Sensors used for the high limit control shall be located to prevent false readings, e.g. including but not limited to being properly shielded from direct sunlight.

7. Relief air systems shall be capable of providing 100 percent outside air without over-pressurizing the building.

E. Compressor Unloading

Systems that include and air economizer must comply with the following requirements:

1. Unit controls shall have mechanical capacity controls interlocked with economizer controls such that the economizer is at 100 percent open position when mechanical cooling is on and does not begin to close until the leaving air temperature is less than 45°F.

2. Direct Expansion (DX) units greater than 65,000 Btu/hr that control the capacity of the mechanical cooling directly based on occupied space temperature shall have a minimum of 2 stages of mechanical cooling capacity.

3. DX units not within the scope of 2, shall comply with the requirements in Table 4-20, and have controls that do not false load the mechanical cooling system by limiting or disabling the economizer or by any other means, except at the lowest stage of mechanical cooling capacity.

|

Cooling Capacity |

Minimum Number of Mechanical Cooling Stages |

Minimum Compressor Displacement |

|

≥65,000 Btu/h and < 240,000 Btu/h |

3 stages |

≤ 35% full load |

|

≥ 240,000 Btu/h |

4 stages |

≤ 25% full load |

Energy Standards Table 140.4-C

Chapter 13 of this manual describes mandated acceptance test requirements for economizers.

If the economizer is factory-calibrated the economizer acceptance test is not required at installation. A calibration certificate of economizer control sensors (outdoor air temperature, return air temperature, etc.) must be submitted to the local code enforcement agency in the permit application.

Figure 4-24: Single-Fan Dual-Duct

System

Example 4-36

Question

If my design conditions are 94°Fdb/82°Fwb can I use my design cooling loads to size a water-side economizer?

Answer

No. The design cooling load calculations must be rerun with the outdoor air temperature set to 50°Fdb/45°Fwb. The specified tower, as well as cooling coils and other devices, must be checked to determine if it has adequate capacity at this lower load and wet-bulb condition.

Example 4-37

Question

Will a strainer cycle water-side economizer meet the prescriptive economizer requirements? (Refer to Figure 4-33)

Answer

No. It cannot be integrated to cool simultaneously with the chillers.

Example 4-38

Question

Does a 12 ton packaged AC unit in climate zone 10 need an economizer?

Answer

Yes and the economizer must be equipped with an economizer fault detection and diagnostic system. However the requirement for an economizer can be waived if the AC unit’s efficiency is greater than or equal to an EER of 14.3. Refer to Table 4-18

4.5.2.3 VAV Supply Fan Controls

§140.4(c)2 and §140.4(m)

Both single and multiple zone systems are required to have VAV supply based on the system type as described in Table 4-21. The VAV requirements for supply fans are as follows:

1. Single zone systems (where the fans are controlled directly by the space thermostat) shall have a minimum of 2 stages of fan speed with no more than 66 percent speed when operating on stage 1 while drawing no more than 40 percent full fan power when running at 66 percent speed.

2. All systems with air-side economizers to satisfy Section 4.5.2.2 are required to have a minimum of 2 speeds of fan control during economizer operation.

3. Multiple zone systems shall limit the fan motor demand to no more than 30 percent of design wattage at 50 percent design air volume.

Variable speed drives can be used to meet any of these three requirements.

Actual fan part load performance, available from the fan manufacturer, should be used to test for compliance with item 3 above. Figure 4-25 shows typical performance curves for different types of fans. As can be seen, both air foil fans and backward inclined fans using either discharge dampers or inlet vanes consume more than 30 percent power at 50 percent flow when static pressure set point is one-third of total design static pressure using certified manufacturer’s test data. These fans will not normally comply with these requirements unless a variable speed drive is used.

VAV fan systems that don’t have DDC to the zone level are required to have the static pressure sensor located in a position such that the control setpoint is ≤1/3 of the design static pressure of the fan. For systems without static pressure reset the further the sensor is from the fan the more energy will be saved. For systems with multiple duct branches in the distribution you must provide separate sensors in each branch and control the fan to satisfy the sensor with the greatest demand. When locating sensors, care should be taken to have at least one sensor between the fan and all operable dampers (e.g. at the bottom of a supply shaft riser before the floor fire/smoke damper) to prevent loss of fan static pressure control.

For systems with DDC to the zone level the sensor(s) may be anywhere in the distribution system and the duct static pressure setpoint must be reset by the zone demand. Typically this is done by one of the following methods:

1. Controlling so that the most open VAV box damper is 95 percent open.

2. Using a “trim and respond” algorithm to continually reduce the pressure until one or more zones indicate that they are unable to maintain airflow rate setpoints.

