This section of the manual focuses on the

Energy Standards

provisions unique to refrigerated warehouses. The Energy Standards described in

this chapter of the manual address refrigerated space insulation levels,

underslab heating requirements in freezers, infiltration barriers, evaporator

fan controls, condenser sizing and efficiency requirements, condenser fan

controls, and screw compressor variable-speed requirements.

All buildings regulated under Part 6 of the Energy

Standards must also comply with the general provisions of the Energy Standards

(§100.0 – §100.2,

§110.0 – §110.10, §120.0 – §120.9, §130.0 – §130.5) and additions and

alterations requirements (§141.1).

These topics are generally addressed in Chapter 3 of this manual.

10.6.1.1 Mandatory Measures

and Compliance Approaches

The energy efficiency requirements

for refrigerated warehouses are all mandatory. There are no prescriptive

requirements or performance compliance paths for refrigerated warehouses. Since

the provisions are all mandatory, there are no trade-offs allowed between the

various requirements. The application must demonstrate compliance with each of

the mandatory measures. Exceptions to each mandatory requirement, when

applicable, are described in each of the mandatory measure sections

below.

10.6.1.2 Scope and

Application

§120.6(a)

of the Energy Standards addresses the energy efficiency of refrigerated

spaces within buildings, including coolers and freezers, as well as the

refrigeration equipment that serves those spaces. Coolers are defined as

refrigerated spaces designed to operate between 28°F (-2°C) and 55°F (13°C).

Freezers are defined as refrigerated spaces designed to operate below 28°F

(-2°C). The Energy Standards does not address walk-in coolers and freezers,

defined as refrigerated spaces less than 3,000 ft2, as these are

covered by the Appliance

Efficiency Regulations (Title 20). However, refrigerated warehouses and

spaces with a total of 3,000 ft² or more and served by a common refrigeration system are covered by

the Energy Standards and required to comply with §120.6(a).

Furthermore, areas within

refrigerated warehouses designed solely for quick chilling or quick freezing of

products have some exceptions for evaporators and compressors. Quick chilling

and freezing spaces are defined as spaces with a design refrigeration evaporator

load of greater than 240 Btu/hr-ft² of floor space, which is equivalent to 2

tons per 100 ft² of floor space. A space used for quick chilling or freezing and

used for refrigerated storage must still meet the requirements of §120.6(a).

The intent of the Energy Standards

is to regulate storage space, not quick chilling or freezing space or process equipment.

Recognizing that there is often a variety of space types and equipment connected

to a particular suction group in a refrigerated warehouse,

it is not always possible to identify compressor plant equipment that serves the

storage space only. It would be outside the intent of the Energy Standards to

apply the compressor plant requirements to an industrial process that is not

covered by the Energy Standards simply because a small storage space is also

attached to the suction group. Similarly, it would be outside the intent of the

Energy Standards to exclude a compressor plant connected to a suction group

serving a large storage space covered by the Energy Standards on the basis of a

small process cooler or quick chill space also connected to the same suction

group. For compliance, the compressor plant requirements in §120.6(a)5B

apply when 80 percent or more of the design refrigeration capacity connected to

the suction group is from refrigerated storage space(s). A suction group refers

to one or more compressors that are connected to one or more refrigeration loads

whose suction inlets share a common suction header or manifold.

A variety of space types and

processes may be served by a compressor plant at different suction pressures.

When all of these compressors share a common condensing loop, it is impossible

to address only the equipment serving refrigerated storage spaces. For

compliance, the provisions addressing condensers, subsection §120.6(a)4A.

and 4B, apply only to new condensers that are part of new refrigeration systems

when the total design capacity of all refrigerated storage spaces served by

compressors using a common condensing loop is greater than or equal to 80

percent of the total design capacity.

In addition to an all-new refrigerated

facility, the Energy Standards cover expansions and modifications to an existing

facility and an existing refrigeration plant. The Energy Standards do not

require that all existing equipment must comply when a refrigerated warehouse is

expanded or modified using existing refrigeration equipment. Exceptions are

stated in the individual equipment requirements and an explanation of

applicability to additions and alterations is included in Section 10.4.

10.6.1.3 Ventilation

Section 120.1(a)1

of the Energy Standards, concerning ventilation requirements, includes an

exception for “Refrigerated warehouses and other spaces or buildings that are

not normally used for human occupancy and work.” The definition of refrigerated warehouses

covers all refrigerated spaces at or below 55°F (13°C), which will in some

instances include spaces with occupancy levels or durations, effect of stored

product on space conditions, or other factors that may require ventilation for

one or more reasons. Accordingly, while the Energy Standards do not require

ventilation for refrigerated warehouses, it is acknowledged that ventilation may

be needed in some instances and is left to the determination of the owner and

project engineer.

Example 10-27

Question

A space that

is part of a refrigerated facility is used solely to freeze meat products and

not for storage. The design evaporator load is 310 Btu/hr-ft² at the applied

conditions. Does the space have to comply with the space requirements in §120.1(a)1

of the Energy Standards?

Answer

Yes.

If the warehouse is 3,000 ft2 or larger or served by a

refrigeration system serving 3,000 ft2 or more, it must meet all

the requirements in subsections 1,2, 6, and 7. It also must meet the

requirements of subsections 3A, 4C, 4D, 4E, 4F, 4G, 5A, and 5C. There are

exceptions for 3B, 3C, 4A, 4B, and 5B.

Example

10-28

Question

A refrigerated warehouse space is used to cool and store melons

received from the field. After the product temperature is lowered, the product

is stored in the same space for a few days until being shipped or sent to

packaging. The design evaporator capacity is 300 Btu/hr-ft2 at the

applied conditions. Does the space have to comply with all the space

requirements of §120.1(a)1

of the Energy Standards?

Answer

Yes. While

the design evaporator capacity is greater than 240 Btu/hr-ft² and the space is

used for product pull down for part of the time, the space is also used for

holding product after it has been cooled. Accordingly, the space has to comply

with the space requirements of §120.1(a)1

of the Energy Standards.

Comment: This

measure does not define a specific time limit that a quick chill (which for

clarity includes quick “freeze”) space could operate as a holding space (i.e. at

full speed and thus full fan power). The typical high fan power density in a quick

chill space, particularly at full speed after the high cooling load has been removed, is

very inefficient. Thus a reasonable expectation for a dedicated quick chill

space is to allow no more time (at full speed) than is appropriate to remove the

product in a normal business cycle of loading, cooling/freezing, and removing

product once it has been reduced to temperature. If product is to be held any

longer, variable-speed is required to reduce fan power. Variable-speed

requirements are discussed in under mechanical system requirements (sub-section

10.6.3B) of Chapter

10.

Example

10-29

Question

A new

refrigeration system serves both storage and quick chilling space. The design

refrigeration capacity of the storage space is 500 tons. The design capacity of

the quick chilling space is 50 tons. Is the refrigeration system required to

meet all the requirements of §120.1(a)1

of the Energy Standards?

Answer

Yes. Since

more than 80 percent of the design capacity of the system serves storage space,

the refrigeration system requirements apply.

Example

10-30

Question

A new

refrigerated warehouse is being constructed, which will include a 1,500 ft² cooler space and a

2,500 ft² freezer

space. Both the cooler and freezer are served by a common refrigeration system.

Is the refrigeration system required to comply with this standard?

Answer

Since the

suction group serves a total 4,000 ft² of refrigerated floor area, the spaces

must meet all the requirements of §120.6(a).

Section 120.6(a).

subsections 1, 2, and 6 of the Energy Standards address the mandatory

requirements for refrigerated space insulation, underslab heating, and

infiltration

barriers.

10.6.2.1 Envelope

Insulation

A.

Wall and Roof Insulation

Manufacturers must certify that insulating materials comply

with California Quality Standards for Insulating

Material (C.C.R., Title 24, Part 12, Chapters 12-13), which ensure that

insulation sold or installed in the state performs according to stated R-values

and meets minimum quality, health, and safety standards. These standards state

that all thermal performance tests shall be conducted on materials that have

been conditioned at 73.4° ± 3.6°F and a relative humidity of 50 ± 5 percent for

24 hours immediately preceding the tests. The average testing temperature shall

be 75° ± 2°F with at least a 40°F temperature difference. Builders may not

install insulating materials unless the product has been certified by the Department of

Consumer Affairs, Bureau of Home Furnishing and Thermal Insulation. Builders and

enforcement agencies shall use the Department of Consumer Affairs Directory

of Certified Insulation Material to verify certification of the insulating

material.

Refrigerated spaces with 3,000 ft² of floor area or more

shall meet the minimum R-Value requirements shown in Table 10-3.

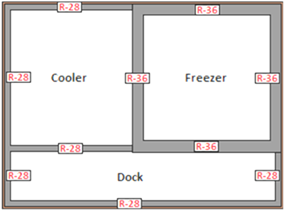

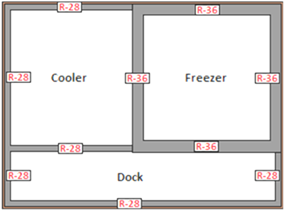

Table 10-3: Refrigerated Warehouse Insulation

|

SPACE |

SURFACE |

MINIMUM R-VALUE

(°F⋅hr⋅ft²/Btu) |

|

Freezers |

Roof/Ceiling |

R-40 |

|

Wall |

R-36 |

|

Floor |

R-35 |

|

Floor with all heating from

productive refrigeration capacity |

R-20 |

|

Coolers |

Roof/Ceiling |

R-28 |

|

Wall |

R-28 |

The R-values shown in Table 10-3 apply to all surfaces

enclosing a refrigerated space, including refrigerated spaces adjoining

conditioned spaces, other refrigerated spaces, unconditioned spaces and the

outdoors. If a partition is used between refrigerated spaces that are designed

to always operate at the same temperature, the requirements do not apply. The

R-values are the nominal insulation R-values and do not include other building materials

or internal or external “film” resistances.

Example 10-31

Question

A refrigerated warehouse designed to store produce at 45°F (7°C)

is constructed from tilt-up concrete walls and concrete roof sections. What is

the minimum R-value of the wall and roof insulation?

