3.3

Fenestration (Window/Skylight/Glazed Door) and Opaque Doors

Fenestration products such as

windows, glazed doors, dynamic glazing, window films, and skylights have a significant impact on energy

use and heating and cooling loads in a home. The size, orientation, and types of

fenestration products can dramatically affect the overall energy performance of

a house. Glazing type, orientation, shading, and shading devices not only play a major role in the

energy use of a building, but can affect the operation of the lighting system, HVAC system, and

comfort of occupants.

Table 3-1: Relevant Sections in the Energy Standards

3.3.1

Fenestration Types

3.3.1.1 Windows and Glazed

Doors

A window is a vertical fenestration

product that is an assembled unit consisting of a frame and sash component holding

one or more pieces of glazing. Window performance is measured with the U-factor and solar

heat gain coefficient (SHGC).

Glazed doors are an exterior

door having a glazed

area of 25 percent or more of the area of the door. Glazed doors are treated the

same as windows and must meet the U-factor and SHGC requirements for windows.

Most sliding glass doors, French doors, and some entry doors with large amounts

of glazing will meet the definition to be treated as glazed doors.

3.3.1.2 Opaque Doors

When the door has less than 25 percent glazing material, it

is considered an opaque door and is subject to the door U-factor requirements. Doors between

the garage and conditioned

space that are required to have fire protection are not required to meet the

U-factor requirement.

3.3.1.3 Skylights and

Tubular Daylight Devices

Skylights and tubular

daylight devices (TDD) are an exceptional source of daylight and passive solar

heating, illuminating rooms with direct and indirect sunlight. When used

appropriately, daylighting can increase the quality of light in a room and reduce dependence

upon electrical lighting.

Skylights and TDDs don’t

typically have the same thermal properties as vertical fenestration and

can be prone to greater heat loss in winter and solar heat gain during the

summer. When a building designer optimizes the whole envelope glazing arrangement for daylight and

thermal control, significant heating and cooling energy savings can be realized,

especially when skylights and TDDs are as efficient as other vertical windows

used.

Windows are considered part

of an exterior

wall when the slope is 60° or more as measured from the horizontal. Where

the slope of fenestration is less than 60°, the glazing indicated as a window is considered a

skylight and part

of the roof.

3.3.1.4 Fenestration

Subcategories

A.

Manufactured fenestration is a fenestration product

constructed of materials that are factory-cut or otherwise factory-formed with the specific

intention of being used to fabricate a fenestration product. Knocked down or

partially assembled products may be sold as a fenestration product when provided

with temporary and permanent labels, as described in §10-111,

or as a site-built fenestration product when not provided with

temporary and permanent labels, as described in §10-111.

B.

Site-built fenestration is designed to be field-glazed or field-assembled

units, using specific factory-cut or other factory-formed framing, and glazing units that

are manufactured with the intention of being assembled at the construction site.

These include storefront systems, curtain walls or large-track sliding glass

walls, and atrium

roof systems.

C.

Field-fabricated fenestration is when the windows

are fabricated at the building site from elements that are not sold together as a

fenestration product (that is, separate glazing, framing, and weatherstripping elements). Field-fabricated does not include

site-assembled frame components that were manufactured elsewhere with the

intention of being assembled on site (such as knocked-down products, sunspace

kits, and curtain walls).

3.3.1.5 Fenestration

Definitions

A.

Center of glass. U-factor, SHGC, and VT are measured only through glass at least

2.5 inches from the edge of the glass or dividers.

B.

Clear glass has little, if any, observable tint with an IG unit with an SHGC

of 0.5 or greater.

C.

Chromogenic is a class of glazing that can change the optical properties by including

active materials (e.g. electrochromic) and passive materials (e.g. photochromic

and thermochromic) permanently integrated into the glazing assembly.

Electrochromatic is a

class of glazing that tints on demand using a small amount of electricity.

D.

Divider (muntin). An element that physically or visually divides

different lites of glass. It may be a true divided lite, between the panes,

and/or applied to the exterior or interior of the glazing.

E.

Double-pane ‘window. Double-pane (or

dual-pane) glazing is made of two panes of glass (or other glazing material)

separated by space (generally 1/4" [6 mm] to 3/4" [18 mm]) filled with air or

other gas. Two panes of glazing laminated together do not constitute double-pane

glazing

F.

Dynamic glazing. Glazing systems that have the ability to reversibly

change the performance properties, including U-factor, solar heat gain

coefficient (SHGC), and/or visible transmittance

(VT) between well-defined end points. Includes active materials (for

example, electrochromic) and passive materials (for example, photochromic and

thermochromic) permanently integrated into the glazing assembly.

With appropriate controls,

electrochromic glass can be darkened or lightened to adjust the levels of

daylight and solar heat gain. These products have the ability to reversibly

change the SHGC and VT between well-defined endpoints.

Integrated shading systems is a class of

fenestration products including an active layer (for example, shades, louvers,

blinds, or other materials) permanently integrated between two or more glazing

layers and that has the ability to reversibly change performance properties,

including U-factor, SHGC, and/or VT between well-defined end points.

G.

‘Fixed. The fenestration

product cannot be opened.

H.

‘Gap width. The distance

between glazing in multiglazed systems (e.g., double or triple glazing). This

dimension is measured from inside surface to inside surface. Some manufacturers

may report "overall" IG unit thickness, which is measured from outside surface

to outside surface.

I.

Grille. See Divider.

J.

‘Insulating glass

unit (IG unit or IG). An IG unit includes the glazing, coatings,

tinting, spacer(s), films (if any), gas infills, and edge caulking.

K.

‘Light or lite. A layer of

glazing material, especially in a multilayered IG unit. Referred to as panes in

§110.6

when the lites are separated by a spacer from inside to outside of the

fenestration.

L.

Low-e coatings. Low-emissivity coatings are special coatings applied to

the second, third, or fourth surfaces in double-glazed windows or skylights. As

the name implies, the surface has a low emittance, meaning that radiation from

that surface to the surface it “looks at” is reduced. Since radiation transfer

from the hot side to the cool side of the window is a major component of heat transfer in

glazing, low-e coatings are very effective in reducing the U-factor. They do

nothing, however, to reduce losses through the frame.

