There are no acceptance tests for these requirements.

4.6.1.1 Water Conservation Measures for Cooling Towers

§110.2(e) establishes mandatory requirements for the efficient use of water in the operation of open (direct) and closed (indirect) cooling towers. The building standard applies to the new construction and retrofit of commercial, industrial and institutional cooling towers with a rated capacity of 150 tons or greater. For these towers all of the following are required:

1. The towers shall be equipped with either conductivity or flow-based controls to control cycles of concentration based on local water quality conditions. The controls shall automate system bleed and chemical feed based on conductivity, or in proportion to metered makeup volume, metered bleed volume, recirculating pump run time, or bleed time. Where employed, conductivity controllers shall be installed in accordance with manufacturer’s specifications.

2. Design documents have to document maximum achievable cycles of concentration based on local water supply as reported by the local water supplier, and using a calculator approved by the Energy Commission. The calculator shall determine maximum cycles based on a Langelier Saturation Index (LSI) of 2.5 or less. An approved calculator can be downloaded from the Energy Commission’s website: http://www.energy.ca.gov/title24/2013standards/documents/maximum_cycles_calculator.xls

3. The towers shall be equipped with a flow meter with an analog output for flow. This can be connected to the water treatment control system using either a hardwired connection or gateway.

4. The towers shall be equipped with an overflow alarm to prevent overflow of the sump in case of makeup water valve failure. This requires either a water level sensor or a moisture detector in the overflow drain. The alarm contact should be connected to the building Energy Management Control System to initiate an EMCS alarm to alert the operators.

5. The towers shall be equipped with drift eliminators that achieve a maximum rated drift of 0.002 percent of the circulated water volume for counter-flow towers and 0.005 percent for cross-flow towers.

As water is evaporated off the tower, the concentration of dissolved solids like calcium carbonate and silica will increase. The pH of the water will also change. With high levels of silica or dissolved solids you will get deposits on the tower fill or clogging in the tower nozzles which will reduce the tower's heat rejection capacity. High pH is a concern for metal tower basins and structural members. As the thresholds of these contaminants of concern are approached the automated controls should bleed some of the concentrated water out and dilute it with make-up water. The bleed can be controlled by measurement of make-up water flow (an indirect measurement of water drift and evaporation) or through conductivity (a measurement of the dissolved solids). The term "cycles of concentration" is the metric of how concentrated the contaminants are at the controlled level. The right value depends on the characteristics of the supply water, the rate of tower drift, the weather characteristics, and the load on the tower. Good practice is to maintain the following levels:

•Silica levels should be maintained at ≤ 150 ppm

•The Langelier Saturation Index should be maintained at ≤ 2.5 (see explanation of LSI below)

•pH in new cooling towers using galvanized metal should be maintained at ≤ 8.3 until metal is passivated, which occurs after 3-6 months of operation

To meet compliance, an Energy Commission-approved calculator (NRCC-MCH-06-E) allows the building owner to enter makeup water quality parameters including conductivity, alkalinity, calcium hardness, magnesium hardness, and silica. These values are available from the local water supplier in the most recent annual Consumer Confidence Report or Water Quality Report. These reports are generally posted on the water supplier’s website, or by contacting the local water supplier by telephone. Many water districts have multiple sources of water which often are changed seasonally. For example many water districts use a reservoir in the winter and spring then switch to well water in the summer and fall. Each supply will typically have different characteristics so the water treatment and control cycles of concentration should be seasonally shifted as well.

After entering the required water quality data, the user must also enter skin temperature; the default value of 110 degrees Fahrenheit is acceptable. Lastly, target tower cycles of concentration is entered into the calculator. The calculator calculates the Langelier Saturation Index (LSI) based on the cycles of concentration entered by the user. The maximum value of the LSI is 2.5; therefore, the user should enter the highest cycles of concentration value in 0.10 units that results in a calculated LSI not to exceed 2.5. The resulting cycles of concentration is considered by the Commission to be the Maximum Achievable Cycles of Concentration and must be recorded on the mechanical compliance document (NRCC-MCH-06-E), to which a copy of the Consumer Confidence Report or Water Quality Report must be attached. The Professional Engineer of Record must sign the compliance document (NRCC-MCH-06-E) attesting to the calculated maximum cycles of concentration.

