5.7 HVAC Secondary Systems

This group of building descriptors relate to the secondary HVAC

systems. There is not a one-to-one relationship between secondary HVAC system components in the proposed and

standard design since the standard design system is determined from building type, size,

and number of floors. The standard design for a given building descriptor

indicates the appropriate value for each applicable system type.

|

HVAC System Name |

|

Applicability |

All system

types |

|

Definition |

A unique descriptor for each HVAC system |

|

Units |

Text, unique |

|

Input Restrictions |

When applicable, input

should match the tags that are used on the plans |

|

Standard Design |

None |

|

Standard Design:

Existing Buildings |

None |

|

System Type |

|

Applicability |

All system types |

|

Definition |

A unique descriptor which identifies the HVAC system

type. The System Type indicates the cooling and heat source, and

whether the system serves a single zone or multiple zones. |

|

Units |

List from the choices

below |

|

Input Restrictions |

PTAC – Packaged Terminal Air Conditioner

SZAC – Single-zone Air

Conditioner

PTHP – Packaged Terminal Heat Pump

PSZ-AC – Packaged Single

Zone Air Conditioner

PSZ-HP – Packaged Single

Zone Heat Pump Air Conditioner

PVAV* – Packaged Variable

Air Volume (VAV) with Reheat

VAV* – Built-up VAV with

Reheat

SZVAV-AC – Single Zone VAV

Air Conditioner

SZVAV-HP – Single Zone VAV

Heat Pump

HV – Heating and

Ventilation Only

CRAC – Computer Room Air Conditioner

CRAH – Computer Room Air

Handler

FPFC – Four-pipe Fan

Coil

WSHP – Water-source Heat

Pump

SPVAC – Single package

vertical air conditioner

SPVHP – Single package

vertical heat pump

* Choice includes series

and parallel fan-powered boxes as zone terminal units |

|

Standard Design |

Based on the prescribed system type in the HVAC system

map (see Section 5.1.2). |

|

Standard Design:

Existing Buildings |

|

5.7.2 System Controls

5.7.2.1 Control

System Type

|

Control System Type |

|

Applicability |

All HVAC systems that serve more than one control zone,

as well as the hydronic systems that serve building HVAC systems |

|

Definition |

The type of control system for multi-zone HVAC systems

and their related equipment.

This input affects the proposed design system

specification for zone level controls, supply air temperature reset

controls, ventilation controls and fan and pump static pressure part-load

curves. See the following building descriptors:

•

Ventilation control method

•

Terminal heating control type

•

Pump part-load curve

•

Fan part-load curve

•

Optimal start |

|

Units |

None |

|

Input Restrictions |

List one of the following

inputs:

Direct digital control (DDC) control to the

zone level – DDC systems with control to the zone level

Other – other control

systems, including pneumatic and DDC systems without control to the zone

level |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

DDC control to the zone level |

|

Standard Design:

Existing Buildings |

|

5.7.2.2 Schedules

|

Air

Handler Schedule |

|

Applicability |

All systems that do not cycle with loads |

|

Definition |

A schedule that indicates when the air handler operates

continuously |

|

Units |

Data structure: schedule,

on/off |

|

Input Restrictions |

For healthcare facilities, same as the Proposed

Design. For all others,

Schedule group is

prescribed in Appendix 5.4A and schedule values are prescribed in Appendix

5.4B. See Section 2.3.3 on how software

shall assign schedules when the spaces served by the system are assigned to different schedule

groups in Appendix 5.4A.

The fan schedules and HVAC

operations are defined so that the air handlers provide the necessary outside air 1 hour prior to scheduled occupancy.

When a fan system serves

several occupancies, the fan schedule remains ON to serve the operating

hours of each occupancy. |

|

Standard Design |

Same as the proposed design |

|

Standard Design:

Existing Buildings |

|

|

Air Handler Fan

Cycling |

|

Applicability |

All fan systems |

|

Definition |

This building

descriptor indicates whether the system supply fan operates continuously

or cycles with building loads when the HVAC schedule indicates the

building is occupied. (See night cycle control input for fan operation

during unoccupied hours.) The fan systems in most commercial buildings

operate continuously. |

|

Units |

List continuous or cycles

with loads |

|

Input Restrictions |

As designed if the HVAC system serves zones with a dedicated

outside air source for ventilation; otherwise, continuous.

|

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Cycles with loads for FPFC systems; continuous for all

other standard design system types |

|

Standard Design:

Existing Buildings |

|

|

Optimal Start

Control |

|

Applicability |

Systems with the control capability for flexible

scheduling of system start time based on building loads |

|

Definition |

Optimal start control adjusts the start time of the

HVAC unit such that the space is brought to setpoint just prior to

occupancy. This control strategy modifies the heating, cooling, and fan

schedules. |

|

Units |

Boolean (Yes/No) |

|

Input Restrictions |

Fixed at yes if control system type is DDC

to the zone level; otherwise, as designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Fixed at yes, if control system type is DDC to the zone

level |

|

Standard Design:

Existing Buildings |

|

|

Night-Cycle HVAC Fan

Control |

|

Applicability |

All air systems – not applicable for zone

systems |

|

Definition |

The control of an HVAC system that is triggered by the

heating or cooling temperature setpoint for thermal zones during periods

when the heating, cooling and fan systems are scheduled to be off. For

this control, the space is controlled to the setback or setup temperature

only; this control is not equivalent to a night purge control. The choices

are:

•

Cycle on call from any zone

•

Cycle on call from the primary control zone

•

Stay off

•

Cycle zone fans only (for systems with fan-powered boxes) Restart

fans below given ambient temperature. |

|

Units |

None |

|

Input Restrictions |

Cycle on call from any

zone, except for systems with fan-powered boxes, where either cycle on

call from any zone or cycle zone fans only is allowed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Cycle on call from any zone |

|

Standard Design:

Existing Buildings |

|

5.7.2.3 Supply Air

Temperature Control

|

Cooling Supply Air

Temperature |

|

Applicability |

Applicable to all systems |

|

Definition |

The supply air temperature setpoint at design cooling

conditions |

|

Units |

Degrees Fahrenheit

(°F) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

15°F below the space temperature setpoint for interior

zones that are served by multiple zone

systems; for all other zones, 20°F below the space temperature

setpoint |

|

Standard Design:

Existing Buildings |

|

|

Heating Supply Air

Temperature |

|

Applicability |

All systems |

|

Definition |

The supply air temperature leaving the air handler when

the system is in a heating mode (not the

air temperature leaving the reheat coils

in VAV boxes) |

|

Units |

Degrees Fahrenheit

(°F) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

95°F for system types 1-4; 60°F for multiple zone

systems; no heating for data centers and computer rooms |

|

Standard Design:

Existing Buildings |

|

|

Supply Air Temperature

Control |

|

Applicability |

Any cooling system |

|

Definition |

The method of controlling the supply air temperature.