3. Other methods that dynamically reduce duct static pressure setpoint as low

as possible while maintaining adequate pressure at the VAV box zone(s) of

greatest demand.

Reset of supply pressure by demand not only saves energy but it also protects fans from operation in surge at low loads.Chapter 13. Acceptance Requirements, describes mandated acceptance test requirements for VAV system fan control.

|

|

A. Air foil or backward inclined centrifugal fan with

discharge dampers B. Air foil centrifugal fan with inlet

vanes C. Forward curved centrifugal fan with discharge

dampers or riding curve D. Forward curved centrifugal fan with inlet

vanes E. Vane-axial fan with variable pitch

blades F. Any fan with variable speed drive (mechanical drives will be slightly less efficient) |

|

Cooling System Type |

Fan Motor Size |

Cooling Capacity |

|

DX Cooling |

any |

≥ 65,000 Btu/hr |

|

Chilled Water and Evaporative |

≥ 1/4 HP |

ANY |

Energy Standards Table 140.4-D

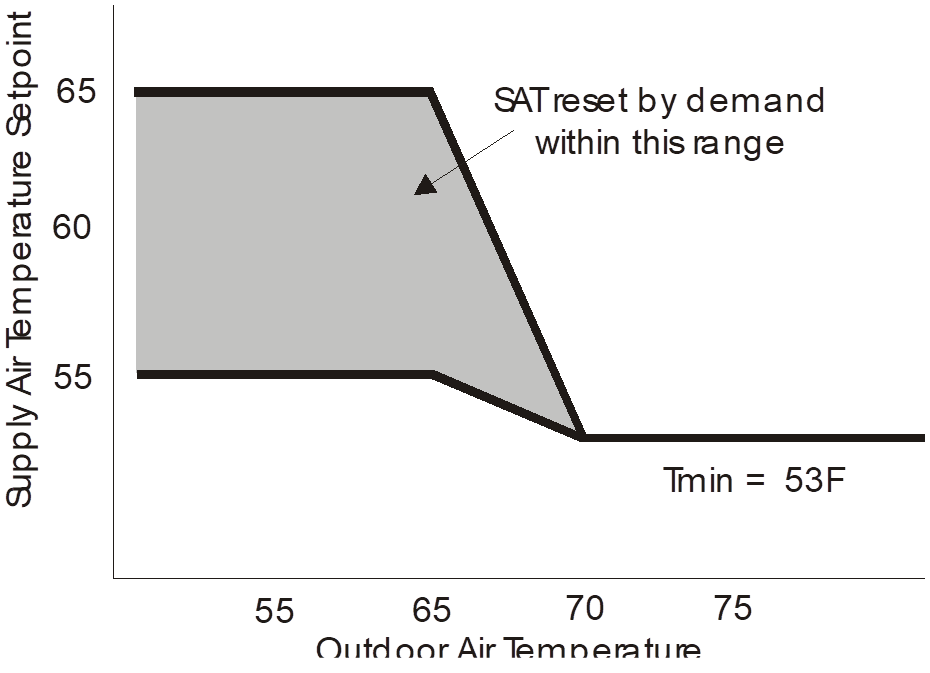

4.5.2.4 Supply-Air Temperature Reset Control

Mechanical space-conditioning systems supplying heated or cooled air to multiple zones must include controls that automatically reset the supply-air temperature in response to representative building loads, or to outdoor air temperature. The controls must be capable of resetting the supply-air temperature by at least 25 percent of the difference between the design supply-air temperature and the design room air temperature.

For example, if the design supply temperature is 55°F and the design room temperature is 75°F, then the difference is 20°F, and 25 percent is 5°F. Therefore, the controls must be capable of resetting the supply temperature from 55°F to 60°F.

Air distribution zones that are likely to have constant loads, such as interior zones, shall have airflow rates designed to meet the load at the fully reset temperature. Otherwise, these zones may prevent the controls from fully resetting the temperature, or will unnecessarily limit the hours when the reset can be used.

Supply air reset is required for VAV reheat systems even if they have VSD fan controls. The recommended control sequence is to lead with supply temperature setpoint reset in cool weather where reheat might dominate the equation and to keep the chillers off as long as possible, then return to a fixed low setpoint in warmer weather when the chillers are likely to be on. During reset, employ a demand-based control that uses the warmest supply air temperature that satisfies all of the zones in cooling.

This sequence is described as follows: during occupied mode,

the setpoint is reset from

T-min (53°F) when the outdoor air temperature is

70°F and above, proportionally up to

T-max when the outdoor air temperature

is 65°F and below. T-max shall range from 55°F to 65°F and shall be the output

of a slow reverse-acting proportional-integral (PI) loop that maintains the

cooling loop of the zone served by the system with the highest cooling loop at a

setpoint of 90 percent (See Figure 4-26).

