Certification by Manufacturers. Any space-conditioning equipment listed in this section may be installed only if the manufacturer has certified to the Commission that the equipment complies with all the applicable requirements of this section

Exception 1 to Section 110.2(a):

Water-cooled centrifugal water-chilling packages that are not designed for operation at ANSI/AHRI Standard 550/590 test conditions of 44°F leaving chilled water temperature and 85°F entering condenser water temperature with 3 gallons per minute per ton condenser water flow shall have a maximum full load kW/ton and NPLV ratings adjusted using the following equation:

Adjusted maximum full-load kW/ton rating = (full-load kW/ton from Table 110.2-D)/Kadj

Adjusted maximum NPLV rating = (IPLV from Table 110.2-D)/Kadj

Where:

Kadj = (A) × (B)

A = 0.00000014592 × (LIFT)4 – 0.0000346496 × (LIFT)3+0.00314196 × (LIFT)2 – 0.147199 × (LIFT) + 3.9302

LIFT = LvgCond – LvgEvap (°F)

LvgCond = Full-load leaving condenser fluid temperature (°F)

LvgEvap = Full-load leaving evaporator fluid temperature (°F)

B = (0.0015 × LvgEvap) + 0.934

The adjusted full-load and NPLV values are only applicable for centrifugal chillers meeting all of the following full-load design ranges:

• Minimum Leaving Evaporator Fluid Temperature: 36°F

• Maximum Leaving Condenser Fluid Temperature: 115°F

• LIFT ≥ 20°F and ≤ 80°F

Centrifugal chillers designed to operate outside of these ranges are not covered by this exception.

A. Defrost; and

B. Transient periods such as start-ups and following room thermostat setpoint advance, if the controls provide preferential rate control, intelligent recovery, staging, ramping or another control mechanism designed to preclude the unnecessary operation of supplementary heating.

The maximum achievable cycles of concentrations are based on the local water supply quality as reported by the local water supplier, and shall be the minimum of:

A. 2970 divided by the conductivity of the entering make-up water

B. 1845 divided by the total dissolved solids of the entering make-up water

C. 540 divided by the M-alkalinity excluding galvanized steel of the entering make-up water

D. 450 divided by the M-alkalinity including galvanized steel of the entering make-up water

E. 540 divided by the calcium hardness of the entering make-up water

F. 270 divided by the chlorides of the entering make-up water

G. 225 divided by the sulfates of the entering make-up water

H. 135 divided by the silica of the entering make-up water

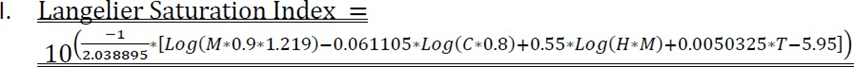

Where:

C = Conductivity of the entering make-up water.

H = Calcium hardness of the entering make-up water.

M = M-alkalinity excluding galvanized steel of the entering make-up water.

T = Max skin temperature

| Recirculating Water Parameters | Maximum Values |

| Conductivity (micro-siemens/cm) | 2,970 micro-siemens/cm |

| Total dissolved solids (ppm) | 1,845 ppm |

| Total alkalinity as CaCO3 (ppm) excluding galvanized steel | 540 ppm |

| Total alkalinity as CaCO3 (ppm) galvanized steel (passivated) | 450 ppm |

| Calcium hardness as CaCO3 (ppm) | 540 ppm |

| Chlorides as Cl (ppm) | 270 ppm |

| Sulfates (ppm) | 225 ppm |

| Silica (ppm) | 135 ppm |

| Langelier saturation index (LSI) | 2.5 (LSI) |

4. Be equipped with a flow meter with an analog output for flow either hardwired or available through a gateway on the makeup water line.

5. Be equipped with an overflow alarm to prevent overflow of the sump in case of makeup water valve failure. Overflow alarm shall send an audible signal or provide an alert via the energy management control system to the tower operator in case of sump overflow.

7. Conductivity controls and overflow alarm shall be verified according to NA 7.5.18.

| Equipment Type | Size Category | Efficiency | Test Procedure |

| Air conditioners, air cooled both split system and single package | ≥ 65,000 Btu/h and < 135,000 Btu/h | 11.2 EERa Federal Minimum IEERa |

AHRI 340/360 |

| Air conditioners, air cooled both split system and single package | ≥ 135,000 Btu/h and < 240,000 Btu/h | 11.0 EERa Federal Minimum IEERa |

AHRI 340/360 |

| Air conditioners, air cooled both split system and single package | ≥ 240,000 Btu/h and < 760,000 Btu/h | 10.0 EERa Federal Minimum IEERa |

AHRI 340/360 |

| Air conditioners, air cooled both split system and single package | ≥ 760,000 Btu/h | 9.7 EERa 12.5 IEERa |

AHRI 340/360 |

| Air conditioners, water cooled | ≥ 65,000 Btu/h and < 135,000 Btu/h | Federal Minimum EERa 13.9 IEERa |

AHRI 340/360 |

| Air conditioners, water cooled | ≥135,000 Btu/h and < 240,000 Btu/h | Federal Minimum EERa 13.9 IEERa |

AHRI 340/360 |

| Air conditioners, water cooled | ≥240,000 Btu/h and < 760,000 Btu/h | Federal Minimum EERa 13.6 IEERa |