Choices are:

•

No control – for this scheme the coils are energized whenever there

is a call for heating or cooling at the zone.

•

Fixed (constant)

•

Reset by warmest zone, airflow first

•

Reset by warmest zone, temperature first

•

Reset by outside air dry-bulb

temperature

•

Scheduled setpoint

|

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

For standard design systems 1 through 4, the SAT

control is No Control. For systems 5 through 8, 10, and 11, the SAT

control shall be reset by warmest zone, airflow first. For system 9

(heating and ventilation), this input is not applicable. |

|

Standard Design:

Existing Buildings |

|

|

Reset Schedule by OSA |

|

Applicability |

When the proposed design resets SAT by outside air

dry-bulb temperature |

|

Definition |

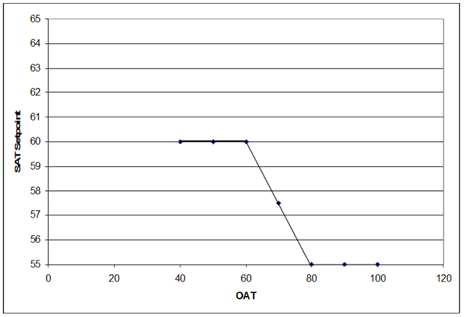

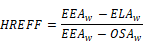

A linear reset schedule that represents the SAT

setpoint as a function of outdoor air dry-bulb temperature

This schedule is defined by the following data points

(see Figure 9):

•

The coldest supply air temperature

•

The corresponding (hot) outdoor air dry-bulb setpoint

•

The warmest supply air temperature

•

The corresponding (cool) outdoor air dry-bulb setpoint

Figure 11: SAT

Cooling Setpoint Reset Based On Outdoor Air Temperature (OAT)

Source: NORESCO for California Energy

Commission |

|

Units |

Data structure (two matched

pairs of SAT and OAT, see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Not applicable |

|

Standard Design:

Existing Buildings |

|

5.7.3 Fan and Duct Systems

5.7.3.1 Standard

Design Fan System Summary

The standard design fan system is summarized in this section. See section 5.7.1, Table 27 for the HVAC standard

design system mapping.

When the proposed design has

exhaust fans (toilets or kitchens) or fume hood exhaust systems, the standard design has the

same exhaust systems.

5.7.3.2 Supply Fans

|

Supply Fan Modeling Method |

|

Applicability |

All fan systems |

|

Definition |

Fans can be modeled in one of three ways. The simple

method is for the user to enter the electric power per unit of flow

(W/cfm). This method is commonly used for zonal equipment and other small fan systems. A

more detailed method is to model the fan

as a system whereby the static pressure,

fan efficiency, part-load curve, and motor efficiency are specified at design conditions. A third method is to

specify brake horsepower at design conditions instead of fan efficiency

and static pressure. This is a variation of the second method whereby

brake horsepower is specified in lieu of static pressure and fan

efficiency. The latter two methods are commonly used for VAV and fan

systems with significant static pressure. |

|

Units |

List power-per-unit-flow,

static pressure, or brake horsepower |

|

Input Restrictions |

As designed

|

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

The standard design shall use the brake horsepower

method for all HVAC systems except the SZAC unit used in residential

spaces, the heating and ventilation only system, and the four-pipe fan

coil system, which shall use the power-per-unit-flow method. |

|

Standard Design:

Existing Buildings |

|

|

Supply Fan Power

Ratio |

|

Applicability |

All fan systems |

|

Definition |

The standard design fan power requirements apply to all

fans that operate at design conditions. To apportion the fan power to the

supply fan and exhaust fans, a ratio is defined that is the ratio of

supply fan power to total system fan power. |

|

Units |

Unitless ratio |

|

Input Restrictions |

As designed, not a user

input.

This is the ratio of the

supply fan power to total system fan power, which includes supply fans,

exhaust fans, any return fans, and any series-powered fans. |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as

proposed |

|

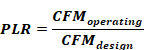

Supply Fan Design Airflow |

|

Applicability |

All fan systems |

|

Definition |

The air flow rate of the supply fan(s) at design

conditions.

This building

descriptor sets the 100 percent point for the fan part-load

curve. |

|

Units |

CFM

(ft3/min) |

|

Input Restrictions |

As designed*

*The airflow is

typically between 250 cfm/ton and 500 cfm/ton; values well outside of this

range may cause simulation engine runtime efforts that must be addressed

by the user (currently there are no input restrictions on

this). |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

The program shall automatically size the air flow at

each thermal zone to meet the loads. The design air flow rate calculation

shall be based on a 20°F temperature differential between supply air and

the room air 20°F temperature differential between the supply air and the

return air for exterior zones and a 15°F temperature differential for

interior zones served by multiple zone

systems. The design supply air flow rate is the larger of the flow rate

required to meet space conditioning requirements and the required

ventilation flow rate.

For equipment with DX cooling coils, the program

applies the results of a sizing run, and oversizes both the cooling coil

capacity and airflows by 15% to obtain the appropriate airflow.

