| Single-phase | Three-phase | ||

| kVA | Impedance (%) | kVA | Impedance (%) |

| 10 | 1.0-4.5 | 15 | 1.0-4.5 |

| 15 | 1.0-4.5 | 30 | 1.0-4.5 |

| 25 | 1.0-4.5 | 45 | 1.0-4.5 |

| 37.5 | 1.0-4.5 | 75 | 1.0-5.0 |

| 50 | 1.5-4.5 | 112.5 | 1.2-6.0 |

| 75 | 1.5-4.5 | 150 | 1.2-6.0 |

| 100 | 1.5-4.5 | 225 | 1.2-6.0 |

| 167 | 1.5-4.5 | 300 | 1.2-6.0 |

| 250 | 1.5-6.0 | 500 | 1.5-7.0 |

| 333 | 1.5-6.0 | 750 | 5.0-7.5 |

| 500 | 1.5-7.0 | 1000 | 5.0-7.5 |

| 667 | 5.0-7.5 | 1500 | 5.0-7.5 |

| 833 | 5.0-7.5 | 2000 | 5.0-7.5 |

|

|

|

2500 | 5.0-7.5 |

| Single-phase | Three-phase | ||

| kVA | Impedance (%) | kVA | Impedance (%) |

| 15 | 1.5-6.0 | 15 | 1.5-6.0 |

| 25 | 1.5-6.0 | 30 | 1.5-6.0 |

| 37.5 | 1.5-6.0 | 45 | 1.5-6.0 |

| 50 | 1.5-6.0 | 75 | 1.5-6.0 |

| 75 | 2.0-7.0 | 112.5 | 1.5-6.0 |

| 100 | 2.0-7.0 | 150 | 1.5-6.0 |

| 167 | 2.5-8.0 | 225 | 3.0-7.0 |

| 250 | 3.5-8.0 | 300 | 3.0-7.0 |

| 333 | 3.5-8.0 | 500 | 4.5-8.0 |

| 500 | 3.5-8.0 | 750 | 5.0-8.0 |

| 667 | 5.0-8.0 | 1000 | 5.0-8.0 |

| 833 | 5.0-8.0 | 1500 | 5.0-8.0 |

| 2000 | 5.0-8.0 | ||

| 2500 | 5.0-8.0 | ||

| Appliance | Test Method |

| Non-commercial refrigerators, designed for the integrated storage of food at temperatures above 32°F and below 39°F, configured for general refrigerated food storage, refrigerator-freezers, and freezers. | 10 C.F.R. sections 430.23(a) (Appendix A1 to Subpart B of part 430) and 430.23(b) (Appendix B1 to Subpart B of part 430), as applicable for models manufactured before September 15, 2014

10 C.F.R. sections 430.23(a) (Appendix A to Subpart B of part 430) and 430.23(b) (Appendix B to Subpart B of part 430), as applicable for models manufactured on or after September 15, 2014 |

|

Wine chillers that are consumer products |

10 C.F.R. section 430.23(a) (Appendix A1 to Subpart B of part 430), with the following modifications:

Standardized temperature as referred to in Section 3.2 of Appendix A1 shall be 55°F (12.8°C) The calculation of test cycle energy expended (ET) in section 5.2.1.1 of Appendix A1 shall be made using the modified formula: ET=(EP x 1440 x k)/T Where k = 0.85 |

| Appliance | Test Method |

| Automatic commercial ice makers | 10 C.F.R. sections 431.133 and 431.134 |

| Refrigerated bottled or canned beverage vending machines | 10 C.F.R. sections 431.293 and 431.294 |

| Refrigerated buffet and preparation tables | ANSI/ASTM F2143-01 |

| Other commercial refrigerators, refrigerator-freezers, and freezers, with doors | 10 C.F.R. sections 431.63 and 431.64 |

| Other commercial refrigerators, refrigerator-freezers, and freezers, without doors | 10 C.F.R. sections 431.63 and 431.64 |

| Walk-in coolers and walk-in freezers | 10 C.F.R. sections 431.303 and 431.304 |

| Appliance | Test Method |

| Room air conditioners and room air-conditioning heat pumps | 10 C.F.R. section 430.23(f) (Appendix F to Subpart B of part 430) |

| Packaged terminal air conditioners and packaged terminal heat pumps | 10 C.F.R. sections 431.95 and 431.96 |

| Appliance | Test Method |

| Computer Room Air Conditioners

evaporatively-cooled

air-cooled, glycol-cooled, water-cooled

|

ANSI/ASHRAE 127-2001

10 C.F.R. sections 431.95 and 431.96

|

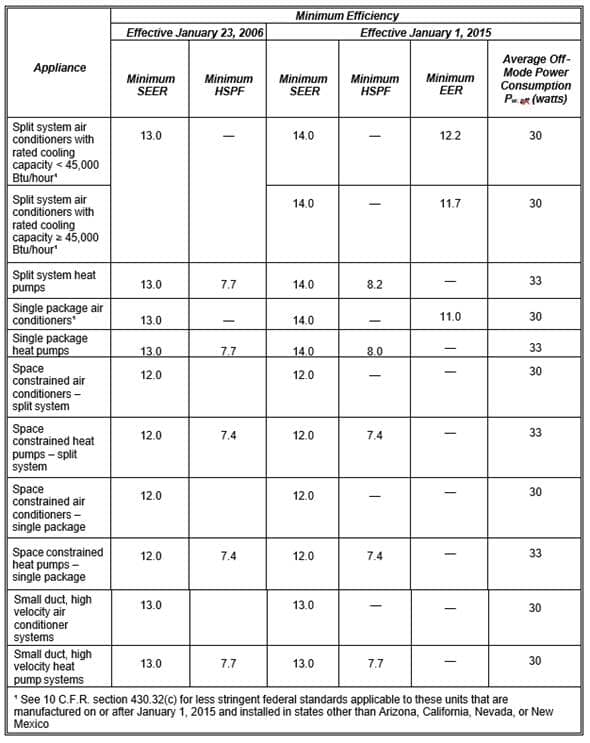

| Other electric-powered unitary air-conditioners and electric-powered heat pumps:

air-cooled air conditioners and air-source heat pumps

< 65,000 Btu/hr, single-phase

< 65,000 Btu/hr, three-phase

≥ 65,000 and < 760,000

evaporatively-cooled air conditioners < 240,000 Btu/hr

water-cooled air conditioners and water-source heat pumps

< 240,000 Btu/hr

Ground water-source heat pumps

Ground-source closed-loop heat pumps

|

10 C.F.R. section 430.23(m) (Appendix M to Subpart B of part 430)

10 C.F.R. sections 431.95 and 431.96 10 C.F.R. sections 431.95 and 431.96 10 C.F.R. sections 431.95 and 431.96 10 C.F.R. sections 431.95 and 431.96 ARI/ISO-13256-1:1998 ARI/ISO-13256-1:1998 |

| Variable Refrigerant Flow Multi-Split Systems | 10 C.F.R. sections 431.95 and 431.96 |

| Single Package Vertical Air Conditioners and Single Package Vertical Heat Pumps | 10 C.F.R. sections 431.95 and 431.96 |

| Gas-fired air conditioners and gas-fired heat pumps | ANSI Z21.40.4-1996 as modified by CEC, Efficiency Calculation Method for Gas-Fired Heat Pumps as a New Compliance Option (1996) |

| Appliance | Test Method |

| Spot Air Conditioners | ANSI/ASHRAE 128-2001 |

| Ceiling Fans, Except Low-Profile Ceiling Fans | 10 C.F.R. section 430.23(w) (Appendix U to Subpart B of part 430) |

| Ceiling Fan Light Kits | 10 C.F.R. section 430.23(x) (Appendix V to Subpart B of part 430) |

| Evaporative Coolers | ANSI/ASHRAE 133-2008 for packaged direct evaporative coolers and packaged indirect/direct evaporative coolers; ANSI/ASHRAE 143-2007 for packaged indirect evaporative coolers |

| Whole House Fans | HVI-916, tested with manufacturer-provided louvers in place (2009) |

| Dehumidifiers | 10 C.F.R. section 430.23(z) (Appendix X to Subpart B of part 430) OR 10 C.F.R. section 430.23(z) (Appendix X1 to Subpart B of part 430) (at manufacturer's discretion) for models manufactured before April 29, 2013

10 C.F.R. section 430.23(z) (Appendix X1 to Subpart B of part 430) for models manufactured on or after April 29, 2013 |

| Residential Exhaust Fans | HVI-916 (2009) |

| Appliance | Test Method |

| Central furnaces

< 225,000 Btu/hr, single phase < 225,000 Btu/hr, three phase ≥ 225,000 Btu/hr |

10 C.F.R. section 430.23(n) (Appendix N to Subpart B of part 430) 10 C.F.R. section 430.23(n) (Appendix N to Subpart B of part 430) or 10 C.F.R. sections 431.75 and 431.76 (at manufacturer's option) 10 C.F.R. sections 431.75 and 431.76 |

| Gas infrared heaters

patio heaters gas-fired high-intensity infrared heaters gas-fired low-intensity infrared heaters |

