Some requirements in the nonresidential lighting Standards are classified as “Mandatory Measures” because they are required regardless of the compliance approach used. All projects must comply with all Mandatory Measures.

It is the responsibility of the designer to specify products that meet these requirements. It is the responsibility of the installer to comply with all of the mandatory requirements, even if the plans mistakenly do not. It is the responsibility of code enforcement officials, in turn, to check that the mandatory features and specified devices are installed.

The mandatory measures for nonresidential indoor lighting include the following:

•Some functional areas in nonresidential buildings are required to comply with the low-rise residential lighting Energy Standards (§130.0(b)).

•Manufactured lighting equipment, products, and devices must be appropriately certified (§110.0(b) and §110.1).

•Requirements for how luminaires shall be classified according to technology and how installed lighting power shall be determined (§110.9).

•Required indoor lighting controls (Section 5.4).

•Lighting control acceptance testing (Section 5.4.6).

•Lighting control Certificates of Installation (Section 5.4.7).

Although not related exclusively to lighting, the Energy Standards impose mandatory measures for electrical power distribution systems. See Chapter 8 of this manual for additional information about mandatory measures for electrical power distribution systems.

The following function areas in nonresidential, high-rise residential, and hotel/motel occupancies are required to comply with the low-rise residential lighting Standards (§130.0(b)).

1. High-rise residential dwelling units.

2. Outdoor lighting attached to a high-rise residential or hotel/motel building, and is separately controlled from inside a dwelling unit or guest room.

3. Fire station dwelling units.

4. Hotel and motel guest rooms. Note that hotel and motel guest rooms are also required to comply with the nonresidential lighting requirements in §130.1(c)8, which require captive card key controls, occupant sensing controls, or automatic controls. In addition, hotel and motel guest rooms shall meet the controlled receptacle requirements of §130.5(d)4.

5. Dormitory and senior housing dwelling units.

All other function areas in nonresidential, high-rise residential, and hotel/motel occupancies, such as common areas, shall comply with the applicable nonresidential lighting Standards.

For lighting products that are subject to State or federal appliance regulations, installation shall be limited to those products that have been certified to the Energy Commission by their manufacturer, pursuant to the provisions of the Appliance Efficiency Regulations (Title 20 California Code of Regulations, §1606).

Once a device is certified, it will be listed in the Appliance Efficiency Database, which is available from: http://www.energy.ca.gov/appliances/database/

Call the Energy Hotline at 1-800-772-3300 to obtain more information.

If a device is certified to the Energy Commission, the Energy Standards do not require a builder, designer, owner, operator, or enforcing agency to independently test it to confirm its compliance with the Appliance Efficiency Regulations.

For the purposes of the Energy Standards, lighting controls are separated into two categories:

•Self-Contained Lighting Controls are unitary lighting control modules that do not require any additional components to be fully functional.

•Lighting Control Systems require two or more components to be installed in the building to provide all of the functionality required to make up a fully functional and compliant lighting control.

Both categories of lighting controls must meet specified performance and certification requirements.

The Energy Standards also cover lighting controls which are not covered by the Title 20 Appliance Efficiency Regulations, such as field assembled lighting control systems, line-voltage track lighting integral current limiters, supplementary overcurrent protection panels for use with track lighting, ballasts for residential recessed compact fluorescent luminaires, and qualifications for residential high efficacy LED luminaires.

The requirements in §110.9 for ballasts used in residential recessed compact fluorescent luminaires, and for residential high efficacy LED luminaires, do not apply to most nonresidential lighting function areas, except for inside dwelling units of high-rise residential, hotel/motel, fire stations, and dormitory/senior housing.

5.2.3.1 General Lighting Control Requirements

The following lighting controls systems must comply with the applicable part of the Title 20 Appliance Efficiency Regulations and must include the specific functionality listed below (§110.9(b)). In addition, all components of the systems considered together as installed shall meet all applicable requirements for the application for which they are installed, as required in §130.0 through 130.5, §140.6 through 140.8, §141.0, and §150.0(k)