Example 4-41

Question

What is the Langelier Saturation Index (LSI)?

Answer

The Langelier Saturation Index (LSI) predicts scaling. The LSI indicates whether water will precipitate, dissolve, or be in equilibrium with calcium carbonate, and is a function of hardness, alkalinity, conductivity, pH and temperature. LSI is expressed as the difference between the actual system pH and the saturation pH.

Example 4-42

Question

Where can I find data for makeup water quality?

Answer

Water agencies are required to make their annual water quality data available to the public. Water quality data is generally organized into an annual Consumer Confidence Report or Water Quality Report, which can often be found posted on the water agency’s website by searching for the key words “water quality”. Since many water districts have more than one water supply ask for a report for each source

Example 4-43

Question

What if all, or some, of the water quality data is not provided in the Consumer Confidence Report or Water Quality Report?

Answer

Some data may be available by calling the local water agency’s Water Quality Division. For example, agencies are not required to test for and report alkalinity; however, they often do test for it and will provide data over the phone or in an email. You can also check with water treatment firms that are doing business in the area. They often have test data that they will share. Finally you can hire a water treatment firm to take samples of the water to test.

4.6.1.2 Low Leakage Air Handling Unit (AHU)

The standard provides a compliance credit for low leakage AHUs. To achieve this credit you must meet the qualifications in Reference Joint Appendix JA9 and verify installation in accordance with the procedures specified in Reference Residential Appendix RA3.1.4.3.9. In order for an AHU to qualify as low leakage the AHU manufacturer must certify to the Energy Commission that the AHU complies with ASHRAE Standard 193. Once installed the AHU and distribution system is pressurized and the leakage measured according to the testing methods in RA 3.1.4.3.1. The credit is achieved by specifying the leakage amount in the approved compliance software which would use the inputted amount of duct leakage rather than use the default duct leakage rates that are based on either new or altered ducts.

4.6.2.1 Sizing and Equipment Selection

The Energy Standards require that mechanical heating and cooling equipment (including electric heaters and boilers) to be the smallest size available, within the available options of the desired equipment line that meets the design heating and cooling loads of the building or spaces being served. Depending on the equipment, oversizing can be either a penalty or benefit to energy usage. For vapor compression equipment, gross oversizing can drastically increase the energy usage and in some cases cause premature failure from short cycling of compressors. Boilers and water-heaters generally suffer lower efficiencies and higher standby losses if they are oversized. On the other hand, cooling towers, cooling coils, and variable speed driven cooling tower fans can actually improve in efficiency if oversized. Oversized distribution ductwork and piping can reduce system pressure losses and reduce fan and pump energy.

When equipment is offered in size increments, such that one size is too small and the next is too large, the larger size may be selected.

Packaged HVAC equipment may serve a space having substantially different heating and cooling loads. The unit size should be selected on the larger of the loads, based on either capacity or airflow. The capacity for the other load should be selected as required to meet the load, or if very small, should be the smallest capacity available in the selected unit. For example, packaged air-conditioning units with gas heat are usually sized on the basis of cooling loads. The furnace is sized on the basis of airflow, and is almost always larger than the design heating load.

Equipment may be oversized provided one or more of the following conditions are met:

1. It can be demonstrated to the satisfaction of the enforcing agency that oversizing will not increase building source energy use; or

2. Oversizing is the result of standby equipment that will operate only when the primary equipment is not operating. Controls must be provided that prevent the standby equipment from operating simultaneously with the primary equipment; or

3. Multiple units of the same equipment type are used, each having a capacity less than the design load, but in combination having a capacity greater than the design load. Controls must be provided to sequence or otherwise optimally control the operation of each unit based on load.

