For a definition of an addition in the Standards, and several useful examples of additions, see the Introduction, Section 9.1 of this chapter.

For a summary of compliance alternatives for additions, see Compliance Approaches, Section 9.2 of this chapter.

Beyond the outline provided in Section 9.2, this section provides more specific information, descriptions and guidelines on how to meet the Standards using each of the available compliance paths. Copies of compliance forms referenced here are included in the Compliance Forms Summary, Appendix A of this 'manual.

In general, the prescriptive requirements apply to additions in the same way they apply to entirely new buildings and must be documented on the CF1R-ADD Form. However, there are a few exceptions as noted below and summarized in Table 9-3A.

There are three prescriptive paths available for additions based on the total conditioned floor area (CFA) of the addition. The total CFA of the addition may include floor areas representing several physically separate additions to the building under the same permit.

Table 9-3A summarizes the key features of the prescriptive envelope requirements for the three prescriptive addition options in §150.2(a)1 of the Standards. Envelope requirements unique to that type of prescriptive addition are shown in bold face on white background. Table 9-3B shows that all prescriptive additions have the same mechanical system and water heating system requirements as the Package A prescriptive measures for new construction 'listed in §150.1(c) and explained in Chapters 4 and 5.

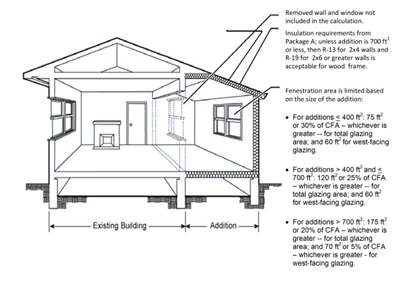

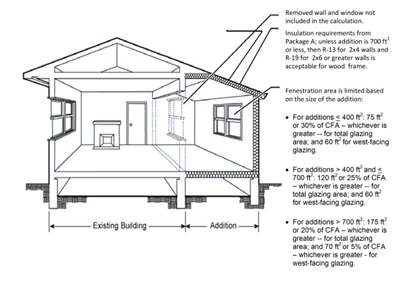

A. Additions ≤ 400 ft2

All prescriptive Package A requirements must be met except:

1. Total glazing area may be up to 75 ft2 or 30% of conditioned floor area, whichever is greater;

2. West-facing glazing area may be up to 60 ft2;

3. Required exterior wall insulation:

a. In 2x4 wood frame walls, insulation shall be R-13 or an overall construction assembly U-factor < 0.102, for wood or metal frame walls;

b. In 2x6 or greater wood frame walls, insulation shall be R-19 or an overall construction assembly U-factor < 0.074, for wood or metal frame walls;

4. No requirement for a whole house fan (WHF) to provide ventilation cooling;

5. For additions ≤ 300 ft2 cool roof compliance is not required.

B. Additions > 400 ft2 and ≤ 700 ft2:

All prescriptive Package A requirements must be met except:

1. Total glazing area may be up to 120 ft2 or 25% of conditioned floor area, whichever is greater;

2. West-facing glazing area may be up to 60 ft2;

3. Required exterior wall insulation:

a. In 2x4 wood frame walls, insulation shall be R-13 or an overall construction assembly U-factor < 0.102, for wood or metal frame walls;

b. In 2x6 or greater wood frame walls, insulation shall be R-19 or an overall construction assembly U-factor < 0.074, for wood or metal frame walls;

4. No requirement for a whole house fan (WHF) to provide ventilation cooling.

C. Additions > 700 ft2

All prescriptive Package A requirements must be met except:

1. Total glazing area may be up to 175 ft2 or 20% of conditioned floor area, whichever is greater;

2. West-facing glazing area may be up to 70 ft2 or 5% of conditioned floor area, whichever is greater;

3. If the addition is < 1,000 ft2, there is no requirement for a whole house fan (WHF) to provide ventilation cooling;

4. Additions > 1,000 ft2 must include provide ventilation cooling with a WHF as indicated in §150.1(c)12;

5. If the Total Proposed fenestration area exceeds the Standard Maximum Glazing Area of 20% then the performance compliance approach must be used. Likewise, if the Proposed West-Facing fenestration area in climate zones 2, 4, and 6-16 exceeds 5% of the conditioned floor area, then the performance compliance approach must be used;

6. If the addition has a floor area >700 ft² and < 1,000 ft², all requirements of Package A apply except the West-Facing Glazing Area may be up to 70 ft² for additions up to 1,400 ft² (since 70 ft² is 5% of 1,400 ft²). See §150.2(a)1A.

|

Compliance Forms for Prescriptive Additions

The permit applicant must submit a completed version of the Certificate of Compliance, CF1R-ADD form, for prescriptive additions when less than 100 ft2 .