Answer

Since the

storage temperature is greater than 28°F (-2°C), the space is defined as a cooler. The minimum

R-value of the wall and roof insulation according to Table 10-3 is R-28.

Example

10-32

Question

A

refrigerated warehouse is constructed of a wall section consisting of 4

inches of concrete, 6 inches of medium density (2 lb/ft³) foam insulation,

and another 4 inches of concrete. The nominal R-value of the foam insulation is

R-5.8 per inch. What is the R-value of this wall section for code

compliance?

Answer

The

insulating value of the concrete walls is ignored. The R-value of this wall

section for code compliance purposes is based on the 6 inches of foam insulation

at R-5.8 per inch, or R-34.8.

Example

10-33

Question

A 35°F cooler

space is adjacent to a -10°F freezer space. What is the minimum required insulation R-value

of the shared wall between the cooler and freezer spaces?

Answer

The minimum

insulation R-value requirements should be interpreted to apply to all surfaces

enclosing the refrigerated space at the subject temperature. Therefore, since

the freezer space walls must be insulated to the minimum R-value requirements

shown in Table 10-3, the R-value of the shared wall insulation must be at least

R-36. The minimum insulation R-value requirement of the other three cooler walls

is R-28. The figure below illustrates this example.

B.

Freezer Floor Insulation

Freezer spaces with 3,000 ft² of floor area or more shall

meet the minimum floor insulation R-value requirements shown in Table 10-3. The

requirement is a minimum R-value of R-35, with an exception if the underslab

heating system

increases productive refrigeration capacity, in which case the minimum R-value

is R-20.

The predominant insulating material used in freezer floors

is extruded polystyrene, which is commonly available in 2”-thick increments but

can be purchased in 1”-thick increments as well. Extruded polystyrene has an

R-value of R-5 per inch at standardized rating conditions, and extruded

polystyrene panels can be stacked, so the freezer floor can be constructed with

R-value multiples of 5 (R-30, R-35, R-40).

A lower floor insulation R-value of R-20 is allowed if all

the underslab heat is provided by an underslab heating system that increases

productive refrigeration capacity. An example of an underslab heating system

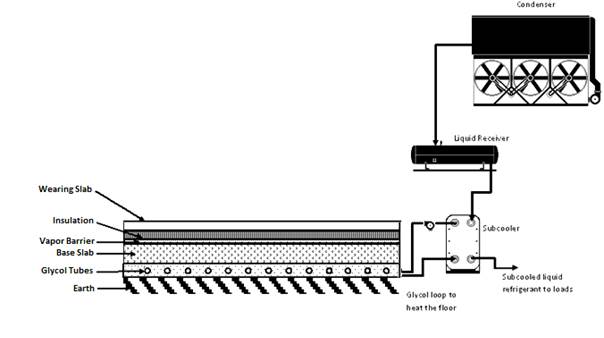

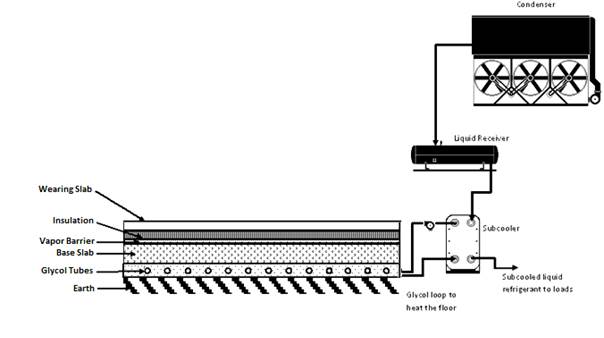

using heat from a refrigerant liquid subcooler is shown in Figure 10-27.

Figure 10-27: Underslab Heating

System That Uses Refrigerant Subcooling

The lower R-value requirement when

this type of underslab heating system is used is justified because the increased

underslab heat gain to the space due to reduced insulation is offset by the heat

extracted from the refrigerant liquid, which is a direct reduction in compressor

load. The minimum requirement of R-20 does not mean that R-20 is the optimum or

appropriate insulation choice in all installations. Rather, R-20 is a

cost-effective trade-off when underfloor heating is obtained via productive

refrigeration. Higher insulation levels combined with heating from productive

refrigeration would improve efficiency.

10.6.2.2 Underslab Heating

Controls

Underslab heating systems should be

used under freezer

spaces to prevent soil freezing and expansion. The underslab heating element

might be electric resistance, forced air, or heated fluid; however, underslab

heating systems using electric resistance

heating elements are not permitted unless they are thermostatically

controlled and disabled during the summer on-peak period. The summer on-peak

period is defined by the supplying electric utility but generally occurs from 12

p.m. to 6 p.m. weekdays from May through October. The control system used to control

any electric resistance underslab heating elements must automatically turn the

elements off during this on-peak period. The control system used to control

electric resistance underslab heating elements must be shown on the building drawings,

and the control sequence demonstrating compliance with this requirement must be

documented on the drawings and in the control system specifications.

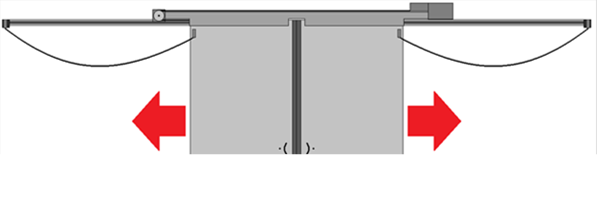

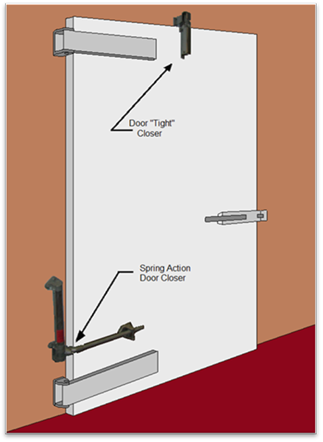

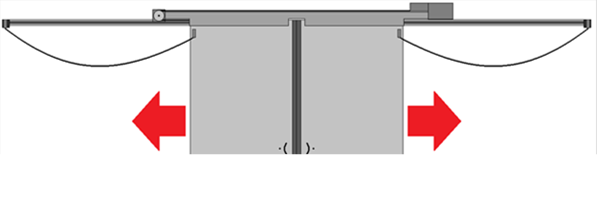

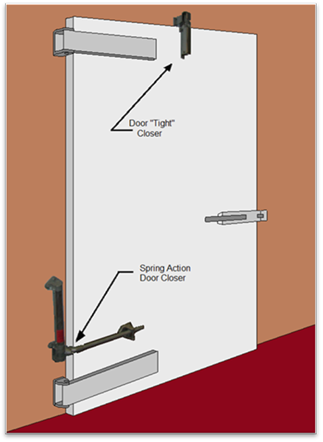

10.6.2.3 Infiltration

Barriers

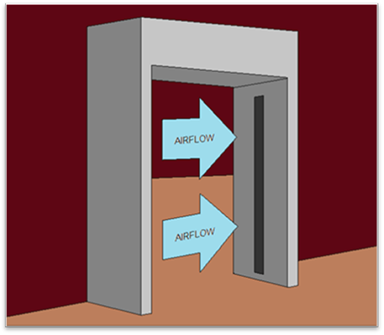

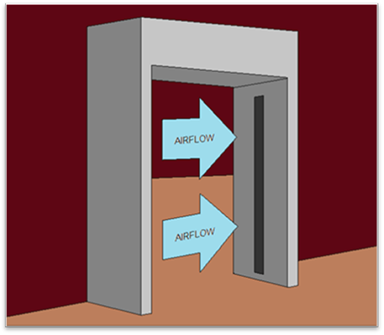

120.6(a)6..

Passageways between freezers and higher-temperature spaces, and passageways

between coolers and nonrefrigerated spaces, shall have an infiltration barrier such as:

• Strip

curtains.

• An

automatically closing door.

• Air

curtain.

Examples of each are shown in the

figures below.

Figure 10-28:

Strip Curtains

Figure 10-29:

Biparting Automatic Door

Figure 10-30: Hinged

Door With Spring-Action Door Closer and Door “Tight” Closer

Figure 10.31: Air

Curtain

The passageways may be for, but are

not limited to, people, forklifts, pallet lifts, hand trucks, or conveyor

belts.

Strip curtains are commercial

flexible plastic strips made for refrigerated openings with material type,

weight, and overlap designed for the size of the passageway opening and the

temperatures of the subject spaces.

An automatically closing door is a

door that fully closes under its own power. Examples include:

a.

Single-acting or double-acting hinge-mounted doors with a spring assembly or

cam-type gravity hinges.

b.

Powered single-sliding, biparting, or rollup doors that open based on a pull

cord, proximity or similar sensors, or by operator signal and close

automatically through similar actions or after a period sufficient to allow

passageway transit.

An air curtain is a commercial

fan-powered assembly intended to reduce air infiltration and designed by the

manufacturer for use on refrigerated warehouse

passageways and on the opening size and the temperatures for which it is

applied.

There are two exceptions to the

requirements for infiltration barriers:

1.

Openings with less than 16 ft2 of opening area, such as small

passageways for conveyor belts

2.

Loading dock doorways for trailers.

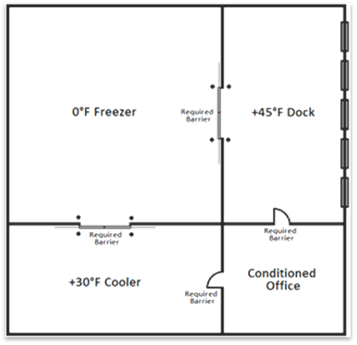

Example 10-34

Question

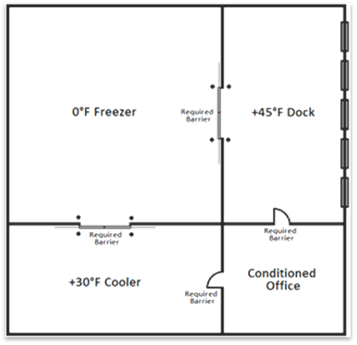

A

refrigerated warehouse includes a freezer, cooler, a refrigerated dock, and a

conditioned office, as shown in the following figure. Where are infiltration

barriers required?