4.6.2.2 Load Calculations

For the purposes of sizing HVAC equipment, the designer shall use all of the following criteria for load calculations:

1. The heating and cooling system design loads must be calculated in accordance with the procedures described in the ASHRAE Handbook, Fundamentals Volume, Chapter 30, Table 1. Other load calculation methods, e.g. ACCA, SMACNA, etc., are acceptable provided that the method is ASHRAE-based. When submitting load calculations of this type, the designer must accompany the load calculations with a written affidavit certifying that the method used is ASHRAE-based. If the designer is unclear as to whether or not the calculation method is ASHRAE-based, the vendor or organization providing the calculation method should be contacted to verify that the method is derived from ASHRAE.

2. Indoor design conditions of temperature and relative humidity for general comfort applications are not explicitly defined. Designers are allowed to use any temperature conditions within the “comfort envelope” defined by ANSI/ASHRAE 55-1992 or Chapter 8 of the ASHRAE Handbook, Fundamentals Volume. Winter humidification or summer dehumidification is not required.

3. Outdoor design conditions shall be selected from Reference Joint Appendix JA2, which is based on data from the ASHRAE Climatic Data for Region X, for the following design conditions:

a. Heating design temperatures shall be no lower than the temperature 'listed in the Heating Winter Median of Extremes value.

b. Cooling design temperatures shall be no greater than the 0.5 percent Cooling Dry Bulb and Mean Coincident Wet Bulb values.

c. Cooling design temperatures for cooling towers shall be no greater than the 0.5 percent cooling design wet bulb values.

4. Outdoor Air Ventilation loads must be calculated using the ventilation rates required in Section 4.3.

5. Envelope heating and cooling loads must be calculated using envelope characteristics including square footage, thermal conductance, solar heat gain coefficient or shading coefficient and air leakage, consistent with the proposed design.

6. Lighting loads shall be based on actual design lighting levels or power densities consistent with Chapter 5.

7. People sensible and latent gains must be based on the expected occupant density of the building and occupant activities as determined under Section 4.3. If ventilation requirements are based on a cfm/person basis, then people loads must be based on the same number of people as ventilation. Sensible and latent gains must be selected for the expected activities as 'listed in 2005 ASHRAE Handbook, Fundamentals Volume, Chapter 30, Table 1.

8. Loads caused by a process shall be based on actual information (not speculative) on the intended use of the building.

9. Miscellaneous equipment loads include such things as duct losses, process loads and infiltration and shall be calculated using design data compiled from one or more of the following sources:

a. Actual information based on the intended use of the building; or

b. Published data from manufacturer’s technical publications or from technical societies, such as the ASHRAE Handbook, HVAC Applications Volume; or

c. Other data based on the designer’s experience of expected loads and occupancy patterns.

10. Internal heat gains may be ignored for heating load calculations.

11. A safety factor of up to 10 percent may be applied to design loads to account for unexpected loads or changes in space usage.

12. Other loads such as warm-up or cool-down shall be calculated using one of the following methods:

a. A method using principles based on the heat capacity of the building and its contents, the degree of setback, and desired recovery time; or

b. The steady state design loads may be increased by no more than 30 percent for heating and 10 percent for cooling. The steady state load may include a safety factor of up to 10 percent as discussed above in Item 11.

13. The combination of safety factor and other loads allows design cooling loads to be increased by up to 21 percent (1.10 safety x 1.10 other), and heating loads by up to 43 percent (1.10 safety x 1.30 other).

Example 4-44

Question

Do the sizing requirements restrict the size of duct work, coils, filter banks, etc. in a built-up system?