Low-e coatings can be engineered

to have different levels of solar heat gain. Generally, there are two kinds of

low-e coatings:

1.

Low-solar-gain low-e coatings are formulated to reduce air-conditioning loads.

Fenestration products with low-solar-gain low-e coatings typically have an SHGC

of 0.40 or less. Low-solar-gain low-e coatings are sometimes called

spectrally selective coatings because they filter much of the infrared

and ultraviolet portions of the sun’s radiation while allowing visible light to

pass through.

2.

High-solar-gain low-e coatings, by contrast, are formulated to maximize solar

gains. Such coatings would be preferable in passive solar applications or where

there is little air conditioning.

Another advantage of low-e

coatings, especially low-solar-gain low-e coatings, is that when they filter the

sun’s energy, they generally remove between 80 percent and 85 percent of the

ultraviolet light that would otherwise pass through the window and damage

fabrics and other interior furnishings. This is a major advantage for homeowners

and can be a selling point for builders.

M.

‘Mullion. A frame member

that is used to join two windows into one fenestration unit.

N.

Muntin. See Dividers.

O.

Nonmetal frame. Includes vinyl, wood, fiberglass, and other

low-conductance materials. Vinyl is a polyvinyl chloride (PVC) compound used for

frame and divider elements with a significantly lower conductivity than metal

and a similar conductivity to wood. Fiberglass has similar thermal

characteristics. Nonmetal frames may have metal strengthening bars entirely

inside the frame extrusions or metal-cladding only on the surface.

P.

‘Operable. The fenestration

product can be opened for ventilation.

Q.

Solar heat gain coefficient (SHGC). A measure of the relative amount of

heat gain from sunlight that passes through a fenestration product. SHGC is a

number between zero and one that represents the ratio of solar heat that passes

through the fenestration product to the total solar heat that is incident on the

outside of the window. A low SHGC number (closer to 0) means that the

fenestration product keeps out most solar heat. A higher SHGC number (closer to

1) means that the fenestration product lets in most of the solar heat.

SHGC or SHGCt is the

SHGC for the total fenestration product and is the value used for compliance

with the standards.

R.

Spacer or gap space. A material that separates multiple panes of glass in

an insulating glass unit.

S.

Thermal break frame. Includes metal frames that are not solid metal from

the inside to the outside but are separated in the middle by a material with a

significantly lower conductivity.

T.

Tinted. Glazing products formulated to have the appearance of color that

alters the solar heat gain and visible transmittance. Common colors include

gray, bronze, green, and blue. Some coatings can also appear tinted.

U.

U-factor. A measure of how much heat can pass through a construction

assembly or a fenestration product. The lower the U-factor, the more energy

efficient the product is. The units for U-factor are British thermal units (Btu)

of heat loss each hour per square foot (ft²) of window area per degree Fahrenheit

(°F) of temperature difference (Btu/hr-ft²-°F). U-factor is the inverse of R-value.

The U-factor considers the entire

product, including losses through the center of glass, at the edge of glass

where a metal spacer typically separates the double-glazing panes, losses

through the frame, and through the mullions. For metal-framed fenestration

products, the frame losses can be significant.

V.

Visible transmittance (VT) is the ratio of visible light transmitted

through the fenestration. The higher the VT rating, the more light is allowed

through a window.

W.

Window films are composed of a polyester substrate to which a special

scratch-resistant coating is applied on one side, with a mounting adhesive layer

and protective release liner applied to the other side.

3.3.2

Mandatory Requirements §10-111, §10-112, §110.6

3.3.2.1 Fenestration

Products and Labeling §10-111; §110.6(a)5

The National Fenestration Rating

Council (NFRC) is the

entity recognized by the California Energy

Commission to supervise the rating and labeling of fenestration products.

NFRC maintains the Certified Product Directory, containing NFRC certified

U-factors, SHGC and VT values for thousands of fenestration products, on its

website at http://www.nfrc.org.

Fenestration product

performance data used in compliance calculations must be provided through the

NFRC rating program and must be labeled by the manufacturer with the rated U-factor, SHGC, and

VT in accordance with §10-111

procedures.

Estimating the rate of heat

transfer through a fenestration product is complicated by the variety of frame

configurations for operable windows, the different combinations of materials used

for sashes and frames, and the difference in sizes available in various

applications. The NFRC rating system makes the differences uniform, so that an entire

fenestration product line is assumed to have only one typical size. The

NFRC-rated U-factor may be obtained from the directory of certified fenestration

products, directly from a manufacturer's listing in product literature, or from

the product label.

U-factor and solar heat

gain (SHGC) are factors that affect the energy performance of a window. There is no

minimum requirement for visual transmittance (VT) for low-rise residential

buildings but is used for informational purposes. Product labels that clearly

state these energy performance ratings help consumers compare the energy

efficiency of window and glazed door products of different brands and manufacturers.

There are two

types of labels that may be used to meet the requirements in the Energy Standards: an

NFRC-certified product label or a default label. Manufactured products will need

to have both an NFRC temporary label listing certified performance values and a

permanent label with information that can be used to trace the product certification

file and show that the manufacturer has certified the product per one of the

testing methods described in Table 3-2. See the “Certified Product Labels”

section for more information. Default U-factors and SHGC are used when the

manufacturer has not certified the product through the NFRC and for site-built

fenestration. The temporary default label shall meet the requirements per §10-111.

See the “Default Label” section for more information.

3.3.2.2 Certified Product

Labels: Temporary and Permanent

1.

Temporary Label for NFRC Certified

Manufactured Fenestration Products

The Energy Standards require that manufactured

fenestration have both temporary and permanent labels. The temporary label shows

the U-factor and

SHGC for each rated window unit. The label must also show that the product meets

the air infiltration criteria of §110.6(a).

The temporary label must not be removed before inspection by the enforcement

agency.

Figure 3-2:

Sample Temporary NFRC Label

Source: National Fenestration Rating

Council

2.

National Fenestration Rating Council (NFRC) Permanent Label

The

permanent label must, at a minimum, identify the certifying organization

and have an ID number or code to allow tracking ‘back to the original information on file with the certifying

organization, NFRC. The permanent label can also be inscribed on the spacer,

etched on the glass, engraved on the frame, or otherwise located so as not to

affect aesthetics.