Important note: All projects which require third party diagnostic testing and/or field verification by a HERS rater must also have the CF1R-ADD form uploaded and registered online with a HERS provider (see Chapter 2).

Use the CF1R-ADD form to document fenestration by orientation. The total percentage of fenestration should be no greater than the amount summarized above and in Table 9-3A. West facing area includes skylights tilted to the west or tilted in any direction when the pitch is less than 1:12 (9.5 degrees from the horizontal), and must not exceed 5 percent of the conditioned floor area (CFA) in climate zones 2, 4, and 6-16.

Note: Plan checkers will verify on the CF1R-ADD form that the Total Proposed Glazing Area is less than or equal to the Standard Maximum Glazing Area; and that the Proposed West-Facing Glazing Area is less than or equal to the Standard West-Facing Glazing Area.

New fenestration in prescriptive additions must meet the area-weighted average U-factor and SHGC requirements in §150.1(c)3A with the following exceptions particularly relevant to additions:

1. EXCEPTION 1: For each dwelling unit, up to 3 ft2 of new glazing in doors and up to 3 ft2 of tubular skylights with dual pane diffusers are exempt;

2. EXCEPTION 2: For each dwelling unit, up to 16 ft2 of skylights with a maximum U-factor of 0.55 and a maximum SHGC of 0.30 is exempt.

See Section 3.5 for further information on fenestration which meets or is exempt from §150.1(c)3A in new construction.

Other Prescriptive Addition Envelope Measures

For further information on prescriptive envelope measures which are not specific to additions and not highlighted above, see Chapter 3.

Prescriptive Mechanical Measures

For a summary and discussion of prescriptive mechanical

requirements when installing new or replacement space conditioning equipment

and/or ducts, see Section 9.6.1.

Example 9-9

Question

When using the performance approach for the addition alone, do the refrigerant charge requirements in §150.1(c)7A, and fan airflow and watt draw measurements in §150.0(m)13 need to be met for existing central split system air conditioners serving an addition?

Answer

If existing equipment is used to serve the addition, the refrigerant charge, airflow and watt draw requirements do not need to be met as specified by Exception 5 to §150.2(a). However, if added ducts to serve the addition are more than 40 linear feet and they are in unconditioned space, then the ducts must be tested and verified by a HERS rater as described in §150.2(b)1D. All installed ducts regardless of their length and location shall be sealed and meet insulation levels as described in §150.0(m) items 1 through 6.

If a new central split system is installed to serve the addition, it must meet all of the requirements for air conditioners in a new residence.

|

Component |

Requirements of |

Requirements of and < 700 ft2 |

Requirements of Additions > 700 ft2 |

|

Roof/Ceiling |

Package A: CZ1, 11-16: R-38 / U=0.025; CZ2-10: R-30 / U=0.031 |

Package A: CZ1, 11-16: R-38 / U=0.025; CZ2-10: R-30 / U=0.031 |

Package A: CZ1, 11-16: R-38 / U=0.025; CZ2-10: R-30 / U=0.031 |

|

Package A: Steep-Sloped (> 2:12): CZ10-15: Reflect.=0.20 and Emittance=0.75; or SRI=16 |

Package A: Steep-Sloped (> 2:12): CZ10-15: Reflect.=0.20 and Emittance=0.75; or SRI=16 |