Answer

No. The intent of the Energy Standards is to limit the size of equipment, which if oversized will consume more energy on an annual basis. Coils with larger face areas will usually have lower pressure drops than otherwise, and may also allow the chilled water temperature to be higher, both of which may result in a decrease in energy usage. Larger filter banks will also usually save energy. Larger duct work will have lower static pressure losses, which may save energy, depending on the duct’s location, length, and degree of insulation.

Oversizing fans, on the other hand, may or may not improve energy performance. An oversized airfoil fan with inlet vanes will not usually save energy, as the part load characteristics of this device are poor. But the same fan with a variable frequency drive may save energy. Controls are also an important part of any system design.

The relationship between various energy consuming components may be complex, and is left to the designer’s professional judgment. Note however, that when components are oversized, it must be demonstrated to the satisfaction of the enforcement agency that energy usage will not increase.

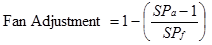

4.6.2.3 Fan Power Consumption

Maximum fan power is regulated in individual fan systems where the total power of the supply (including fan-powered terminal units), return and exhaust fans within the fan system exceed 25 hp at design conditions (see Section 4.10 for definitions). A system consists of only the components that must function together to deliver air to a given area; fans that can operate independently of each other comprise separate systems. Included are all fans associated with moving air from a given space-conditioning system to the conditioned spaces and back to the source, or to exhaust it to the outdoors.

The 25 hp total criteria apply to:

1. All supply and return fans within the space-conditioning system that operate at peak load conditions.

2. All exhaust fans at the system level that operate at peak load conditions. Exhaust fans associated with economizers are not counted, provided they do not operate at peak conditions.

3. Fan-powered VAV boxes, if these fans run during the cooling peak. This is always the case for fans in series type boxes. Fans in parallel boxes may be ignored if they are controlled to operate only when zone heating is required, and are normally off during the cooling peak.

4. Elevator equipment room exhausts, or other exhausts that draw air from a conditioned space, through an otherwise unconditioned space, to the outdoors.

The criteria are applied individually to each space-conditioning system. In buildings having multiple space-conditioning systems, the criteria apply only to the systems having fans whose total demand exceeds 25 hp.

Not included are fans not directly associated with moving conditioned air to or from the space-conditioning system, or fans associated with a process within the building.

For the purposes of the 25 hp criteria, horsepower is the brake horsepower as 'listed by the manufacturer for the design conditions, plus any losses associated with the drive, including belt losses or variable frequency drive losses. If the brake horsepower is not known, then the nameplate horsepower should be used.

If drive losses are not known, the designer may assume that direct drive efficiencies are 1.0, and belt drives are 0.97. Variable speed drive efficiency should be taken from the manufacturer’s literature; if it includes a belt drive, it should be multiplied by 0.97.

Total fan horsepower need not include the additional power

demand caused solely by air treatment or filtering systems with final pressure

drops of more than

1 inch water gauge (w.g.). It is assumed that

conventional systems may have filter pressure drops as high as 1 inch w.g.;

therefore only the horsepower associated with the portion of the pressure drop

exceeding 1 in., or fan system power caused solely by process loads, may be

excluded.

For buildings whose systems exceed the 25 hp criteria, the total space-conditioning system power requirements are:

1. Constant volume fan systems. The total fan power index at design conditions of each fan system with total horsepower over 25 hp shall not exceed 0.8 W/cfm of supply air.

2. Variable air volume (VAV) systems. The total fan power index at design conditions of each fan system with total horsepower over 25 hp shall not exceed 1.25 W/cfm of supply air; and

3. Air-treatment or filtering systems. For systems with air-treatment or filtering systems, calculate the adjusted fan power index using Energy Standards Equation 140.4-A:

Equation 4-8 – (Energy Standards Equation 140.4-A) Adjusted Total Fan Power Index

Adjusted total fan power index = Fan power index X Fan Adjustment

Where:

SPa = Air pressure drop across the air-treatment or filtering system.

SPf = Total pressure drop across the fan.