For multizone systems, the supply fan design air flow

rate shall be the system airflow rate that satisfies that coincident peak

of all thermal zones at the design supply air temperature.

|

|

Standard Design:

Existing Buildings |

|

|

Fan Control Method |

|

Applicability |

All fan systems |

|

Definition |

A description of how the supply (and return/relief)

fan(s) are controlled

The options include:

•

Constant volume

•

Variable-flow, inlet, or discharge dampers

•

Variable-flow, inlet guide vanes

•

Variable-flow, variable speed drive (VSD)

•

Variable-flow, variable pitch blades

•

Two-speed

For variable-speed fans, the fan control method

determines which part-load performance curve to use. |

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

Based on the prescribed system type. Refer to the HVAC System Map in 5.1.2. |

|

Standard Design:

Existing Buildings |

|

Table 10: Standard Design Fan Control Method

|

Standard Design building System |

Fan Control

Method |

|

System 1 –

SZAC |

Constant volume,

cycling |

|

System 2 –

FPFC |

Constant volume, cycling

|

|

System 3 –

PSZ-AC |

Constant volume

|

|

System 5 – Packaged VAV

with Reheat |

Variable-flow, variable

speed drive (VSD) |

|

System 6 – VAV with

Reheat |

Variable-flow, variable

speed drive (VSD) |

|

System 7 – Single Zone

VAV |

Variable-flow,

variable-speed drive (VSD) |

|

System 9 – Heating and

Ventilation |

Constant

volume |

|

System 10 – CRAH

Units |

Variable-flow, variable

speed drive (VSD)* |

|

System 11 – CRAC

Units |

Variable-flow, variable

speed drive (VSD)* |

* For CRAH

Units, fan volume shall be linearly reset from 100 percent air flow at 100

percent cooling load to minimum airflow at 50 percent cooling load and

below.

|

Supply Fan Brake

Horsepower |

|

Applicability |

All fan systems, except those specified using the

power-per-unit-flow method |

|

Definition |

The design shaft brake horsepower of each supply

fan.

This input does not need to be supplied if the supply

fan kW is supplied. |

|

Units |

Horsepower (hp) |

|

Input Restrictions |

As designed

If this building descriptor is specified for the

proposed design, then the static pressure and fan efficiency are not.

The compliance software shall apply the

following rule to specify the proposed design bhp, based on user

input:

A standard motor size table

(hp) is defined as: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20,

25, 30, 40, 50, 60, 75, 100, 125, 150, and 200.

The user entered brake

horsepower for the proposed design is compared against the next smaller

motor size from the user entered supply fan motor horsepower. The proposed

design supply fan brake horsepower (bhp) is set to the maximum of the user

entered bhp and 95 percent of the next smaller motor horsepower:

Proposed bhp = max(user

bhp, 95 percent ×MHPi-1)

Where User bhp is the user

entered supply fan brake horsepower:

MHPi is the proposed

(nameplate) motor horsepower

MHPi-1 is the next smaller

motor horsepower from the Standard Motor Size table above. For example, if

the proposed motor horsepower is 25, the next smaller motor horsepower

from the table above is 20, and 95 percent of the next smaller motor

horsepower is 19. |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design.

For FPFC and heating and ventilation systems, not

applicable.

For laboratory systems where the building lab design

exhaust flow is greater than 10,000 cfm, a separate exhaust fan power

allowance is given, and the entire fan power budget can be allocated to

the supply fan:

VAV Supply Fan BHP = (0.0013 x cfmmax + A)

CAV Supply Fan BHP = (0.00094 x cfmmax + A)

For PVAV and built-up VAV systems:

Supply Fan BHP = (0.0013 x cfmmax + A) x Supply Fan

Ratio,

For other systems,

Supply Fan BHP = (0.00094 x cfm + A) x SupplyFanRatio,

where

cfm = the design supply air

flow, and

A = the fan power adjustment (see separate

building descriptor)

SupplyFanRatio is the ratio of supply fan brake horse

power at design conditions to total

system brake horsepower at design conditions

|

|

Standard Design:

Existing Buildings |

Same as proposed if

existing and unaltered; otherwise, same as new

construction |

Not

applicable

|

Supply Fan Motor

Horsepower |

|

Applicability |

All fan systems, except those specified using the

power-per-unit-flow method |

|

Definition |

The motor nameplate horsepower of the supply

fan |

|

Units |

List: choose from standard

motor sizes: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 25, 30,

40, 50, 60, 75, 100, 125, 150, 200 |

|

Input Restrictions |

As designed.

This building descriptor is

required for the static pressure or the brake horsepower

methods. |

|

Standard Design |

Set to the standard motor efficiency for the next

larger nominal HP size, from NEMA standards |

|

Standard Design:

Existing Buildings |

Set to the standard motor

efficiency for the next larger nominal HP size, from NEMA

standards |

|

Supply Fan Static

Pressure |

|

Applicability |

All fan systems using the static pressure

method |

|

Definition |

The design static pressure for the supply fan.

This is important for both fan electric energy usage

and duct heat gain calculations. |

|

Units |

Inches of water column (in.

H20) |

|

Input Restrictions |

As designed

The design static pressure

for the supply fan does not need to be specified if the supply fan brake

horsepower (bhp) is specified. |

|

Standard Design |

Not applicable. Defined in the software as a function

of brake horsepower or power-per-unit flow. |

|

Standard Design:

Existing Buildings |

Not

applicable |

|

Supply Fan

Efficiency |

|

Applicability |

All fan systems using the static pressure

method |

|

Definition |

The efficiency of the fan at design conditions; this is

the static efficiency and does not include motor losses |

|

Units |

Unitless |

|

Input Restrictions |

As designed

The supply fan efficiency

does not need to be specified if the supply fan brake horsepower (bhp) is

specified. |

|

Standard Design |

65%

Not applicable for the four-pipe fan coil

system. |

|

Standard Design:

Existing Buildings |

Not applicable |

|

|

|

Supply Motor

Efficiency |

|

Applicability |

All supply fans, except those specified using the

power-per-unit-flow method |

|

Definition |

The full-load efficiency of the motor serving the

supply fan |

|

Units |

Unitless |

|

Input Restrictions |

As designed

Not applicable when the

power-per-unit-flow method is used. |

|

Standard Design |

The motor efficiency is determined from Table 11

for the next motor size greater than the bhp. |

|

Standard Design:

Existing Buildings |

Same as

proposed |

|

Fan Power

Adjustment |

|

Applicability |

Any system with special requirements for filtration or

other process requirements |

|

Definition |

Additional system brake horsepower related to

application-specific filtration requirements or other process

requirements

An exceptional condition shall be included on

compliance documentation when the user selects one of these adjustment

conditions. |

|

Units |

List |

|

Input Restrictions |

The user chooses one or

more fan power adjustment credits from the list below. If the adjustment

credit is specified in terms of static pressure, the static pressure

adjustment is fixed. For the credits

that depend on the design, the user enters the pressure drop for each

device.