ASTM F2644-07

ANSI Z83.19-001 ANSI Z83.20- |

| Unit heaters gas:

fired oil-fired |

ANSI Z83.8-2002*

UL 731-1995* |

| Gas duct furnaces | ANSI Z83.8- |

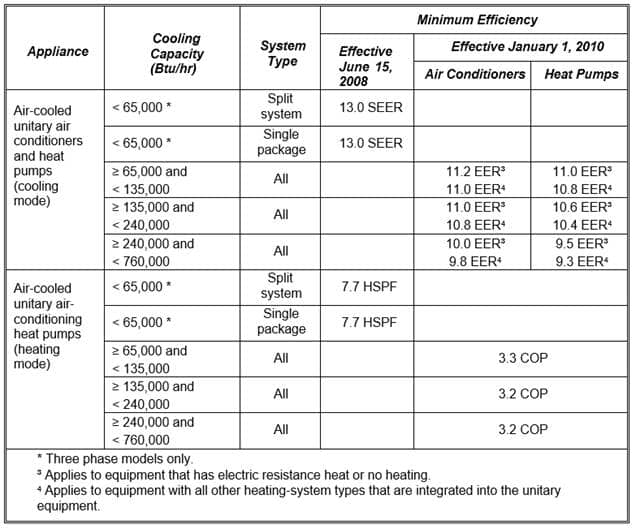

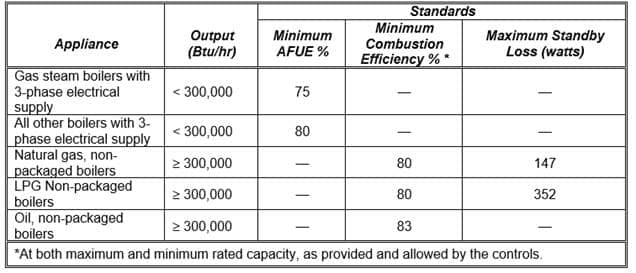

| Boilers

< 300,000 Btu/hr ≥ 300,000 Btu/hr |

10 C.F.R. section 430.23(n) (Appendix N to Subpart B of part 430)

10 C.F.R. sections 431.85 and 431.86 |

| Wall furnaces, floor furnaces, and room heaters | 10 C.F.R. section 430.23(o) (Appendix O to Subpart B of part 430) |

| * To calculate maximum energy consumption in standby, measure the gas energy used in one hour (in Btus) and the electrical energy used in watt-hours) over a one-hour period, when the main burner is off. Divide Btus per hour by one foot to obtain Btus per watt. Divide Btus per hour by 3.412 to obtain watts. Add watts of gas energy to watts of electrical energy to obtain standby energy consumption in watts. | |

| Appliance | Test Method |

| Small water heaters that are federally regulated consumer products | 10 CFR Section 430.23(e) (Appendix E to Subpart B of Part 430) (2008) |

| Small water heaters that are not federally regulated consumer products

Gas and oil storage-type < 20 gallons rated capacity

Booster water heaters Hot water dispensers Mini-tank electric water heaters All others

|

ANSI/ASHRAE 118.2-1993 ANSI/ASTM F2022-00 (all matters other than volume); ANSI Z21.10.3-1998 (for volume) Test Method in 1604(f)(4) Test Method in 1604(f)(5) 10 CFR Section 430.23(e) (Appendix E to Subpart B of Part 430) (2008) |

| Appliance | Input to Volume Ratio | Size (Volume) | Minimum Thermal Efficiency (%) | Maximum Standby Loss1 |

| Gas storage water heaters | < 4,000 Btu/hr/gal | Any | 80 | Q/800 + 110(Vr)1/2 Btu/hr |

| Gas instantaneous water heaters | ≥ 4,000 Btu/hr/gal | < 10 gal |

80

|

- |

| ≥ 10 gal | 80 | Q/800 + 110(Vr)1/2 Btu/hr | ||

| Gas hot water supply boilers | ≥ 4,000 Btu/hr/gal | < 10 gal | 80 | |

| ≥ 10 gal | 80 | Q/800 + 110(Vr)1/2 Btu/hr | ||

| Oil storage water heaters | < 4,000 Btu/hr/gal | Any | 78 | Q/800 + 110(Vr)1/2 Btu/hr |

| Oil instantaneous water heaters | ≥ 4,000 Btu/hr/gal | < 10 gal | 80 |

-

|

| ≥ 10 gal | 78 | Q/800 + 110(Vr)1/2 Btu/hr | ||

| Oil hot water supply boilers | ≥ 4,000 Btu/hr/gal | < 10 gal | 80 |

-

|

| ≥ 10 gal | 78 | Q/800 + 110(Vr)1/2 Btu/hr | ||

| Electric storage water heaters | < 4,000 Btu/hr/gal | Any | - | 0.3 + 27/Vm %/hr |

| 1Standby loss is based on a 70°F temperature difference between stored water and ambient requirements. In the standby loss equations, Vt is the rated volume in gallons. Vm is the measured volume in gallons, and Q is the nameplate input rate in Btu/hr.

2Water heaters and hot water supply boilers having more than 140 gallons of storage capacity are not required to meet the standby loss requirement if the tank surface is thermally insulated to R-12.5. If a standing pilot light is not installed, and for gas- or oil-fired storage water heaters, there is a flue damper or fan-assisted combustion. | ||||

| Appliance | Test Method |

| Gas-fired and oil-fired pool heaters | 10 C.F.R. section 430.23(p) (Appendix P to Subpart B of part 430) |

| Electric resistance pool heaters | ANSI/ASHRAE 146-1998 |

| Heat pump pool heaters | ANSI/ASHRAE 146-1998, as modified by Addendum Test Procedure published by Pool Heat Pump Manufacturers Association dated April 1999, Rev 4: Feb 28, 2000 |

| Reading | Standard Temperature Rating | Low-Temperature Rating | Spa Conditions Rating |

| Air Temperature

Dry bulb Wet bulb |

27.0°C (80.6°F)

21.7°C (71.0°F) |

10.0°C (50.0°F)

6.9°C (44.4°F) |

27.0°C (80.6°F)

21.7°C (71.0°F) |

| Relative Humidity | 63% | 63% | 63% |

| Pool Water Temperature | 26.7°C (80.0°F) | 26.7°C (80.0°F) | 40.0°C (104.0°F) |

| Appliance | Test Method |

| Cooking products that are consumer products

Commercial hot food holding cabinets Commercial convection ovens Commercial range tops |

10 CFR Section 430.23(i) (Appendix I to Subpart B of Part 430) (2008)

ANSI/ASTM F2140-01 (Test for idle energy rate-dry test) and US EPA's Energy Star Guidelines, "Measuring Interior Volume" (Test for interior volume) ANSI/ASTM F1496-99 (Test for energy input rate and idle energy consumption only) ANSI/ASTM F1521-96 (Test for cooking energy efficiency only) |

| Appliance | Defrost | Compact, Built-in, Neither | Ice | Maximum Energy Consumption (kWh/year) | ||

| Equipped with Automatic Ice Maker? | Dispenses Ice Through Door? | July 1, 20011 | Sept. 15, 20142 | |||

| Refrigerators

|

Manual | Neither | -- | -- | 8.82AV + 248.4 | 7.99AV + 225.0 |

| Not 'all refrigerator' | ||||||

| Not 'all refrigerator' | Manual | Compact | -- | -- | 10.70AV + 299.0 | 9.03AV + 252.3 |

| 'All refrigerator' | Manual | Compact | -- | -- | 10.70AV + 299.0 | 7.84AV + 219.1 |

| 'All refrigerator' | Manual | Neither | -- | -- | -- | 6.79AV + 193.6 |

| 'All refrigerator' | Automatic | Neither | -- | -- | 9.80AV + 276.0 | 7.07AV + 201.6 |

| 'All refrigerator' | Automatic | Built-in | -- | -- | -- | 8.02AV + 228.5 |

| 'All refrigerator' | Automatic | Compact | -- | -- | 12.70AV + 355.0 | 9.17AV + 259.3 |

| Refrigerator-freezers | Manual | Neither | -- | -- | 8.82AV + 248.4 | 7.99AV + 225.0 |

| Partial | Neither | -- | -- | 8.82AV + 248.4 | 7.99AV + 225.0 | |

| Manual | Compact | -- | -- | -- | 9.03AV + 252.3 | |

| Partial | Compact | -- | -- | 7.00AV + 398.0 | 5.91AV + 335.8 | |

| Refrigerator-freezers Bottom-Freezer | Automatic | Neither | No | -- | 4.60AV + 459.0 | 8.85AV + 317.0 |

| Automatic | Neither | Yes | No | -- | 8.85AV + 401.0 | |

| Automatic | Neither | Yes | Yes | -- | 9.25AV + 475.4 | |

| Automatic | Compact | No | -- | 13.10AV + 397.0 | 11.80AV + 339.2 | |

| Automatic | Compact | Yes | -- | -- | 11.80AV + 423.2 | |

| Automatic | Built-in | No | -- | -- | 9.40AV + 336.9 | |

| Automatic | Built-in | Yes | No | -- | 9.40AV + 420.9 | |

| Automatic | Built-in | Yes | Yes | -- | 9.83AV + 499.9 | |

| Refrigerator-freezers Side-by-side | Automatic | Neither | No | -- | 4.91AV+507.5 | 8.51AV + 297.8 |