The total system power demand is based on brake horsepower at design static and cfm, and includes drive losses and motor efficiency. If the motor efficiency is not known, values from Reference Nonresidential Appendix NA3 may be used.

Example 4-45

Question

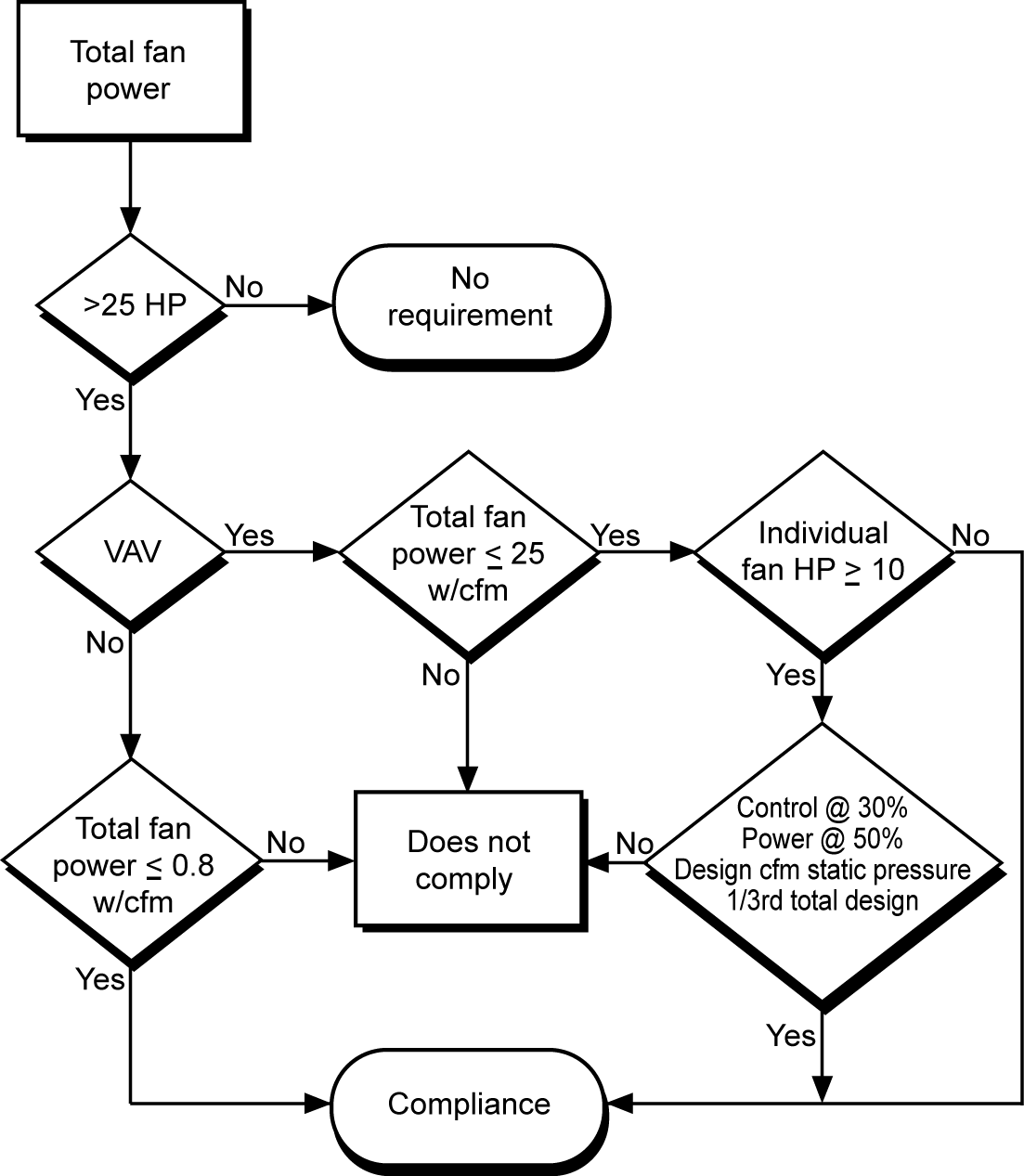

In the system depicted below, which fans are included in the fan power criteria?