AHRI 340/360 |

(CONTINUED) TABLE 110.2-A AIR CONDITIONERS AND CONDENSING UNITS - MINIMUM EFFICIENCY REQUIREMENTS

| Equipment Type | Size Category | Efficiency | Test Procedure |

| Air conditioners, water cooled | ≥ 760,000 Btu/h | 12.2EERa

13.5 IEERa |

AHRI 340/360 |

| Air conditioners, evaporatively cooled | ≥65,000 Btu/h and

<135,000 Btu/h |

Federal

Minimum EERa 12.3 IEERa |

AHRI 340/360 |

| Air conditioners, evaporatively cooled | ≥ 135,000 Btu/h

and < 240,000 Btu/h |

Federal

Minimum EERa 12.2 IEERa |

AHRI 340/360 |

| Air conditioners, evaporatively cooled | ≥240,000 Btu/h

and < 760,000 Btu/h |

Federal

Minimum EERa 12.1 IEERa |

AHRI 340/360 |

| Air conditioners, evaporatively cooled | ≥ 760,000 Btu/h | 11.7 EERa

11.9 IEERa |

AHRI 340/360 |

| Condensing units, air cooled | ≥ 135,000 Btu/h | 10.5 EER

Federal Minimum IEER |

AHRI 365 |

| Condensing units, water cooled | ≥ 135,000 Btu/h | 13.5 EER

Federal Minimum IEER |

AHRI 365 |

| Condensing units, evaporatively cooled | ≥ 135,000 Btu/h | 13.5 EER

Federal Minimum IEER |

AHRI 365 |

a Deduct 0.2 from the required EERs and IEERs for units with a heating section other than electric resistance heat.

b Applicable test procedure and reference year are provided under the definitions.

| Equipment Type | Size Category | Rating Condition | Efficiency* | Test Procedure* |

| Air Cooled (Cooling Mode), both split system and single package | ≥ 65,000 Btu/h and < 135,000 Btu/h | 11.0 EER Federal Minimum IEER |

AHRI 340/360 Federal Minimum IEER | |

| Air Cooled (Cooling Mode), both split system and single package | ≥ 135,000 Btu/h and < 240,000 Btu/h | 10.6 EER Federal Minimum IEER | AHRI 340/360 Federal Minimum IEER | |

| Air Cooled (Cooling Mode), both split system and single package | ≥ 240,000 Btu/h | 9.5 EER Federal Minimum IEER | AHRI 340/360 Federal Minimum IEER | |

| Water source (cooling mode) | ≥ 65,000 Btu/h and < 135,000 Btu/h | 86°F entering water | Federal Minimum EER | ISO-13256-1 |

| Groundwater source (cooling mode) | ≥ 135,000 Btu/h | 59°F entering water | 18.0 EER | ISO-13256-1 |

| Ground source (cooling mode) | ≥ 135,000 Btu/h | 77°F entering water | 14.1 EER | ISO-13256-1 |

| Water source

water-to-water (cooling mode) |

≥ 135,000 Btu/h | 86°F entering water | 10.6 EER | ISO-13256-2 |

| Groundwater source water-to-water (cooling mode) | ≥ 135,000 Btu/h | 59°F entering water | 16.3 EER | ISO-13256-2 |

| Ground source brine-to-water (cooling mode) | ≥ 135,000 Btu/h | 77°F entering water | 12.1 EER | ISO-13256-2 |

| Air Cooled (Heating Mode) Split system and single package | ≥ 65,000 Btu/h and < 135,000 Btu/h (cooling capacity) | 47° F db/43° F wb outdoor air | Federal Minimum COP | AHRI 340/360 |

(CONTINUED) TABLE 110.2-B HEAT PUMPS, MINIMUM EFFICIENCY REQUIREMENTS

| Equipment Type | Size Category | Rating Condition | Efficiencya | Test Procedureb |

| Air Cooled (Heating Mode) Split system and single package | ≥ 65,000 Btu/h and < 135,000 Btu/h (cooling capacity) | 17° F db/15° F wb outdoor air | 2.25 COP | AHRI 340/360 |

| Air Cooled (Heating Mode) Split system and single package | ≥ 135,000 Btu/h and < 240,000 Btu/h (cooling capacity) | 47° F db/43° F wb outdoor air | Federal Minimum COP | AHRI 340/360 |

| Air Cooled (Heating Mode) Split system and single package | ≥ 240,000 Btu/h and < 760,000 Btu/h | 47° F db/43° F wb outdoor air | Federal Minimum COP | AHRI 340/360 |

| Air Cooled (Heating Mode) Split system and single package | ≥ 135,000 Btu/h (cooling capacity) | 17° F db/15° F wb outdoor air | 2.05 COP | AHRI 340/360 |

| Water source (heating mode) | < 135,000 Btu/h (cooling capacity) | 68°F entering water | Federal Minimum COP | ISO-13256-1 |

| Water source (heating mode) | ≥ 135,000 Btu/h and < 240,000 Btu/h | 68°F entering water | Federal Minimum COP | ISO-13256-1 |

| Groundwater source (heating mode) | < 135,000 Btu/h (cooling capacity) | 50°F entering water | 3.7 COP | ISO-13256-1 |

| Ground source (heating mode) | < 135,000 Btu/h (cooling capacity) | 32°F entering water | 3.2 COP | ISO-13256-1 |

| Water source water-to-water (heating mode) | < 135,000 Btu/h (cooling capacity) | 68°F entering water | 3.7 COP | ISO-13256-2 |

| Groundwater source water-to-water (heating mode) | < 135,000 Btu/h (cooling capacity) | 50°F entering water | 3.1 COP | ISO-13256-2 |

| Ground source brine-to-water (heating mode) | < 135,000 Btu/h (cooling capacity) | 32°F entering water | 2.5 COP | ISO-13256-2 |

a Deduct 0.2 from the required EERs and IEERs for units with a heating section other than electric resistance heat.

b Applicable test procedure and reference year are provided under the definitions.

| Equipment Type | Size Category | Subcategory or Rating Condition | Efficiency | Test Procedurea |

| Air-Cooled Gas-Engine Heat Pump (Cooling Mode) |

All Capacities | 95°F db Outdoor Air | 0.60 COP | ANSI Z21.40.4A |

| Air-Cooled Gas-Engine Heat Pump (Heating Mode) |

All Capacities | 47°F db/43°F wb Outdoor Air | 0.72 COP | ANSI Z21.40.4A |

a Applicable test procedure and reference year are provided under the definitions.