3.3.2.3 Default Label:

Temporary

The manufacturer can choose to use

Energy Standards

default values from Table

110.6-A for U-factors and Table

110.6-B for SHGC. The product shall meet the air infiltration requirements of §110.6(a)1,

U-factor criteria

of §110.6(a)2, and SHGC criteria of §110.6(a)3 in the Energy Standards. The

manufacturer must attach a temporary label meeting the following specific

requirements. (Permanent etching labels are not required.)

There is no template for the

default temporary label. It must be clearly visible and large enough for the enforcement

agency field inspectors to read easily. It must include all information

required by the Energy Standards. The minimum suggested label size is 4 in. x 4

in., and the label must have the following words at the bottom of the label as

noted in Figure 3-3:

“Product meets the air

infiltration requirements of §110.6(a)1,

U-factor criteria of §110.6(a)2, SHGC criteria of §110.6(a)3 and VT criteria of

§110.6(a)4 of the 2019 California Building Energy

Efficiency Standards for Residential and Nonresidential Buildings.”

The manufacturer ensures the

U-factor and SHGC default values are large enough to be readable from four feet

away. The manufacturer ensures the appropriate boxes are checked and indicated

on the default label.

Figure 3-3: Sample of Default Temporary Label

|

2019 California Energy

Commission Default Label

XYZ Manufacturing Co. |

|

Key Features: |

o Doors |

o Double-Pane |

|

o Skylight |

o Glass Block |

|

|

|

|

|

Frame Type |

Product Type: |

Product Glazing Type: |

|

o Metal |

o Operable |

o Clear |

|

o Non-Metal |

o Fixed |

o Tinted |

|

o Metal, Thermal Break |

o Greenhouse/Garden Window |

o Single-Pane |

|

o Air space 7/16 in.

or greater

o With built-in curb

o Meets Thermal-Break Default Criteria |

---------- |

To

calculate VT see NA6 |

|

California Energy

Commission

Default U-factor = |

California Energy Commission

Default SHGC = |

California Energy Commission

Calculated VT = |

|

Product meets the air infiltration requirements of

§110.6(a)1,

U-factor criteria of §110.6(a)2, SHGC criteria of §110.6(a)3 and VT

criteria of §110.6(a)4 of the 2019 Building Energy Efficiency

Standards for Residential and Nonresidential

Buildings. |

Source: California Energy Commission

|

|

At the field inspection,

the field inspector verifies that the fenestration U-factor and SHGC

values meet the energy compliance values by checking the label sticker on

the product. If no labels are available on site for verification, the

field inspector should not allow any further installation of fenestration

until proof of efficiency (label) is produced. In cases when proof is not

met, the field inspector should not allow construction until the designer

or builder

can produce such labels. |

Manufactured Products.

Product must be rated by the National Fenestration Rating Council (NFRC) and be listed in NFRC’s Certified Product

Directory (CPD). The test procedure for U-factor is NFRC 100, and for SHGC and VT is NFRC 200 and NFRC 202, or ASTM E972 for

translucent panels, and NFRC 203 for tubular daylighting devices (TDDs) and for certain

types of other skylights.

Energy Commission Default Tables

110.6-A and 110.6-B

in the Energy Standards list the worst-case values that must be assumed in most

cases when fenestration is not rated by NFRC. For example, a single-pane,

operable, metal-framed fenestration product has a default U-factor of 1.28. To get

credit for high-performance window features such as low-emissivity (low-e)

coatings and thermal break frames, the window manufacturer must have the window

tested, labeled, and certified according to NFRC procedures. When the Energy

Standards default values are used, they must be documented on a temporary

default label (Figure 3-3).

Site-Built

Products. For special cases in low-rise residential construction in which

site-built products are installed, the site-built products shall be treated the

same as manufactured products. U-factor and SHGC values must come from NFRC

ratings or from the default Table

110.6-A and 110.6-B

of the Energy Standards. Alternatively, calculation procedures in Reference

Appendix NA6

for nonrated site-built fenestration may be used if the area of the site-built

fenestration in a dwelling is less than 250 ft2 or 5 percent of the

conditioned floor area, whichever is larger.

Field-Fabricated Products. Field-fabricated

fenestration must always use the Energy Commission default U-factors from Table

110.6-A and SHGC values from Table

110.6-B of the Energy Standards.

Example

3-1: Labels When Using CEC Default Values

Question:

When windows are labeled with a default value, are there any special

requirements that apply to the label?

Answer:

All windows must meet the mandatory requirements in §110.6

and §110.7, unless

exempted. These criteria apply to fenestration products labeled with

default values:

The

administrative regulations (§10-111)

require that the words “CEC Default U-factor” and “CEC Default SHGC” appear on

the temporary label before the U-factor or SHGC (not in a footnote).

The

U-factor and SHGC for the specific product must be listed. If multiple values

are listed on the label, the manufacturer must identify the appropriate value

for the labeled product. Marking the correct value must be done in one of the

following ways:

1.

Circle the correct U-factor and SHGC (permanent ink).

2.

Black out all values except the correct U-factor and SHGC (permanent ink).

3.

Make a hole punch next to the appropriate values.

3.3.3

U-Factor and SHGC Ratings §110.6(a), Table 110.6-A, Table 110.6-B

Determining U-Factor and SHGC. The Energy Standards require that U-factor and

solar heat gain coefficient (SHGC) be calculated using

standardized procedures to ensure that the thermal performance or efficiency

data for fenestration products is accurate. The data provided by different

manufacturers within each fenestration type (windows, doors, skylights, TDDs)

can easily be compared to others within that type and can be verified

independently.

Acceptable methods of determining

U-factor and SHGC are shown in Table 3-2.

Table 3-2: Methods for Determining U-Factor and SHGC

|

U-Factor/SHGC

Determination Method |

Manufactured Windows and Doors |

Manufactured Skylights |

Site-Built Fenestration (Vertical &

Skylight) |

Field-Fabricated Fenestration |

Glass

Block |

|

NFRC-100 (U-Factor)

NFRC-200 (SHGC) |

ü |

ü |

ü |

N/A |

N/A |

|

Standards Default

Table 110.6-A (U-Factor)

Table 110.6-B (SHGC) |

ü |

ü |

ü |

ü |

ü |

|

NFRC’s

Component

Modeling Approach (CMA)1 |

N/A |

N/A |

N/A |

N/A |

N/A |

|

NA62 |

N/A |

N/A |

ü |

N/A |

N/A |

|

1. The

NFRC CMA method is limited to nonresidential and is not currently approved for

residential use.