Package A: Steep-Sloped (> 2:12): CZ10-15: Reflect.=0.20 and Emittance=0.75; or SRI=16 | |

|

Package A: Low-Sloped (< 2:12): |

Package A: Low-Sloped (< 2:12): |

Package A: Low-Sloped (< 2:12): | |

|

Exception: Additions < 300 ft2 exempt from all cool roof requirements. | |||

|

Radiant Barrier Above Attic: |

Package A: CZ2-15: Radiant Barrier |

Package A: CZ2-15: Radiant Barrier |

Package A: CZ2-15: Radiant Barrier |

|

Component |

Requirements of |

Requirements of |

Requirements of Additions > 700 ft2 |

|

Total Glazing Area: |

Up to 75 ft2 or 30% of Conditioned Floor Area, whichever is greater |

Up to 120 ft2 or 25% of Conditioned Floor Area, whichever is greater |

Up to 175 ft2 or 20% of Conditioned Floor Area, whichever is greater |

|

West-Facing Glazing Area: In Climate Zone 2, 4, 6-16 |

Up to 60 ft2 |

Up to 60 ft2 |

Up to 70 ft2 or 5% of Conditioned Floor Area, whichever is greater |

|

Glazing U-Factor & SHGC1: |

Package A: All CZs: U = 0.32 |

Package A: All CZs: U = 0.32 CZ 2, 4 & 6-16: SHGC = 0.25 |

Package A: All CZs: U = 0.32 |

|

1. See §150.0(q) and §150.1(c)3 for new and replaced window and skylight exceptions . | |||

|

Component |

Requirements of Additions < 400 ft2 |

Requirements of Additions > 400 ft2 and < 700 ft2 |

Requirements of |

|

Exterior Wall1 Insulation: |

In 2x4 Framing: R-13, U=0.102 |

In 2x4 Framing: R-13, U=0.102 In 2x6 Framing: R-19, U=0.074 |

Package A: All CZs: U=0.065 |

|

Raised Floor1 Insulation: |

Package A: All CZs: R-19 or |

Package A: All CZs: R-19 or |

Package A: All CZs: R-19 or |

|

Slab Floor1 Insulation: |

Package A: CZ1-15: No Requirement; CZ 16: R-7.0 or U=0.58 |

Package A: CZ1-15: No Requirement; CZ 16: R-7.0 or U=0.58 |

Package A: CZ1-15: No Requirement; CZ 16: R-7.0 or U=0.58 |

|

1. R-values refer to wood framing and U-factors refer to metal framing. |

|||

|

Component |

Requirements of Additions < 400 ft2 |

Requirements of Additions > 400

ft2 |

Requirements of Additions > 700 ft2 |

|

Ventilation Cooling1 (Whole House Fan) |

No Requirement. |

No Requirement. |

Additions < 1,000 ft2: No requirement Additions > 1,000 ft2: Package A Whole House Fan, §150.1(c)12 |

|

Adding New Space Conditioning System(s) |

All Package A requirements. |

All Package A requirements. |

All Package A requirements. |

|

Replacing Existing Space Conditioning System(s) |

All Package A requirements. |

All Package A requirements. |

All Package A requirements. |

|

Adding All New Complete Duct System(s) |

All Package A requirements. |

All Package A requirements. |

All Package A requirements. |

|

Extending Existing Duct System(s) by > 40 Feet |

All Package A duct insulation requirements; duct system sealing and HERS Verified |

All Package A duct insulation requirements; duct system sealing and HERS Verified |

All Package A duct insulation requirements; duct system sealing and HERS Verified |

|

(Note: also mandatory mechanical ventilation per ASHRAE 62.2 with HERS verification for additions > 1,000 ft2) | |||

If an addition increases the number of water heaters serving a dwelling unit, then the addition can comply prescriptively if any one of the following conditions contained in §150.2(a)1D.i, ii and iii:

The additional water heater is a 50 gallon or less, gas storage or gas instantaneous, non-recirculating water heater with an EF (Energy Factor) equal to or greater than the federal minimum standards as defined in Section 5.4; or

The building does not have natural gas or propane available; and the additional water heater is a 50 gallon or less electric storage tank water heater, or electric instantaneous with an EF equal to or greater than the federal minimum standards; or

A water-heating system determined by the Executive Director of the Energy Commission to use no more energy than the one specified in item 1 above; or if no natural gas is connected to the building, a water-heating system determined by the Executive Director to use no more energy than the one specified in item 2 above.

If none of these conditions can be met when adding a water heater to an existing dwelling unit, then the prescriptive addition compliance path cannot be used. In that case, the Existing + Addition + Alterations compliance approach must be used to demonstrate overall compliance with whatever combination of existing and new water heaters serve the dwelling unit. This is summarized in §150.2(a)1D.iv and discussed as part of the overall performance method in Section 9.5.2.