The proposed design fan

power adjustment (bhp) is given by the equation:

FPA = Σ SPi x

CFMi / 4131

Where SPi = the static

pressure through the device, inches w.c.

CFMi = the design airflow

through the device

|

Device |

Adjustment Credits |

|

Return of exhaust systems required by code to be

fully ducted |

0.5 in. of water |

|

Exhaust filters, scrubbers, or other exhaust

treatment |

The pressure drop of the proposed

design |

|

Particulate filtration credit: MERV 16 or greater and electronically

enhanced filters |

Pressure drop calculated at 2 x clean filter

pressure drop at fan system design condition |

|

Carbon and other gas-phase air cleaners |

Clean filter pressure drop at fan system design

condition |

|

Biosafety cabinet |

Pressure drop of device at fan system design

condition |

|

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as proposed for new

HVAC equipment; not applicable for

existing, unaltered systems. |

Table 11: Minimum Nominal Efficiency for Electric

Motors (Percent)

|

Motor Horse Power |

Efficiency

(%) |

|

1 |

85.5 |

|

1.5 |

86.5 |

|

2 |

86.5 |

|

3 |

89.5 |

|

5 |

89.5 |

|

7.5 |

91.7 |

|

10 |

91.7 |

|

15 |

92.4 |

|

20 |

93.0 |

|

25 |

93.6 |

|

30 |

93.6 |

|

40 |

94.1 |

|

50 |

94.5 |

|

60 |

95.0 |

|

75 |

95.4 |

|

100 |

95.4 |

|

125 |

95.4 |

|

150 |

95.8 |

|

200 |

96.2 |

|

250 |

96.2 |

|

300 |

96.2 |

|

350 |

96.2 |

|

400 |

96.2 |

|

450 |

96.2 |

|

500 |

96.2 |

|

Fan

Position |

|

Applicability |

All supply fans |

|

Definition |

The position of the supply fan relative to the cooling

coil.

The configuration is either draw through (fan is

downstream of the coil) or blow through (fan is upstream of the

coil). |

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

Draw through |

|

Standard Design:

Existing Buildings |

|

|

Motor

Position |

|

Applicability |

All supply fans |

|

Definition |

The position of the supply fan motor relative to the

cooling air stream.

The choices are in the air stream or out of the air

stream. |

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

In the air stream |

|

Standard Design:

Existing Buildings |

|

|

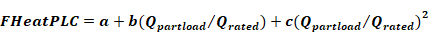

Fan Part-Flow Power

Curve |

|

Applicability |

All variable flow fan systems |

|

Definition |

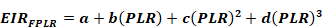

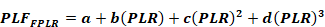

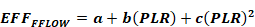

A part-load power curve that represents the percentage

full-load power draw of the supply fan as a function of the percentage

full-load air flow.

The curve is typically represented as a quadratic

equation with an absolute minimum power draw specified. |

|

Units |

Unitless ratio |

|

Input Restrictions |

As designed

The user shall not be able

to select VSD with static pressure reset if the building does not have DDC controls to the

zone level. The default fan curve shall be selected from Appendix 5.7 for

the type of fan specified in the proposed design.

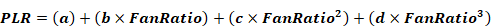

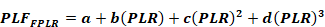

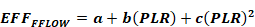

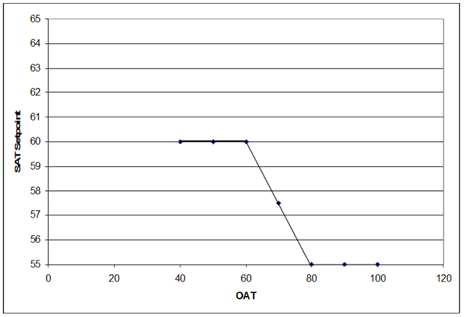

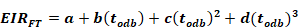

Where:

|

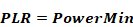

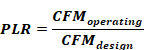

PLR |

Ratio of fan power at

part load conditions to full load fan power |

|

PowerMn |

Minimum fan power

ratio |

|

FanRatio |

Ratio of cfm at

part-load to full-load cfm |

|

a, b, c and d |

Constants from the

table below |

|

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

Not applicable for standard design constant volume

systems. The curve VSD with static pressure reset fans shall be used for

variable volume systems. |

|

Standard Design:

Existing Buildings |

|

|

Supply Fan Power

Index |

|

Applicability |

Fan systems that use the power-per-unit-flow

method |

|

Definition |

The supply fan power (at the motor) per unit of

flow |

|

Units |

W/cfm |

|

Input Restrictions |

As designed or specified in

the manufacturers’ literature |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

For FPFC systems, 0.35 W/cfm for heating and

ventilation only systems, 0.53 W/cfm ;

For CRAC and CRAH systems, 0.81 W/cfm

(approximate value for 27 W/kBtu-h of sensible cooling capacity assuming

400 cfm/ton).

For other systems, not applicable. |

|

Standard Design:

Existing Buildings |

|

Not applicable for all systems

except the four-pipe fan coil (FPFC).

For the FPFC system, the

standard design is 0.35 W/cfm.

5.7.3.3 Return/Relief

Fans

The standard design building has no return fan. The

standard design system has a relief fan only

if the standard design system has an economizer.

|

Plenum Zone |

|

Applicability |

Any system with return ducts or return air plenum |

|

Definition |

A reference to the thermal zone that serves as return

plenum or where the return ducts are located |

|

Units |

Text, unique |

|

Input Restrictions |

As designed |

|

Standard Design |

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Return Air

Path |

|

Applicability |

Any system with return ducts or return air

plenum |

|

Definition |

Describes the return path for air.