Answer

Infiltration

barrier are required between all spaces, including the hinge-mounted doors

between the dock and the office. The dock doors do not require infiltration

barriers.

Example

10-35

Question

A

refrigerated warehouse is being constructed for a flower distribution company.

Strip curtains cannot be used on the doors because the strips will damage the

flowers when the pallet jack passes through. Is the warehouse still required to

have infiltration barriers?

Answer

Yes, the

warehouse is required to have infiltration barriers. If strip curtains cannot be

used, the designer may choose another method, such as double-acting hinged

doors, sliding doors, or rollup doors with automatic door

closers.

10.6.2.4 Acceptance

Requirements

The Energy Standards include acceptance test

requirements for electric resistance underslab heating systems in accordance

with NA7.10.1.

The test requirements are described in Chapter 13 and the Reference

Nonresidential Appendix NA7.10.

The test requirements are described briefly in the following paragraph.

A.

Electric Resistance Underslab Heating System

The acceptance requirements

include functional tests that are to be performed to verify that the electric

resistance underslab heating system automatically turns off during a test

on-peak period.

10.6.3.1 Overview

This section addresses mandatory

requirements for mechanical systems serving refrigerated spaces. Mechanical system components

addressed by the Energy Standards include evaporators (air units), compressors,

condensers, and refrigeration system controls. The requirements for each of

these components are described in the following sections. The requirements apply

to all system and component types with the exception of the specific exclusions

noted in §120.6(a)..

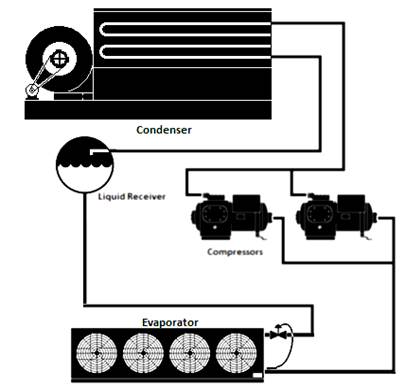

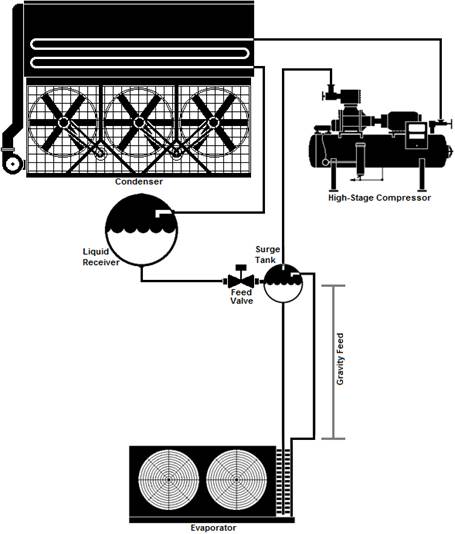

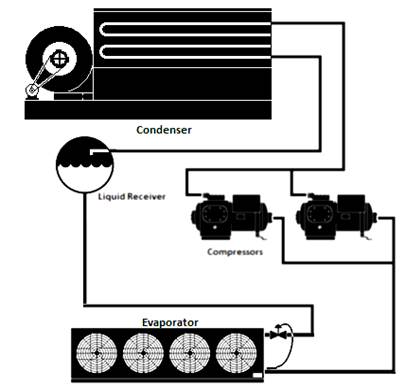

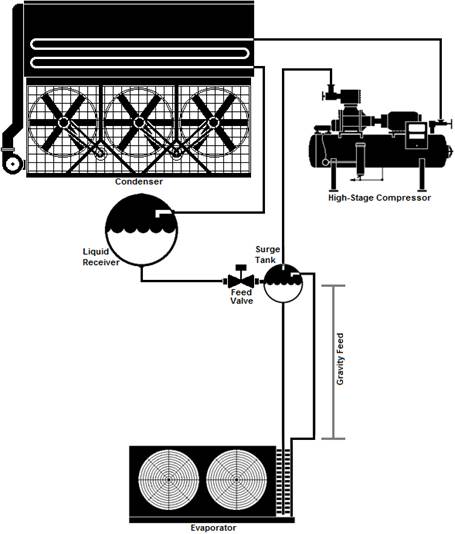

The following figures identify some of the common system and component

configurations that fall under §120.6(a)..