Supply temperature reset is also required for constant volume systems with reheat justified on the basis of special zone pressurization relationships or cross-contamination control needs.

Supply-air temperature reset is not required when:

1. The zone(s) must have specific humidity levels required to meet exempt process needs. Computer rooms cannot use this exception.

2. Where it can be demonstrated to the satisfaction of the enforcement agency that supply air reset would increase overall building energy use.

3. The space-conditioning zone has controls that prevent reheating and recooling and simultaneously provide heating and cooling to the same zone.

Recommended Supply Air Temperature Reset Method

4.5.2.5 Heat Rejection Fan Control

When the fans on cooling towers, closed-circuit fluid coolers, air-cooled condensers and evaporative condensers are powered by a fan motor or 7.5 hp or larger, the system must be capable of operating at 2/3 of full speed or less and have controls that automatically change the fan speed to control the leaving fluid temperature or condensing temperature or pressure of the heat rejection device. Fan speed controls are exempt when:

1. Fans powered by motors smaller than 7.5 hp.

2. Heat rejection devices included as an integral part of the equipment 'listed in Table 4-1 through Table 4-11.

3. Condenser fans serving multiple refrigerant circuits or flooded condensers.

4. Up to 1/3 of the fans on a condenser or tower with multiple fans where the lead fans comply with the speed control requirement.

Example 4-39

Question

A chilled water plant has a three-cell tower with 10 hp motors on each cell. Are speed controls required?

Answer

Yes. At minimum the designer must provide 2-speed motors, pony motors or variable speed drives on two

of the three fans for this tower.

4.5.2.6 Hydronic System Measures

A. Hydronic Variable Flow Systems

Hot water and chilled water systems are required to be designed for variable flow. Variable flow is provided by using 2-way control valves. The Energy Standards only require that flow is reduced to the greater of 50 percent design flow (or less) or the minimum flow required by the equipment manufacturer for operation of the central plant equipment.

There are two exceptions for this requirement:

1. Systems that include no more than three control valves.

2.

Systems having a total pump system power less than or equal to

1.5 hp.

It is not necessary for each individual pump to meet the variable flow requirement. These requirements can be met by varying the total flow for the entire pumping system in the plant. Strategies that can be used to meet these requirements include but are not limited to variable frequency drives on pumps and staging of the pumps.

It should be noted that the primary loop on a primary/secondary or primary/secondary/tertiary system could be designed for constant flow even if the secondary or tertiary loop serves more than 3 control valves. This is allowed because the primary loop does not directly serve any coil control valves. However the secondary (and tertiary loops) of these systems must be designed for variable flow if they have 4 or more control valves.

The flow limitations are provided for primary-only variable flow chilled water systems where a minimum flow is typically required to keep a chiller on-line. In these systems minimum flow can be provided with either a bypass with a control valve or some 3-way valves to ensure minimum flow at all times. The system with a bypass valve is more efficient as it only provides bypass when absolutely required to keep the plant on line.

For hot water systems application of slant-tube or bent tube boilers will provide the greatest flow turndown. Typically copper fin tube boilers require a higher minimum flow.

Example 4-40

Question

In my plant, I am trying to meet the variable flow requirements of Section 5.2.6. Must each individual pump meet these requirements for the plant to comply with the Energy Standards?

Answer

No, individual pumps do not need to meet the variable flow requirements of this section. As long as the entire plant meets the variable flow requirements, the plant is in compliance. For example, the larger pumps may be equipped with variable frequency drives or the pumps can be staged in a way that can meet these requirements.

B. Isolation for Chillers and Boilers

Plants with multiple chillers or boilers are required to provide either isolation valves or dedicated pumps and check valves to ensure that flow will only go through the chillers or boilers that are staged on. Chillers that are piped-in series for the purpose of increased temperature differential shall be considered as one chiller.

C. Chilled and Hot Water Reset

Similar to the requirements for supply air temperature reset, chilled and hot water systems that have a design capacity > 500,000 Btu/h are required to provide controls to reset the hot or cold water temperature setpoints as a function of building loads or the outdoor air temperature. This reset can be achieved either using a direct indication of demand (usually cooling or heating valve position) or an indirect indication of demand (typically outdoor air temperature). On systems with DDC controls reset using valve position is recommended.

There is an exception to this requirement for hydronic systems that are designed for variable flow complying with 4.5.2.6.A (§140.4(k)1).

D. Isolation Valves for Water-Loop Heat Pump Systems

Water circulation systems serving water-cooled air conditioner and hydronic heat pump systems that have a design circulation pump brake horsepower >5 bhp are required to be provided with 2-way isolation valves that close whenever the compressor is off. These systems are also required to be provided with the variable speed drives and pressure controls described in the following section.