Can be ducted return, plenum return, or

direct-to-unit. |

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

Applicable when the standard design has a relief fan.

For standard design systems 1 and 2, the return air path shall be

direct-to-unit. For standard design systems 3 through 11, the standard

design shall be ducted return. |

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Fan

Modeling Method |

|

Applicability |

All fan systems |

|

Definition |

The specification method for return fan power. The

simple method is for the user to enter the electric power-per-unit of flow

(W/cfm). A more detailed method is to model the fan as a system whereby the

static pressure, fan efficiency, part-load curve, and motor efficiency are

specified at design conditions. A third

method is to specify brake horsepower at design conditions instead of fan

efficiency and static pressure. This is a variation of the second method

whereby brake horsepower is specified in lieu of static pressure and fan

efficiency. The latter two methods are commonly used for VAV and fan

systems with significant static pressure. |

|

Units |

List power-per-unit-flow,

static pressure, or brake horsepower |

|

Input Restrictions |

As designed

|

|

Standard Design |

Not applicable (the standard design does not include

return fans, and relief fans are not explicitly modeled) |

|

Standard Design:

Existing Buildings |

Not

applicable |

|

Return/Relief Fan Design

Airflow |

|

Applicability |

All systems with a return or relief fan |

|

Definition |

The design air flow fan capacity of the return or

relief fan(s).

This sets the 100 percent fan flow point for the

part-load curve (see below). |

|

Units |

Cfm |

|

Input Restrictions |

For return fans, as

designed

|

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others, not

modeled.

|

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Fan Brake Horsepower |

|

Applicability |

Any system with return fans that uses the brake

horsepower method |

|

Definition |

The design shaft brake horsepower of the return/relief

fan(s) |

|

Units |

Brake horsepower

(bhp) |

|

Input Restrictions |

As designed

The compliance software shall apply the

following pre-processing rule to specify the proposed design return/relief

fan brake horsepower, based on user input:

A standard motor size table

(hp) is defined as: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20,

25, 30, 40, 50, 60, 75, 100, 125, 150, and 200.

The return/relief fan brake

horsepower is determined from user inputs of brake horsepower and motor

horsepower for the proposed design, in the same manner as the supply fan

brake horsepower.

Proposed bhp = min (user

bhp, 95 percent x MHPi-1)

Where:

Proposed bhp is the

return/relief fan brake horsepower used in the simulation;

User bhp is the actual fan

bhp as entered by the user; and

MHPi-1 is the

motor horsepower of the next smaller motor size from the standard motor

size table above; MHPi is the motor size that the user enters

for the return/relief fan.

See the supply fan brake

horsepower descriptor for further details. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others, not modeled.

|

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Fan Motor Horsepower |

|

Applicability |

All fan systems, except those specified using the

power-per-unit-flow method |

|

Definition |

The motor nameplate horsepower of the supply

fan |

|

Units |

List choose from standard

motor sizes: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 25, 30,

40, 50, 60, 75, 100, 125, 150, 200 |

|

Input Restrictions |

As designed

This building descriptor is required for the

static pressure or the brake horsepower methods. |

|

Standard Design |

Not modeled |

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Design

Static Pressure |

|

Applicability |

Any system with return or relief fans that uses the

static pressure method |

|

Definition |

The design static pressure for return fan system.

This is important for both fan electric energy usage

and duct heat gain calculations. |

|

Units |

Inches of water column (in.

H20 gauge) |

|

Input Restrictions |

As designed. The design

static pressure for the return fan does not need to be specified if the

return fan brake horsepower (bhp) is specified. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others, not applicable (there are no return fans, and the relief

fan is not modeled.

|

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Fan

Efficiency |

|

Applicability |

Any system with return or relief fans that uses the

static pressure method |

|

Definition |

The efficiency of the fan at design conditions. This is

the static efficiency and does not include the efficiency loss of the

motor. |

|

Units |

Unitless |

|

Input Restrictions |

As designed. The

return/relief fan efficiency does not need to be specified if the return

fan brake horsepower (bhp) is specified. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others, not applicable.

|

|

Standard Design:

Existing Buildings |

|

|

Return/Relief Motor

Efficiency |

|

Applicability |

All return fans, except those specified using the

power-per-unit-flow method |

|

Definition |

The full-load efficiency of the motor serving the

supply fan |

|

Units |

Unitless |

|

Input Restrictions |

As designed. Not applicable

when the power-per-unit-flow method is used. |

|

Standard Design |

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Motor

Position |

|

Applicability |

All return fans |

|

Definition |

The position of the supply fan motor relative to the

cooling air stream. The choices are in the air stream or out of the air

stream. |

|

Units |

List (see above) |

|

Input Restrictions |

As designed. |

|

Standard Design |

In the air stream |

|

Standard Design:

Existing Buildings |

|

|

Fan Part-Flow Power

Curve |

|

Applicability |

All return fans for variable flow fan

systems. |

|

Definition |

A part-load power curve which represents the percentage

full-load power draw of the supply fan as a function of the percentage

full-load air flow. |

|

Units |

Unitless ratio |

|

Input Restrictions |

As designed. The default

fan curve shall be selected from Appendix 5.7 for the type of fan

specified in the proposed design. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Not applicable |

|

Standard Design:

Existing Buildings |

|

5.7.3.4 Exhaust Fan

Systems

The standard design shall track the

proposed design exempt process exhaust flow

rate up to the prescribed outside air

ventilation rate by space type (see Appendix 5.4A for the standard design

maximum exhaust rate). Covered process exhaust includes garage ventilation, lab exhaust and exhaust from

kitchens with over 5,000 cfm of exhaust. Rules for the standard design

covered process exhaust rate and fan power are discussed in the following

sections.