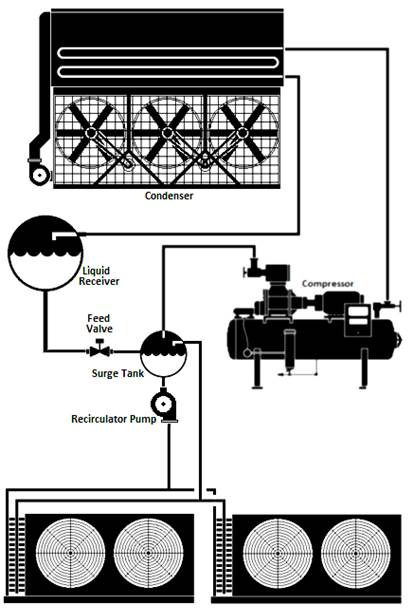

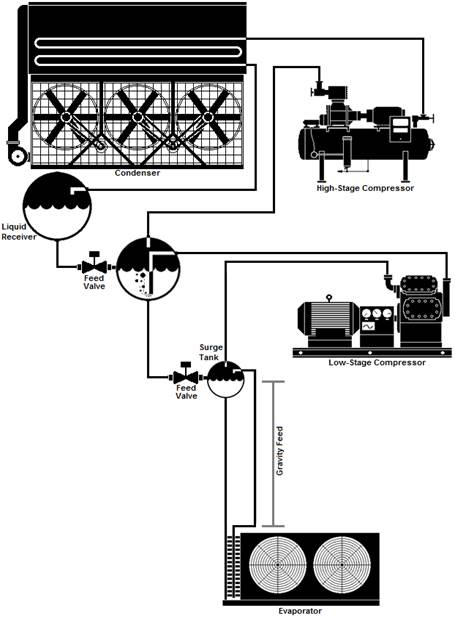

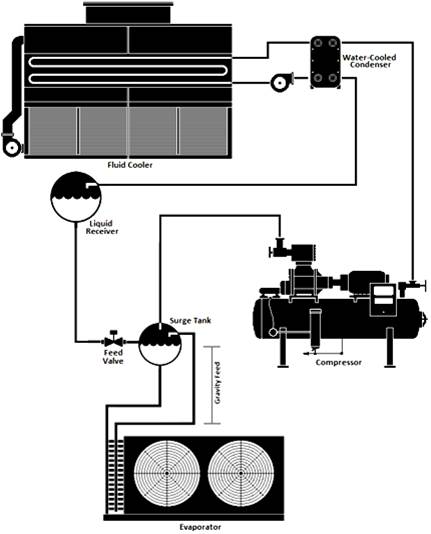

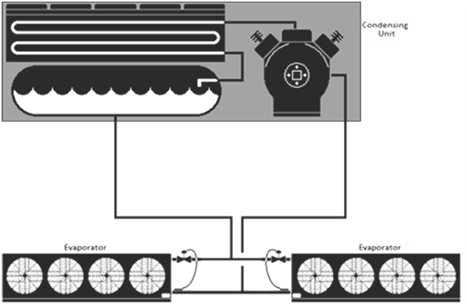

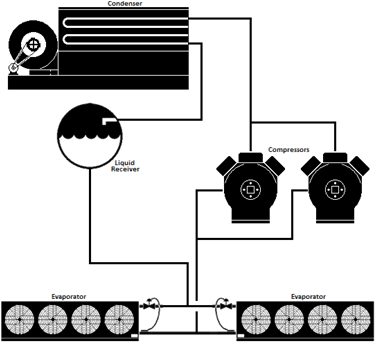

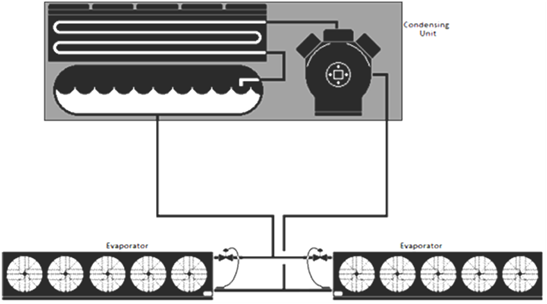

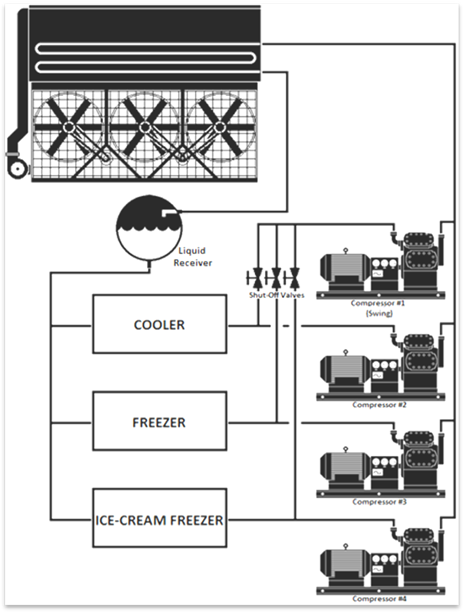

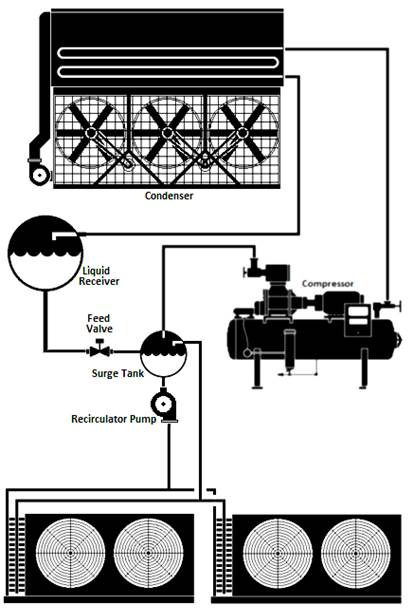

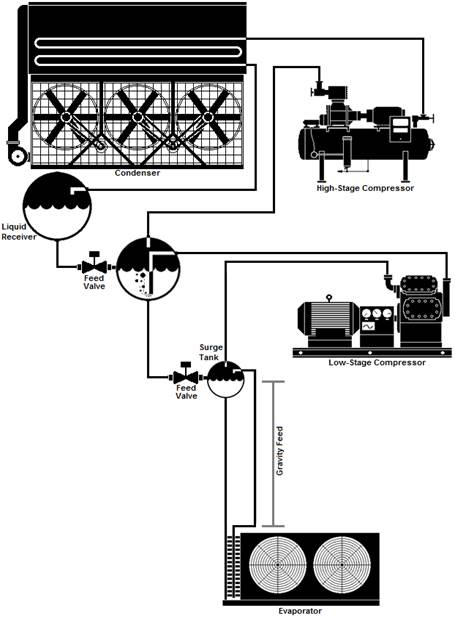

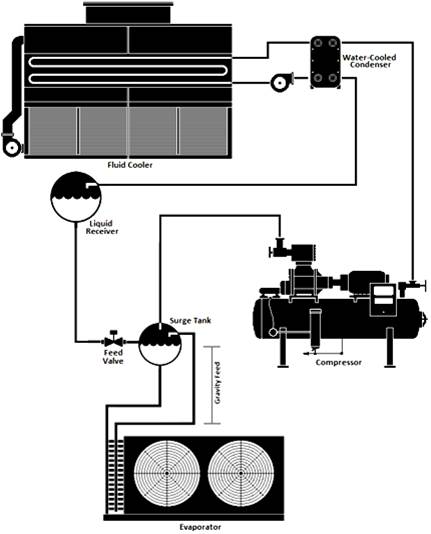

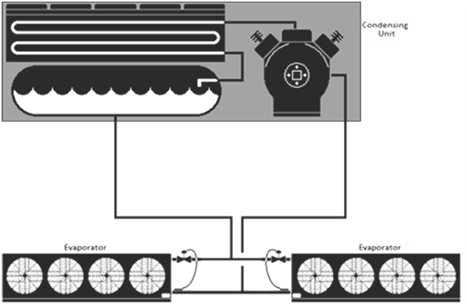

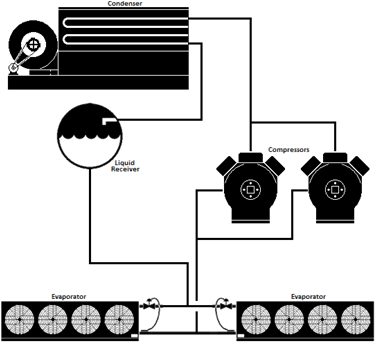

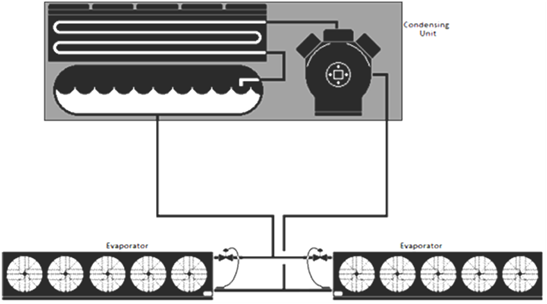

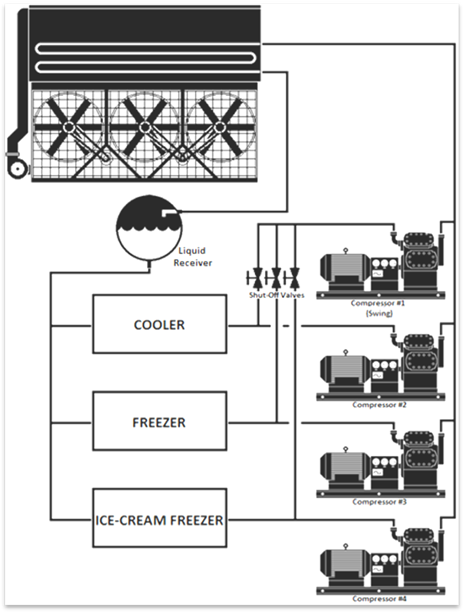

Figure 10-32 is a schematic of a

single-stage system with direct expansion (DX) evaporator coils. Figure 10-33

identifies a single-stage system with flooded evaporator coils, while Figure

10-34 shows a single-stage system with pump recirculated evaporators. Figure

10-35 is a schematic of a typical two-stage system with an intercooler between

the compressor stages. Figure 10-36 is a single-stage system with a water-cooled

condenser and fluid cooler.

Figure 10-32: Single-Stage System With DX Evaporator

Coil

Figure 10-33: Single-Stage System With Flooded Evaporator

Coil

Figure 10-34: Single-Stage System With Pump Recirculated

Evaporator Coils

Figure 10-35: Two-Stage System With Flooded Evaporator

Coil

Figure 10-36: Single-Stage System With Water-Cooled

Condenser Served by Fluid Cooler

10.6.3.2 Evaporators

New fan-powered evaporators used in

coolers and freezers must meet the fan motor type, efficiency, and fan control

requirements outlined in the Energy Standards.

A.

Allowed Fan Motor Types

Single-phase fan motors less than 1

horsepower and less than 460 volts must be either electronically commutated

(EC), also known as Brushless Direct Current (DC), or must have an efficiency of

70 percent or more when rated in accordance with NEMA Standard MG 1-2006 at

full-load rating conditions. This requirement is designed to reduce fan power in

small evaporator fans.

B.

Fan Motor Control

The speed of all evaporator fans

served by either a suction group with multiple compressors or by a single

compressor with variable-capacity capability must be controlled in response to

space temperature or humidity using a continuously variable-speed control

method. Two-speed control of evaporator fans is not an acceptable control

method.

The fan speed is controlled in

response to space temperature or humidity. Fan speed should increase

proportionally when the space temperature is above the setpoint and decrease

when the space temperature is at or below the setpoint, with refrigerant supply

and pressure being maintained in the evaporator cooling coil. Fan speed is

equivalent to air volume being circulated, resulting in direct control of

cooling capacity, analogous to “variable air volume” cooling in commercial

buildings. The control logic requires design and tuning to provide “variable” capacity

operation.

The use of humidity as the control

variable for speed control is very limited in practice but is included in the

Energy Standards to accommodate special strategies for humidity-sensitive

perishable product. Control logic in these applications will often employ

humidity in conjunction with temperature.

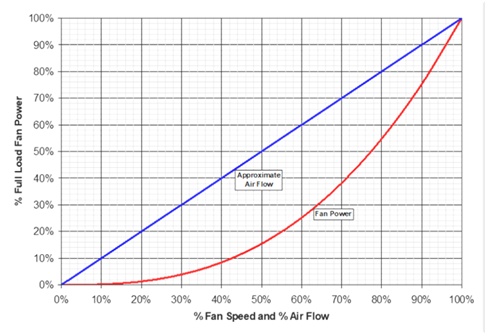

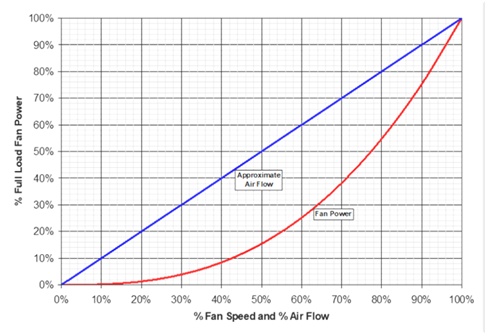

The intent of this requirement is

to take advantage of the “third-power” fan affinity law, which states that the

percentage of required fan motor power is roughly equal to the cube of the

percentage of fan speed, while the airflow is linearly proportional to the fan

speed. For example, a fan running at 80 percent speed requires about 51 percent

(80%3 = 51%) power while providing nearly 80 percent airflow (Figure

10-37). Actual power is somewhat higher due to inefficiencies and drive losses.

This shows the relationship between fan speed and both required fan power and

approximate airflow.

There is no requirement in the

Energy Standards for the minimum speed setting (i.e. how low the fan speed must

go at minimum load). Variable-speed controls of evaporator fans have commonly

used minimum speeds of 80 percent or lower on direct expansion coils and 70

percent or lower on flooded or recirculated coils. The allowable minimum fan

speed setting is to be determined by the refrigeration system designer. The fan speed may be

adjusted or controlled to maintain adequate air circulation to ensure product

integrity and quality.

Figure 10-37: Relationship Between Fan Speed and Required

Power

Correct fan speed control requires

the associated system suction pressure to be controlled such that evaporator

capacity is sufficient to meet space loads. If the evaporator suction pressure

is too high relative to the desired room temperature, the evaporator fans will

run at excessively high speed, and energy savings will not be realized. If

floating suction pressure automation is used to optimize the suction pressure

setpoint, suction pressure should be allowed only to float up after fan speeds

are at minimum and should be controlled to float back down prior to increasing fan

speeds.

The Energy Standards have three

exceptions to the evaporator variable speed requirement:

1.

In case of a replacement, addition or alteration of existing evaporators with no variable-speed

control, the variable-speed control of the evaporators is mandatory only if the

replacement, addition, or alteration is done for all the evaporators in an

existing space. [Exception 1 to §120.6(a)3B.]

2.

A controlled atmosphere (CA) storage where products that require

100 percent of the design airflow at all times are stored may be exempt from the

variable-speed control requirement. A licensed engineer must certify that the

products in the cooler require continuous airflow at 100 percent speed.

Variable-speed control must be implemented if the space will also be used for

non-CA product or operation. [Exception 2 to §120.6(a)3B.]

3.

The variable-speed control is not mandatory for spaces that are used solely for

quick chilling or quick freezing of products. Such spaces have design cooling

capacities that are greater than 240 Btu/hr-ft² of floor area, which is

equivalent to 2 tons per 100ft² of floor area. However, variable-speed control

must be implemented if the spaces are used for storage for any length of time,

regardless of how much refrigeration capacity is installed in the space.