2. The Alternative Default U-factors and SHGCs from

Reference Appendix NA6 may be

used only for total site-built vertical

fenestration plus skylights up to 250 ft2 or 5% of the

conditioned floor area, whichever is larger. Residential area allowances

are defined in NA6.1(b). |

|

|

When the

alternative procedure from NA6

for unrated site-built fenestration is used in a residential application,

it may not meet the prescriptive values as required by Table 150.1-A,

even if area-weighted averaging is implemented. In this case, it would

be necessary to use the performance approach to meet energy

complianc |

Example

3-2: Multiple Window Types in a Project

Question:

My new home will have a combination of window types, including fixed, operable, wood,

metal, and so forth, some of which are field-fabricated. What are the options

for showing compliance with the standards?

Answer:

All windows must meet the mandatory requirements of §110.6

and §110.7 and the

mandatory maximum area-weighted average U-factor of 0.58 from §150.0(q),

unless exempted. For field-fabricated windows, you must select U-factors and

SHGC values from the default tables (Table

110.6-A and Table

110.6-B of the Energy Standards). Windows that are not field-fabricated must

be labeled with NFRC-‘certified or

default efficiencies. Few fenestration products in the default tables meet the

mandatory maximum U-factor of 0.58 on their own.

If

the area-weighted average U-factors or SHGC values do not comply with the

prescriptive requirements, the performance method must be used. To simplify data

entry into the compliance software, you may choose the U-factor from Table

110.6-A of the Energy Standards that is the highest of any of the windows

planned to be installed and use this for all windows for compliance. However,

you must use the appropriate SHGC from Table

110.6-B for each window type being installed.

Example

3-3: Glass Block

Question

1: Which U-factor is used for an operable metal-framed glass block?

Answer

1: For glass block, use the U-factor from Table

110.6-A of the Energy Standards for the frame type in which the glass blocks

are installed and for the fenestration product type.

The U-factor for operable metal-framed glass block from Table

110.6-A is 0.87.

Question

2: Which SHGC is used for clear glass block, and can it be used for tinted glass

block?

Answer

2: Use the default SHGC values from Table

110.6-B, depending upon whether the glass block has a metal or nonmetal

frame and whether it is operable or fixed. The default SHGC table does not

include tinted glass block, so use the clear glass block SHGC as the default for

both clear and tinted glass block.

Question

3: Does it need a label?

Answer

3: Glass block is considered a field-fabricated product and may be installed

only if compliance is demonstrated on the compliance documents.

Example

3-4: Sunrooms

Question:

Is there a default U-factor for the glass in sunrooms?

Answer:

If the sunroom is part of the conditioned floor area, then yes. For the

horizontal or sloped portions of the sunroom glazing, use the U-factor for

skylights. For the vertical portions, use the U-factors for fixed windows,

operable windows, or doors, as appropriate. As a simple alternative, the

manufacturer may label the entire sunroom with the highest U-factor of any of

the fenestration types within the assembly.

Example

3-5: Glazed Doors

Question

1: How are exterior glazed doors treated in compliance documentation for

U-factor and SHGC?

Answer

1: All doors with glass area greater than or equal to 25 percent of the door area, which

includes French doors, are defined as fenestration products and are covered by

the NFRC Rating and Certification Program. The U-factor and SHGC for doors with 25

percent or more glass area may be determined in one of two ways:

1.

Use the NFRC rated and labeled values.

2.

Refer to Table

110.6-A and 110.6-B

of the Energy Standards. The values are based upon glazing and framing type.

In

special cases where site-built fenestration is being installed in a residential

application, the site-built windows and glazed doors can use an alternative

method to calculate the U-factor and the SHGC by using the manufacturer’s

center-of-glass values (COG). The COG values are calculated in accordance with

Reference Appendix NA6.

To use this calculation, the maximum allowed site-built fenestration is 250

ft2 or 5% of the conditioned floor area, whichever is larger.

Question

2: How can I determine a U-factor and SHGC for doors when less than 25

percent of the door

area is glass?

Answer

2: Doors with less than 25 percent glass area are treated as opaque exterior

doors. For prescriptive or performance approaches, only the U-factor is used for

this product type. Use one of the following options for U-factor of the door:

1.

The NFRC label if one is available

2.

The default values from Table

JA4.5.1 of the Reference

Appendices

Example

3-6: Tubular Daylighting Device With Single-Pane Diffuser

Question:

A tubular daylighting device will be used to get daylight into a house. The

skylight has a clear plastic dome exterior to the roof, a single-pane ¼-inch (6 mm)-thick

acrylic diffuser mounted at the ceiling, and a metal tube connecting the two. How are U-factor

and SHGC determined for the performance approach to comply with the Energy

Standards, if Uc is 1.20 and SHGCc is 0.85?

Answer:

There are three methods available for determining the U-factor for tubular

daylighting devices (TDD):

1.

Use the NFRC label if the product has been tested and certified under NFRC

procedures. This requires a label that states: “Manufacturer stipulates that

this rating was determined in accordance with applicable NFRC procedures NFRC 100,” followed

by the U-factor.

2.

Use the default U-factor from Table

110.6-A of the Energy Standards. This tubular product would be considered a

metal frame, fixed, single-pane skylight resulting in a U-factor of 1.19, which

must appear on a label preceded by the words “CEC Default U-factor.” (A tubular

daylighting device would have to have two panes of glazing with an air space of

less than 2 inches [50 mm] between them at the plane of the ceiling insulation for it

to be considered double-pane.)

3.

Determine the U-factor from Reference Appendix NA6,

Equation NA6-1. The U-factor for this tubular daylighting device would be based

on metal with no curb (Table NA6-5). The U-factor for this skylight, using

Equation NA6-1, is 1.25, where Ut = (0.195 + (0.882 x 1.20)). This

must appear on a label stated as “CEC Default U-factor 1.25.”