A. Time-Switch Lighting Controls

•Automatic Time-Switch Controls

•Astronomical Time-Switch Controls

•Multi-Level Astronomical Time-Switch Controls

•Outdoor Astronomical Time-Switch Controls

B. Daylighting Controls

•Automatic Daylight Controls

•Photo Controls

C. Dimmers

D. Occupant Sensing Controls

•Occupant Sensors

•Motion Sensors

•Vacancy Sensors

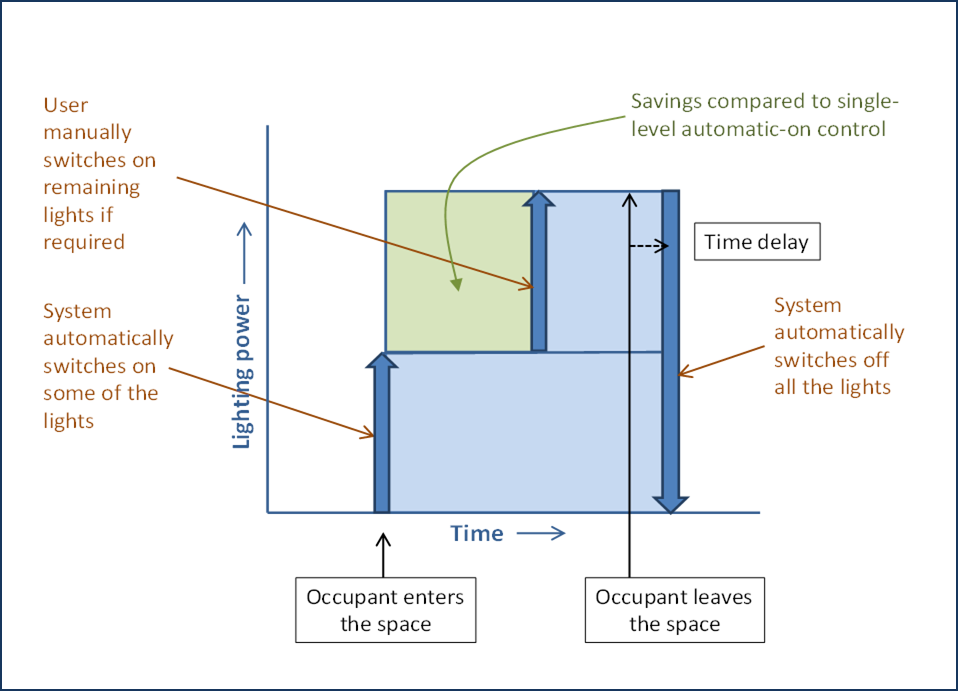

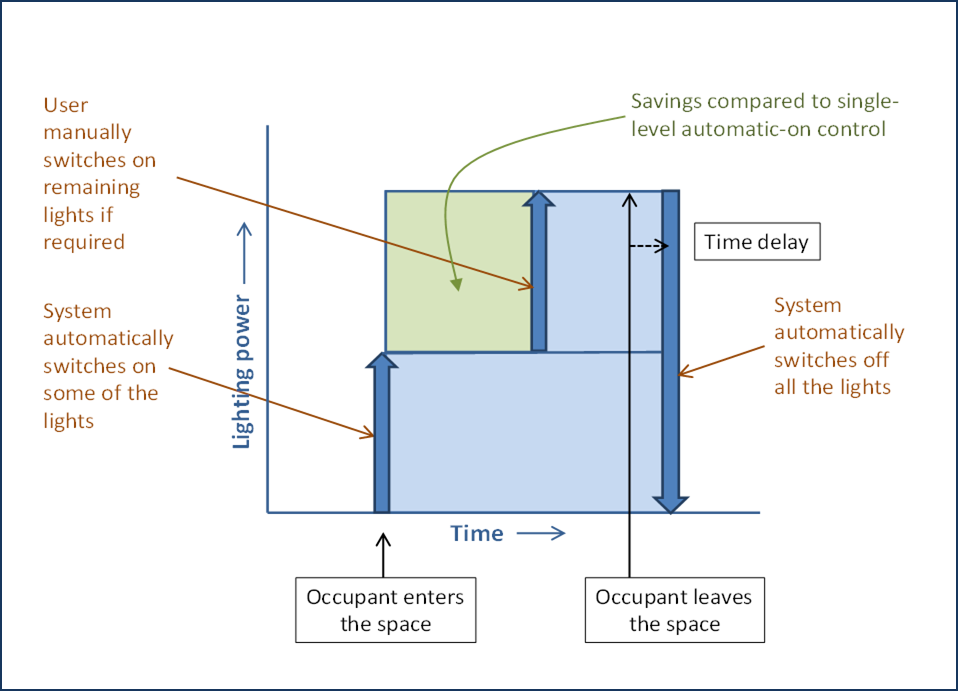

•Partial-ON Sensors

•Partial-OFF Sensors

5.2.3.2 Self-Contained Lighting Control Devices

A Self-Contained Lighting Control is defined in §100.1 as a unitary lighting control module that requires no additional components to be a fully functional lighting control. Self-Contained Lighting Controls are required by §110.9(a)3 to be certified by the manufacturer according to the Title 20 Appliance Efficiency Regulations. Lighting controls regulated by the Energy Standards, but not regulated by the Title 20 Appliance Efficiency Regulations, shall meet the following requirements:

A. Part-Night Outdoor Lighting Control (§110.9(b)5)

Part-Night outdoor lighting controls do not apply to nonresidential indoor lighting requirements (see Section 6.3.4 for additional information).