[Exception 3 to §120.6(a)3B.].

Example

10-36

Question

A

split system with a packaged air-cooled condensing unit with a single 30 HP

compressor with unloaders serves two direct expansion evaporators in a 3,200 ft²

cooler. Are the evaporator fans required to have variable-speed control?

Answer

Yes.

Since the compressor has a variable-capacity capability in the form of

unloaders, the evaporator fans are required to have variable-speed control.

Example

10-37

Question

A

refrigeration system uses two reciprocating compressors without

variable-capacity capability connected in parallel and serves multiple

evaporators in a 10,000 ft² cooler. Are the evaporator fans required to have

variable-speed control

Answer

Yes.

Since the evaporators are served by more than one compressor, they must have

variable-speed control, even though the compressors are not equipped with

capacity control devices (e.g. unloaders).

In

practice, the designer should consider the steps of capacity necessary to allow

stable control. For small systems, the designer may consider use of proportional

controls for compressor capacity steps and speed steps in unison. As long as

this control scheme is in response to space temperature, it would be consistent

with the Energy Standards.

Example

10-38

Question

A

-20°F (-29°C) freezer has several recirculated evaporator coils that were

selected to meet the design load at a 10°F (5.5°C) temperature difference (TD).

The evaporator fan motors use variable-speed drives and the control system

varies the fan speed in response to space temperature. What should the freezer

saturated suction temperature be to achieve proper control and savings – by

allowing fan speed control to act as the primary means of temperature

control.

Answer

Since

the coils were designed at a 10°F (5.5°C) TD and the target freezer temperature

is -20°F (-29°C), the saturated evaporating temperature should be -30°F (-34°C)

(-20°F minus 10°F), with the compressor controlled at a lower temperature, based

on the design piping pressure drop. For example, with 2°F (1°C) of piping

losses, the compressor control setpoint would be -32°F (-36°C).

This

example sought to show how evaporator temperature and coil capacity can be

considered and maintained to achieve proper variable-speed fan operation and

savings. Settings could be fine-tuned through observation of the required

suction pressure to meet cooling loads and achieve minimum fan speeds average

load periods, yet with a suction pressure no lower than necessary.

Example 10-39

Question

An existing refrigerated warehouse

space has eight evaporators that do not have variable-speed control. Six of the

eight evaporators are being replaced with new evaporators. Do the new

evaporators require variable-speed control?

Answer

No. Since all the evaporators are not being

replaced, the new evaporators do not require variable-speed control.

The reason for this is that effective space

temperature control would often require that the entire space use a consistent

control scheme that could require a disproportional cost. While not required by

the Energy Standards, in many instances it may still be very cost-effective to

add variable-speed control to existing as well as new evaporators in this

situation.

Continuously variable-speed control is not mandatory for

evaporators that are served by a single compressor that does not have

variable-capacity capability (i.e. the compressor cycles on and off in response

to space temperature). For these systems, evaporator airflow must be reduced by

at least 40 percent when the compressor is off. This can be accomplished in

several ways, for example:

1.

Two-speed evaporator fan control, with speed reduced by at least 40 percent when

cooling is satisfied and the compressor is off.

2.

Turning off a portion of the fans in each evaporator to accomplish at least 40

percent reduction in fan power. Typically, baffles are required to prevent

reverse flow through fans that are turned off.

3.

Turning off all fans when the compressor is off. With this strategy a duty cycle

can be employed to provide period forced fan operation to maintain air

circulation, if the “on” period is limited to 25 percent of the duty cycle while

the compressor is off.

Example 10-40

Question

A split

system with a packaged air-cooled condensing unit using a single cycling

compressor without unloaders serves two evaporators in a cooler. Each evaporator

has five fans. What options does the system designer have to meet the

requirements for evaporator coils served by a single cycling compressor?

Answer

Multiple

methods can be used to reduce airflow by at least 40% when the compressor is

off, or turn all fans off with a 25% duty cycle.

Example 1:

The designer may specify two-speed fans or utilize variable-frequency drives or

other speed-reduction devices to reduce the fan speed to 60% or less when the

compressor is off.

Example 2: The

designer may use controls that cycle at least 4 of the 10 fans off when the

compressor is cycled off. This would most likely be accomplished by cycling two

fans off on each evaporator.

10.6.3.3 Condensers

New condensers on new refrigeration

systems must follow the condenser sizing, fan control, and efficiency requirements as

described in §120.6(a)4..

A.

Condenser Sizing

§120.6(a)4A.

and §120.6(a)4B.

describe minimum sizing requirements for new condensers serving new

refrigeration systems. Fan-powered evaporative condensers, as well as

water-cooled condensers served by fluid coolers and cooling towers, are covered

in §120.6(a)4A. Fan-powered air-cooled condensers are covered by §120.6(a)4B.

Fan-powered adiabatic condensers are covered by §120.6(a)4C..

Condensers must be sized to provide

sufficient heat rejection capacity under design conditions while

maintaining a specified maximum temperature difference between the refrigeration

system saturated

condensing temperature (SCT) and ambient temperature. The design condenser

capacity shall be greater than the calculated combined total heat of rejection

(THR) of the dedicated compressors that are served by the condenser. If multiple

condensers are specified, then the combined capacity of the installed condensers

shall be greater than the calculated heat of rejection. When determining the

design THR for this requirement, reserve or backup compressors may be excluded

from the calculations.

There is no limitation on the type

of condenser that may be used. The choice may be made by the system designer,

considering the specific application, climate, water availability, etc.

The Energy Standards include an exception to

§120.6(a)4A.,

4B, and 4C for condensers serving refrigeration systems for which more than 20

percent of the design cooling load comes from quick chilling or freezing space, or process (nonspace)

refrigeration cooling. The Energy Standard defines quick chilling or freezing

space as a space with a design refrigeration evaporator capacity greater than

240 Btu/hr-ft² of floor area, which is equivalent to 2 tons per 100 ft² of floor

area, at system design conditions.

Another exception to §120.6(a)4B.,

for air-cooled condenser sizing, applies if a condensing unit has a total

compressor power less than 100 hp. A condensing unit includes compressor(s),

condenser, liquid receiver, and control electronics that are packaged in a

single product.

Example 10-40

Question

A new food

processing plant is being constructed that will include an 800 ft² blast freezer, a holding

freezer, and a loading dock. The design evaporator capacity of the blast freezer

is 40 tons of refrigeration (TR). The combined evaporator capacity of the

freezer and loading dock is 60 TR. Does the condenser group have to comply with

the sizing requirements in §120.6(a)4A.?

Answer

The blast

freezer evaporator capacity divided by the floor area is 40 TR/800 ft², which is

equal to 5 TR/100 ft². That means this particular blast freezer is deemed quick

freezing space by the Energy Standards. Therefore, the condenser group serving

the refrigeration system does not have to comply with §120.6(a)4A.,

because 40% (i.e. greater than 20%) of the design refrigeration capacity is from

quick freezing.

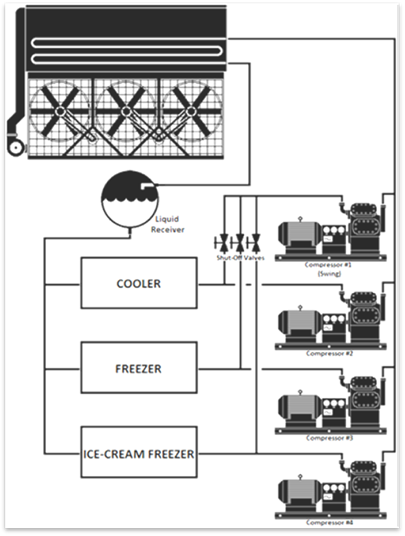

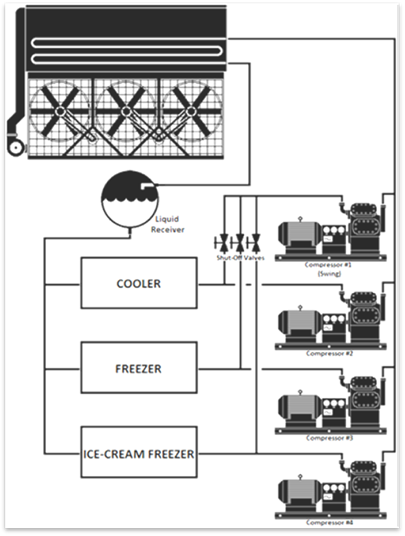

Example

10-42

Question

The refrigerated warehouse system shown below has a backup or

“swing” compressor. Does the heat rejection from this compressor need to be

included in the condenser sizing calculations?

Answer

It

depends.

A swing

compressor may be designed solely for backup of multiple suction groups or it

may be included in one suction group and necessary to meet the design load of

that suction group, but in an emergency is also capable of providing backup for

other compressors. If the compressor is solely for use as backup, it would be

excluded from the heat rejection calculation for the purposes of the Energy

Standards. In this case, the calculations would include the heat of rejection

from Compressors 2, 3, and 4 and would exclude Compressor 1.

1.

Sizing of Evaporative Condensers, Fluid Coolers, and Cooling

Towers

§120.6(a)4A.

provides maximum design SCT values for evaporative condensers as well as systems

consisting of a water-cooled condenser served by a cooling tower or fluid cooler. For

this section, designers should use the 0.5 percent design wetbulb temperature

(WBT) from Table 10-4 – Design Day Data for California Cities in the Reference Joint Appendices JA2 to demonstrate

compliance with this requirement. The maximum design SCT requirements are listed in Table 10-4

below.

Table 10-4: Maximum Design SCT

Requirements for Evaporative Condensers and

Water-Cooled Condensers Served

by Cooling Towers and Fluid Coolers

|

0.5% DESIGN WETBULB

TEMPERATURE |

MAXIMUM DESIGN

SCT |

|

≤ 76°F (24°C) |

Design WBT plus 20°F

(11°C) |

|

Between 76°F (24°C)

and 78°F (26°C) |

Design WBT plus 19°F

(10.5°C) |

|

≥ 78°F (26°C) |

Design WBT plus 18°F

(10°C) |

|

|

|

Example 10-43

Question

A refrigerated warehouse is being constructed in

Fresno. The refrigeration system will be served by an evaporative condenser.