There

also are three methods available for determining SHGC for tubular daylighting

devices (TDD):

1.

Use the NFRC label if the skylight has been tested and certified under NFRC

procedures and requires a label that states: “Manufacturer stipulates that this

rating was determined in accordance with applicable NFRC procedures.”

2.

Use the default table SHGC in Table

110.6-B of the Energy Standards. This tubular daylight device would be

considered a metal-frame, fixed, clear, single-pane skylight resulting in an

SHGC of 0.83, which must appear on a label stated as “CEC Default SHGC 0.83.”

3.

Determine the SHGC from Reference Appendix NA6,

Equation NA6-2. The SHGC for this skylight using Equation NA6-2 is 0.81, where

SHGCt = (0.08 + (0.86 x 0.85)). This must appear on a label stated as

“CEC Default SHGC 0.81.”

Example

3-7: Tubular Daylighting Device With Dual-Pane Diffuser

Question:

How are the U-factor and the SHGC determined if the tubular daylighting

device in the previous example has a dual-pane diffuser (instead of single-pane)

mounted at the ceiling?

Answer:

The procedure would be exactly the same as Example 3-6, except that the

double-pane U-factor and SHGC values from Tables

110.6-A and 110.6-B

of the Energy Standards would be used instead of single-pane values. Up to 3

ft2 of tubular daylighting device with a dual-pane diffuser is

assumed to have the prescriptive U-factor and SHGC from Table 150.1-A

or Table 150.1-B

for compliance calculations (Exception 1 to §150.1[c]3A).

3.3.4

Air Leakage §110.6(a)1, §110.7

Air leakage (AL) is a measurement

of heat loss and gain by infiltration through cracks in the window assembly, which can affect

occupant comfort. The lower the AL, the lower the amount of air that will pass

through cracks in the window assembly.

A.

Manufactured Products. Must be tested and certified to leak no more than 0.3

cubic feet per minute (cfm) per ft² of the window area. This mandatory measure

applies to all manufactured windows that are installed in newly constructed

residential (including high-rise) buildings or newly installed in existing

buildings. To determine leakage, the standard test procedure requires

manufacturers to use either NFRC 400 or ASTM E283 at a pressure differential of 75 Pascal (or 1.57

pounds/ft2).

B.

Site-Built Products. There are no specific air

leakage requirements for site-built fenestration products, but the Energy Standards require

limiting air leakage by weatherstripping and caulking.

C.

Field-Fabricated Products. No air leakage testing is

required for field-fabricated fenestration products; however, the Energy

Standards still require limiting air leakage by weatherstripping and

caulking.

D.

Exterior Doors. Exterior doors, which includes pet doors, must meet the

following requirements:

1.

Manufactured exterior doors must be certified as meeting an air leakage rate of

0.3 cfm/ft² of door

area at a pressure differential of 75 Pascal, which is the same as

windows.

2.

Field-fabricated exterior doors must comply with the requirements of §110.6,

as described by “Other Openings.” For example, these must be caulked and

weatherstripped.

3.

Any door with a

surface area greater than or equal to 25 percent glass is considered a glazed door and

must comply with the mandatory and applicable prescriptive and performance

requirements of §150.0, §150.1(b),

and §§150.2.

4.

For any door with a surface area less than 25 percent glass, the area may be

exempt in accordance with one of the exceptions of §150.0, §150.1(b),

and §150.2.

Example

3-8: Which Fenestration Products Must Be Tested and Certified for Air

Leakage?

Question:

As a manufacturer of fenestration products, I place a temporary label with

the air infiltration rates on my products. Can you clarify which products must

be tested and certified?

Answer:

Each product line must be tested and certified for air infiltration rates.

Features such as weather seal, frame design, operator type, and direction of

operation affect air leakage. Every product must have a temporary label

certifying that the air infiltration requirements are met. This temporary label

may be combined with the temporary U-factor, SHGC, and VT label.

Example

3-9: Infiltration Requirements for Custom Windows

Question:

Is a custom window “field-fabricated” for meeting air infiltration

requirements?

Answer:

No. Most custom windows are manufactured and delivered to the site either

completely assembled or “knocked down,” which means they are a manufactured

product. A window is considered field-fabricated when the windows are assembled

at the building

site from the various elements that are not sold together as a fenestration

product (such as glazing, framing, and weatherstripping). Field-fabricated does

not include site-assembled frame components that were manufactured elsewhere

with the intention of being assembled on site (such as knocked-down products,

sunspace kits, and curtain walls).

Example

3-10: Pet Doors to the Exterior

Question:

How is a pet door installed in an exterior wall accounted for in a

newly constructed residential building design?

Answer:

Pet doors must meet all exterior door requirements. U-factor must be

determined by an NFRC

accredited testing lab using NFRC 100 U-factor requirements; otherwise, nonrated pet doors

will assume no more than the maximum U-factor of 0.99 based on a nonmetal

single-pane door U-factor. (See Table

110.6-A of the Energy Standards.) The rated pet door shall not exceed 0.3

cfm/ft² air leakage when tested using ASTM E283. The performance compliance approach must be

used when a pet door is installed.

3.3.5

Prescriptive Requirements §150.1(c)3, §150.1(c)4, §150.1(c)5, Table 150.1-A and

Table 150.1-B

Fenestration

Prescriptive requirements described

in this chapter typically refer to Table 150.1-A

or 150.1-B.

The maximum fenestration U-factor required prescriptively for all climate zones is 0.30, and the

maximum SHGC is 0.23 for residences in Climate Zones 2, 4, and 6 through 15.

Homes constructed in Climate Zones 1, 3, 5, and 16 have no SHGC requirements.

The requirements apply to

fenestration products without consideration of insect screens or interior shading devices. With

some exceptions, some fenestration products may exceed the prescriptive

requirement as long as the U-factor and SHGC of windows, glazed doors, and

skylights can be area weight-averaged together to meet the prescriptive

requirement using the CF1R-ENV-02-E compliance document in Appendix A of this ‘manual.

Opaque Doors

An opaque door is an installed

swinging door separating conditioned space from outside or adjacent unconditioned space with

less than 25 percent glazed area. A door that has 25 percent or more glazed area

is considered a glazed door and is treated like a fenestration product (Section

3.5.8).