TABLE 110.2-D WATER CHILLING PACKAGES – MINIMUM EFFICIENCY REQUIREMENTS

| Equipment Type | Size Category | Path A Efficiency a,b | Path B Efficiency a,b | Test Procedure c |

| Air Cooled, With Condenser Electrically Operated | <150 Tons | ≥10.100 EER

≥ 13.700 IPLV |

≥9.700 EER

≥ 15,800 IPLV |

AHRI 550/590 |

| Air Cooled, With Condenser Electrically Operated | ≥150 Tons | ≥10.100 EER

≥14.000 IPLV |

≥9.700 EER

≥16.100 IPLV |

AHRI 550/590 |

| Air Cooled, Without Condenser Electrically Operated | All Capacities | Air-cooled chillers without condensers must be rated with matching condensers and comply with the air-cooled chiller efficiency requirements. | Air-cooled chillers without condensers must be rated with matching condensers and comply with the air-cooled chiller efficiency requirements. | AHRI 550/590 |

| Water Cooled, Electrically Operated, Reciprocating | All Capacities | Reciprocating units must comply with the water-cooled positive displacement efficiency requirements. | Reciprocating units must comply with the water-cooled positive displacement efficiency requirements. | AHRI 550/590 |

| Water Cooled, Electrically Operated Positive Displacement | <75 Tons | ≤0.750kW/ton

≤0.600 IPLV |

≤0.780 kW/ton

≤0.500 IPLV |

AHRI 550/590 |

| Water Cooled, Electrically Operated Positive Displacement | ≥75 tons and

<150 tons |

≤0.720 kW/ton

≤0.560 IPLV |

≤0.750 kW/ton

≤0.490 IPLV |

AHRI 550/590 |

| Water Cooled, Electrically Operated Positive Displacement | ≥150 tons and

<300 tons |

≤0.660 kW/ton

≤0.540 IPLV |

≤0.680 kW/ton

≤0.440 IPLV |

AHRI 550/590 |

| Water Cooled, Electrically Operated Positive Displacement | ≥300 Tons

and <600 tons |

≤0.610kW/ton

≤0.520 IPLV |

≤0.625 kW/ton

≤0.410 IPLV |

AHRI 550/590 |

| Water Cooled, Electrically Operated Positive Displacement | ≥600 Tons | ≤0.560 kW/ton

≤0.500 IPLV |

≤0.585 kW/ton

≤0.380 IPLV |

AHRI 550/590 |

CONTINUED: TABLE 110.2-D WATER CHILLING PACKAGES – MINIMUM EFFICIENCY REQUIREMENTS

|

Equipment Type |

Size Category |

Path A Efficiency a,b |

Path B Efficiency a,b |

Test Procedure c |

|

Water Cooled, Electrically Operated, Centrifugal |

< 150 Tons |

≤ 0.610 kW/ton ≤ 0.550IPLV |

≤ 0.695 kW/ton ≤ 0.440 IPLV |

AHRI 550/590 |

Water Cooled, Electrically Operated, Centrifugal |

≥ 150 tons and < 300 tons |

≤ 0.610 kW/ton ≤ 0.550 IPLV |

≤ 0.635 kW/ton ≤ 0.400 IPLV |

AHRI 550/590 |

Water Cooled, Electrically Operated, Centrifugal |

≥ 300 tons and < 400 tons |

≤ 0.560 kW/ton ≤ 0.520 IPLV |

≤ 0.595 kW/ton ≤ 0.390 IPLV |

AHRI 550/590 |

Water Cooled, Electrically Operated, Centrifugal |

≥ 400 tons and < 600 tons |

≤ 0.560 kW/ton ≤ 0.500 IPLV |

≤ 0.585 kW/ton ≤ 0.380 IPLV |

AHRI 550/590 |

Water Cooled, Electrically Operated, Centrifugal |

≥ 600 tons |

≤ 0.560 kW/ton ≤ 0.500 IPLV |

≤ 0.585 kW/ton ≤ 0.380 IPLV |

AHRI 550/590 |

|

Air Cooled Absorption, Single Effect |

All Capacities |

≥0.600 COP |

N.A. d |

AHRI 560 |

|

Water Cooled Absorption, Single Effect |

All Capacities |

≥ 0.700 COP |

N.A. d |

AHRI 560 |

|

Absorption Double Effect, Indirect-Fired |

All Capacities |

≥ 1.000 COP ≥ 1.050 IPLV |

N.A. d |

AHRI 560 |

|

Absorption Double Effect, Direct-Fired |

All Capacities |

≥ 1.000 COP ≥1.000 IPLV |

N.A. d |

AHRI 560 |

|

Water Cooled Gas Engine Driven Chiller |

All Capacities |

≥ 1.2 COP ≥ 2.0 IPLV |

N.A. d |

ANSI Z21.40.4A |

a No requirements for:

- Centrifugal chillers with design leaving evaporator temperature < 36°F; or

- Positive displacement chillers with design leaving fluid temperature ≤ 32°F; or

- Absorption chillers with design leaving fluid temperature < 40°F.

b Must meet the minimum requirements of Path A or Path B. However, both the full load (COP) and IPLV must be met to fulfill the requirements of the applicable Path.

c See Section 100.1 for definitions.

d N.A. means not applicable.

| Equipment Type | Total System Heat Rejection Capacity at Rated Conditions | Subcategory or Rating Condition | Performance Requireda, b, c, d | Test Proceduree |

| Propeller or axial fan Open-circuit cooling towers

|

All

|

95°F entering water

85°F leaving water 75°F entering air wb |

≥ 42.1 gpm/hp

|

CTI ATC-105 and CTI STD-201 RS |

| Centrifugal fan Open-circuit cooling towers

|

All

|

95°F entering water 85°F leaving water 75°F entering air wb |

≥ 20.0 gpm/hp

|

CTI ATC-105 and CTI STD-201 RS |

| Propeller or axial fan closed-circuit cooling towers | All | 102°F entering water