For other alterations to the water heating system that occur as part of an addition, see Section 9.6.

Example 9-10

Question

A small addition of 75 ft² is being planned for a house located in climate zone 7. An existing porch off the master bedroom is being enclosed. The existing heating and air conditioning system will serve the new conditioned space including an extension of less than 40 linear feet of new ducts. The contractor wants to follow the prescriptive requirements. What requirements apply?

Answer

Since the addition is smaller than 400 ft², the total fenestration area is limited to a maximum of 75 ft² and west-facing fenestration area is limited to 60 ft². The fenestration must meet the U-factor and SHGC requirements of Package A. For climate zone 7, these fenestration requirements are a maximum U-factor of 0.32 and a maximum SHGC of 0.25. For an addition of this size, insulation only must meet the mandatory requirements of R-30 ceiling insulation; R-13 wall insulation and R-19 floor insulation. Since the addition is also less than 300 ft2, there is no cool roof requirement.

Since the existing heating and cooling equipment is being used for the addition, that equipment does not have to meet the mandatory equipment efficiency requirements. Mandatory duct insulation requirements of §150.0(m) apply (including R-6.0 minimum in unconditioned space). All other mandatory requirements in §150.0 must be met.

Example 9-11

Question

If I remove a window from the existing house and re-use this window in an addition to that house, does the relocated window have to meet the prescriptive requirements of Package A?

Answer

Yes, if using prescriptive

compliance, in which case the relocated window must be treated as a new window

and must meet the U-factor and SHGC requirements of Package A, §150.1(c)3. If you use this existing window in the addition,

you must use the actual or default U-factor and SHGC of the window in showing

compliance. Therefore, meeting the prescriptive requirements may not be

possible, and performance compliance may be the only option. Window

certification and labeling requirements of §110.6(a) do not apply to existing used

windows.

Relocated windows must also

meet the maximum area-weighted average U-factor in §150.0(q) with the EXCEPTION of up to 10 square feet or 0.5% of

conditioned floor area, whichever is greater.

Example 9-12

Question

I am doing an alteration in Climate Zone 12 in which I am moving an existing 25 ft2 window to another location within the same existing wall; and am not increasing total glazing area. Does the re-located window need to meet any prescriptive requirements?

Answer

Removing an area of glazing in an existing wall, and re-inserting up to the same area of glazing in a different opening, is considered replacement fenestration as defined in §150.2(b)1B. Exception 1 to §150.2(b)1B states that up to 75 ft2 of vertical replacement fenestration in Climate Zone 12 must meet a prescriptive U-factor = 0.40 and an SHGC = 0.35.

Question

For additions and alterations that include a greenhouse window (also known as garden window), what are the U factor and SHGC requirements? What is the area used for calculations for greenhouse windows?

Answer

For greenhouse windows in alterations, they must also meet the prescriptive U-factor and SHGC requirements of Package A; however, not many greenhouses can meet the new efficiency prescriptive requirements. In the performance approach, any dual-glazed greenhouse or garden window installed as part of an alteration complies with the U-factor requirements, §150.1(b)1B.

Alternatively, Greenhouse windows can also meet the prescriptive maximum area-weighted average U-factor in §150.0(q) with the Exception of up to 10 square feet or 0.5% of conditioned floor area, whichever is greater is allowed. Note For greenhouse windows, the window area is the rough opening.

However, the SHGC for greenhouse windows must meet the requirements shown in the prescriptive Package A, or must meet the SHGC used to show compliance in the performance approach. To meet the SHGC for greenhouse windows, the proposed fenestration may use the NFRC rated SHGC or the default SHGC from Standards Table 110.6-B, if the area weighted average SHGC of the greenhouse window plus other fenestration in the proposed design meets the values used for compliance is also allowed.

For skylights, Exception to §150.1(c)3A, exempts up to two square foot of tubular skylights from the U-factor requirements, provided that the ceiling diffusers are dual-paned; and any additional skylights must meet the U-factor requirements. Skylights may use one of three methods for determining the proposed SHGC:

1) NFRC rated SHGC; or

2) Default SHGC from Standards Table 110.6-B; or

3) If site-built greenhouses then SHGCfen can be calculated from the manufacturer’s center of glass SHGC (SHGCc) and using the following equation: SHGCfen = 0.08 + 0.86 x SHGCc.