Exhaust fan flow is specified and

scheduled for each thermal zone. An exhaust fan system may serve multiple thermal zones. For the

standard design, total outside air ventilation supply airflow may need to be

adjusted so that the design supply airflow for each floor of the building matches the total design exhaust airflow

for that floor.

|

Exhaust Fan

Name |

|

Applicability |

All exhaust systems serving multiple thermal

zones |

|

Definition |

A unique descriptor for each exhaust fan. This should

be keyed to the construction documents, if possible, to facilitate plan

checking. Exhaust rates and schedules at the thermal zone level refer to

this name. |

|

Units |

Text, unique |

|

Input Restrictions |

Where applicable, this

should match the tags that are used on the plans. |

|

Standard Design |

The standard design shall have an exhaust system that

corresponds to the proposed design. However, if the user has specified an

exhaust system as the ventilation system an equivalent standard design

system will not be modeled since the standard design has its own

definition for ventilation systems. The name can be identical to that used

for the proposed design or some other appropriate name may be

used. |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan System Modeling Method |

|

Applicability |

All exhaust fan systems |

|

Definition |

Compliance software

can model fans in three ways. See

definition for supply system modeling method. |

|

Units |

List: power-per-unit-flow,

static pressure or brake horsepower |

|

Input Restrictions |

As designed |

|

Standard Design |

The standard design shall use the static pressure

method. |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan Power

Ratio |

|

Applicability |

All fan systems |

|

Definition |

The standard design fan power requirements apply to all

fans that operate at design conditions.

To apportion the fan power to the supply fan and exhaust fans, a ratio is

defined that is the ratio of non-exempt exhaust fan power to total system

fan power. |

|

Units |

List power-per-unit-flow,

static pressure, or brake horsepower |

|

Input Restrictions |

As designed, not a user

input.

This is the ratio of the

exhaust fan power to total system fan power, which includes: supply fans,

exhaust fans, return fans, and any series-powered fans. |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

Same as

proposed |

|

Exhaust Fan Design

Airflow |

|

Applicability |

All exhaust fan systems |

|

Definition |

The rated design air flow rate of the exhaust fan

system. This building descriptor defines the 100 percent flow point of the

part-flow curve. Actual air flow is the sum of the flow specified for each

thermal zone, as modified by the schedule for each thermal zone. |

|

Units |

Cfm |

|

Input Restrictions |

As designed. The total

design exhaust flow capacity for building (conditioned space) shall not exceed the sum

of building story minimum ventilation (outdoor) air flow. Exhaust makeup

can be transferred from other zones in the building provided that the

total building exhaust rate does not exceed the total minimum outside air

flow rate. |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

Same as proposed design, but with the same limitations

described under input restrictions. The design supply air ventilation rate

for zone(s) may need to be adjusted by the software, so that the total

design outside air ventilation rate supplied to all zones on a floor

equals the total exhaust fan design airflow for all zones on the

floor. |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan Control Method |

|

Applicability |

All exhaust fan systems |

|

Definition |

A description of how the exhaust fan(s) are controlled.

The options include:

•

Constant volume

•

Variable-flow, variable speed drive (VSD) |

|

Units |

List (see above) |

|

Input Restrictions |

As designed, when exhaust

fan flow at the thermal zone level is varied through a schedule, one of

the variable-flow options shall be specified. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

The standard design exhaust fan control shall be the

same as the proposed design, but subject to the conditions described

above.

For exhaust fans serving kitchen spaces, the fan control method is

constant volume for fans with flow rate 5,000 cfm and below, and variable

flow, variable speed drive for fans with flow rate greater than 5,000

cfm.

For exhaust fans serving laboratory spaces, the fan

control method is variable-flow, variable speed drive when the minimum

exhaust flow is 10 ACH or less. If the lab exhaust flow minimum is greater

than 10 ACH, the control method is the same as proposed. |

|

Standard Design:

Existing Buildings |

|

|

|

|

Exhaust Fan Brake

Horsepower |

|

Applicability |

All exhaust fan systems |

|

Definition |

The design shaft brake horsepower of the exhaust

fan(s). |

|

Units |

Brake horsepower

(bhp) |

|

Input Restrictions |

As designed

The compliance software implements a pre-processing

rule to specify the proposed design exhaust fan brake horsepower (bhp),

based on user input:

A standard motor size table (hp) is defined as: 1/12,

1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 75,

100, 125, 150, 200

The exhaust fan brake horsepower is determined from

user inputs of brake horsepower and motor horsepower for the proposed

design, in the same manner as the supply fan brake horsepower.

Proposed bhp = max (user bhp, 95 percent x

MHPi-1)

Where:

Proposed bhp is the return/relief fan brake horsepower

used in the simulation,

User bhp is the actual fan bhp as entered by the

user

MHPi-1 is the motor horsepower of the next

smaller motor size from the standard motor size table above;

MHPi is the motor size that the user enters for the exhaust

fan

See the supply fan brake

horsepower descriptor for further details. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For laboratory exhaust, where the building lab design

exhaust flow exceeds 10,000 cfm, 0.65 W/cfm. If the user designates that

the system includes scrubbers or other air treatment devices, the standard

design exhaust fan power shall be 0.85 W/cfm.

For all others, the standard design exhaust fan brake

horsepower is equal to the fan system power allowance times the exhaust

fan power ratio:

For constant volume systems, (0.00094 x

cfmmax + A) x ExhaustFanPowerRatio

For variable volume systems, 0.0013 x cfmmax

+ A) x ExhaustFanPowerRatio |

|

Exhaust Fan Motor

Horsepower |

|

Applicability |

All fan systems, except those specified using the

power-per-unit-flow method |

|

Definition |

The motor nameplate horsepower of the supply

fan |

|

Units |

List - choose from standard

motor sizes: 1/12, 1/8, ¼, ½, ¾, 1, 1.5, 2, 3, 5, 7.5, 10, 15, 20, 25, 30,

40, 50, 60, 75, 100, 125, 150, 200 |

|

Input Restrictions |

As designed

This building descriptor is

required for the static pressure or the brake horsepower

methods. |

|

Standard Design |

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan Design Static

Pressure |

|

Applicability |

Any system with exhaust fans that uses the static

pressure method |

|

Definition |

The design static pressure for exhaust fan system.

|

|

Units |

Inches of water column (in.

of water) |

|

Input Restrictions |

As designed. The design

static pressure for the exhaust fan does not need to be specified if the

exhaust fan brake horsepower (bhp) or power-per-unit flow is

specified. |

|

Standard Design |

For healthcare facilities, same as the Proposed

Design.