What is the sizing requirement for the condenser selected for this

system?

Answer

The 0.5% design wetbulb temperature (WBT) from Joint

Appendix JA-2 for Fresno is 73°F. Therefore, the maximum design SCT for the

refrigerant condenser is 73°F + 20°F = 93°F. The selected condenser for this

system must be capable of rejecting the total system design THR at 93°F SCT and

73°F WBT.

Example 10-44

Question

What is the minimum size for a condenser for a

refrigeration system with the following parameters?

Located in Fresno

Design SST: 10°F

Suction group: Three equal-sized dedicated 100

hp screw compressors (none are backup units)

Evaporative condenser

240 TR cooling load

Answer

From the previous example, it was determined that

the design wetbulb temperature (WBT) to demonstrate compliance for Fresno is

73°F, and the maximum design SCT for the evaporative condenser is 93°F (73°F +

20°F). We will assume the system designer determined a 2°F loss between the

compressors and condenser. The designer first calculates the THR for the suction

group at the design conditions of 10°F SST and 95°F SCT. Each selected

compressor has a rated capacity of 240 TR and will absorb 300 horsepower at the

design conditions. Therefore, the calculated THR for one compressor

is:

240 TR / compressor x 3 compressor x 12,000 Btuh/TR

+ 300HP x 2,545 Btuh/HP = 9,403,500 Btuh

To comply with the Energy Standards, a condenser (or

group of condensers) must be selected that is capable of rejecting at least

9,403,500 Btu/hr at 93°F SCT and 73°F WBT.

2.

Sizing of Air-Cooled Condensers

§120.6(a)4B.

provides maximum design SCT values for air-cooled condensers. For this section,

designers should use the 0.5 percent design drybulb temperature (DBT) from Table

10-4 – Design Day Data for California Cities in the Reference Joint Appendices

JA2 to

demonstrate compliance with this requirement.

Standard practice is for

published condenser ratings to assume the capacity of air-cooled condensers is

proportional to the temperature difference (TD) between SCT and DBT, regardless

of the actual ambient temperature entering the condenser. For example, the

capacity of an air-cooled condenser operating at an SCT of 80°F with a DBT of

70°F is assumed to be equal to the same unit operating at 110°F SCT and 100°F

DBT, since the TD across the condenser is 10°F in both examples. Thus, unlike

evaporative condensers, the requirement for air-cooled condensers does not have

varying sizing requirements for different design ambient temperatures.

However, the Energy Standards

have different requirements for air-cooled condensers depending on the space

temperatures served by the refrigeration system. The maximum design SCT

requirements are listed in Table 10-5 below:

Table 10-5: Maximum Design SCT Requirements for Air-Cooled Condensers

Often, a single refrigeration system and the

associated condenser will serve a mix of cooler and freezer spaces. In

this instance, the maximum design SCT shall be a weighted average of the

requirements for cooler and freezer spaces, based on the design evaporator

capacity of the spaces served.

Example 10-45

Question

An air-cooled

condenser is being sized for a system that has half of the associated installed

capacity serving cooler space and the other half serving freezer space. What is

the design TD to be added to the design drybulb temperature?

Answer

This measure

specifies a design approach of 15°F (8.3°C) for coolers and 10°F (5.6°C) for

freezers. When a system serves freezer and cooler spaces, a weighted average

should be used based on the installed capacity. To calculate the weighted

average, multiply the percentage of the total installed capacity dedicated to

coolers by 15°F (8.3°C). Next, multiply the percentage of the total installed

capacity dedicated to freezers by 10°F (5.6°C). The sum of the two results is

the design condensing temperature approach. In this example, the installed

capacity is evenly split between freezer and cooler space. As a result, the

design approach for the air-cooled condenser is 12.5°F (6.9°C).

(50% x

15°F) + (50% x 10°F) = 7.5°F + 5°F =

12.5°F

3.

Adiabatic Condenser Sizing

§120.6(a)4C. provides maximum

design

SCT values for

adiabatic condensers. These requirements are the same as for

§120.6(b)1E.

See section

10.5.2.3 for details.

A.

Fan Control

Condenser fans for new air-cooled,

evaporative or adiabatic condensers, or fans on cooling towers or fluid coolers

used to reject heat on new refrigeration systems, must use continuously

variable-speed. Variable-frequency drives are commonly used to provide

continuously variable-speed control of condenser fans, although controllers

designed to vary the speed of electronically commutated motors may be used to

control these types of motors. All fans serving a common high side, or cooling

water loop for cooling towers and fluid coolers, shall be controlled in unison.

Thus, in normal operation, the fan speed of all fans within a single condenser

or set of condensers serving a common high side should modulate together, rather

than running fans at different speeds or staging fans off. However, when fan

speed is at the minimum practical level usually no higher than 10-20%, the fans

may be staged off to reduce condenser capacity. As load increases, fans should

be turned back on

before significantly increasing fan speed, recognizing a control band is

necessary to avoid excessive fan cycling.

To minimize overall system energy

consumption, the condensing temperature setpoint must be continuously reset in

response to ambient temperatures, rather than using a fixed setpoint value. This strategy is

also termed ambient-following control, ambient-reset, wetbulb following and

drybulb following—all referring to the control logic that changes the condensing

temperature target in response to ambient conditions at the condenser. The

control system calculates a target saturated condensing temperature that is

higher than the ambient temperature by a predetermined temperature difference

(i.e. the condenser control TD). Fan speed is then modulated according to the

calculated target SCT. The target SCT for evaporative condensers or water-cooled

condensers (via cooling towers or fluid coolers) must be reset according to

ambient wetbulb temperature, the target SCT for air-cooled condensers must be

reset according to ambient drybulb temperature, and the target SCT for adiabatic

condensers when operating in dry mode must be reset according to ambient drybulb

temperature. There is no requirement for SCT control during wetbulb (adiabatic)

operation. This requirement for the adiabatic condenser is applicable to all

systems and is independent of the type of refrigerant used

The condenser control TD is not

specified in the Energy Standards. The nominal control value is often less than the

condenser design TD; however, the value for a particular system is left up to

the system designer. Since the intent is to use as much condenser capacity as

possible without excessive fan power, a common practice for refrigerated warehouse

systems is to optimize the control TD over a period such that the fan speed is

between approximately 60 and 80% during normal operation (i.e. when not at

minimum SCT). While not required, evaporative condensers and systems using fluid

coolers and cooling towers may also vary the condenser control TD as a function

of actual WBT to account for the properties of moist air, which reduce the

effective condenser capacity at lower wetbulb temperatures.

The minimum saturated condensing

temperature setpoint must be 70°F (21°C) or less. For systems using halocarbon

refrigerants with glide, the SCT setpoint shall correlate with a midpoint

temperature (between the refrigerant bubble-point and dew-point temperatures) of

70°F (21°C) or less. As a practical matter, a maximum SCT setpoint is also

commonly employed to set an upper bound on the control setpoint in the event of

a sensor failure and to force full condenser operation during peak ambient

conditions. This value should be set high enough that it does not interfere with

normal operation.

Split air-cooled condensers are

sometimes used for separate refrigeration systems, with two circuits and two

rows of condenser fans. Each condenser half would be controlled as a separate

condenser. If a condenser has multiple circuits served by a common fan or set of

fans, the control strategy may use the average condensing temperature or the

highest condensing temperature of the individual circuits as the control

variable for controlling fan speed.

Alternative control strategies are

permitted to the condensing temperature reset control required in §120.6(a)4E..

The alternative control strategy must be demonstrated to provide equal or better

performance, as approved by the Executive Director.

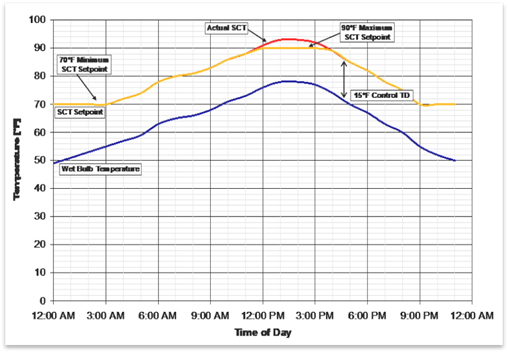

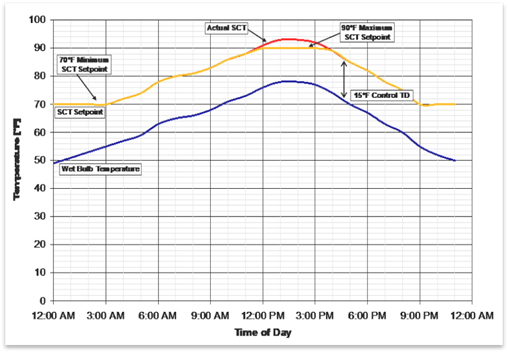

Example 10-46

Question

A

refrigerated warehouse with evaporative condensers is being commissioned.

The control system designer has used a wetbulb-following control strategy to

reset the system saturated condensing temperature (SCT) setpoint. The

refrigeration engineer has calculated that adding a TD of 15°F (8.3°C) above the

ambient wetbulb temperature should provide a saturated condensing temperature

setpoint that minimizes the combined compressor and condenser fan power usage

throughout the year. What might the system SCT and SCT setpoint trends look like

over an example day?

Answer

The following

figure illustrates what the actual saturated condensing temperature and SCT

setpoints could be over an example day using the wetbulb-following control

strategy with a 15°F (8.3°C) TD and observing the 70°F (21°C) minimum condensing

temperature requirement. As the figure shows, the SCT setpoint is continuously

reset to 15°F (8.3°C) above the ambient wetbulb temperature until the minimum

SCT setpoint of 70°F is reached. The figure also shows a maximum SCT setpoint

(in this example, 90°F (32.2°C) that may be used to limit the maximum control

setpoint, regardless of the ambient temperature value or TD parameter.