Opaque doors are

prescriptively required to have an area-weighted average U-factor no greater

than U-0.20, per Table 150.1-A

and Table 150.1-B.

Swinging doors between the garage and conditioned space that are required to have fire

protection are exempt from the prescriptive requirement. The U-factor must be

rated in accordance with NFRC 100, or the applicable default U-factor defined in

Reference Appendix Table 4.5.1 must

be used.

|

|

At the field inspection, the field inspector

verifies that the door U-factor meets the energy compliance values by

checking the NFRC label sticker on the product. When manufacturers do

not rate the thermal efficiencies by NFRC procedures, the Energy

Commission default values must be used and documented on a temporary

default label (Figure 3-3). |

Table 3-3: Maximum U-Factors, SHGC, and Fenestration Area by Climate Zone

in the Prescriptive Package

|

Climate Zone |

1, 3, 5, 16 |

2,4,6-15 |

|

Maximum Fenestration U-Factor |

0.30 |

0.30 |

|

Maximum Fenestration SHGC |

NR |

0.23 |

|

Maximum Fenestration

Area |

20% |

20% |

|

Maximum West-Facing Fenestration

Area |

NR |

5% |

|

Maximum Opaque Door U-Factor |

0.20 |

0.20 |

Figure 3-4: Prescriptive Package, SHGC, and West-Facing Area

Criteria by Climate Zone

3.3.5.1 Fenestration and

Opaque Door Prescriptive and Mandatory Exceptions

A.

Glazed Doors

Any ‘door that is more than 25 percent or greater glass is

considered a glazed

door and must comply with the mandatory measures and other requirements

applicable to a fenestration product. Up to 3 ft2 of glass in a

door is exempt from the U-factor and SHGC requirements (or can be considered equivalent

to the prescriptive package values). The U-factor and SHGC shall be based on

either the NFRC

values for the entire door, including glass area, or use default values in Table

110.6-A for the U-factor and Table

110.6-B for the SGHC. If the door has less than 25 percent glazing, the opaque

part of the door is ignored in the prescriptive approach.

B.

Tubular Daylighting Device (TDD)

In each dwelling unit, up to 3

ft2 of tubular daylighting devices area with dual-pane diffusers at

the ceiling are

exempt from the prescriptive U-factor and SHGC requirements, where the TDD area

is included in the maximum of 20 percent fenestration area. However,

the U-factor shall not exceed a maximum of 0.58. See §150.0(q)

and Exception 1 of §150.1(c)3A.

C.

Opaque Doors

Opaque doors between the garage and conditioned

space that are required to have fire protection are not required to meet the

prescriptive U-factor requirement of 0.20. See Exception to §150.1(c)5.

D.

Skylights

Each new dwelling unit may have up to 16

ft2 of skylight area. The total area of skylights is included in the

maximum of 20 percent fenestration area and must meet a maximum 0.55 U-factor

and a maximum SHGC of 0.30. See Exception 2 of §150.1(c)3A.

Aside from the specific

exceptions to the fenestration prescriptive requirements, the area

weight-averaged U-factor and SHGC must not exceed the 0.55 U-factor and cannot

be greater than the 0.30 SHGC when large numbers of skylights are used for

prescriptive compliance. Alternatively, the performance approach may be used to

meet energy compliance.

E.

Dynamic Glazing

If a dwelling unit includes a type of dynamic glazing

that is electrochromatic, chromogenic, or an integrated shading device and the glazing is

automatically controlled, use the lowest U-factor and lowest SHGC to determine

compliance with prescriptive package fenestration requirements. Since this type

of product has compliance ratings that vary, it cannot be weight averaged with

nonchromogenic products as per Exception 3 of §150.1(c)3A.

F.

Site-Built Fenestration

When a dwelling unit contains a combination of

manufactured and site-built fenestration, only the site-built fenestration

values can be determined by using Reference Appendix NA6.

All fenestration, including site-built, can default to Table

110.6-A and Table

110.6-B.

G.

Maximum Area

The prescriptive requirements limit total glass area to

a maximum of 20 percent of the conditioned floor area in all climate zones.

Note: There are

exceptions to the prescriptive requirements for alterations in §150.2(b)1A that allow additional

glass area beyond the 20 percent limitation, including west-facing glass. See Chapter 9 for

more information on alterations.

H.

Greenhouse Windows/Garden Windows

Compared to other

fenestration products, the NFRC-rated U-factor for greenhouse windows are

comparatively high. Section §150.0(q)

includes an exception from the U-factor requirement for dual-glazed greenhouse

or garden windows that total up to 30 ft² of fenestration area.

3.3.5.2 Prescriptive Credit

for Exterior Shading Devices §150.1(c)4

The prescriptive requirements

require fenestration products with a SHGC of 0.23 or lower in Climate Zones 2,

4, and 6 through 15. However, a fenestration product with

an SHGC greater than 0.23 may be used with the prescriptive requirements if a

qualifying exterior shading device is used and the combined area-weighted average

complies with the prescriptive requirements. Exterior shading devices and

associated SHGC values are shown in Table 3-4. These include woven sunscreens as

well as perforated metal sunscreens. As shown in the table, these devices

transmit between 13 percent and 30 percent of the sun that strikes them.

Table 3-4: Exterior Shades and Solar Heat Gain Coefficients

|

Exterior Shading Device |

SHGC* |

|

Standard Bug (insect) Screen

(default for windows) |

0.76 |

|

Exterior Sunscreens With Weave

53 x 16/inch |

0.30 |

|

Louvered Sunscreens w/Louvers

as Wide as Window Openings |

0.27 |

|

Low-Sun-Angle Louvered

Sunscreen |

0.13 |

|

Vertical Roller Shades or

Retractable/Drop Arm/ Combination/Marquisolette and Operable Awnings |

0.13 |

|

Roll Down Blinds or

Slats |

0.13 |

|

None (for skylights

only) |

1.00 |

|

*

Reference glass values assume single-pane clear glass and metal framing

1/8-inch double-strength (DSS) glass. Use CF1R-ENV-03 worksheet for

calculation. |

When

exterior overhangs are used, the SHGC requirements of the prescriptive package

may be met if the calculated combination of the overhang and fenestration SHGC

efficiency is equal or lower than 0.23.