90°F leaving water 75°F entering air wb |

≥ 16.1 gpm/hp | CTI ATC-105S

and CTI STD-201 RS |

| Centrifugal fan closed-circuit cooling towers | All | 102°F entering water

90°F leaving water 75°F entering air wb |

≥ 7.0 gpm/hp | CTI ATC-105S

and CTI STD-201 RS |

| Propeller or axial fan evaporative condensers | All | R-448A test fluid

165°F entering gas temp 105°F condensing temp 75°F entering air wb |

≥ 157,000

Btu/h • hp |

CTI ATC-106 |

| Propeller or axial fan evaporative condensers | All | Ammonia test fluid

140°F entering gas temp 96.3°F condensing temp 75°F entering air wb |

≥ 134,000

Btu/h • hp |

CTI ATC-106 |

| Centrifugal fan evaporative condensers | All | R-448A test fluid

165°F entering gas temp 105°F condensing temp 75°F entering air wb |

≥ 135,000

Btu/h • hp |

CTI ATC-106 |

(CONTINUED) TABLE 110.2-E PERFORMANCE REQUIREMENTS FOR HEAT REJECTION EQUIPMENT

| Equipment Type | Total System Heat Rejection Capacity at Rated Conditions | Subcategory or Rating Condition | Performance Requireda, b, c, d | Test Proceduree |

| Centrifugal fan evaporative condensers | All | Ammonia test fluid

140°F entering gas temp 96.3°F condensing temp 75°F entering air wb |

≥ 110,000

Btu/h · hp |

CTI ATC-106 |

| Air cooled condensers | All | 125°F condensing temperature

190°F entering gas temperature 15°F subcooling 95°F entering drybulb |

≥ 176,000 Btu/h · hp | AHRI 460 |

| Propeller or axial fan dry coolers (air-cooled fluid coolers) | All | 115°F entering water

105°F leaving water 95°F entering air db |

> 4.5 gpm/hp | CTI ATC-105DS |

a For purposes of this table, open-circuit cooling tower performance is defined as the water flow rating of the tower at the given rated conditions divided by the fan motor nameplate power.

b For purposes of this table, closed-circuit cooling tower performance is defined as the process water flow rating of the tower at the given rated conditions divided by the sum of the fan motor nameplate rated power and the integral spray pump motor nameplate power.

c For purposes of this table dry cooler performance is defined as the process water flow rating of the unit at the given thermal rating condition divided by the total fan motor nameplate power of the unit and air-cooled condenser performance is defined as the heat rejected from the refrigerant divided by the fan motor nameplate power of the unit.

d Open cooling towers shall be tested using the test procedures in CTI ATC-105. Performance of factory assembled open cooling towers shall be either certified as base models as specified in CTI STD-201 or verified by testing in the field by a CTI approved testing agency. Open factory assembled cooling towers with custom options added to a CTI certified base model for the purpose of safe maintenance or to reduce environmental or noise impact shall be rated at 90 percent of the CTI certified performance of the associated base model or at the manufacturer’s stated performance, whichever is less. Base models of open factory assembled cooling towers are open cooling towers configured in exact accordance with the Data of Record submitted to CTI as specified by CTI STD-201. There are no certification requirements for field erected cooling towers.

e Applicable test procedure and reference year are provided under the definitions. For refrigerated warehouses or commercial refrigeration applications, condensers shall comply with requirements specified by Section 120.6(a) or Section 120.6(b).

| Equipment Type | Size Category | Heating Section Type | Sub-Category or Rating Condition | Minimum Efficiency | Test Procedurea |

| VRF Air Conditioners, Air Cooled | <65,000 Btu/h | All | VRF Multi-split System | 13.0 SEER Before 1/1/2023 Federal Minimum SEER2 On or After 1/1/2023 | AHRI 1230 Before 1/1/2023 AHRI 210/240 On or After 1/1/2023 |

| VRF Air Conditioners, Air Cooled | ≥65,000 Btu/h and <135,000 Btu/h | Electric Resistance (or none) | VRF Multi-split System | 10.5 EER Federal Minimum IEERb | AHRI 1230 |

| VRF Air Conditioners, Air Cooled | ≥135,000 Btu/h and <240,000 Btu/h | Electric Resistance (or none) | VRF Multi-split System | 10.3 EER Federal Minimum IEERb | AHRI 1230 |

| VRF Air Conditioners, Air Cooled | ≥240,000 Btu/h | Electric Resistance (or none) | VRF Multi-split System | 9.5 EER Federal Minimum IEERb | AHRI 1230 |

a Applicable test procedure and reference year are provided under the definitions.

b IEERs are only applicable to equipment with capacity control as specified by AHRI 1230 test procedures.

| Equipment Type | Size Category | Heating Section Type | Sub-Category or Rating Condition | Minimum Efficiency | Test Procedureb |

| VRF Air Cooled, (cooling mode) | <65,000 Btu/h | All | VRF Multi-split System | 13.0 SEER Before 1/1/2023

Federal Minimum = SEER2 On or after 1/1/2023 |

AHRI 1230 Before 1/1/2023

AHRI 210/240 On or After 1/1/2023 |

| VRF Air Cooled, (cooling mode) | ≥65,000 Btu/h and <135,000 Btu/h | Electric Resistance (or none) | VRF Multi-split Systema | 10.3 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Air Cooled, (cooling mode) | ≥135,000 Btu/h and <240,000 Btu/h | Electric Resistance (or none) | VRF Multi-split Systema | 9.9 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Air Cooled, (cooling mode) | ≥240,000 Btu/h | Electric Resistance (or none) | VRF Multi-split Systema | 9.1 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Water source (cooling mode) | <65,000 Btu/h | All | VRF Multi-split Systema

86°F entering water |

12.0 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Water source (cooling mode) | ≥65,000 Btu/h and <135,000 Btu/h | All | VRF Multi-split Systema

86°F entering water |

12.0 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Water source (cooling mode) | ≥135,000 Btu/h and < 240,000 | All | VRF Multi-split Systema

86°F entering water |

10.0 EER

Federal Minimum IEER |

AHRI 1230 |

| VRF Water source (cooling mode) | ≥ 240,000 Btu/h | All | VRF Multi-split Systema 86°F entering water | 10.0 EER

Federal Minimum IEER |

AHRI 1230 |

TABLE 110.2-G Electrically Operated Variable Refrigerant Flow (VRF) Air Conditioners Minimum Efficiency Requirements (CONTINUED)

| Equipment Type | Size Category | Heating Section Type | Sub-Category or Rating Condition | Minimum Efficiency | Test Procedureb |

| VRF Groundwater source (cooling mode) | <135,000 Btu/h | All | VRF Multi-split Systema 59°F entering water |