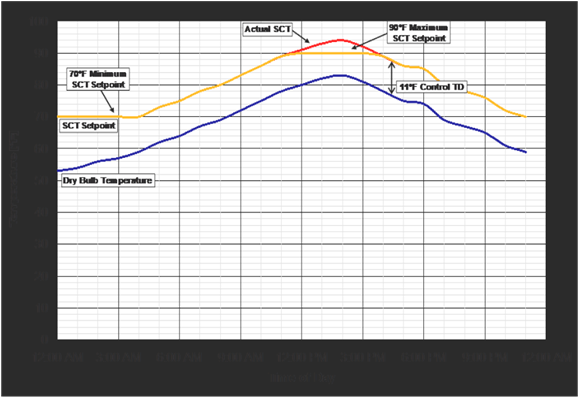

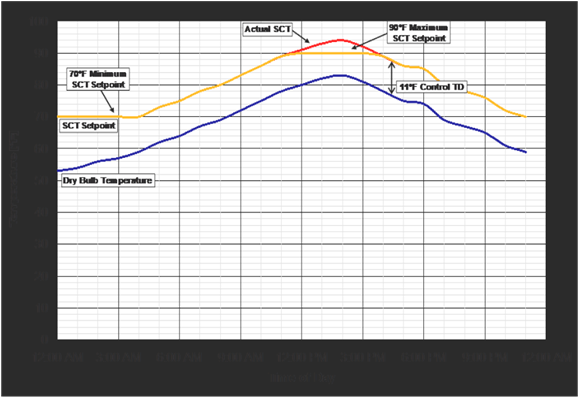

Example

10-47

Question

A cold

storage facility with an air-cooled condenser is being commissioned. The control

system designer has used a drybulb-following control strategy to reset the

system saturated condensing temperature (SCT) setpoint. The refrigeration

engineer has calculated that adding a TD of 11°F (6.1°C) above the ambient

drybulb temperature should provide a saturated condensing temperature setpoint

that minimizes the combined compressor and condenser fan power usage throughout

the year. What might the system SCT and SCT setpoint trends look like over an

example day?

Answer

The following

figure illustrates the actual saturated condensing temperature and SCT setpoints

over an example day using the drybulb-following control strategy with an 11°F

(6.1°C) TD and observing the 70°F (21°C) minimum condensing temperature

requirement. As the figure shows, the SCT setpoint is continuously reset 11°F

(6.1°C) above the ambient drybulb temperature, but is bounded by the minimum and

maximum SCT setpoints. The figure also shows a maximum SCT setpoint (in this

example, 90°F (32.2°C) that may be used to limit the maximum control setpoint,

regardless of the ambient temperature value or TD parameter.

B.

Condenser Specific Efficiency

Requirements for design

condensing temperatures relative to design ambient temperatures, as described

above for §120.6(a)4A.,

B, and C, help assure that there is enough condenser capacity to keeping

condensing temperatures compressor head pressures at reasonable levels. However,

the sizing requirements do not address condenser efficiency. For example, rather

than providing amply sized condenser surface area, a condenser selection could

consist of a small condenser area using a large motor to blow a large amount of

air through the heat exchanger surface to achieve the design condenser TD.

However, this would come at the expense of excessive fan motor horsepower. Also,

relatively high fan power consumption can result from using condenser fans that

have poor fan efficiency or low fan motor efficiency. §120.6(a)4F.

addresses these and other factors affecting condenser fan power by setting

minimum specific efficiency requirements for condensers.

All newly installed indoor and

outdoor evaporative condensers and outdoor air-cooled and adiabatic condensers

to be installed on new refrigeration systems shall meet the minimum specific

efficiency requirements shown in Table 10-6.

|

CONDENSER

TYPE |

REFRIGERANT TYPE |

MINIMUM SPECIFIC

EFFICIENCY* |

RATING CONDITION |

|

Outdoor

Evaporative-Cooled with THR Capacity > 8,000 MBH |

All |

350

Btuh/W |

100°F

Saturated Condensing Temperature (SCT), 70°F Outdoor Wetbulb

Temperature |

|

Outdoor

Evaporative-Cooled with THR Capacity < 8,000 MBH and Indoor

Evaporative-Cooled |

All |

160

Btuh/W |

|

Outdoor

Air-Cooled |

Ammonia |

75

Btuh/W |

105°F

Saturated Condensing Temperature (SCT), 95°F Outdoor Drybulb

Temperature |

|

Halocarbon |

65

Btuh/W |

|

Adiabatic

Dry Mode |

Halocarbon |

45

Btuh/W |

105°F

Saturated Condensing Temperature (SCT), 95°F Outdoor Drybulb

Temperature |

|

Indoor

Air-Cooled |

All |

Exempt |

Condenser specific

efficiency is defined as:

Condenser Specific Efficiency

= Total Heat Rejection (THR) Capacity / Input Power

The total heat rejection capacity

is at the rating conditions of 100°F saturated condensing temperature (SCT) and

70°F outdoor wetbulb temperature for evaporative condensers, and 105°F SCT and

95°F outdoor drybulb temperature for air-cooled condensers. Input power is the

electric input power draw of the condenser fan motors (at full speed), plus the

electric input power of the spray pumps for evaporative condensers. The motor

power is the manufacturer’s published applied power for the subject equipment, which is

not necessarily equal to the motor nameplate rating. Power input for secondary

devices such as sump heaters shall not be included in the specific efficiency

calculation.

As shown in Table 10-6 the Energy

Standards have

different minimum efficiencies depending on the type of condenser that is being

used. The different classifications of condenser are:

a.

Outdoor, evaporative, THR greater than 8,000 MBH at specific efficiency rating

conditions.

b.

Outdoor, evaporative, THR less than 8,000 MBH at specific efficiency rating

conditions.

c.

Indoor, evaporatively cooled.

d.

Outdoor, air-cooled, ammonia refrigerant.

e.

Outdoor, air-cooled, halocarbon refrigerant.

f.

Adiabatic (dry-mode operation), halocarbon refrigerant.

g.

Indoor, air-cooled.

The data published in the condenser

manufacturer’s published rating for capacity and power shall be used to

calculate specific efficiency. For evaporative condensers, manufacturers

typically provide nominal condenser capacity and tables of correction factors

that are used to convert the nominal condenser capacity to the capacity at

various applied condensing temperatures and wetbulb temperatures. Usually the

manufacturer publishes two sets of correction factors: one is a set of “heat

rejection” capacity factors, while the others are “evaporator ton” capacity

factors. Only the “heat rejection” capacity factors shall be used to calculate

the condenser capacity at the efficiency rating conditions for determining

compliance with this section.

For air-cooled and adiabatic

condensers, manufacturers typically provide the capacity at a given temperature

difference (TD) between SCT and drybulb temperature. Manufacturers typically

assume that condenser capacity is linearly proportional to TD; the catalog

capacity at 20°F TD is typically twice as much as at 10°F TD. The condenser

capacity for air-cooled condensers at a TD of 10°F shall be used to calculate

efficiency. For adiabatic condensers, the dry mode capacity at a TD of 10°F

shall be used to calculate efficiency. If the capacity at 10°F TD is not

provided, the capacity shall be scaled linearly.

Depending on the type of condenser,

the actual manufacturer’s rated motor power may vary from motor nameplate in

different ways. Air cooled condensers with direct-drive OEM motors may use far

greater input power than the nominal motor horsepower would indicate. On the

other hand, evaporative condenser fans may have a degree of safety factor to

allow for higher motor load in cold weather (vs. the 100°F SCT/70°F WBT specific

efficiency rating conditions). Thus, actual motor input power from the

manufacturer must be used for direct-drive air-cooled condensers, while for

large (i.e. > 8,000 MBH) evaporative condensers and other belt-drive

condensers, the full load motor rating is generally conservative, but

manufacturer’s applied power should be used whenever possible to more accurately

determine specific efficiency.

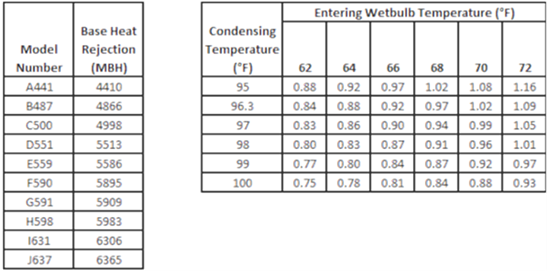

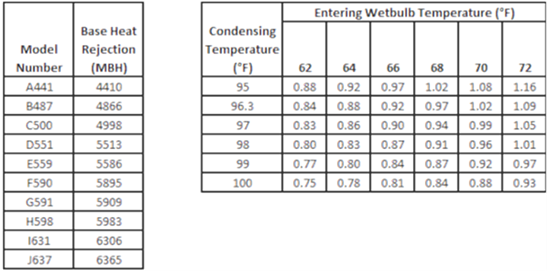

Example 10-48

Question

An

evaporative condenser is being considered for use in an outdoor application on a

new refrigerated warehouse. The refrigerant is ammonia. The

condenser manufacturer’s catalog provides the following information:

For this

example, model

number D551 is being considered. Elsewhere in the catalog, it states that

condenser model D551 has two 7.5 HP fan motors and one 5 HP pump motor. Fan

motor efficiencies and motor loading factors are not provided. Does this

condenser meet the minimum efficiency requirements?

Answer

First, the

condenser capacity must be calculated at the efficiency rating condition. From

Table 10-4, we see that the rating conditions for an outdoor evaporative

condenser are 100°F SCT, 70°F WBT. From the Base Heat Rejection table above, we

see the nominal capacity for model D551 is 5,513 MBH. From the Heat Rejection

Capacity Factors table, we see that the correction factor for 100°F SCT, 70°F

WBT is 0.88. The capacity of this model at specific efficiency rating conditions

is 5,513 MBH / 0.88 = 6,264 MBH. Since 6,264 MBH is less than 8,000 MBH, we can

see from Table10-4 that the minimum specific efficiency requirement is 160

(Btu/hr)/watt.