A Part Night Outdoor Lighting Control is defined by §100.1 as a time or occupancy-based lighting control device or system that is programmed to reduce or turn off the lighting power to an outdoor luminaire for a portion of the night. (Note that this lighting control does not apply to nonresidential indoor lighting Standards).

B. Track lighting integral current limiter (§110.9(c))

A track lighting current limiter is used to limit the rated power that can go through a section of track lighting. Without the current limiter, the “installed” wattage of a long section of track could be excessive and use up all of the allotted lighting power for a space. With track lighting and a current limiter, one can space the track heads far apart and use high efficacy sources in the track heads so it is possible to stay below the rated wattage of the current limiter. If the wattage served by the current limiter exceeds the rated wattage of the current limiter, the current limiter turns off the current to the controlled lighting.

A track lighting integral current limiter shall be recognized for compliance with the Energy Standards only for line-voltage track lighting systems and only if it meets all of the following requirements:

1. Shall be certified to the Energy Commission by the manufacturer in accordance with the requirements in §110.9(c).

2. Before a Line-Voltage Track Lighting Integral Current Limiter will be recognized for compliance with the lighting requirements, the person who is eligible under Division 3 of the Business and Professions Code to accept responsibility for the construction or installation of features, materials, components, or manufactured devices shall sign and submit the Certificate of Installation.

a. If any of the requirements in the Certificate of Installation are not met, the Line-Voltage Track Lighting Integral Current Limiter shall not be recognized for compliance with the Energy Standards.

3. Shall be manufactured so that the current limiter housing is used exclusively on the same manufacturer's track for which it is designed.

4. Shall be designed so that the current limiter housing is permanently attached to the track so that the system will be irreparably damaged if the current limiter housing were to be removed after installation into the track. Methods of attachment may include but are not limited to one-way barbs, rivets, and one-way screws.

5. Shall employ tamper resistant fasteners for the cover to the wiring compartment.

6. Shall have the identical volt-ampere (VA) rating of the current limiter, as the system is installed and rated for compliance with the Energy Standards clearly marked on all of the following places:

a. So that it is visible for the building officials’ field inspection without opening coverplates, fixtures, or panels.

b. Permanently marked on the circuit breaker.

c. On a factory-printed label that is permanently affixed to a non-removable base-plate inside the wiring compartment.

d. Shall have a conspicuous factory installed label permanently affixed to the inside of the wiring compartment warning against removing, tampering with, rewiring, or bypassing the device

7. Each electrical panel from which track lighting integral current limiters are energized shall have a factory printed label permanently affixed and prominently located, stating the following:

"NOTICE: Current limiting devices installed in track lighting integral current limiters connected to this panel shall only be replaced with the same or lower amperage. Adding track or replacement of existing current limiters with higher continuous ampere rating will void the track lighting integral current limiter certification, and will require re-submittal of compliance documentation to the enforcement agency responsible for compliance with the California Title 24, Part 6 Building Energy Efficiency Standards.”

C. Track Lighting Supplementary Overcurrent Protection Panel (§110.9(d))

A Track Lighting Supplementary Overcurrent Protection Panel is a subpanel that contains current limiters for use with multiple track lighting circuits only.

A Track Lighting Supplementary Overcurrent Protection Panel shall be used only for line-voltage track lighting and shall be recognized for compliance with the Energy Standards only if it meets all of the following requirements:

1. Before a Track Lighting Supplementary Overcurrent Protection Panel will be recognized for compliance with the lighting requirements in the Energy Standards, the person who is eligible under Division 3 of the Business and Professions Code to accept responsibility for the construction or installation of features, materials, components, or manufactured devices shall sign and submit the Certificate of Installation.

a. If any of the requirements in the Certificate of Installation are not met, the Track Lighting Supplementary Overcurrent Protection Panel shall not be recognized for compliance with the Energy Standards.

2. Shall be 'listed in accordance with Article 100 of the California Electric Code.

3. Shall be used only for line voltage track lighting. No other lighting or building power shall be used in a Supplementary Overcurrent Protection Panel, and no other lighting or building power shall be recognized for compliance with the Energy Standards by using a Supplementary Overcurrent Protection Panel.

4. Be permanently installed in an electrical equipment room, or permanently installed adjacent to the lighting panel board providing supplementary overcurrent protection for the track lighting circuits served by the supplementary over current protection pane.