For kitchen exhaust fans, the static pressure is fixed at 2.5 in. of water. For lab exhaust

fans, fan power is specified as W/cfm, so this input is not

applicable.

For all other exhaust fans, the standard design fan

static pressure shall be the same as the proposed design. |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan

Efficiency |

|

Applicability |

Any exhaust fan system that uses the static pressure

method |

|

Definition |

The efficiency of the exhaust fan at rated

capacity.

This is the static efficiency and does not include

losses through the motor. |

|

Units |

Unitless |

|

Input Restrictions |

For kitchen exhaust fans,

the fan efficiency is prescribed at 50 percent.

For all other exhaust fans,

as designed. The exhaust fan efficiency does not need to be specified if

the return fan brake horsepower (bhp) is specified. |

|

Standard Design |

For healthcare facilities, same as the Proposed

Design.

For kitchen exhaust fans, the fan efficiency is 50

percent, while for lab exhaust it is 62 percent.

For all other exhaust fans, the standard design

efficiency (and resulting W/cfm) is 65% |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan Motor

Efficiency |

|

Applicability |

All exhaust fan systems |

|

Definition |

The full-load efficiency of the motor serving the

exhaust fan |

|

Units |

Unitless |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed

Design.

For exempt process fans other than lab, kitchen, and

garage exhaust fans, same as proposed. For all other fans, the value is

taken from Table 11. |

|

Standard Design:

Existing Buildings |

|

|

Fan Part-Flow Power

Curve |

|

Applicability |

All variable flow exhaust fan systems |

|

Definition |

A part-load power curve that represents the ratio

full-load power draw of the exhaust fan as a function of the ratio

full-load air flow. |

|

Units |

Unitless ratio |

|

Input Restrictions |

As designed

The default fan curve shall

be selected from Appendix 5.7 for the type of fan specified in the

proposed design. |

|

Standard Design |

For healthcare facilities, same as the proposed design.

For all others, the standard design fan curve shall be selected from

Appendix 5.7 for the type of fan specified in the proposed

design. |

|

Standard Design:

Existing Buildings |

|

|

Exhaust Fan Power

Index |

|

Applicability |

Exhaust systems serving high-rise residential units and

hotel/motel guestrooms |

|

Definition |

The fan power of the exhaust fan per unit of flow.

This building descriptor is applicable only with the

power-per-unit-flow method. |

|

Units |

W/cfm |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed

Design.

For high-rise residential units and hotel/motel

guestrooms, 0.58 W/cfm |

|

Standard Design:

Existing Buildings |

|

5.7.3.5 Garage

Exhaust Fan Systems

When garage exhaust fan systems are modeled the fans

shall be modeled as constant volume fans, with the fan power determined by

whether or not the fan has CO controls.

|

Garage Exhaust Fan

Name |

|

Applicability |

All garage exhaust systems |

|

Definition |

A unique descriptor for each garage exhaust fan or fan

system

Fans with equivalent efficiency and motor efficiencies

may be combined and modeled as one fan. |

|

Units |

Text, unique |

|

Input Restrictions |

Where applicable, this

should match the tags that are used on the plans. |

|

Standard Design |

The standard design shall have an exhaust system that

corresponds to the proposed design. The name can be identical to that used

for the proposed design or some other appropriate name may be

used. |

|

Standard Design:

Existing Buildings |

|

|

Garage Exhaust Fan System

Modeling Method |

|

Applicability |

All exhaust fan systems |

|

Definition |

Software commonly models fans in three ways, see

definition for supply system modeling method. |

|

Units |

List power-per-unit-flow,

static pressure, or brake horsepower |

|

Input Restrictions |

Brake horsepower method (fixed value) |

|

Standard Design |

The standard design

building shall use the power-per-unit-flow method. |

|

Standard Design:

Existing Buildings |

|

|

Garage Exhaust Fan Rated

Capacity |

|

Applicability |

All exhaust systems |

|

Definition |

The rated design air flow rate of the garage exhaust

fan system |

|

Units |

Cfm |

|

Input Restrictions |

As designed |

|

Standard Design |

Same as proposed design |

|

Standard Design:

Existing Buildings |

|

|

Garage Exhaust Fan

Control Method |

|

Applicability |

All exhaust fan systems |

|

Definition |

The control method for the garage exhaust fan.

This input determines the fan power for the exhaust

fan. No other fan inputs are required. |

|

Units |

List constant volume or CO

control |

|

Input Restrictions |

None.

If constant volume is

selected, proposed fan power is as designed.

If CO control is selected,

proposed fan power is 12.5 percent of the design fan power. |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

|

5.7.3.6 Duct Systems

in Unconditioned Space

|

Duct Leakage

Rate |

|

Applicability |

Any single-zone systems with ducts in unconditioned space serving zones of 5,000

ft2 or less |

|

Definition |

The leakage rate from the duct system into unconditioned space.

All leakage is assumed to occur to unconditioned space

(not to outdoors). |

|

Units |

Percentage of design airflow

(%) |

|

Input Restrictions |

For new systems: If duct

leakage testing is performed as per instructions in the Reference Appendices and certified by a Home Energy Rating System (HERS) rater or Acceptance Test Technician

(ATT), as designed. If not tested, 15 percent.