To calculate

input power, we will assume 100% fan and pump motor loading and minimum motor

efficiency since the manufacturer has not yet published actual motor input power

at the specific efficiency rating conditions. We look up the minimum motor

efficiency from Nonresidential Appendix NA-3: Fan Motor Efficiencies. For a 7.5

HP four-pole open fan motor, the minimum efficiency is 91.0%. For a 5 HP

six-pole open pump motor, the minimum efficiency is 89.5%. The fan motor input

power is calculated to be:

2

motors x 7.5 HP/motor x 746 watts/HP x 100% assumed loading/ 91% efficiency =

12.297 watts

The pump motor input power is

calculated to be:

1

motors x 5 HP/motor x 746 watts/HP x 100% assumed loading/ 89.5% efficiency =

4.168 watts

The combined

input power is therefore:

12.297

watts + 4.168 watts = 16.464 watts

Note: Actual

motor power should be used when available (see notes in text).

Finally, the

efficiency of the condenser is:

(6,264

MBH x 1000 Btuh/MBH) / 16.464 watts = 381 Btuh/watt

This condenser

meets the minimum efficiency requirements because 381 Btu/hr per watt is higher

than the 160 Btu/hr per watt requirement.

D.

Condenser Fin

Spacing

According to §120.6(a)4G.

air-cooled condensers shall have a fin density no greater than 10 fins per

inch. Condensers with higher fin densities have a higher risk of fouling with

airborne debris. This requirement does not apply to air-cooled condensers that

use a microchannel heat exchange surface, since this type of surface is not as

susceptible to permanent fouling in the same manner as traditional tube-and-fin

condensers with dense fin spacing.

10.6.3.4 Compressors

Compressors on new refrigeration

systems must follow the design and control requirements as described in §120.6(a)5..

A.

Minimum Condensing Temperature

Floating head control is one of the

largest energy savings measures applied to refrigeration systems. This control

attempts to keep condensing temperatures as low as possible (while not consuming

too much condenser fan energy) as this reduces compressor head pressure,

which directly affects compressor energy. When ambient temperatures are low, the

primary constraint on how low the condensing temperature can be reset is the

design requirements of the compressor and associated system components.

§120.6(a)5A.

addresses the compatibility of the compressor design and components with the

requirements for floating head control. All compressors that discharge to the

condenser(s) and all associated components (coalescing oil separators, expansion

valves for liquid injection oil cooling, etc.) must be capable of operating at a

condensing temperature of 70°F (21°C) or less. Oil separator sizing is often

governed by the minimum condensing temperature, as well as other factors, such

as the maximum suction temperature. Suction temperatures above the design value

may occur under floating suction temperature control schemes.

The system designer should also

keep in mind that other design parameters such as piping run lengths or

evaporator defrost requirements must be considered to meet this requirement.

B.

Screw Compressor Control at Part-Load

New open-drive screw compressors in

new refrigeration systems with a design saturated suction temperature (SST) of

28°F or lower shall vary compressor speed as the primary means of capacity

control. The compressor speed shall reduce to the manufacturer-specified minimum

speed before unloading via slide valve. Similarly, when the load increases, the

compressor shall increase to 100 percent slide valve before increasing speed.

This requirement applies only to compressors discharging to the condenser (i.e.

single stage or the high stage of a two-stage system) and only to suction groups

that consist of a single compressor.

An exception to §120.6(a)5B.

(controlling compressor speed in response to refrigeration load) is provided for

compressors on a refrigeration system with more than 20 percent of the design cooling load from

quick chilling or freezing space, or nonspace process refrigeration cooling. The

“refrigeration system” refers to the entire associated system, (i.e. the refrigerant

charge), not the suction group. While variable-speed compressor control may

be cost-effective in many instances and may be considered by the system

designer, this exception exists to allow for situations such as seasonal

processes with low operating hours or loads that may be precisely matched to a

fully loaded compressor.

New screw compressors with a motor

nameplate power greater than 150 HP shall incorporate the capability to

automatically vary the volume ratio (i.e. variable Vi) to optimize efficiency at

off-design operating conditions.

Example 10-49

Question

The system

shown below has three 200 HP open-drive screw compressors serving three suction

levels and one 200 HP backup or swing open-drive screw compressor that can be

connected by valve into any of the three suction lines. Does this count as

having more than one compressor per suction group and exempt the compressors

from the requirements in §120.6(a)5B.?

Answer

Probably not.

Exception 1 to §120.6(a)5B.

applies only when a suction group has two or more dedicated compressors. A

compressor that is used solely as backup does not count as a dedicated

compressor. As a result, all compressors (1, 2, 3, and 4) in the example above

must comply with §120.6(a)5B.

and use variable-speed control as the primary means of capacity control.

However, if Compressor 1 is actually required to meet the design load of one of

the suction groups, it could be considered part of that suction group and

variable-speed control would not be required. Whether a swing compressor is

really a backup compressor or part of a suction group should be apparent from

the design loads and capacities listed in the design documents.

10.6.3.5 Acceptance

Requirements

The Energy Standards have acceptance test

requirements for:

•

Electric underslab heating controls.

•

Evaporator fan motor controls.

•

Evaporative condensers.

•

Adiabatic condensers

•

Air-cooled condensers.

•

Variable-speed compressors.

These test requirements are

described in Chapter

13 and the Reference Nonresidential Appendix NA7.10.

They are described briefly in the following paragraphs.

A.

Electric Underslab Heating Controls

Controls for underslab electric

heating controls, when used for freeze protection on freezer floors, are tested to ensure

heat is automatically turned off during summer on-peak electric periods.

B.

Evaporator Fan Motor Controls

Evaporator equipment and controls are checked

for proper operation. The controls are tested to ensure the fan speed

automatically varies in response the temperature and/or humidity of the

space.

C.

Evaporative Condensers

Evaporative condensers and

variable-speed fan controls are checked to ensure the required minimum SCT

setpoint of 70°F or lower is implemented, and the condenser fans continuously vary in

unison to maintain a target temperature difference between the SCT and the

wetbulb temperature. Trends of wetbulb temperature and SCT can be used to verify

the controls over time.

The condenser control TD or offset

is a key parameter in fine-tuning the operation of the fans and maximizing the energy

savings. In best practice, this control setting should be adjusted during

average load so that the fan average 60-80% speed when in the control range

(i.e. between the minimum and maximum SCT setpoints).

D.

Air-Cooled Condensers

Air-cooled condensers and

variable-speed fan controls are checked to ensure the required minimum SCT

setpoint of 70°F or lower is implemented, and the condenser fans continuously

vary in unison to maintain a target temperature difference between the SCT and

drybulb temperature. Trends of drybulb temperature and SCT can be used to verify

the controls over time.

The condenser control TD is a key

parameter in fine-tuning the operation of the fans and maximizing energy

savings. This control setting should be adjusted during average load so that

condenser capacity is effectively used but fan speed is not excessive.

E.

Adiabatic Condensers

Adiabatic condensers and

variable-speed fan controls are checked to ensure the required minimum SCT

setpoint of 70°F or lower is implemented, and the condenser fans continuously

vary in unison to maintain a target temperature difference between the SCT and

drybulb temperature when operating in dry mode. Trends of drybulb temperature

and SCT can be used to verify the controls over time.

The condenser control TD is

a key parameter in fine-tuning the operation of the fans and maximizing the

energy savings. This control setting should be adjusted during average loaded so

that condenser capacity is effectively used but fan speed is not excessive.

F.

Variable-Speed Compressors

The controls and equipment for the

variable-speed control of screw compressors are checked and certified as part of the acceptance

requirements. The compressor should unload capacity by reducing speed to the

minimum speed setpoint before unloading by slide valve or other means. Control

system trend

screens can also be used to verify that the speed varies automatically in

response to the load.

10.6.4.1 Requirements

Requirements related to refrigerated warehouse additions and alterations are covered by

the Energy Standards in §141.1(a). The specific requirements for additions

and alterations for commercial refrigeration are included in §120.6(a)..

Definitions relevant to refrigerated warehouses include the following:

•

An addition is a change to an existing refrigerated warehouse that

increases refrigerated floor area and volume. Additions are treated like new

construction.

•

When an unconditioned or conditioned building or an unconditioned or

conditioned part of a building adds refrigeration equipment so that it becomes

refrigerated, this area is treated as an addition.

•

An alteration is a change to an existing building that is not an

addition or repair.

An alteration could include installing new evaporators, a new lighting system, or a change to

the building

envelope, such as adding insulation.

•

A repair is the reconstruction or renewal of any part of an existing

building or equipment for maintenance. For example, a repair could include the

replacement of an existing evaporator or condenser.

Any addition or altered space must

meet all applicable mandatory requirements. Repairs must not increase the

preexisting energy consumption of the repaired component, system, or equipment;

otherwise, it is considered an alteration.

Example 10-50

Question

The new

construction is an addition to an existing refrigerated warehouse. The new space

is served by an existing refrigeration plant. Does the refrigeration plant need

to be updated to meet the Energy Standards?

Answer

No. The new

construction must comply with the Energy Standards; however, the existing

refrigeration plant equipment is exempt from the Energy Standards.

Example

10-51

Question

The new

construction includes an addition to refrigerated space and

expansion of the existing refrigeration plant. Is the existing refrigeration

equipment subject to the Energy Standards?

Answer

No. Only the

new equipment installed in the added refrigerated space and any new compressors

added to the existing plant are subject to the requirements of the Energy

Standards. If a new refrigeration system was installed with a new condenser for

the addition, then the new condenser must also comply with the Energy

Standards.

Example

10-52

Question

An upgrade to

an existing refrigerated storage space includes replacing all of the existing

evaporators with new evaporators. Do the new evaporators need to comply with the

Energy Standards?

Answer

Yes. A

complete renovation of the evaporators in the space is considered an alteration.

The alteration requirements apply when all the evaporators in the space are

changed.

Example

10-53

Question

An existing

refrigerated storage space is adding additional evaporators to meet an increase

in the refrigeration load. Do the new evaporators need to comply with the Energy

Standards?

Answer

No. The

alteration requirements apply only when all of the evaporators in the space are

changed.

Example

10-54

Question

An existing

evaporator is being replaced by a new evaporator as part of system maintenance.

Does the new evaporator need to comply with the Energy Standards?

Answer

No.

Replacement of an evaporator during system maintenance is considered a repair.

However, the energy consumption of the new evaporator must not exceed that of

the equipment it replaced.