5. Shall have a permanently installed label that is prominently located stating the following:

"NOTE: This Panel for Track Lighting Energy Code Compliance Only. The overcurrent protection devices in this panel shall only be replaced with the same or lower amperage. No other overcurrent protective device shall be added to this panel. Adding to, or replacement of existing overcurrent protective device(s) with higher continuous ampere rating, will void the panel listing and require re-submittal of compliance documentation to the enforcement agency responsible for compliance with the California Title 24, Part 6 Building Energy Efficiency Standards.”

5.2.3.3 Requirements for Lighting Control Systems

Lighting Control Systems are defined by §100.1 as requiring two or more components to be installed in the building to provide all of the functionality required to make up a fully functional and compliant lighting control. Lighting control systems may be installed for compliance with lighting control requirements in the Energy Standards providing they meet all of the following requirements:

1. A lighting control system shall comply with all requirements 'listed below; and all components of the system considered together as installed shall meet all applicable requirements for the lighting control application for which they are installed as required in §130.0 through §130.5, §140.6 through §140.8, §141.0, and §150(k).

2. Before a Lighting Control System (including an EMCS) can be recognized for compliance with the lighting control requirements in the Energy Standards, the person who is eligible under Division 3 of the Business and Professions Code to accept responsibility for the construction or installation of features, materials, components, or manufactured devices shall sign and submit the Certificate of Installation.

If any of the requirements in the Certificate of Installation are not met, the Lighting Control System (or EMCS) shall be considered noncompliant.

3. If there are indicator lights that are integral to a lighting control system, they shall consume no more than one watt of power per indicator light.

4. A lighting control system shall meet all of the functional requirements in the Title 20 Appliance Efficiency Regulations for the comparable self-contained lighting control devices.

For example, if a lighting control system is installed to comply with the Energy Standards for an occupancy sensor, then the lighting control system shall comply with all of the requirements for an occupancy sensor in Title 20. If that same lighting control system is also installed to comply with the Energy Standards for a daylighting control, then it shall also comply with all of the requirements for a daylighting control in Title 20. Each of these functions shall be documented in the Certificate of Installation (see item 2 above).

5. If the system is installed to function as a partial-on or partial-off occupant sensor, the installation may be made up of a combination of single or multi-level Occupant, Motion, or Vacancy Sensor Controls, provided that the components installed to comply with manual-on requirements shall not be capable of conversion by the user from manual-on to automatic-on functionality.

5.2.3.4 Requirements for Residential Luminaires

The following requirements apply only to residential lighting installations:

1. The requirements for residential lighting only apply when installed in specifically defined residential function areas that are within a nonresidential building. (See Section 5.2.1)

2. There are no requirements for certifying nonresidential luminaires in accordance with the Energy Standards. However, there are some luminaires and light sources that are designed to be installed in either residential or nonresidential applications.

If the luminaires are designed to be installed in residential lighting applications as specified in §150.0(k) and the luminaires are classified as JA8 high efficacy luminaires in accordance with Table 150.0-A, the luminaires shall be certified to the Energy Commission according to the requirements in Reference Joint Appendix JA8 as a JA8 High Efficacy Light Source.

3. Residential High Efficacy Luminaires. Certain types of light sources are automatically classified as high efficacy, unless they are in recessed downlight luminaires. (Recessed downlight luminaires in ceilings have specific requirements, outlined in Residential Compliance Manual Chapter 6.)

Luminaires with the following light sources are automatically classified as high efficacy:

•Pin-based linear fluorescent luminaires using electronic ballasts

•Pin-based compact fluorescent luminaires using electronic ballasts

•Pulse-start metal halide luminaires

•High pressure sodium luminaires

•Luminaires with GU-24 sockets other than LEDs

•Luminaires with hardwired high frequency generator and induction lamp

•Inseparable SSL luminaires installed outdoors

•Inseparable SSL luminaries with colored light sources for decorative lighting purpose

The luminaire types listed here are the only types that are automatically classified as high efficacy for residential lighting application. All other luminaire types must have a light source or lamp that meets the requirements of Reference Joint Appendix JA8.

4. Ballasts for Residential Recessed Luminaires. To qualify as high efficacy for compliance with the residential lighting in §150.0(k), any compact fluorescent lamp ballast in a residential recessed luminaire shall meet all of the following conditions, in accordance with §110.9(f):

•Be rated by the ballast manufacturer to have a minimum rated life of 30,000 hours when operated at or below a specified maximum case temperature. This maximum ballast case temperature specified by the ballast manufacturer shall not be exceeded when tested in accordance to UL 1598 Section 19.15.

•Have a ballast factor of no less than 0.90 for non-dimming ballasts and a ballast factor of no less than 0.85 for dimming ballasts.