16.2 EER | AHRI 1230 |

| VRF Groundwater source (cooling mode) | ≥135,000 Btu/h | All | VRF Multi-split Systema 59°F entering water |

13.8 EER | AHRI 1230 |

| VRF Ground source (cooling mode) | <135,000 Btu/h | All | VRF Multi-split Systema 77°F entering water |

13.4 EER | AHRI 1230 |

| VRF Ground source (cooling mode) | ≥135,000 Btu/h | All | VRF Multi-split System a

77°F entering water |

11.0 EER | AHRI 1230 |

| VRF Air Cooled (heating mode) | <65,000 Btu/h

(cooling capacity) |

--- | VRF Multi-split System | 7.7 HSPF Before 1/1/2025

7.5 HSPF2 On or after 1/1/2025 |

AHRI 1230 Before 1/1/2025

AHRI 210/240 On or After 1/1/2025 |

| VRF Air Cooled (heating mode) | ≥65,000 Btu/h

and <135,000 Btu/h (cooling capacity) |

--- | VRF Multi-split system

47°F db/ 43°F wb outdoor air |

Federal Minimum COP | AHRI 1230 |

| VRF Air Cooled (heating mode) | ≥65,000 Btu/h

and <135,000 Btu/h (cooling capacity) |

--- | VRF Multi-split system

17°F db/ 15°F wb outdoor air |

2.25 COP | AHRI 1230 |

CONTINUED: TABLE 110.2-G Electrically Operated Variable Refrigerant Flow Air-to-Air and Applied Heat Pumps - Minimum Efficiency Requirements

|

Equipment Type |

Size Category |

Heating Section Type |

Sub-Category or Rating Condition |

Minimum Efficiency |

Test Procedure b |

|

VRF Air Cooled (heating mode) |

≥135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split system 17ºF db/15ºF wb outdoor air |

2.05 COP |

AHRI 1230 |

|

VRF Water source (heating mode) |

< 65,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 68oF entering water |

Federal Minimum COP |

AHRI 1230 |

|

VRF Water source (heating mode) |

≥65,000 Btu/h and <135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 68ºF entering water |

Federal Minimum COP |

AHRI 1230 |

|

VRF Water source (heating mode) |

≥135,000 Btu/h and < 240,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 68ºF entering water |

Federal Minimum COP |

AHRI 1230 |

|

VRF Water source (heating mode) |

≥ 240,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 68oF entering water |

Federal Minimum COP |

AHRI 1230 |

|

VRF Groundwater source (heating mode) |

<135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 50ºF entering water |

3.6 COP |

AHRI 1230 |

|

VRF Groundwater source (heating mode) |

≥135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 50ºF entering water |

3.3 COP |

AHRI 1230 |

|

VRF Ground source (heating mode) |

<135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 32ºF entering water |

3.1 COP |

AHRI 1230 |

|

VRF Ground source (heating mode) |

≥135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-split System 32ºF entering water |

2.8 COP |

AHRI 1230 |

a. Deduct 0.2 from the required EERs and IEERs for Variable Refrigerant Flow (VRF) Multi-split system units with a heating recovery section.

b. Applicable test procedure and reference year are provided under the definitions.

c. IEERs are only applicable to equipment with capacity control as specified by AHRI 1230 test procedures.

| Equipment Type | Energy Recovery | Subcategory or Rating Condition | Minimum Efficiency | Test Procedurea |

| Air cooled (dehumidification mode) | Without energy recovery | NA | 3.8 ISMRE2 | AHRI 920 |

| Air source heat pumps (dehumidification mode) | Without energy recovery | NA | 3.8 ISMRE2 | AHRI 920 |

| Water cooled (dehumidification mode) | Without energy recovery | Cooling Tower Condenser Water | 4.7 ISMRE2 | AHRI 920 |

| Water source heat pump (dehumidification mode) | Without energy recovery | Ground source, closed and open loop | 4.6 ISMRE2 | AHRI 920 |

| Water source heat pump (dehumidification mode) | Without energy recovery | Water source | 3.8 ISMRE2 | AHRI 920 |

| Air source heat pumps (heating mode) | Without energy recovery | NA | 2.05 ISCOP2 | AHRI 920 |

| Water source heat pump (heating mode) | Without energy recovery | Ground source, closed and open loop | 2.13 ISCOP2 | AHRI 920 |

| Water source heat pump (heating mode) | Without energy recovery | Water source | 2.13 ISCOP2 | AHRI 920 |

| Air cooled (dehumidification mode) | With energy recovery | NA | 5.0 ISMRE2 | AHRI 920 |

| Air source heat pumps (dehumidification mode) | With energy recovery | NA | 5.0 ISMRE2 | AHRI 920 |

CONTINUED: TABLE 110.2-H DX-DOAS Units, Single-Package and Remote Condenser – Minimum Efficiency Requirements

| Equipment Type | Energy Recovery | Subcategory or Rating Condition | Minimum Efficiency | Test Procedurea |

| Water cooled (dehumidification mode) | With energy recovery | Cooling tower condenser water | 5.1 ISMRE2 | AHRI 920 |

| Water source heat pump (dehumidification mode) | With energy recovery | Ground source, closed and open loop | 5.0 ISMRE2 | AHRI 920 |

| Water source heat pump (dehumidification mode) | With energy recovery | Water source | 4.6 ISMRE2 | AHRI 920 |

| Air source heat pumps (heating mode) | With energy recovery | 3.2 ISCOP2 | AHRI 920 | |

| Water source heat pump (heating mode) | With energy recovery | Ground source, closed and open loop | 3.5 ISCOP2 | AHRI 920 |

| Water source heat pump (heating mode) | With energy recovery | Water source | 4.04 ISCOP2 | AHRI 920 |

a Applicable test procedure and reference year are provided under the definitions.

| Equipment Type | Size Category Refrigerating Capacitya, tonR | Cooling Operation Efficiencyb,c,d, e, Air Source EER (FL/IPLV), Btu/W h, Liquid Source Power Input per Capacity (FL/IPLV), kW/tonR |