| Automatic | Neither | Yes | No | -- | 8.51AV + 381.8 | |

| Automatic | Neither | Yes | Yes | 10.10AV + 406.0 | 8.54AV + 432.8 | |

| Automatic | Compact | No | -- | 7.60AV + 501.0 | 6.82AV + 456.9 | |

| Automatic | Compact | Yes | -- | -- | 6.82AV + 540.9 | |

| Automatic | Built-in | No | -- | -- | 10.22AV + 357.4

| |

| Automatic | Built-in | Yes | No | -- | 10.22AV + 441.4

| |

| Automatic | Built-in | Yes | Yes | -- | 10.25AV + 502.6

| |

| Refrigerator-freezers Top-Freezer | Automatic | Neither | No | -- | 9.80AV + 276.0 | 8.07AV + 233.7 |

| Automatic | Neither | Yes | No | -- | 8.07AV + 317.7 | |

| Automatic | Neither | Yes | Yes | 10.20AV + 356.0 | 8.40AV + 385.4 | |

| Automatic | Compact | No | -- | 12.70AV + 355.0 | 11.80AV + 339.2 | |

| Automatic | Compact | Yes | -- | -- | 11.80AV + 423.2 | |

| Automatic | Built-in | No | -- | -- | 9.15AV + 264.9 | |

| Automatic | Built-in | Yes | No | -- | 9.15AV + 348.9 | |

| Freezers

Upright Freezer |

Manual | Neither | No | -- | 7.55AV + 258.3 | 5.57AV + 193.7 |

| Manual | Compact | -- | -- | 9.78AV + 250.8 | 8.65AV + 225.7 | |

| Automatic | Neither | No | -- | 12.43AV + 326.1 | 8.62AV + 228.3 | |

| Automatic | Neither | Yes | -- | -- | 8.62AV + 312.3 | |

| Automatic | Compact | -- | -- | 11.40AV + 391.0 | 10.17AV + 351.9 | |

| Automatic | Built-in | No | -- | -- | 9.86AV + 260.9 | |

| Automatic | Built-in | Yes | -- | -- | 9.86AV + 344.9 | |

| Freezers

Chest-Freezer |

Manual | NOT Compact | No | -- | -- | 7.29AV + 107.8 |

| Partial | NOT Compact | No | -- | -- | 7.29AV + 107.8 | |

| Automatic | NOT Compact | No | -- | 9.88AV + 143.7 | 10.24AV + 148.1 | |

| -- | Compact | -- | -- | 10.45AV + 152.0 | 9.25AV + 136.8 | |

| Freezers

Neither Chest Freezer

nor Upright Freezer

|

--

|

NOT Compact

|

No

|

--

|

--

|

7.29AV + 107.8

|

| 1 AV = adjusted total volume in ft³, as determined in 10 C.F.R. part 430, Appendices A1 and B1 of Subpart B, which is:

[1.44 × freezer volume (ft³)] + refrigerator volume (ft³) for refrigerators; [1.63 × freezer volume (ft³)] + refrigerator volume (ft³) for refrigerator/freezers; [1.73 × freezer volume (ft³)] for freezers. ² AV = adjusted total volume in ft³, as determined in 10 C.F.R. part 430, Appendices A and B of Subpart B. |

| Note: Maximum energy consumption standards for refrigerator-freezers with internal freezers are same as those for refrigerator-freezers with top-mounted freezers. |

| Refrigerators and Freezers | Condensing Unit Configuration | Equipment Family | Rating Temperature (°F) | Operating Temperature (°F) | Equipment Class Designation | Maximum Daily Energy Consumption (kWh) |

| Refrigerators and Freezers

Effective January 1, 2010 |

Self-Contained (SC) | Vertical Closed Transparent (VCT) | 38 (M)

0 (L) |

≥32

<32 |

VCT, SC, M

VCT, SC, L |

0.12 × V + 3.34 0.75 × V + 4.10 |

| Horizontal Closed Transparent (HCT) | 38 (M)

0 (L) |

≥32

<32 |

HCT, SC, M

HCT, SC, L |

0.12 × V + 3.34

0.75 × V + 4.10 | ||

| Vertical Closed Solid (VCS) | 38 (M)

0 (L) |

≥32

<32 |

VCS, SC, M

VCS, SC, L |

0.10 × V + 2.04

0.40 × V + 1.38 | ||

| Horizontal Closed Solid (HCS) | 38 (M)

0 (L) |

≥32

<32 |

HCS, SC, M

HCS, SC, L |

0.10 × V + 2.04

0.40 × V + 1.38 | ||

| Service Over Counter (SOC) | 38 (M)

0 (L) |

≥32 | SOC, SC, M

SOC, SC, L |

0.12 × V + 3.34

0.75 × V + 4.10 | ||

| Refrigerators with transparent doors designed for pull-down temperature applications

Effective January 1, 2010 |

Self-Contained (SC)

|

Vertical Closed Transparent (VCT) | 38 (P) | ≥32 | VCT, SC, P | 0.126 × V + 3.51 |

| Horizontal Closed Transparent (HCT) | 38 (P) | ≥32 | HCT, SC, P | 0.126 × V + 3.51 | ||

|

Refrigerators and Freezers without doors Effective January 1, 2012 |

Self-Contained (SC) |

Vertical Open (VOP) | 38 (M)

0 (L) |

≥32

<32 |

VOP, SC, M

VOP, SC, L |

1.74 × TDA + 4.71 4.37 × TDA + 11.82 |

| Semi-vertical Open (SVO) | 38 (M)

0 (L) |

≥32

<32 |

SVO, SC, M

SVO, SC, L |

1.73 × TDA + 4.59 4.34 × TDA + 11.51 | ||

| Horizontal Open (HZO) | 38 (M)

0 (L) |

≥32

<32 |

HZO, SC, M

HZO, SC, L |

0.77 × TDA + 5.55 1.92 × TDA + 7.08 | ||

| * The meaning of the letters in this column is indicated in the Condensing Unit Configuration, Equipment Family, and Rating Temperature (°F) columns to the left. | ||||||

| Equipment Category | Condensing Unit Configuration | Equipment Family | Rating Temperature (°F) | Operating Temperature (°F) | Equipment Class Designation* | Maximum Daily Energy Consumption (kWh) |

| Refrigerators and Freezers | Remote (RC) | Vertical Open (VOP) | 38 (M)

0 (L) |

≥32

<32 |

VOP, RC, M VOP, RC, L | 0.82 × TDA + 4.07

2.27 × TDA + 6.85 |

| Effective

January 1, 2012 |

Semi-vertical Open (SVO) | 38 (M)

0 (L) |

≥32

<32 |

SVO, RC, M SVO, RC, L | 0.83 × TDA + 3.18

2.27 × TDA + 6.85 | |

| Horizontal Open (HZO) | 38 (M)

0 (L) |

≥32

<32 |

HZO, RC, M HZO, RC, L | 0.35 × TDA + 2.88

0.57 × TDA + 6.88 | ||

| Vertical Closed Transparent (VCT) | 38 (M)

0 (L) |

≥32

<32 |

VCT, RC, M

VCT, RC, L |

0.22 × TDA + 1.95

0.56 × TDA + 2.61 | ||

| Horizontal Closed Transparent (HCT) | 38 (M)

0 (L) |

≥32

<32 |

HCT, RC, M HCT, RC, L | 0.16 × TDA + 0.13

0.34 × TDA + 0.26 | ||

| Vertical Closed Solid (VCS) | 38 (M)

0 (L) |

≥32

<32 |

VCS, RC, M

VCS, RC, L |

0.11 × V + 0.26

0.23 × V + 0.54 | ||

| Horizontal Closed Solid (HCS) | 38 (M)

0 (L) |

≥32

<32 |

HCS, RC, M HCS, RC, L | 0.11 × V + 0.26

0.23 × V + 0.54 | ||

| Service Over Counter (SOC) | 38 (M)

0 (L) |

≥32

<32 |

SOC, RC, M SOC, RC, L | 0.51 × TDA + 0.11

1.08 × TDA + 0.22 | ||

| * The meaning of the letters in this column is indicated in the Condensing Unit Configuration, Equipment Family, and Rating Temperature (°F) columns to the left. | ||||||

| Equipment type | Type of cooling | Harvest rate (lbs ice/24 hours) | Maximum energy use (kWh/100 lbs ice) | Maximum condenser water use* (gal/100 lbs ice) |

| Ice Making Head | Water | < 500 | 7.80–0.0055H | 200–0.022H |

| Ice Making Head | Water | ≥ 500 and < 1436

|

5.58–0.0011H

|

200–0.022H |

| Ice Making Head | Water | ≥ 1436

|

4.0 | 200–0.022H

|

| Ice Making Head | Air | < 450 | 10.26–0.0086H | Not applicable |

| Ice Making Head | Air | ≥ 450 | 6.89–0.0011H | Not applicable |

| Remote Condensing (but not remote compressor) | Air | < 1000 | 8.85–0.0038H | Not applicable |

| Remote Condensing (but not remote compressor)

|

Air | ≥ 1000 | 5.1 | Not applicable |

| Remote Condensing and Remote Compressor | Air | < 934 | 8.85–0.0038H | Not applicable |

| Remote Condensing and Remote Compressor

|

Air | ≥ 934 | 5.3 | Not applicable |

| Self-Contained | Water | < 200 | 11.40–0.019H | 191–0.0315H |

| Self-Contained

|

Water | ≥ 200 | 7.6 | 191–0.0315H |

| Self-Contained | Air | < 175 | 18.0–0.0469H | Not applicable |

| Self-Contained

|

Air | ≥ 175 | 9.8 | Not applicable |

| H Harvest rate in pounds per 24 hours.