When

exterior overhangs are used, the SHGC requirements of the prescriptive package

may be met if the calculated combination of the overhang and fenestration SHGC

efficiency is equal or lower than 0.23.

For credit, exterior shading

devices must be permanently attached as opposed to being attached using clips,

hooks, latches, snaps, or ties. Exterior shading devices on windows or skylights

that are prohibited by life-safety codes from being permanently attached for

emergency egress reasons are exempt from this requirement.

|

|

Compliance document

CF1R-ENV-03 is used to calculate the combined SHGC of windows and exterior

shading devices. When exterior shades are required for compliance, they

must be listed on the CF1R and be documented on the

plans. |

The SHGC of the window in

combination with an exterior device is given by the following:

Equation 3-1

SHGCcombined = (0.2875 x SHGCmax + 0.75) x

SHGCmin

All operable windows and skylights

are assumed to have an insect screen as the default condition against which

other window and exterior shading device combinations are compared. The standard

case is a window with an SHGC of 0.23 and an insect screen with an SHGC of 0.76.

For this default case, the SHGC of the window is the SHGCmin, and the

SHGC of the exterior sunscreen is SHGCmax. Working through the math

on the CF1R-ENV-03 form, SHGCcombined is 0.23. This means that any

combination of window SHGC and exterior SHGC that results in a SHGCcombined

of 0.23 or less complies with the prescriptive requirements.

Most of the shading devices (other

than the default insect screen) have an SHGC of 0.30 or lower. Combining this

with the SHGC of any window may result in a combined SHGC that is equal to or

lower than the prescriptive criterion of 0.23. This method of combining the SHGC

of the window with the SHGC of the exterior shading device can also be used in

the whole-building performance approach.

3.3.6

Fenestration in the Performance Approach §150.1(b)

While the prescriptive

requirements and mandatory measures establish a minimum level of building energy

performance, opportunities to exceed the requirements of the Energy Standards are

considerable. More information is included in the Performance Compliance section

(Chapter 8).

|

|

Options that are recognized for

credit through the performance method are called compliance

options. Most require using the performance approach, but a few

exterior shading devices and south-facing overhangs may

be used to comply when using the prescriptive

approach. |

3.3.6.1 Fenestration Area

and Orientation

The performance approach includes

consideration of the fenestration area and orientation, which can have a big effect

on energy use. Compliance is determined by comparing the proposed fenestration

to the standard design fenestration.

For buildings with glazing areas less

than or equal to 20 percent of the conditioned floor area (CFA), the standard

design fenestration for new construction is modeled with the same glazing area as

the proposed home with one-quarter of the window area on the north, east,

south, and west orientations. For buildings with more than 20 percent of the

CFA, the standard design is limited to 20 percent glass area.

Because of the effects of

orientation and the fenestration product performance levels and other building features

like overhangs, judging the particular area, orientation, and performance level

is a compliance credit or penalty and can be difficult to determine without

performance approach calculations.

3.3.6.2 Improved

Fenestration Performance

The fenestration weighted average

U-factor in the

standard design for newly constructed buildings is 0.30 in all climate zones,

as indicated in the single-family and multifamily prescriptive packages.

Choosing high-performance fenestration that performs better than the

prescriptive requirements level can earn significant credit through the

performance method. For example, in air-conditioning climates, choosing a window with an SHGC

lower than 0.23 will reduce the cooling loads compared to the standard

design.

The magnitude of the effect will

vary by climate zone. In mild coastal climates, the benefit from reducing

fenestration U-factor will be smaller than in cold, mountain climates. Several

factors affect window performance. For fenestration with NFRC ratings, the following performance

features are accounted for in the U-factor and SHGC ratings:

1.

Frame materials, design, and configuration (including cross-sectional

characteristics). Fenestration can be framed in many materials. The most common

include wood, aluminum, vinyl, fiberglass, or composites of these materials.

Frames made of low-conductance materials like wood, vinyl, and fiberglass are

better insulators than metal. Some aluminum-framed units have thermal breaks

that reduce the conductive heat transfer through the framing element compared

with similar units having no such conductive thermal break.

2.

Number of panes of glazing, low-emissivity coatings, tints, fill gases, cavity

dimensions, and spacer construction. Windows compliant with the prescriptive

requirements are likely to have at least double-glazing with a low-emissivity

coating and argon gas fill with an improved spacer. The choice of low-emissivity

coating is particularly important as cooling climates will generally benefit

from a low SHGC coating, while heating climates may benefit from a high SHGC

coating. There are many ways to improve performance beyond the prescriptive

levels. Adding glazing layers such as triple glazing and low-emissivity coatings

such as those facing the conditioned space are two likely improvements.

3.

Dynamic glazing with appropriate controls may also offer opportunities for

improving performance.

3.3.6.3 Fixed Permanent

Shading Devices

Shading of windows is also an

important compliance option. Overhangs or sidefins that are attached to

the building or

shading from the building itself are compliance options for which credit is

offered through the performance approach. However, no credit is offered for

shading from trees, adjacent buildings, or terrain.

The ideal overhang is one that provides shade

during the months when the building is likely to be in cooling mode and allows

direct solar gains in the heating months. During the summer, the sun is high as

it passes over the south side, while in the winter it is low, enabling solar

radiation to pass beneath the overhang. Windows that face south can be

effectively shaded by overhangs positioned above the window. Due to the potential

effectiveness of south-facing overhangs, a prescriptive compliance option is

offered. See Section

3.3.5.2 for details.

Shading is more challenging on the

east and west sides of the house. When the sun strikes these façades, it is

fairly low in the sky, making overhangs ineffective. Vertical fins can be

effective, but they degrade the quality of the view from the window and limit

the natural light

that can enter. In cooling-dominated climates, the best approach is to minimize

windows that face east and west. Landscaping features can be considered to

increase comfort and energy performance of the building but cannot be used for

compliance credit.

3.3.6.4 Interior Shading

Devices

Figure 3-5:

Diagram of Integrated Shading System

Source: NFRC Dynamic Glazing Productes Fact

Sheet

There is no credit for interior aftermarket shading devices,

although they can be effective in reducing solar gains and should

be considered by homeowners. These added interior shades are

in the category of home furnishings and not a feature of the house that is

provided by the builder or fenestration manufacturer. Draperies, interior

blinds, interior shades, and other interior devices are not credited toward

energy compliance. A default standard bug screen is still considered in

performance calculations, so that estimates of energy use are more realistic and

tradeoffs against other measures are more equitable.