Cooling Operation Efficiencyb,c,d, e Air Source EER (FL/IPLV), Btu/W h, Liquid Source Power Input per

|

Test Procedure |

| Air Source | < 150 | > 5.595 FL

> 13.02 IPLV.IP |

> 9.215 FL

> 15.01 IPLV.IP |

AHRI/550/590 |

| Air Source | > 150 | > 5.595 FL

> 13.30 IPLV.IP |

> 9.215 FL

> 15.30 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated positive displacement | > 11.25f and < 150 | < 0.7895 FL

< 0.6316 IPLV.IP |

< 0.8211 FL

< 0.5263 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated positive displacement | > 150 and < 300 | < 0.7579 FL

< 0.5895 IPLV.IP |

< 0.7895 FL

< 0.5158 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated positive displacement | > 300 and < 400 | < 0.6947 FL

< 0.5684 IPLV.IP |

< 0.7158 FL

< 0.4632 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated positive displacement | > 400 and < 600 | < 0.6421 FL

< 0.5474 IPLV.IP |

< 0.6579 FL

< 0.4316 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated positive displacement | > 600 | < 0.5895 FL

< 0.5263 IPLV.IP |

< 0.6158 FL

< 0.4000 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated centrifugal | > 11.25f and < 150 | < 0.6421 FL

< 0.5789 IPLV.IP |

< 0.7316 FL

< 0.4632 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated centrifugal | > 150 and < 300 | < 0.6190 FL

< 0.5748 IPLV.IP |

< 0.6684 FL

< 0.4211 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated centrifugal | > 300 and < 400 | < 0.5895 FL

< 0.5526 IPLV.IP |

< 0.6263 FL

< 0.4105 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated centrifugal | > 400 and < 600 | < 0.5895 FL

< 0.5263 IPLV.IP |

< 0.6158 FL

< 0.4000 IPLV.IP |

AHRI/550/590 |

| Liquid source electrically operated centrifugal | > 600 | < 0.5895 FL

< 0.5263 IPLV.IP |

< 0.6158 FL

< 0.4000 IPLV.IP |

AHRI/550/590 |

a. The size category is the full-load net refrigeration cooling mode capacity, which is the capacity of the evaporator available for cooling of the thermal load external to the chilling package.

b. Cooling rating conditions are standard rating conditions defined in AHRI 550/590 (I-P), Table 4, except for liquid cooled centrifugal chilling packages which can adjust cooling efficiency for nonstandard rating conditions using Kadj procedure in accordance with Section 110.2(a).

c. For cooling operation, compliance with both the FL and IPLV is required, but only compliance with Path A or Path B cooling efficiency is required.

d. For units that operate in both cooling and heating, compliance with both the cooling and heating efficiency is required.

e. For heat recovery heating chilling package applications where there is simultaneous cooling and heating, compliance with the heating performance heat recover COPHR is only required at one of the four heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, Hot-Water 1 or Hot-Water 2. Compliance with the cooling only performance is required as defined in footnotes b and c.

f. Water to water heat pumps with capacity less than 135,000 Btu/h are included in Table 110.2-B Heat Pumps, Minimum Efficiency Requirements.

Equipment Type: Air Source

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F |

Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F |

Test Procedure |

| < 150 | 47 db

43 wb |

> 3.29 | > 2.77 | > 2.31 | N/A | AHRI 550/590 |

| < 150

|

17 db

15 wb |

> 2.029 | > 1.775 | > 1.483 | N/A | AHRI 550/590 |

| > 150 | 47 db

43 wb |

> 3.29 | > 2.77 | > 2.31 | N/A | AHRI 550/590 |

| > 150 | 17 db

15 wb |

> 2.029 | > 1.775 | > 1.483 | N/A | AHRI 550/590 |

(CONTINUED) TABLE 110.2-J Heat Pump and Heat Recovery Chiller Packages, Heat Pump, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated positive displacement

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F | Test Procedure |

| 11.25h and < 150 | 44i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| 11.25h and < 150

|

65i | NAj | NAj | NAj | > 3.55 | AHRI 550/590 |

| > 150 and < 300 | 44i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| > 150 and < 300 | 65i | NAj | NAj | NAj | > 3.55 | AHRI 550/590 |

| > 300 and < 400 | 44i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| > 300 and < 400 | 65i | NAg | NAg | NAg | > 3.55 | AHRI 550/590 |

| > 400 and < 600 | 44i | > 4.93 | > 3.96 | > 2.97 | NAj | AHRI 550/590 |

| > 400 and < 600 | 65i | NAj | NAj | NAj | > 3.9 | AHRI 550/590 |

| > 600 | 44i | > 4.93 | > 3.96 | > 2.97 | NAj | AHRI 550/590 |

| > 600 | 65i | NAj | NAj | NAj | > 3.9 | AHRI 550/590 |

(CONTINUED) TABLE 110.2-J Heat Pump and Heat Recovery Chiller Packages, Heat Pump, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated centrifugal

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F |

Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F |

Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F |

Heat Pump Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F |

Test Procedure |

| > 11.25h and < 150

|

44 i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| > 11.25h and < 150 | 44i | NAj | NAj | NAj | > 3.55 | AHRI 550/590 |

| > 150 and < 300 | 44i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| > 150 and < 300 | 65i | NAj | NAj | NAj | > 3.55 | AHRI 550/590 |

| > 300 and < 400 | 44i | > 4.64 | > 3.68 | > 2.68 | NAj | AHRI 550/590 |

| > 300 and < 400 | 65i | NAg | NAg | NAg | > 3.55 | AHRI 550/590 |

| > 400 and < 600 | 44i | > 4.93 | > 3.96 | > 2.97 | NAj | AHRI 550/590 |

| > 400 and < 600 | 65i | NAj | NAj | NAj | > 3.9 | AHRI 550/590 |

| > 600 | 44i | > 4.93 | > 3.96 | > 2.97 | NAj | AHRI 550/590 |

| > 600 | 65i | NAj | NAj | NAj | > 3.9 | AHRI 550/590 |

a. The size category is the full-load net refrigeration cooling mode capacity, which is the capacity of the evaporator available for cooling of the thermal load external to the chilling package.