* Water use is for the condenser only and does not include potable water used to make ice. | ||||

| Appliance | Louvered Sides | Cooling Capacity (Btu/hr) | Minimum EER |

| Room Air Conditioner | Yes | < 6,000 | 9.7 |

| Room Air Conditioner

|

Yes | ≥ 6,000 - 7,999 | 9.7 |

| Room Air Conditioner

|

Yes | ≥ 8,000 - 13,999 | 9.8 |

| Room Air Conditioner

|

Yes | ≥ 14,000 - 19,999 | 9.7 |

| Room Air Conditioner

|

Yes | ≥ 20,000 | 8.5 |

| Room Air Conditioner | No | < 6,000 | 9.0 |

| Room Air Conditioner

|

No | ≥ 6,000 - 7,999 | 9.0 |

| Room Air Conditioner

|

No | ≥ 8,000 - 19,999 | 8.5 |

| Room Air Conditioner

|

No | ≥ 20,000 | 8.5 |

| Room Air Conditioning Heat Pump | Yes | < 20,000 | 9.0 |

| Room Air Conditioning Heat Pump

|

Yes | ≥ 20,000 | 8.5 |

| Room Air Conditioning Heat Pump | No | < 14,000 | 8.5 |

| Room Air Conditioning Heat Pump

|

No | ≥ 14,000 | 8.0 |

| Casement-Only Room Air Conditioner | Either | Any | 8.7 |

| Casement-Slider Room Air Conditioner | Either | Any | 9.5 |

| Appliance | Louvered Sides |

Cooling Capacity (Btu/hr) |

Minimum Combined EER |

| Room Air Conditioner | Yes | < 6,000 | 11.0 |

| Room Air Conditioner | Yes | ≥ 6,000 - 7,999 | 11.0 |

| Room Air Conditioner | Yes | ≥ 8,000 - 13,999 | 10.9 |

| Room Air Conditioner | Yes | ≥ 14,000 - 19,999 | 10.7 |

| Room Air Conditioner | Yes | ≥ 20,000 - 27,999 | 9.4 |

| Room Air Conditioner | Yes | ≥ 28,000 | 9.0 |

| Room Air Conditioner | No | < 6,000 | 10.0 |

| Room Air Conditioner | No | ≥ 6,000 - 7,999 | 10.0 |

| Room Air Conditioner | No | ≥ 8,000 - 10,999 | 9.6 |

| Room Air Conditioner | No | ≥ 11,000 - 13,999 | 9.5 |

| Room Air Conditioner | No | ≥ 14,000 - 19,999 | 9.3 |

| Room Air Conditioner | No | ≥ 20,000 | 9.4 |

| Room Air Conditioning Heat Pump | Yes | < 20,000 | 9.8 |

| Room Air Conditioning Heat Pump | Yes | ≥ 20,000 | 9.3 |

| Room Air Conditioning Heat Pump | No | < 14,000 | 9.3 |

| Room Air Conditioning Heat Pump | No | ≥ 14,000 | 8.7 |

| Casement-Only Room Air Conditioner | Either | Any | 9.5 |

| Casement-Slider Room Air Conditioner

|

Either

|

Any | 10.4 |

| Appliance | Cooling Capacity (Btu/hour) | Minimum Efficiency | |

| Minimum EER | Minimum COP | ||

| Packaged Terminal Air Conditioners | < 7,000 | 11.7 | — |

| ≥ 7,000 < 15,000 | 13.8 − (0.300 × Cap¹) | — | |

| ≥ 15,000 | 9.3 | — | |

| Packaged Terminal Heat Pumps | < 7,000 | 11.9 | 3.3 |

| ≥ 7,000 < 15,000 | 14.0 − (0.300 × Cap¹) | 3.7 − (0.052 × Cap¹) | |

| ≥ 15,000 | 9.5 | 2.9 | |

| 1 Cap means cooling capacity in thousand British thermal units per hour (Btu/h) at 95° F outdoor dry-bulb temperature. | |||

| Appliance | Cooling Capacity (Btu per hour) | Minimum Efficiency | |||

| Effective

Prior to October 29, 2012 |

Effective January 10, 2011 | Effective

†October 29, 2012 or ††October 29, 2013 |

Effective

*June 1, 2013 or **June 1, 2014 | ||

| Minimum

EER COP |

Minimum

EER COP |

Minimum

EER COP |

Minimum

EER COP | ||

| Water-cooled air conditioners and evaporatively cooled air conditioners | < 17,000 | 12.1 — |

|

|

|

| Water-source heat pumps | < 17,000 | 11.2 4.2 |

|

|

|

| VRF multi-split heat pumps | < 17,000 | — 4.2 |

|

12.01† 4.2 |

|

| Water-cooled air conditioners and evaporatively cooled air | ≥17,000 and <65,000 | 12.1 — |

|

|

|

| Water-source heat pumps, including VRF | ≥17,000 and <65,000 | 12.0 4.2 |

|

|

|

| Water-cooled air conditioners and evaporatively cooled air | ≥65,000 and <135,000 | 11.51 — |

|

|

12.11* — |

| Water-source heat pumps, including VRF | ≥65,000 and <135,000 | 12.0 4.2 |

|

|

11.9* 4.2 |

| Water-cooled air conditioners | ≥135,000 and <240,000 | 11.0 — |

|

|

12.51** — |

| Evaporatively cooled air conditioners | ≥135,000 and <240,000 | 11.0 — |

|

|

12.0†** — |

| Water-source heat pumps | ≥135,000 and <240,000 | 11.0 2.9 |

|

|

12.3** 2.9 |

| Water-source VRF multi-split heat pumps | ≥135,000 and <760,000 |

|

|

10.01†† 3.9†† |

|

| Water-cooled air conditioners | ≥240,000 and <760,000 | 11.01 — | 11.01 — |

|

12.41** — |

| Evaporatively cooled air conditioners | ≥240,000 and <760,000 | 11.01 — | 11.01 — |

|

11.91** — |

| Water-source heat pumps | ≥240,000 and <760,000 | 11.01 — | 11.01 — |

|

12.2** — |

| 1Deduct 0.2 from the required EER for units with heating sections other than electric resistance heat. For VRF multi-split heat pumps this applies to units with heat recovery. | |||||

| Appliance | Cooling Capacity (BTU/hr) | System Type | Minimum Efficiency | |

| Cooling Mode | Heating Mode | |||

| Single package vertical air conditioners | < 65,000 | Single-phase | 9.0 EER | N/A |

| < 65,000 | 3-phase | 9.0 EER | N/A | |

| ≥ 65,000 and < 135,000 | All | 8.9 EER | N/A | |

| ≥ 135,000 and < 240,000 | All | 8.6 EER | N/A | |

| Single package vertical heat pumps | < 65,000 | Single-phase | 9.0 EER | 3.0 COP |

| < 65,000 | 3-phase | 9.0 EER | 3.0 COP | |

| ≥ 65,000 and < 135,000 | All | 8.9 EER | 3.0 COP | |

| ≥ 135,000 and < 240,000 | All | 8.6 EER | 2.9 COP | |

| Product capacity (pint/day) |

Minimum energy factor (liters/kWh) | |

| Effective October 1, 2007 |

Effective October 1, 2012 | |

| 25.00 or less | 1.00 | 1.35 |

| 25.01 - 35.00 | 1.20 | 1.35 |

| 35.01 - 45.00 | 1.30 | 1.50 |

| 45.01 - 54.00 | 1.30 | 1.60 |

| 54.01 - 74.99 | 1.50 | 1.70 |

| 75.00 or more | 2.25 | 2.50 |

| Appliance | Design Type |

Capacity (Btu per hour) |

Minimum AFUE (%) | |

| Effective Before April 16, 2013 |

Effective On or After April 16, 2013 | |||

| Wall furnace | Fan | ≤ 42,000 | 73 | 75 |

| Wall furnace | Fan | > 42,000 | 74 | 76 |

| Wall furnace | Gravity | ≤ 10,000 | 59 |

65 |

| Wall furnace | Gravity | > 10,000 and ≤ 12,000 | 60 | |

| Wall furnace | Gravity | > 12,000 and ≤ 15,000 | 61 | |

| Wall furnace | Gravity | > 15,000 and ≤ 19,000 | 62 | |

| Wall furnace | Gravity | > 19,000 and ≤ 27,000 | 63 | |

| Wall furnace | Gravity | > 27,000 and ≤ 46,000 | 64 | 66 |

| Wall furnace | Gravity | > 46,000 | 65 | 67 |

| Floor furnace | All | ≤ 37,000 | 56 | 57 |

| Floor furnace | All | > 37,000 | 57 | 58 |

| Room heater | All | ≤ 18,000 | 57 | 61 |

| Room heater | All | > 18,000 and ≤ 20,000 | 58 | |

| Room heater | All | > 20,000 and ≤ 27,000 | 63 | 66 |

| Room Heater | All | > 27,000 and ≤ 46,000 | 64 | 67 |

| Room heater

|

All | > 46,000 | 65 | 68 |

| Appliance |

Minimum AFUE (%)

| |

|

Effective January 1, 1992

| ||

| 75 | Effective September 1, 2012 | |

| Gas steam boilers with single phase electrical supply | 80 | 80 ¹ |

| Gas hot water boilers with single phase electrical supply | — | 82 ¹, ² |

| Oil steam boilers with single phase electrical supply | — | 82 |

| Oil hot water boilers with single phase electrical supply | — | 84 ² |

| Electric steam residential boilers | — | NONE |

| Electric hot water residential boilers | 80 | NONE ² |

| All other boilers with single phase electrical supply | — | — |

| 1 No constant burning pilot light design standard effective September 1, 2012.