Answer

The fans included are those that operate during the design cooling load. These include the supply fan, the return fan, the series fan-powered VAV box(es), the general exhaust fan, and conference room exhaust fans other than those that are manually controlled. The parallel fan-powered VAV box(es) are not included as those fans only operate during a call for zone heating.

Example 4-46

Question

If a building has five zones with 15,000 cfm air handlers that are served by a common central plant, and each air handler has a 15 hp supply fan, does the 25 hp limit apply?

Answer

No. Each air handler, while served by a common central plant, is a separate fan system. Since the demand of each air handler is only 15 hp, the 25 hp criteria does not apply.

Example 4-47

Question

The space-conditioning system in a laboratory has a 30 percent filter with a design pressure drop at change out of 0.5 inch w.g., and an 80 percent filter with a design pressure drop of 1.2 inch w.g. The design total static pressure of the fan is 5.0 inch w.g. What percentage of the power may be excluded from the W/cfm calculation?

Answer

The total filter drop at change out (final pressure drop) is 0.5 inch + 1.2 inch = 1.7 inch w.g. The amount that may be excluded is 1.7 inch - 1.0 inch = 0.7 inch w.g. The percentage of the horsepower that may be excluded is 0.7 inch /5.0 inch = 14 percent

If the supply fan requires 45 BHP, the adjusted horsepower of the supply fan in the W/cfm calculation is

45 BHP x (1 – 14 percent) = 38.7 BHP

The horsepower of any associated return or exhaust fan is not adjusted by this factor, as the filters have no impact on these fans.

Example 4-48

Question

What is the maximum allowed power consumption for the fans in a VAV bypass system?

Answer

A VAV bypass, while variable volume at the zone level, is constant volume at the fan level. If the total fan power demand of this system exceeds 25 hp, then the fan power may not exceed 0.8 W/cfm.

Example 4-49

Question

What is the power consumption of a 20,000 cfm VAV system having an 18 bhp supply fan, a 5 bhp return fan, a 3 bhp economizer relief fan, a 2 hp outside air ventilation fan and a 1 hp toilet exhaust fan? Note that the exhaust and outside air ventilation fans are direct drive and 'listed in hp not bhp. The supply and return fans are controlled with variable frequency drives having an efficiency of 96 percent.

Answer

The economizer fan is excluded provided it does not run at the time of the cooling peak.

Power consumption is then based on the supply; return, outdoor and toilet exhaust fans. The ventilation fan is direct drive so its efficiency is 1. The supply and return fans have default drive efficiencies of 0.97. From Tables NA3-1 and NA3-2 from Reference Nonresidential Appendix NA3, the assumed efficiencies of the motors are 91.7 percent and 87.5 percent for a 25 and 7.5 hp 4-pole motor respectively. Fan power demand in units of horsepower must first be calculated to determine whether the requirements apply:

a. 18 bhp / (0.97 x 0.917 x 0.96) = 21.1 hp

b. 5 bhp / (0.97 x 0.875 x 0.96) = 6.1 hp

Total power consumption, adjusted for efficiencies, is calculated as:

21.1 hp + 6.1 hp + 2 hp + 1 hp = 30.2 hp

Since this is larger than 25 hp, the limitations apply. W/cfm is calculated as:

30.2 hp x 746 W/cfm/20,000 cfm = 1.13 W/cfm

The system complies because power consumption is below 1.25 W/cfm. Note that, while this system has variable frequency drives, they are only required by the Energy Standards for the 18 bhp fan since each other fan is less than 10 hp.