b. For air source heat pumps, compliance with both the 47 F and 17 F heating source outdoor air temperature (OAT) rating efficiency is required for heating.

c. Heating full load rating conditions are at standard rating conditions defined in AHRI 550/590 (I-P), Table 4, includes the impact of defrost for air source heating ratings.

d. For units that operate in both cooling and heating, compliance with both the cooling and heating efficiency is required.

e. For heat recovery heating chilling package applications where there is simultaneous cooling and heating, compliance with the heating performance heat recover COPHR is only required at one of the four heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, Hot-Water 1 or Hot-Water 2. Compliance with the cooling only performance is required as defined in footnotes b and c of Table 110.2-I.

f. For applications where the chilling package is installed to operate only in heating, compliance only with the heating performance COPH is required at only one of the heating AHRI 550/590 (I-P) standard rating conditions of Low, Medium, High, or Boost. Compliance with cooling performance is not required.

g. For heat pump chilling package applications where the cooling capacity is not being used for conditioning, compliance with the heating performance COPH is only required at one of the heating AHRI 550/590 (I-P) standard rating conditions of Low, Medium, High, or Boost. Compliance with the cooling performance is required as defined in footnotes b and c of Table 110.2-I, except as noted in footnote f.

h. Water to water heat pumps with capacity less than 135,000 Btu/h are included in Table 110.2-B Heat Pumps, Minimum Efficiency Requirements.

i. Source leaving liquid temperature.

- 1. The cooling evaporator liquid flow rate used for the heating rating for a reverse cycle air to water heat pump shall be the flow rate determined during the full load cooling rating.

- 2. The cooling evaporator liquid flow rate for the simultaneous cooling and heating and heat recovery liquid cooled chilling packages rating shall be the liquid flow rates from the cooling operation full load rating.

- 3. For heating only fluid to fluid chiller packages, the evaporator flow rate obtained with an entering liquid temperature of 54 F and a leaving liquid temperature of 44 F shall be used.

j. NA means the requirements are not applicable.

Equipment Type: Air Source

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPSHC)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPSHC)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPSHC)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F | Simultaneous Cooling and Heating Full Load Heating Efficiency COPSHC)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F | Test Procedure |

| < 150 | 47 db

43 wb |

NAj | NAj | NAj | NAj | AHRI 550/590 |

| < 150 | 17 db

15 wb |

NAj | NAj | NAj | NAj | AHRI 550/590

|

| > 150 | 47 db

43 wb |

NAj | NAj | NAj | NAj | AHRI 550/590 |

| > 150 | 17 db

15 wb |

NAj | NAj | NAj | NAj | AHRI 550/590

|

(CONTINUED) TABLE 110.2-K Heat Pump and Heat Recovery Chiller Packages, Simultaneous Cooling and Heating, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated positive displacement

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F | Test Procedure |

| > 11.25h and < 150 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj | AHRI 550/590 |

| > 11.25h and < 150 | 65i | NAj | NAj |

NAj |

> 6.150 | AHRI 550/590 |

| > 150 and < 300 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj |

AHRI 550/590 |

| > 150 and < 300 | 65i | NAj | NAj |

NAj |

> 6.150 | AHRI 550/590 |

| > 300 and < 400 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj |

AHRI 550/590 |

| > 300 and < 400 | 65i | NAj | NAj |

NAj |

> 6.150 | AHRI 550/590 |

| > 400 and < 600 | 44i | > 8.9 | > 6.98 | > 5 | NAj |

AHRI 550/590 |

| > 400 and < 600 | 65i | NAj | NAj |

NAj |

> 6.85 | AHRI 550/590 |

| > 600 | 44i | > 8.9 | > 6.98 | > 5 | NAj |

AHRI 550/590 |

| > 600 | 65i | NAj | NAj |

NAj |

> 6.85 | AHRI 550/590 |

(CONTINUED) TABLE 110.2-K Heat Pump and Heat Recovery Chiller Packages, Simultaneous Cooling and Heating, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated centrifugal

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshcc,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F |

Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F |

Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F |

Simultaneous Cooling and Heating Full Load Heating Efficiency (COPshc)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F |

Test Procedure |

| < 11.25h and < 150 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj | AHRI 550/590 |

| > 11.25h and < 150 | 65i | NAj | NAj | NAj | > 6.150 | AHRI 550/590 |

| > 150 and < 300 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj | AHRI 550/590 |

| > 150 and < 300 | 65i | NAj | NAj | NAj | > 6.150 | AHRI 550/590 |

| > 300 and < 400 | 44i | > 8.33 | > 6.41 | > 4.42 | NAj | AHRI 550/590 |

| > 300 and < 400 | 65i | NAj | NAj | NAj | > 6.150 | AHRI 550/590 |

| > 400 and < 600 | 44i | > 8.9 | > 6.98 | > 5 | NAj | AHRI 550/590 |

| > 400 and < 600 | 65i | NAj | NAj | NAj | > 6.85 | AHRI 550/590 |

| > 600 | 44i | > 8.9 | > 6.98 | > 5 | NAj | AHRI 550/590 |

| > 600 | 65i | NAj | NAj | NAj | > 6.85 | AHRI 550/590 |

a. The size category is the full-load net refrigeration cooling mode capacity, which is the capacity of the evaporator available for cooling of the thermal load external to the chilling package.

b. For air source heat pumps, compliance with both the 47 F and 17 F heating source outdoor air temperature (OAT) rating efficiency is required for heating.

c. Heating full load rating conditions are at standard rating conditions defined in AHRI 550/590 (I-P), Table 4, includes the impact of defrost for air source heating ratings.

d. For units that operate in both cooling and heating, compliance with both the cooling and heating efficiency is required.

e. For heat recovery heating chilling package applications where there is simultaneous cooling and heating, compliance with the heating performance heat recover COPHR is only required at one of the four heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, Hot-Water 1 or Hot- Water 2. Compliance with the cooling only performance is required as defined in footnotes b and c of Table 110.2-I.

f. Heating full load rating conditions are at standard rating conditions defined in AHRI 550/590 (I-P), Table 4, includes the impact of defrost for air source heating ratings.

g. For simultaneous cooling and heating chillers applications where there is simultaneous cooling and heating, compliance with the simultaneous cooling performance heat recovery COPSHC is only required at one of the heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, High, or Boost. Compliance with cooling performance is required as defined in footnotes b and c of Table 110.2-I.

h. Water to water heat pumps with capacity less than 135,000 Btu/h are included in Table 110.2-B Heat Pumps, Minimum Efficiency Requirements.

i. Source leaving liquid temperature.