2 Automatic means for adjusting temperature design standard effective September 1, 2012. (Boilers equipped with tankless domestic water heating coils do not need to comply with this requirement.) | ||

| Appliance | Rated Input (Btu/hr) |

Minimum Thermal Efficiency |

| Gas central furnaces | ≥ 225,000 | 80 |

| Oil central furnaces | ≥ 225,000 | 81 |

| Appliance | Input to Volume Ratio |

Size (Volume) |

Minimum Thermal Efficiency (%) |

Maximum Standby Loss¹,² |

| Gas storage water heaters | < 4,000 Btu/hr/gal | any | 80 | Q/800 + 110(Vc)1/2 Btu/hr |

| Gas instantaneous water heaters

|

≥ 4,000 Btu/hr/gal

|

< 10 gal | 80 | — |

| ≥ 10 gal | 80 | Q/800 + 110(Vc)1/2 Btu/hr | ||

| Gas hot water supply boilers

|

≥ 4,000 Btu/hr/gal

|

< 10 gal | 80 | — |

| ≥ 10 gal | 80 | Q/800 + 110(Vc)1/2 Btu/hr | ||

| Oil storage water heaters | < 4,000 Btu/hr/gal | any | 78 | Q/800 + 110(Vc)1/2 Btu/hr |

| Oil instantaneous water heaters

|

≥ 4,000 Btu/hr/gal

|

< 10 gal | 80 | — |

| ≥ 10 gal | 78 | Q/800 + 110(Vc)1/2 Btu/hr | ||

| Oil hot water supply boilers

|

≥ 4,000 Btu/hr/gal

|

< 10 gal | 80 | — |

| ≥ 10 gal | 78 | Q/800 + 110(Vc)1/2 Btu/hr | ||

| Electric storage water heaters | < 4,000 Btu/hr/gal | Any | — | 0.3 + 27/Vm %/hr |

|

¹ Standby loss is based on a 70°F temperature difference between stored water and ambient requirements. In the standby loss equations, Vc is the rated volume in gallons, Vm is the measured volume in gallons, and Q is the nameplate input rate in Btu/hr. ² Water heaters and hot water supply boilers having more than 140 gallons of storage capacity are not required to meet the standby loss requirement if the tank surface is thermally insulated to R-12.5, if a standing pilot light is not installed, and for gas- or oil-fired storage water heaters, there is a flue damper or fan-assisted combustion. | ||||

| Appliance | Rated Storage Volume (gallons) |

Minimum Energy Factor | |

| Effective January 20, 2004 |

Effective April 16, 2015 | ||

| Gas-fired storage-type water heaters | ≤ 55 | 0.67 - (.0019 x V) | 0.675 - (0.0015 x V) |

| > 55 | 0.8012 - (0.00078 x V) | ||

| Oil-fired water heaters (storage and instantaneous) | Any | 0.59 - (.0019 x V) | 0.68 - (.0019 x V) |

| Electric storage water heaters (excluding tabletop water heaters) | ≤ 55 | 0.97 - (.00132 x V) | 0.960 - (0.0003 x V) |

| > 55 | 2.057 - (0.00113 x V) | ||

| Electric tabletop water heaters | Any | 0.93 - (.00132 x V) | 0.93 - (.00132 x V) |

| Gas-fired instantaneous water heaters | Any | 0.62 - (.0019 x V) | 0.82 - (.0019 x V) |

| Electric instantaneous water heaters (excluding tabletop water heaters) | Any | 0.93 - (.00132 x V) | 0.93 - (.00132 x V) |

| Heat pump water heaters | Any | 0.97 - (.00132 x V) | 0.97 - (.00132 x V) |

| V = Rated storage volume in gallons. | |||

| Appliance | Maximum Flow Rate |

| Showerheads | 2.5 gpm at 80 psi |

| Lavatory faucets | 2.2 gpm at 60 psi |

| Kitchen faucets | 2.2 gpm at 60 psi |

| Replacement aerators | 2.2 gpm at 60 psi |

| Wash fountains | 2.2 x rim space (inches) / 20 gpm at 60 psi |

| Metering faucets | 0.25 gallons/cycle1,2 |

| Metering faucets for wash fountains | 0.25 x rim space (inches) / 20 gpm at 60 psi 1,2 |

| 1 Sprayheads with independently controlled orifices and metered controls. The maximum flow rate of each orifice that delivers a pre-set volume of water before gradually shutting itself off shall not exceed the maximum flow rate for a metering faucet.

2 Sprayheads with collectively controlled orifices and metered controls. The maximum flow rate of a sprayed that delivers a pre-set volume of water before gradually shutting itself off shall be the product of (a) the maximum flow rate for a metering faucet and (b) the number of component lavatories (rim space of the lavatory in inches (millimeters) divided by 20 inches (508 millimeters)). | |

| Application for Operation of |

Ballast Input Voltage |

Total Nominal Lamp Watts |

Minimum Ballast Efficacy Factor | |

| one F40T12 lamp | 120 or 277 | 40 | 2.291

|

1.8052

|

| two F40T12 lamps | 120 | 80 | 1.171 | 1.0602

|

| 277 | 80 | 1.171

|

1.0502

| |

| two F96T12 lamps | 120 or 277 | 150 | 0.631 | 0.5702

|

| two F96T12HO lamps | 120 or 277 | 220 | 0.391 | 0.3902

|

| 1 For fluorescent lamp balasts manufactured on or after April 1, 2005; sold by the manufacturer on or after July 1, 2005; or incorporated into a luminaire by a luminaire manufacturer on or after April 1, 2006.

2 For fluorescent lamp ballasts designed, marked, and shipped as replacement ballasts. | ||||

| Application for Operation of |

Ballast Input Voltage |

Total Nominal Lamp Watts |

Minimum Ballast Efficacy Factor |

| one F34T12 lamp | 120 or 277 | 34 | 2.61 |

| two F34T12 lamps | 120 or 277 | 68 | 1.35 |

| two F96T12/ES lamps | 120 or 277 | 120 | 0.77 |

| two F96T12HO/ES lamps | 120 or 277 | 190 | 0.42 |

| 1 For fluorescent lamp ballasts manufactured on or after July 1, 2009; sold by the manufacturer on or after October 1, 2009; or fluorescent lamp ballasts incorporated into a luminaire by a luminaire manufacturer on or after July 1, 2010. | |||

| Appliance | Nominal Lamp Wattage |

Minimum Color Rendering Index (CRI) |

Minimum Average Lamp Efficacy (LPW) |

| 4-foot medium bi-pin lamps | > 35 | 69 | 75.0 |

| ≤ 35 | 45 | 75.0 | |

| 2-foot U-shaped lamps

|

> 35 | 69 | 68.0 |

| ≤ 35 | 45 | 64.0 | |

| 8-foot slimline lamps | > 65 | 69 | 80.0 |

| ≤ 65 | 45 | 80.0 | |

| 8-foot high output lamps | > 100 | 69 | 80.0 |

| ≤ 100 | 45 | 80.0 |

| Appliance | Correlated Color

Temperature |

Minimum Average

Lamp Efficacy (LPW) |

| 4-foot medium bipin lamps | ≤ 4,500K | 89 |

| > 4,500K and ≤ 7,000K | 88 | |

| 2-foot U-shaped lamps | ≤ 4,500K | 84 |

| > 4,500K and ≤ 7,000K | 81 | |

| 8-foot slimline lamps | ≤ 4,500K | 97 |

| > 4,500K and ≤ 7,000K | 93 | |

| 8-foot high output lamps | ≤ 4,500K | 92 |

| > 4,500K and ≤ 7,000K | 88 | |

| 4-foot miniature bipin standard output | ≤ 4,500K | 86 |

| > 4,500K and ≤ 7,000K | 81 | |

| 4-foot miniature bipin high output | ≤ 4,500K | 76 |

| > 4,500K and ≤ 7,000K | 72 |

| Nominal Lamp Wattage | Minimum Average Lamp Efficacy (LPW) |

| 40-50 | 10.5 |

| 51-66 | 11.0 |

| 67-85 | 12.5 |

| 86-115 | 14.0 |

| 116-155 | 14.5 |

| 156-205 | 15.0 |

| Lamp Spectrum | Lamp Diameter (inches) |

Rated Voltage | Minimum Average Lamp Efficacy (LPW)1 |

| Standard Spectrum | > 2.5

|

≥ 125 | 6.8 x P0.27 |

| < 125 | 5.9 x P0.27 | ||

| ≤ 2.5

|

≥ 125 | 5.7 x P0.27 | |

| < 125 | 5.0 x P0.27 | ||

| Modified Spectrum | > 2.5

|

≥ 125 | 5.8 x P0.27 |

| < 125 | 5.0 x P0.27 | ||

| ≤ 2.5

|

≥ 125 | 4.9 x P0.27 | |

| < 125 | 4.2 x P0.27 | ||

| 1 P = Rated Lamp Wattage, in Watts | |||

| Factor | Requirements |

| Lamp Power (Watts) and Configuration1 | Minimum Efficacy: lumens/watt (Based upon initial lumen data)2 |

| Bare Lamp:

Lamp Power < 15

Lamp Power ≥ 15

|

45.0

60.0 |

| Covered Lamp (no reflector)

Lamp Power < 15 15 ≥ Lamp Power < 19 19 ≥ Lamp Power < 25 Lamp Power ≥ 25 |

40.0

48.0 50.0 55.0 |

| 1,000-hour Lumen Maintenance | The average of at least 5 lamps must be a minimum 90% of initial (100-hour) lumen output @ 1,000 hours of rated life. |

| Lumen Maintenance | 80% of initial (100-hour) rating at 40 percent of rated life (per ANSI C78.5 Clause 4.10). |

| Rapid Cycle Stress Test | Per ANSI C78.5 and IESNA LM-65 (Clauses 2, 3, 5, and 6)

Exception: Cycle times must be 5 minutes on, 5 minutes off. Lamp will be cycled once for every two hours of rated life. At least 5 lamps must meet or exceed the minimum number of cycles. |

| Average Rated Lamp Life | ≥ 6,000 hours as declared by the manufacturer on the packaging. 80% of rated life, statistical methods may be used to confirm lifetime claims based on sampling performance. |

| 1 Take performance and electrical requirements at the end of the 100-hour aging period according to ANSI Standard C78.5. The lamp efficacy shall be the average of the lesser of the lumens per watt measured in the base up and/or other specified positions. Use wattages placed on packaging to select proper specification efficacy in this table, not measured wattage. Labeled wattages are for reference only. | |

| 2 Efficacies are based on measured values for lumens and wattages from pertinent test data. Wattages and lumens placed on packages may not be used in calculation and are not governed by this specification. For multi-level or dimmable systems, measurements shall be at the highest setting. Acceptable measurement error is ±3%. | |

| Rated Lumen Ranges | Maximum Rate Wattage | Minimum Rate Lifetime | Effective Date |

| 1490 - 2600 | 72 | 1,000 hours | January 1, 2012 |

| 1050 - 1489 | 53 | 1,000 hours | January 1, 2013 |

| 750 - 1049 | 43 | 1,000 hours | January 1, 2014 |

| 310 - 749 | 29 | 1,000 hours | January 1, 2014 |

| Rated Lumen Ranges | Maximum Rate Wattage | Minimum Rate Lifetime | Effective Date |

| 1118-1950 | 72 | 1,000 hours | January 1, 2012 |

| 788-1117 | 53 | 1,000 hours | January 1, 2013 |

| 563-787 | 43 | 1,000 hours | January 1, 2014 |

| 232-562 | 29 | 1,000 hours | January 1, 2014 |

| Appliance | Maximum Wattage

(at 74°C) |

Nominal Wattage

(at 25°C) |

| Traffic Signal Module Type: | ||

|

12-inch; Red Ball

|

17 | 11 |

|

8-inch; Red Ball

|

13 | 8 |

|

12-inch; Red Arrow

|

12 | 9 |

|

12-inch; Green Ball

|

15 | 15 |

|

8-inch; Green Ball

|

12 | 12 |

|

12-inch; Green Arrow

|

11 | 11 |

| Pedestrian Module Type: | ||

|

Combination Walking Man/Hand

|

16 | 13 |

|

Walking Man

|

12 | 9 |

|

Orange Hand

|

16 | 13 |

| Appliance | Effective January 1, 2010 | Effective May 30, 2013 | ||

| Maximum Energy Use (kWh/year) | Maximum Water Use (gallons/cycle) | Maximum Energy Use (kWh/year) | Maximum Water Use (gallons/cycle) | |

| Compact dishwashers | 260 | 4.5 | 222 | 3.5 |

| Standard dishwashers | 355 | 6.5 | 307 | 5.0 |

| Appliance | Minimum Modified Energy Factor Effective January 1, 2007 |

Maximum Water Factor Effective January 1, 2011 |

| Top-loading compact clothes washers | 0.65 | - |

| Top-loading standard clothes washers | 1.26 | 9.5 |

| Top-loading, semi-automatic | N/A¹ | - |

| Front-loading clothes washers | 1.26 | 9.5 |

| Suds-saving | N/A¹ | - |

| ¹ Must have an unheated rinse water option. | ||

| Appliance | Minimum Integrated Modified Energy Factor | Maximum Integrated Water Factor | ||

| March 7, 2015 | January 1, 2018 | March 7, 2015 | January 1, 2018 | |

| Top-loading, Compact | 0.86 | 1.15 | 14.4 | 12.0 |

| Top-loading, Standard | 1.29 | 1.57 | 8.4 | 6.5 |

| Front-loading, Compact | 1.13 | 1.13 | 8.3 | 8.3 |

| Front-loading, Standard | 1.84 | 1.84 | 4.7 | 4.7 |

| Appliance | Minimum Modified Energy Factor | Maximum Water Factor | ||

| Effective

January 1, 2007 |

Effective

January 8, 2013 |

Effective

January 1, 2007 |

Effective

January 8, 2013 | |

| Top-loading clothes washers | 1.26 | 1.60 | 9.5 | 8.5 |

| Front-loading clothes washers | 1.26 | 2.00 | 9.5 | 5.5 |

| Appliance | Minimum Energy Factor

(lbs/kWh) |

| Electric, standard clothes dryers | 3.01 |

| Electric, compact, 120-volt clothes dryers | 3.13 |

| Electric, compact, 240-volt clothes dryers | 2.90 |

| Gas clothes dryers | 2.67 |

| Motor

Horsepower/ Standard

Kilowatt Equivalent |

Minimum Nominal Full-Load Efficiency

| |||||

| Open Motors

|

Enclosed Motors

| |||||

| 6 poles | 4 poles | 2 poles | 6 poles | 4 poles | 2 poles | |

| 1/0.75 | 80.0 | 82.5 | ... | 80.0 | 82.5 | 75.5 |

| 1.5/1.1 | 84.0 | 84.0 | 82.5 | 85.5 | 84.0 | 82.5 |

| 2/1.5 | 85.5 | 84.0 | 84.0 | 86.5 | 84.0 | 84.0 |

| 3/2.2 | 86.5 | 86.5 | 84.0 | 87.5 | 87.5 | 85.5 |

| 5/3.7 | 87.5 | 87.5 | 85.5 | 87.5 | 87.5 | 87.5 |

| 7.5/5.5 | 88.5 | 88.5 | 87.5 | 89.5 | 89.5 | 88.5 |

| 10/7.5 | 90.2 | 89.5 | 88.5 | 89.5 | 89.5 | 89.5 |

| 15/11 | 90.2 | 91.0 | 89.5 | 90.2 | 91.0 | 90.2 |

| 20/15 | 91.0 | 91.0 | 90.2 | 90.2 | 91.0 | 90.2 |

| 25/18.5 | 91.7 | 91.7 | 91.0 | 91.7 | 92.4 | 91.0 |

| 30/22 | 92.4 | 92.4 | 91.0 | 91.7 | 92.4 | 91.0 |

| 40/30 | 93.0 | 93.0 | 91.7 | 93.0 | 93.0 | 91.7 |

| 50/37 | 93.0 | 93.0 | 92.4 | 93.0 | 93.0 | 92.4 |

| 60/45 | 93.6 | 93.6 | 93.0 | 93.6 | 93.6 | 93.0 |

| 75/55 | 93.6 | 94.1 | 93.0 | 93.6 | 94.1 | 93.0 |

| 100/75 | 94.1 | 94.1 | 93.0 | 94.1 | 94.5 | 93.6 |

| 125/90 | 94.1 | 94.5 | 93.6 | 94.1 | 94.5 | 94.5 |

| 150/110 | 94.5 | 95.0 | 93.6 | 95.0 | 95.0 | 94.5 |

| 200/150 | 94.5 | 95.0 | 94.5 | 95.0 | 95.0 | 95.0 |

| Single phase | Three phase | ||||

| kVA | Efficiency (%)¹

|

kVA | Efficiency (%)¹ | ||

| Effective January 1, 2007 | Effective January 1, 2016 | Effective January 1, 2007 | Effective January 1, 2016 | ||