4.6.2.4 Fractional HVAC Motors for Fans

HVAC fan motors that are less than1 hp or less and 1/12 hp or greater shall be electronically-commutated motors or shall have a minimum motor efficiency of 70 percent when rated in accordance with NEMA Standard MG 1-2006 at full load rating conditions. These motors shall also have the means to adjust motor speed for either balancing or remote control. Belt-driven fans may use sheave adjustments for airflow balancing in lieu of a varying motor speed.

This requirement can be met with either electronically commutated motors or brushless DC motors. These motors have higher efficiency than PSC motors and inherently have speed control that can be used for VAV operation or balancing.

This requirement includes fan-powered terminal units, fan-coil units, exhaust fans, transfer fans, and supply fans. There are two exceptions to this requirement:

1. Motors in fan-coil units and terminal units that operate only when providing heating to the space served. This includes parallel style fan-powered VAV boxes and heating only fan-coils.

2. Motors that are part of space conditioning equipment certified under §110.1 or §110.2. This includes supply fans, condenser fans, ventilation fans for boilers and other fans that are part of equipment that is rated as a whole.

4.6.2.5 Electric-Resistance Heating

The Energy Standards strongly discourage the use of electric-resistance space heat. Electric-resistance space heat is not allowed in the prescriptive approach except where:

1. Site-recovered or site-solar energy provides at least 60 percent of the annual heating energy requirements; or

2. A heat pump is supplemented by an electric-resistance heating system, and the heating capacity of the heat pump is more than 75 percent of the design heating load at the design outdoor temperature, determined in accordance with the Energy Standards; or

3. The total capacity of all electric-resistance heating systems serving the entire building is less than 10 percent of the total design output capacity of all heating equipment serving the entire building; or

4. The total capacity of all electric-resistance heating systems serving the building, excluding those that supplement a heat pump, is no more than 3 kW; or

5. An electric-resistance heating system serves an entire building that:

a. Is not a high-rise residential or hotel/motel building.

b. Has a conditioned floor area no greater than 5,000 ft².

c. Has no mechanical cooling.

d. Is in an area where natural gas is not currently available and an extension of a natural gas system is impractical, as determined by the natural gas utility.

6. In alterations where the existing mechanical systems use electric reheat (when adding variable air volume boxes) added capacity cannot exceed 20 percent of the existing installed electric capacity, under any one permit application.

7. In an addition where the existing variable air volume system with electric reheat is being expanded the added capacity cannot exceed 50 percent of the existing installed electric reheat capacity under any one permit.

The Energy Standards in effect allow a small amount of electric-resistance heat to be used for local space heating or reheating (provided reheat is in accordance with these regulations).

Example 4-50

Question

If a heat pump is used to condition a building having a design heating load of 100,000 Btu/h at 35°F, what are the sizing requirements for the compressor and heating coils?

Answer

The compressor must be sized to provide at least 75 percent of the heating load at the design heating conditions, or 75,000 Btu/h at 35°F. The Energy Standards do not address the size of the resistance heating coils. Normally, they will be sized based on heating requirements during defrost.

4.6.2.6 Cooling Tower Flow Turndown

The Energy Standards require that open cooling towers with multiple condenser water pumps be designed so that all cells can be run in parallel with the larger of

1. The flow that is produced by the smallest pump, or

2. 50 percent of the design flow for the cell.

Note that in a large plant at low load operation you would typically run less than all of the cells at once. This is allowed in the Energy Standards.

Cooling towers are very efficient at unloading (the fan energy drops off as the cube of the airflow). It is always more efficient to run the water through as many cells as possible; 2 fans at 1/2 speed use less than 1/3 of the energy of 1 fan at full speed for the same load. Unfortunately there is a limitation with flow on towers, the flow must be sufficient to provide full coverage of the fill. If the nozzles don’t fully wet the fill, air will go through the dry spots providing no cooling benefit and cause the water at the edge of the dry spot to flash evaporate depositing dissolved solids on the fill.