- 1. The cooling evaporator liquid flow rate used for the heating rating for a reverse cycle air to water heat pump shall be the flow rate determined during the full load cooling rating.

- 2. The cooling evaporator liquid flow rate for the simultaneous cooling and heating and heat recovery liquid cooled chilling packages rating shall be the liquid flow rates from the cooling operation full load rating.

- 3. For heating only fluid to fluid chiller packages, the evaporator flow rate obtained with an entering liquid temperature of 54 F and a leaving liquid temperature of 44 F shall be used.

j. NA means the requirements are not applicable.

Equipment Type: Air Source

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F | Test Procedure |

| < 150 | 47 db,

43 wb |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| < 150 | 17 db,

15 wb |

NAj | NAj |

NAj |

NAj |

AHRI 550/590 |

| > 150 | 47 db,

43 wb |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| < 150 | 17 db,

15 wb |

NAj | NAj |

NAj |

NAj |

AHRI 550/590 |

(CONTINUED) TABLE 110.2-L Heat Pump and Heat Recovery Chiller Packages, Heat Recovery, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated positive displacement

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F |

Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F |

Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F |

Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F |

Test Procedure |

| > 11.25h and < 150 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 11.25h and < 150 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 150 and < 300 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 150 and < 300 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 300 and < 400 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 300 and < 400 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 400 and < 600 | 44i |

> 8.9 | > 6.98 | > 5.5 | > 5 | AHRI 550/590 |

| > 400 and < 600 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 600 | 44i |

> 8.9 | > 6.98 | > 5.5 | > 5 | AHRI 550/590 |

| > 600 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

(CONTINUED) TABLE 110.2-L Heat Pump and Heat Recovery Chiller Packages, Heat Recovery, Heating Operation– Minimum Efficiency Requirements

Equipment Type: Liquid source electrically operated centrifugal

| Size Category Refrigerating Capacitya, TonR, | Heating Source Conditions (leaving liquid) or OAT (db/wb)b °F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Low, 95 F/105 F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Medium, 105°F/120°F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, High, 120°F/140°F | Heat Recovery Heating Full Load Heating Efficiency (COPH)c,d,e,f,g, W/W, Entering/Leaving Heating Liquid Temperature, Boost, 120°F/140°F | Test Procedure |

| > 11.25h and < 150 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 11.25h and < 150 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 150 and ≤ 300 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 150 and ≤ 300 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 300 and ≤ 400 | 44i |

> 8.33 | > 6.41 | > 4.862 | > 4.42 | AHRI 550/590 |

| > 300 and ≤ 400 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 400 and ≤ 600 | 44i |

> 8.9 | > 6.98 | > 5.5 | > 5 | AHRI 550/590 |

| > 400 and ≤ 600 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

| > 600 | 44i |

> 8.9 | > 6.98 | > 5.5 | > 5 | AHRI 550/590 |

| > 600 | 65i |

NAj |

NAj |

NAj |

NAj |

AHRI 550/590 |

a. The size category is the full-load net refrigeration cooling mode capacity, which is the capacity of the evaporator available for cooling of the thermal load external to the chilling package.

b. For air source heat pumps, compliance with both the 47 F and 17 F heating source outdoor air temperature (OAT) rating efficiency is required for heating.

c. Heating full load rating conditions are at standard rating conditions defined in AHRI 550/590 (I-P), Table 4, includes the impact of defrost for air source heating ratings.

d. For units that operate in both cooling and heating, compliance with both the cooling and heating efficiency is required.

e. For heat recovery heating chilling package applications where there is simultaneous cooling and heating, compliance with the heating performance heat recover COPHR is only required at one of the four heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, Hot-Water 1 or Hot-Water 2. Compliance with the cooling only performance is required as defined in footnotes b and c of Table 110.2-I.

f. For liquid source heat recovery chilling packages that have capabilities for heat rejection to a heat recovery condenser and a tower condenser the COPHR applies to operation at full load with 100 percent heat recovery (no tower rejection). Units that only have capabilities for partial heat recovery shall meet the requirements of Table 110.2-D Water Chilling Packages Minimum Efficiency.

g. For heat recovery heating chilling package applications where there is simultaneous cooling and heating, compliance with the heating performance heat recover COPHR is only required at one of the four heating AHRI 550/590 (I-P) standard ratings conditions of Low, Medium, Hot-Water 1 or Hot-Water 2. Compliance with the cooling only performance is required as defined in footnotes b and c of Table 110.2-I.

h. Water to water heat pumps with capacity less than 135,000 Btu/h are included in Table 110.2-B Heat Pumps, Minimum Efficiency Requirements.

i. Source leaving liquid temperature.

- The cooling evaporator liquid flow rate used for the heating rating for a reverse cycle air to water heat pump shall be the flow rate determined during the full load cooling rating.

- The cooling evaporator liquid flow rate for the simultaneous cooling and heating and heat recovery liquid cooled chilling packages rating shall be the liquid flow rates from the cooling operation full load rating.

- For heating only fluid to fluid chiller packages, the evaporator flow rate obtained with an entering liquid temperature of 54 F and a leaving liquid temperature of 44 F shall be used.

j. NA means the requirements are not applicable.

Note: Authority: Sections 25213, 25218, 25218.5, 25402 and 25402.1, Public Resources Code. Reference: Sections 25007, 25008, 25218.5, 25310, 25402, 25402.1, 25402.4, 25402.8, and 25943, Public Resources Code