| 15 | 97.7 | 97.70 | 15 | 97.0 | 97.89 |

| 25 | 98.0 | 98.00 | 30 | 97.5 | 98.23 |

| 37.5 | 98.2 | 98.20 | 45 | 97.7 | 98.40 |

| 50 | 98.3 | 98.30 | 75 | 98.0 | 98.60 |

| 75 | 98.5 | 98.50 | 112.5 | 98.2 | 98.74 |

| 100 | 98.6 | 98.60 | 150 | 98.3 | 98.83 |

| 167 | 98.7 | 98.70 | 225 | 98.5 | 98.94 |

| 250 | 98.8 | 98.80 | 300 | 98.6 | 99.02 |

| 333 | 98.9 | 98.90 | 500 | 98.7 | 99.14 |

|

|

|

|

750 | 98.8 | 99.23 |

|

|

|

|

1000 | 98.9 | 99.28 |

|

¹ Efficiencies are determined at the following reference conditions: (1) for no-load losses, at the temperature of 20°C, and (2) for load-losses, at the temperature of 75°C and 35 percent of nameplate load. (Source: Table 4-2 of NEMA Standard TP-1-2002, "Guide for Determining Energy Efficiency for Distribution Transformers.") | |||||

| Single phase | Three phase | ||||

| kVA | Efficiency (%)¹ | kVA | Efficiency (%)¹

| ||

| Effective January 1, 2007 | Effective January 1, 2016 | Effective January 1, 2007 | Effective January 1, 2016 | ||

| 10 | 98.62 | 98.70 | 15 | 98.36 | 98.65 |

| 15 | 98.76 | 98.82 | 30 | 98.62 | 98.83 |

| 25 | 98.91 | 98.95 | 45 | 98.76 | 98.92 |

| 37.5 | 99.01 | 99.05 | 75 | 98.91 | 99.03 |

| 50 | 99.08 | 99.11 | 112.5 | 99.01 | 99.11 |

| 75 | 99.17 | 99.19 | 150 | 99.08 | 99.16 |

| 100 | 99.23 | 99.25 | 225 | 99.17 | 99.23 |

| 167 | 99.25 | 99.33 | 300 | 99.23 | 99.27 |

| 250 | 99.32 | 99.39 | 500 | 99.25 | 99.35 |

| 333 | 99.36 | 99.43 | 750 | 99.32 | 99.40 |

| 500 | 99.42 | 99.49 | 1000 | 99.36 | 99.43 |

| 667 | 99.46 | 99.52 | 1500 | 99.42 | 99.48 |

| 833 | 99.49 | 99.55 | 2000 | 99.46 | 99.51 |

|

|

|

|

2500 | 99.49 | 99.53 |

| 1 Note: All efficiency values are at 50 percent of nameplate-rated load, determined when tested according to the test procedure in Section 1604(t). | |||||

| Single phase | Three phase | ||||||

| BIL kVA | 20-45 kV Efficiency1 (%) | 46-95 kV efficiency1 (%) | ≥96 kV efficiency1 (%) | BIL kVA | 20-45 kV Efficiency1 (%) | 46-95 kV efficiency1 (%) | ≥96 kV efficiency1 (%) |

| 15 | 98.10 | 97.86 | 15 | 97.50 | 97.18 | ||

| 25 | 98.33 | 98.12 | 30 | 97.90 | 97.63 | ||

| 37.5 | 98.49 | 98.30 | 45 | 98.10 | 97.86 | ||

| 50 | 98.60 | 98.42 | 75 | 98.33 | 98.12 | ||

| 75 | 98.73 | 98.57 | 98.53 | 112.5 | 98.49 | 98.30 | |

| 100 | 98.82 | 98.67 | 98.63 | 150 | 98.60 | 98.42 | |

| 167 | 98.96 | 98.83 | 98.80 | 225 | 98.73 | 98.57 | 98.53 |

| 250 | 99.07 | 98.95 | 98.91 | 300 | 98.82 | 98.67 | 98.63 |

| 333 | 99.14 | 99.03 | 98.99 | 500 | 98.96 | 98.83 | 98.80 |

| 500 | 99.22 | 99.12 | 99.09 | 750 | 99.07 | 98.95 | 98.91 |

| 667 | 99.27 | 99.18 | 99.15 | 1000 | 99.14 | 99.03 | 98.99 |

| 833 | 99.31 | 99.23 | 99.20 | 1500 | 99.22 | 99.12 | 99.09 |

| 2000 | 99.27 | 99.18 | 99.15 | ||||

| 2500 | 99.31 | 99.23 | 99.20 | ||||

| 1All efficiency values are at 50 percent of nameplate rated load, determined when tested according to the test procedure in Section 1604(t). | |||||||

| Single phase | Three phase | ||||||

| BIL kVA |

20-45 kV Efficiency¹ (%) |

46-95 kV Efficiency¹ (%) |

≥ 96 kV Efficiency¹ (%) |

BIL kVA |

20-45 kV Efficiency¹ (%) |

46-95 kV Efficiency¹ (%) |

≥ 96 kV Efficiency¹ (%) |

| 15 | 98.10 | 97.86 | 15 | 97.50 | 97.18 | ||

| 25 | 98.33 | 98.12 | 30 | 97.90 | 97.63 | ||

| 37.5 | 98.49 | 98.30 | 45 | 98.10 | 97.86 | ||

| 50 | 98.60 | 98.42 | 75 | 98.33 | 98.13 | ||

| 75 | 98.73 | 98.57 | 98.53 | 112.5 | 98.52 | 98.36 | |

| 100 | 98.82 | 98.67 | 98.63 | 150 | 98.65 | 98.51 | |

| 167 | 98.96 | 98.83 | 98.80 | 225 | 98.82 | 98.69 | 98.57 |

| 250 | 99.07 | 98.95 | 98.91 | 300 | 98.93 | 98.81 | 98.69 |

| 333 | 99.14 | 99.03 | 98.99 | 500 | 99.09 | 98.99 | 98.89 |

| 500 | 99.22 | 99.12 | 99.09 | 750 | 99.21 | 99.12 | 99.02 |

| 667 | 99.27 | 99.18 | 99.15 | 1000 | 99.28 | 99.20 | 99.11 |

| 833 | 99.31 | 99.23 | 99.20 | 1500 | 99.37 | 99.30 | 99.21 |

|

|

|

|

|

2000 | 99.43 | 99.36 | 99.28 |

|

|

|

|

|

2500 | 99.47 | 99.41 | 99.33 |

| 1 All efficiency values are at 50 percent of nameplate rated load, determined when tested according to the test procedure in Section 1604(t) | |||||||

| Nameplate Output | Minimum Efficiency in Active Mode

(Decimal equivalent of a Percentage) |

| < 1 watt | 0.5 * Nameplate Output |

| ≥ 1 and ≤ 51 watts | 0.09 * Ln(Nameplate Output) + 0.5 |

| > 51 watts | 0.85 |

|

|

Maximum Energy Consumption in No-Load Mode

|

| ≤ 250 watts | 0.5 watts |

| Where Ln (Nameplate Output) = Natural Logarithm of the nameplate output expressed in watts.

| |

| Appliance | Maximum Annual Energy Consumption

(kWh) |

| Wine chillers with manual defrost |

13.7V + 267

|

| Wine chillers with automatic defrost |

17.4V + 344

|

| V = volume in ft3 | |

| Appliance | Maximum Annual Energy Consumption (kWh) |

| Upright Freezers with manual defrost |

7.55AV + 258.3

|

| Upright Freezers with automatic defrost |

12.43AV + 326.1

|

| Chest Freezers |

9.88AV + 143.7

|

| AV = adjusted total volume, expressed in ft3, which is 1.73 x freezer volume (ft3). | |

| Appliance | Doors | Maximum Daily Energy Consumption (kWh) | |

| January 1, 2006 | January 1, 2007 | ||

| Refrigerated canned and bottled beverage vending machines when tested at 90° F ambient temperature except multi-package units | Not applicable | 0.55(8.66 + (0.009 x C)) | 0.55(8.66 + (0.009 x C)) |

| Refrigerated multi-package canned and bottled beverage vending machines when tested at 75° F ambient temperature | Not applicable | 0.55(8.66 + (0.009 x C)) | 0.55(8.66 + (0.009 x C)) |

|

V = total volume (ft³) AV = Adjusted Volume = [1.63 x freezer volume (ft³)] + refrigerator volume (ft³) C = Rated capacity (number of 12-ounce cans) | |||

| Appliance | Rating Condition | Minimum

Standard |

| Ground water-source heat pumps (cooling) | 59°F entering water temperature | 16.2 EER |

| Ground water-source heat pumps (heating)

|

50°F entering water temperature | 3.6 COP |

| Ground-source heat pumps (cooling) | 77°F entering brine temperature | 13.4 EER |

| Ground-source heat pumps (heating)

|

32°F entering brine temperature | 3.1 COP |

|

Appliance |

Cooling Capacity (Btu/hr) |

Minimum EER (Btu/watt-hour) | |

| Air-Cooled Effective January 1, 2006

|

Water-Cooled, Glycol-Cooled, and Evaporatively-Cooled Effective October 29, 2006 | ||

| Computer room air conditioners | < 65,000 | 11.0 | 11.1 |

| ≥ 65,000 and < 135,000

|

10.4 | 10.5 | |

| ≥ 135,000 and < 240,000

|

10.2 | 10.0 | |

| Appliance | Output (Btu/hr) | Standards | ||

| Minimum AFUE % | Minimum Combustion Efficiency % * | Maximum Standby Loss (watts) | ||

| Gas steam boilers with 3-phase electrical supply | < 300,000 | 75 | — | — |

| All other boilers witd 3-phase electrical supply | < 300,000 | 80 | — | — |

| Natural gas, non-packaged boilers | ≥ 300,000 | — | 80 | 147 |

| LPG Non-packaged boilers | ≥ 300,000 | — | 80 | 352 |

| Oil, non-packaged boilers | ≥ 300,000 | — | 83 | — |

| *At both maximum and minimum rated capacity, as provided and allowed by the controls.