3.3.6.5 Dynamic Glazing

Dynamic glazing products are either integrated shading systems or

electrochromatic devices and are considered a fenestration

product.

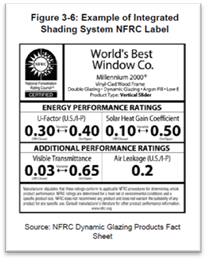

Integrated Shading Systems. These systems include

blinds positioned between glass panes that can be opened and closed using automatic

controls.

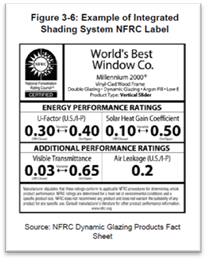

The labels for integrated shading

systems will reflect the endpoints of the product performance for U-factor and SHGC

(Figure 3-6). The unique rating “variable arrow” identifier helps consumers

understand the “dynamics” of the product and allows comparison with other

similar dynamic fenestration products.

If the

fenestration product can operate at intermediate states, a dual directional

arrow (↔) with the word “Variable” will appear on the label. Some dynamic

glazing is able to adjust to intermediate states, allowing for a performance

level between the endpoints.

In Figure 3-6, the low value

rating is displayed to the left (in the closed or darker position), and the high

value rating is displayed to the right (in the open or lighter position). This

lets the consumer know at a glance the best and worst case performance of the

product and the default performance level. To use the high-performance values

for integrated shading systems, the product must have an NFRC Certified Label sticker. Otherwise,

the default values from Tables

110.6-A and Table

110.6-B must be used.

Chromatic Glazing. One type

of dynamic glazing product uses a chromatic type of glass that has the ability

to change the performance properties, allowing occupants to control their

environment manually or automatically by tinting or darkening a glass with the

flip of a switch. Some fenestration products can change performance

automatically with the use of an automatic control or environmental signals.

These high-performance windows can reduce energy costs due to controlled

daylighting and unwanted heat gain or heat loss.

Figure 3-7: Chromatic Glazing

Source: Sage Electrochromics

A view of chromatic glazing in the open (off) and closed (on)

position is shown in Figure 3-7. Best-rated performance values may be used for

compliance with an NFRC Certified Label sticker and when automatic controls are

installed.

If the window includes either an NFRC label or

automatic controls, but not both, then default to Table 150.1-A

maximum U-factor of 0.30 and maximum SHGC of 0.23.

If neither an NFRC label nor

automatic controls are included, then the default values from Tables

110.6-A and 110.6-B

of the Energy Standards must be used.

3.3.6.6 Window Films

§150.1(b)

‘Window films are

polyester films that offer high clarity and can be pretreated to accept

different types of coatings. There are three basic categories of window

films:

Clear (nonreflective) films are used as security film

to reduce ultraviolet (UV) ‘light, which

contributes greatly to fading. They are not commonly used for solar control or

energy savings.

Tinted

or dyed (nonreflective) films reduce both heat and light transmission,

mostly through increased absorbance, and can be used in applications where the

desired primary benefit is glare control, with energy savings being

secondary.

Metalized

(reflective) film can be metalized through vacuum coating, sputtering, or

reactive deposition and may be clear or colored. Metalized films are preferred

for energy savings applications because they reduce transmission primarily

through reflectance and are manufactured to reflect heat more than visible light

through various combinations of metals.

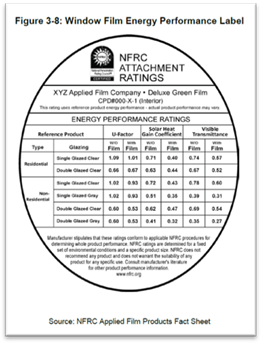

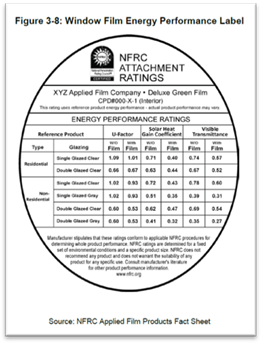

To receive window film compliance credit, the following must be met:

•

The performance approach must be used to meet energy compliance.

•

NFRC Window

Film Energy Performance Label (Figure 3-8) is required for each different film

applied. If there is no NFRC label, the default values from Tables 110.6-A and

Table

110.6-B of the Energy Standards must be used.

•

Window films must have at least a 15-year manufacturer warranty.

Figure 3-8 shows an example of a

NFRC Attachment Ratings Label, which helps identify the energy performance of

window films.

3.3.6.7 Bay Windows

§150.1(b)

Bay windows are a special

compliance case. Bay windows may have a unit NFRC rating (that is, the rating covers

both the window and

all opaque areas of the bay window), an NFRC rating for the window only, or no NFRC

rating. Nonrated bay windows may or may not have factory-installed insulation.

A.

NFRC Rated

For bay windows that come with an NFRC rating for the

entire unit, compliance is determined based on the rough opening area of the

entire unit, applying the NFRC U-factor and SHGC. If the unit U-factor and SHGC do not meet

the package requirements or area-weighted average, the project must show

compliance using the performance approach.

B.

Nonrated

Bay windows with no rating for the entire unit (where there

are multiple windows that make up the bay) and with factory-installed or

field-installed insulation must comply accounting for the performance

characteristics of each component separately.

•

Opaque portions of bay windows including roofs and floors must be

insulated to meet the wall insulation requirements for prescriptive compliance.

The opaque portion must either meet the minimum insulation requirements of the

prescriptive package for the applicable climate zone or be included in a

weighted average U-factor calculation of an overall opaque assembly that does

meet the prescriptive requirements.

•

For the windows, the U-factor and SHGC values may be determined either

from an NFRC rating or by using default values in Tables

110.6-A and 110.6-B

of the Energy Standards. If the window U-factor and SHGC meet the package

requirements, the bay window complies prescriptively (if overall building fenestration

area meets prescriptive compliance requirements).

•

If the bay window does not meet prescriptive requirements, the project

must show compliance using the performance approach.