Although this is not required on central tenant condenser water systems (for water-cooled AC units and HPs) it is a good idea to provide the 2-way isolation valves on these systems as well. 'In addition to providing pump energy savings, these 2-way valves can double as head-pressure control valves to allow aggressive condenser water reset for energy savings in chilled water plants that are also cooled by the towers.

E. VSDs for Pumps Serving Variable Flow Systems

Variable Flow Controls - Pumps on variable flow systems that have a design circulation pump brake horsepower > 5 bhp are required to have either variable speed drives or a different control that will result in pump motor demand of no more than 30 percent of design wattage at 50 percent of design water flow.

Pressure Sensor Location and Setpoint

1. For systems without direct digital control of individual coils reporting to the central control panel, differential pressure must be measured at the most remote heat exchanger or the heat exchanger requiring the most pressure. This includes chilled water systems, condenser water systems serving water-cooled air conditioning (AC) loads and water-loop heat pump systems.

2. For systems with direct digital control of individual coils with a central control panel, the static pressure set point must be reset based on the valve requiring the most pressure and the setpoint shall be no less than 80 percent open. The pressure sensor(s) may be mounted anywhere.

Exceptions are provided for hot-water systems and condenser water systems that only serve water-cooled chillers. The hot water systems are exempted because the heat from the added pumping energy of the pump riding the curve provides a beneficial heat that reduces the boiler use. This reduces the benefit from the reduced pumping energy.

F.

Hydronic Heat Pump (WLHP) Controls  |topic=Section 4.5.2Q. – NR-Related Topics

|topic=Section 4.5.2Q. – NR-Related Topics

Hydronic heat pumps connected to a common heat pump water loop with central devices for heat rejection and heat addition must have controls that are capable of providing a heat pump water supply temperature dead band of at least 20°F between initiation of heat rejection and heat addition by the central devices. Exceptions are provided where a system loop temperature optimization controller is used to determine the most efficient operating temperature based on real-time conditions of demand and capacity, dead bands of less than 20°F shall be allowed.

4.5.2.7 Window/Door Switches for Mechanical System Shut-off

If a directly conditioned zone has a thermostat and has one or more manually operable wall or roof openings to the outdoors, then the openings must all have sensors that communicate to the HVAC system. The HVAC controller must be capable of shutting off the heating or cooling to that zone if the sensor detects that the opening has remained open for more than 5 minutes. This can be accomplished by either the resetting the heating setpoint to 55°F or the heating can be disabled altogether. If the HVAC system is in cooling mode, then similarly this requirement can be satisfied by resetting the cooling setpoint to 90°F unless the outside air temperature is less than the space temperature, in which case the cooling setpoint can be reset or not. If the zone is in cooling and the outside air temperature is less than the space temperature then additional infiltration from the opening provides economizer free cooling and is not an additional cooling load on the mechanical system.

This requirement does not require that any openings be operable but if there are operable openings then they must comply with this requirement.

Note that mechanical ventilation as required by Section 4.3.2 must still be provided. The mechanical system shut off pertains to the space conditioning equipment only. Mechanical ventilation must still be provided if the space does not fall under the natural ventilation criteria. Systems that meet the ventilation requirements with natural ventilation, rather than mechanical ventilation, are not exempt from the window/door switch requirement. Thus, in the same way that most homeowners typically choose between opening the windows and running the heating/cooling, window/door switches will now cause occupants to choose between opening windows/doors and allowing full heating/cooling.

Manually operable openings to the outdoors include manually operable windows, skylights, and doors that do not have automatic closing devices (e.g. sliding balcony doors). Motorized openings (e.g. motorized skylights) are still considered manually operable if occupants can open the openings as desired and they will stay open until manually closed.

If a zone serves more than one room then only the openings in the room with the thermostat are required to be interlocked. For example, if three perimeter private offices are served by a single VAV box then only the operable openings in the office with the thermostat need to be interlocked. The windows in the offices that do not have a thermostat do not need to be interlocked.

If there is a large room with more than one zone then only the zones with operable windows in them need to be interlocked. For example, if a large open office has a perimeter zone and an interior zone in the same room and there are operable windows in the perimeter zone but not the interior zone then only the perimeter zone needs to be interlocked to the windows.

Alterations to existing buildings are exempt from this requirement. Additions to existing buildings only have to comply if the operable opening(s) and associated zone are new.

There are a number of acceptance requirements related to control systems. These include:

1. Automatic time switch control devices.

2. Constant volume package unit.

3. Air-side economizers.

4. VAV supply fan controls.

5. Hydronic system controls.

These tests are described in Chapter 13 as well as the Reference Nonresidential Appendix NA7.