| ||||

| Appliance | Application | Minimum Efficiency % |

| Central furnaces with 3-phase electrical supply < 225,000 Btu/hour |

Mobile Home | 75 AFUE |

| All others | 78 AFUE or 80 Thermal Efficiency (at manufacturer's option) |

| Appliance | Fuel | Standards | ||

| Minimum Thermal Efficiency % 1 | Maximum Energy Consumption during standby (watts) | |||

| At maximum rated capacity | At minimum rated capacity | |||

| Duct furnaces | Natural gas | 80 | 75 | 10 |

| Duct furnaces | LPG 2 | 80 | 75 | 147 |

| 1 As provided and allowed by the controls.

2 Designed expressly for use with LPG. | ||||

| Appliance | Energy Source | Input Rating | Rated Storage Volume (gallons) | Minimum Energy Factor¹ |

| Storage water heaters | Gas | ≤ 75,000 Btu/hr | < 20 | 0.62 - (.0019 x V) |

| Storage water heaters | Gas | ≤ 75,000 Btu/hr | > 100 | 0.62 - (.0019 x V) |

| Storage water heaters | Oil | ≤ 105,000 Btu/hr | > 50 | 0.59 - (.0019 x V) |

| Storage water heaters | Electricity | ≤ 12 kW | > 120 | 0.93 - (.00132 x V) |

| Instantaneous Water Heaters | Gas | ≤ 50,000 Btu/hr | Any | 0.62 - (.0019 x V) |

| Instantaneous Water Heaters | Gas | ≤ 200,000 Btu/hr | ≥ 2 | 0.62 - (.0019 x V) |

| Instantaneous Water Heaters | Oil | ≤ 210,000 Btu/hr | Any | 0.59 - (.0019 x V) |

| Instantaneous Water Heaters | Electricity | ≤ 12 kW | Any | 0.93 - (.00132 x V) |

| ¹ Volume (V) = rated storage volume in gallons.

| ||||

| Appliance | Testing Conditions | Maximum Leakage Rate |

| Tub spout diverters | When new | 0.01 gpm |

| After 15,000 cycles of diverting | 0.05 gpm |

| Rated Lamp Wattage | Minimum Average Lamp Efficacy

(LPW) |

| 40-50 | 10.5 |

| 51-66 | 11.0 |

| 67-85 | 12.5 |

| 86-115 | 14.0 |

| 116-155 | 14.5 |

| 156-205 | 15.0 |

| Rated Lumen Ranges | Maximum Rated Wattage | Minimum Rated Lifetime | Effective Date |

| 1490-2600 Lumens | 72 watts | 1,000 Hours | Jan 1, 2011 |

| 1050-1489 Lumens | 53 watts | 1,000 Hours

|

Jan 1, 2012 |

| 750-1049 Lumens | 43 watts | 1,000 Hours

|

Jan 1, 2013 |

| 310-749 Lumens | 29 watts | 1,000 Hours

|

Jan 1, 2013 |

| Lumen Ranges | Minimum Lamp Efficacy | Minimum Rated Lifetime | Effective Date |

| All | 45 lumens per watt | 1,000 Hours | Jan 1, 2018 |

| Rated Lumen Ranges | Maximum Rated Wattage | Minimum Rated Lifetime | Effective Date |

| 1118-1950 Lumens | 72 watts | 1,000 Hours | Jan 1, 2011 |

| 788-1117 Lumens | 53 watts | 1,000 Hours

|

Jan 1, 2012 |

| 563-787 Lumens | 43 watts | 1,000 Hours

|

Jan 1, 2013 |

| 232-562 Lumens | 29 watts | 1,000 Hours

|

Jan 1, 2013 |

| Mid-frequency of Sound Pressure Third-Octave Band

(in kHz) |

Maximum db Level within third-Octave Band

(in dB reference 20 micropascals) |

| Less than 20 | 80 |

| 20 or more to less than 25 | 105 |

| 25 or more to less than 31.5 | 110 |

| 31.5 or more | 115 |

| Type | at 25°C (77°F) | At 74°C (165.2° F) |

| Hand or 'Don't Walk' sign or countdown. | 10 watts | 12 watts |

| Walking Person or 'Walk' sign | 9 watts | 12 watts |

| Lamp Length

(inches) |

Minimum Ballast Efficacy Factor (BEF) for one lamp | Minimum Ballast Efficacy Factor (BEF) for two lamps |

| ≤29

|

4.70 | 2.80 |

| >29 and ≤35 | 3.95 | 2.30 |

| >35 and ≤41 | 3.40 | 1.90 |

| >41 and ≤47 | 3.05 | 1.65 |

| >47 | 2.80 | 1.45 |

| Criteria | Requirement |

| Light Output | ≥ 200 lumens (initial)

|

| Minimum LED Luminaire Efficacy | 29 lumens/W |

| Minimum LED Light Engine Efficacy | 40 lumens/W |

| Color Correlated Temperature (CCT) | 2700 K through 5000 K |

| Minimum Color Rendering Index (CRI) | 75 |

| Power Factor (for luminaires labeled or sold for residential use) | ≥ 0.70

|

| Nameplate Output | Minimum Efficiency in Active Mode |

| 0 to < 1 watt | 0.49 * Nameplate Output |

| ≥ 1 and ≤ 49 watts | 0.09 * Ln(Nameplate Output) + 0.49 |

| > 49 watts | 0.84 |

|

|

Maximum Energy Consumption in No-Load Mode

|

| 0 to < 10 watts | 0.5 watts |

| ≥ 10 and ≤ 250 watts | 0.75 watts |

| Where Ln (Nameplate Output) = Natural Logarithm of the nameplate output expressed in watts.

| |

| Nameplate Output | Minimum Efficiency in Active Mode |

| < 1 watt | 0.5 * Nameplate Output |

| ≥ 1 and ≤ 51 watts | 0.09 * Ln(Nameplate Output) + 0.5 |

| > 51 watts | 0.85 |

|

|

Maximum Energy Consumption in No-Load Mode

|

| Any output | 0.5 watts |

| Where Ln (Nameplate Output) = Natural Logarithm of the nameplate output expressed in watts.

| |

| Appliance Type | Effective Date | Maximum Power Usage (Watts) |

| Compact Audio Products | January 1, 2007 | 2 W in Audio standby-passive mode for those without a permanently illuminated clock display

4 W in Audio standby-passive mode for those with a permanently illuminated clock display |

| Digital Versatile Disc Players and Digital Versatile Disc Recorders | January 1, 2006 | 3 W in Video standby-passive mode |

| Effective Date | Screen Size (area A in square inches) | Maximum TV Standby-passive Mode Power Usage (watts) | Maximum On Mode Power Usage (P in Watts) | Minimum Power Factor for (P ≥ 100W) |

| January 1, 2006 | All | 3 W | No standard | No standard |

| January 1, 2011 | A < 1400 | 1 W | P ≤ 0.20 x A + 32 | 0.9 |

| January 1, 2013 | A < 1400 | 1 W | P ≤ 0.12 x A + 25 | 0.9 |

| Performance Parameter | Standard | |

| Charge Return Factor (CRF) | 100 percent, 80 percent Depth of discharge

|

CRF ≤ 1.10 |

| 40 percent Depth of discharge

|

CRF ≤ 1.15

| |

| Power Conversion Efficiency | Greater than or equal to: 89 percent | |

| Power Factor | Greater than or equal to: 0.90 | |

| Maintenance Mode Power (Eb = battery capacity of tested battery) | Less than or equal to 10 + 0.0012Eb W | |

| No Battery Mode Power | Less than or equal to 10 W | |

| Performance Parameter | Standard |

| Maximum 24-hour charge and maintenance energy (Wh)

(Eb = capacity of all batteries in ports and N = number of charger ports) |

For Eb of 2.5 Wh or less:

16 × N |

| For Eb greater than 2.5 Wh and less than or equal to 100 Wh:

12 x N +1.6Eb | |

| For Eb greater than 100 Wh and less than or equal to 1000 Wh:

22 x N+1.5Eb | |

| For E₅ greater than 1000 Wh:

36.4 x N+1.486Eb | |

| Maintenance Mode Power and No Battery Mode Power (W)

(Eb = capacity of all batteries in ports and N = number of charger ports) |

The sum of maintenance mode power and no battery mode power must be less than or equal to:

1x N+0.0021×Eb |