Luckily the cooling tower manufacturers do offer low-flow nozzles (and weirs on basin type towers) to provide better flow turndown. This typically only costs $100 to $150 per tower cell. As it can eliminate the need for a tower isolation control point this provides energy savings at a reduced first cost.

Example 4-51

Question

If a large central plant has five equally sized chillers and five equally sized cooling tower cells do all of the cooling tower cells need to operate when only one chiller is on-line?

Answer

No you would probably only run three cells with one chiller. The cooling tower cells must be designed to run at 33 percent of their nominal design flow. With two to five chillers running you would run all of the cells of cooling tower. With only one chiller running you would run three cells. In each case you would need to keep the tower flow above the minimum that it was designed for.

4.6.2.7 Centrifugal Fan Limitation

Open cooling towers with a combined rated capacity of 900 gpm and greater at 95°F condenser water return, 85°F condenser water supply and 75°F outdoor wet-bulb temperature are prohibited to use centrifugal fans. The 95°F condenser water return, 85°F condenser water supply and 75°F outdoor wet-bulb temperature are test conditions for determining the rated flow capacity in gpm. Centrifugal fans use approximately twice the energy as propeller fans for the same duty. There are a couple of exceptions to this requirement.

1. Cooling towers that are ducted (inlet or discharge) or have an external sound trap that requires external static pressure capability.

2. Cooling towers that meet the energy efficiency requirement for propeller fan towers in Table 4-7.

Centrifugal fans may be used on closed circuit fluid coolers.

As with all prescriptive requirements centrifugal fan cooling towers may be used when complying with the performance method. The budget building will be modeled using propeller towers.

4.6.2.8 Chiller Efficiency

In Table 4-4 there are two sets of efficiency for almost every size and type of chiller. Path A representing fixed speed compressors and Path B representing variable speed compressors. For each path there are two efficiency requirements: a full load efficiency and an integrated part-load efficiency. Path A typically has a higher full load efficiency and a lower part-load efficiency than Path B. In all of the California climates the cooling load varies enough to justify the added cost for a Path B chiller. This is a prescriptive requirement so Path B is used in the base case model in the Performance method.

There are a number of exceptions provided to this requirement:

1. Chillers with an electrical service of > 600V. This is due to the fact that the cost of VSDs is much higher on medium voltage service.

2. Chillers attached to a heat recovery system with a design heat recovery capacity >40 percent of the chiller's design cooling capacity. Heat recovery typically requires operation at higher lifts and compressor speeds.

3. Chillers used to charge thermal energy storage (TES) systems with a charging temperature of <40°F. This again requires a high lift operation for chillers

In a building with more than 3 chillers only 3 are required to meet the Path B efficiencies.

4.6.2.9 Limitation on Air Cooled Chillers

New central cooling plants and cooling plant expansions will be limited on the use of air-cooled chillers. For both the limit is 300 tons per plant.

In the studies provided to support this requirement, air cooled chillers always provided a higher life-cycle cost than water cooled chillers even accounting for the water and chemical treatment costs.

There are a few exceptions to this requirement:

1. Where the water quality at the building site fails to meet manufacturer’s specifications for the use of water-cooled chillers.

This exception recognizes that some parts of the state have exceptionally high quantities of dissolved solids that could foul systems or cause excessive chemical treatment or blow down.

2. Chillers that are used to charge a thermal energy storage (TES) system with a design temperature of less than 40°F.

This addresses the fact that air-cooled chillers can operate very efficiently at low ambient air temperatures. Since TES systems operate for long hours at night, these systems may be as efficient as a water-cooled plant. Note that the chiller must be provided with head pressure controls to achieve these savings.

3. Air cooled chillers with minimum efficiencies approved by the Energy Commission pursuant to §10-109(d).

This exception was provided in the event that an exceptionally high efficiency air cooled chiller was developed. None of the high-efficiency air-cooled chillers currently evaluated are as efficient as a water-cooled systems using the lowest chiller efficiency allowed by §110.2.