Additions may comply using the performance approach with one of the following compliance paths summarized in Section 9.2, Table 9-1:

1. Addition Alone;

2. E + A + A Without Third Party Verification;

3. E + A + A With Third Party Verification;

4. E + A + A as New Construction.

Energy Commission-approved compliance software is used to model the building as explained in Chapter 8. Whichever compliance path is selected, the Certificate of Compliance (CF1R) generated by the compliance software must be submitted for permit. If the CF1R includes energy measures that require HERS testing or verification, the CF1R must also be registered online with a HERS provider. See Section 2.2.2.

To learn more about what kinds of alterations are assigned energy credit using the Existing + Addition + Alterations performance approach, see Section 9.5.2.

A. Addition Alone

In this compliance scenario, the addition alone is modeled using the compliance software and the existing building is not modeled at all. This approach may work well when the existing building is not undergoing alterations, and the permitted work scope covers only the addition.

1. Advantages: Data for the existing building is not needed except for the total existing conditioned floor area which is used to calculate the fractional “number of dwelling units” for the addition. The existing building is not modeled and not analyzed for altered components or systems. This typically saves a large amount of time performing the analysis.

2. Disadvantages: If the addition includes a large area of glazing or is otherwise deficient in comparison with the prescriptive requirements, it may be difficult to demonstrate compliance under this approach. Alterations to the existing conditions which improve the energy performance of the existing building cannot be used in this approach as “trade-offs” with the addition.

B. Existing + Addition + Alterations Without Third Party Verification

The existing building with all alterations is modeled together with the addition; and existing conditions are not verified by a third party HERS Rater. The Standard Design that sets the energy budget for this approach is automatically based only on the type of each altered component and not on the existing conditions. Under this performance path the building is modeled as follows:

1.

Addition: All new components at the addition and all new systems serving the

addition are modeled including roof/ceilings and skylights, exterior walls and glazing

(fenestration), raised floors and slab floors, HVAC equipment, ducts and water

heating. All these elements are tagged within the compliance software as “New”;

or

2.

Existing Components to Remain Unchanged: Existing components and systems

to remain as is (untouched) are modeled and tagged within the compliance

software as “Existing”; or

3. Existing Components to be Altered or Replaced, "Altered”: Each altered component (i.e. a new component which replaces an existing component) is modeled and tagged within the performance compliance program as "altered". Each component or system which remains is modeled and tagged within the compliance software as “Altered” such as, a new water heater that replaces an existing water heater would be labeled "altered”; a new water heater that is added to supplement an existing water heater would be labeled "new". Also, new mechanical equipment that does not replace existing mechanical equipment would be tagged as "new". No verification of existing conditions is required in this compliance path; therefore, no “Existing” (pre-alteration) conditions are specified.

Note: Portions of new fenestration including skylights that will occur in the existing opening of fenestration to be replaced are tagged "altered". Portions of new fenestration that will occur where there is no existing fenestration opening are labeled as "new".

C. Existing to be Removed:

Existing roof/ceilings to be removed as part of the permitted work, plus any skylights within those removed roof/ceilings, are excluded from the model (i.e., they are completely omitted from the calculations); exterior walls to be removed, and all fenestration areas in those removed walls, are not modeled; and raised floors and slab-on-grade floors to be removed are also omitted.

Note: This is an important change in the E+A+A modeling rules from the 2008 Standards as discussed in Section 9.6.

Advantages: Energy improvements to the existing building that go beyond the Standard Design levels are an energy credit that can be effectively “traded” against features of the addition that are less energy efficient than required by the prescriptive levels that set the Standard Design for the addition alone. For example, an addition with a large glazing area may comply by replacing the existing HVAC system with high-efficiency equipment.

Disadvantages: Detailed plans and other information on the existing building may be difficult to document and obtain. The E+A+A analysis may be relatively complex and time-consuming.

Refer to Table 9-4 for a summary of E+A+A modeling rules.

D. Existing + Addition + Alterations With Third Party Verification

The existing building with alterations is modeled together with the addition(s); and existing conditions of the components being altered must be verified by a third party HERS Rater before any construction work begins. The Standard Design that sets the energy budget may, depending on the energy efficiency of the altered component or system, be based on the pre-altered existing conditions. In those instances, energy credit is calculated as a function of the difference between pre-altered existing conditions and post-alteration energy measures. Under this approach the building is modeled as follows:

1. Addition: All new components for the addition and all new systems serving the addition are modeled including roof/ceilings and skylights, exterior walls and glazing (fenestration), raised floors and slab floors, HVAC equipment, ducts and water heating. All these elements are tagged within the compliance software as “New”; or

2. Existing Components to Remain Unchanged: Existing components and systems to remain as is (untouched) are modeled and tagged within the compliance software as “Existing”; or

3. Existing Components to be Altered or Replaced: "Existing to be Altered: Each altered component (i.e. a new component which replaces an existing component) is modeled and tagged within the performance compliance program as "altered". Each component or system which remains is modeled and tagged within the compliance software as “Altered” such as, a new water heater that replaces an existing water heater would be labeled "altered”; a new water heater that is added to supplement an existing water heater would be labeled "new". Also, new mechanical equipment that does not replace existing mechanical equipment would be tagged as "new". No verification of existing conditions is required in this compliance path; therefore, the “Existing” (pre-alteration) conditions must be specified.

Note: Removing an area of fenestration in an existing wall or roof, and re-inserting up to the same total area of glazing in different openings, is considered replacement or “altered” fenestration as defined in §150.2(b)1B. Any net glazing area added to the total existing fenestration in an existing wall or existing roof is considered “new” fenestration.

4. Removed Surfaces: Existing roof/ceilings to be removed as part of the permitted work, plus any skylights within those removed roof/ceilings, are excluded from the model (i.e., they are completely omitted from the calculations). Exterior walls to be removed, and all fenestration areas to be removed in those walls, are not modeled; and raised floors and slab-on-grade floors to be removed are also omitted.

Note: This is an important change in the E+A+A modeling rules from the 2008 Standards summarized in Section 9.6.

5. Advantages: Energy improvements meeting certain threshold values are credited based on the difference between existing conditions and the altered component or system. These energy credits can be effectively “traded” against features of the addition that are less energy efficient than required by the prescriptive levels that set the Standard Design for the addition alone. For example, an addition with a large glazing area may comply by upgrading insulation levels in the existing house.

6. Disadvantages: Detailed plans and other information on the existing building may be difficult to document and obtain. The E+A+A analysis may be relatively complex and time-consuming. And a third party verification must be conducted of all existing conditions prior to construction, and that verification must be registered online with a HERS provider prior to permit submittal.

Refer to Table 9-4 for a summary of E+A+A modeling rules.

E. Existing + Addition + Alterations as New Construction

A compliance approach rarely used, but available within the Standards, is to model Existing + Addition + Alterations as all “New” components and systems and the compliance software sets the energy budget as if the project were an entirely new building.

1. Advantages: Modeling the existing building with alterations and additions as all new makes the performance analysis relatively simple and less time-consuming. This method will provide the owner and designer with an energy efficiency compliance relative to requirements for new construction. Any owner who wants to bring their building up to new construction energy efficiency levels should have their project modeled as “new”.

2. Disadvantages: The energy budget with this approach is very stringent. Unless a building is going through a complete retrofit of all its envelope components, as well as replacing all mechanical and water heating systems, it is unlikely that the building will meet the Standards with this approach.

F. Summary of Modeling Rules

Table 9-4 summarizes the basic rules for compliance software users analyzing a residential addition or alteration using the Existing + Addition + Alterations approach. For further information, see the specific compliance software user's 'manual for details on how to input data correctly.

|

Table summarizes basic rules for a low-rise residential building using the Existing + Addition + Alterations performance approach. Note for further details reference the Residential ACM Reference Manual. | ||

|

Type of Component or System Modeled |

Standard Design Without Third Party Verification of Existing Conditions |

Standard Design With Third Party Verification of Existing Conditions |

|

"EXISTING" --

|

Model each component or system as "Existing" |

Model each component or system as "Existing" |

|

"ALTERED" --

|

Model each altered component or system as "Altered" but do not model the "Pre-Altered Existing" conditions |

Model each component or system as "Altered" and also model the "Pre-Altered Existing" conditions |

|

"NEW" --

|

Model each component or system as "New" |

Model each component or system as "New" |

|

"REMOVED" --

|

These components

and systems are omitted entirely from the model. |

These components

and systems are omitted entirely from the model. |