For existing, altered

systems: 15 percent if tested and verified by the HERS procedures in

Reference Appendix NA2. If untested or if failed test, 20

percent. |

|

Standard Design |

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Duct Leakage HERS Fan

Power Adjustment |

|

Applicability |

Single zone, constant volume systems with ducts in

unconditioned space, serving 5000 ft2 |

|

Definition |

A fan power penalty or credit based on the testing

performed when ducts are in unconditioned spaces |

|

Units |

List: Penalty, No

Change Credit |

|

Input Restrictions |

Not a user input

Penalty: if the HERS

duct leakage testing isn’t done when required, or if the testing fails the

duct leakage rate criteria

No Change: testing

not required

Credit: testing not

required, but HERS testing performed and leakage rates are

verified |

|

Standard Design |

All in conditioned

space |

|

Standard Design:

Existing Buildings |

|

5.7.4 Outdoor Air Controls and

Economizers

5.7.4.1 Outside Air

Controls

|

Maximum Outside Air Ratio |

|

Applicability |

All systems with modulating outside air dampers |

|

Definition |

The descriptor is used to limit the maximum amount of

outside air that a system can provide as

a percentage of the design supply air. It is used where the installation

has a restricted intake capacity. |

|

Units |

Ratio |

|

Input Restrictions |

1.0 for all systems above

54,000 Btu/h cooling capacity; 0.9 for

other systems. |

|

Standard Design |

1.0 for all systems above 54,000 Btu/h cooling

capacity; 0.9 for other systems |

|

Standard Design:

Existing Buildings |

|

|

Design Outside Air

Flow |

|

Applicability |

All systems with outside air dampers |

|

Definition |

The rate of outside air that needs to be delivered by

the system at design conditions. This

input may be derived from the sum of the design outside air flow for each

of the zones served by the system. |

|

Units |

Cfm |

|

Input Restrictions |

As designed but no lower

than the ventilation rate of the standard design |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design.

For systems serving laboratory spaces, the system shall

be 100 percent outside air. |

|

Standard Design:

Existing Buildings |

|

|

Outdoor Air Control

Method |

|

Applicability |

All HVAC systems that deliver outside air to

zones |

|

Definition |

The method of determining the amount of outside air

that needs to be delivered by the system

Each of the zones served by the system report their

outside air requirements on an hourly basis. The options for determining

the outside air at the zone level are discussed above. This control method

addresses how the system responds to this information on an hourly basis.

Options include:

•

Average Flow - The outside air delivered by the system is the sum

of the outside air requirement for each zone, without taking into account

the position of the VAV damper in each zone. The assumption is that there

is mixing between zones through the return air path.

|

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

Average flow |

|

Standard Design:

Existing Buildings |

|

5.7.4.2 Air Side

Economizers

|

Economizer Control

Type |

|

Applicability |

All systems with an air-side economizer |

|

Definition |

An air-side economizer increases outside air ventilation during periods when

system cooling loads can be reduced from

increased outside air flow. The control types include:

•

No economizer.

•

Fixed dry-bulb. The economizer is

enabled when the temperature of the outside air is equal to or lower than

temperature fixed setpoint (e.g., 75°F).

•

Differential dry-bulb. The economizer is enabled when the

temperature of the outside air is lower than the return air temperature.

•

Differential enthalpy. The economizer is enabled when the enthalpy

of the outside air is lower than the return air enthalpy.

•

Differential dry-bulb and enthalpy. The system shifts to 100

percent outside air or the maximum outside air position needed to maintain

the cooling SAT setpoint, when the outside air dry-bulb is less than the

return air dry-bulb AND the outside air enthalpy is less than the return

air enthalpy. This control option requires additional sensors.

|

|

Units |

List (see above) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare

facilities, same as the Proposed Design. For all others,

The control should be no economizer when the standard

design total cooling capacity < 54,000 Btu/h and when the standard design cooling

system is not a computer room air

handling unit (CRAH). Otherwise, the standard design shall assume an

integrated differential dry-bulb economizer.

An exception is that economizers shall not be modeled

for systems serving high-rise residential or hotel/motel guestroom

occupancies. |

|

Standard Design:

Existing Buildings |

|

|

Economizer Integration

Level |

|

Applicability |

Airside economizers |

|

Definition |

This input specifies whether or not the economizer is

integrated with mechanical cooling. It

is up to the modeling software to translate this into software-specific

inputs to model this feature. The input

could take the following values:

•

Non-integrated - The system runs the economizer as the first stage

of cooling. When the economizer is unable to meet the load, the economizer

returns the outside air damper to the minimum position and the compressor

turns on as the second stage of cooling.

•

Integrated - The system can operate with the economizer fully open

to outside air and mechanical cooling active (compressor running)

simultaneously, even on the lowest cooling stage. |

|

Units |

List (see above) |

|

Input Restrictions |

List non-integrated or

integrated |

|

Standard Design |

I For healthcare facilities, same as the Proposed

Design. For all others,

integrated for systems above capacity 54,000 Btu/h at

Air-Conditioning, Heating, and Refrigeration Institute (AHRI) conditions |

|

Standard Design:

Existing Buildings |

|

|

Economizer High

Temperature Lockout |

|

Applicability |

Systems with fixed dry-bulb economizer |

|

Definition |

The outside air setpoint temperature above which the

economizer will return to minimum position |

|

Units |

Degrees Fahrenheit

(°F) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Economizer Low

Temperature Lockout |

|

Applicability |

Systems with air-side economizers |

|

Definition |

A feature that permits the lockout of economizer

operation (return to minimum outside air position) when the outside air

temperature is below the lockout setpoint. |

|

Units |

Degrees Fahrenheit

(F°) |

|

Input Restrictions |

As designed |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

Not applicable |

|

Standard Design:

Existing Buildings |

|

|

Economizer High Enthalpy Lockout |

|

Applicability |

Systems with differential enthalpy

economizers |

|

Definition |

The outside air enthalpy above which the economizer

will return to minimum position |

|

Units |

Btu/lb |

|

Input Restrictions |

As designed

The default is 28 Btu/lb

(high altitude locations may require different setpoints.) The compliance software shall apply a fixed

offset and add 2 Btu/lb to the user-entered value. |

|

Standard Design |

For healthcare facilities, same as the Proposed Design.

For all others,

not applicable |

|

Standard Design:

Existing Buildings |

|

5.7.5 Cooling Systems

5.7.5.1 General

This group of building descriptors applies to all cooling

systems.

|

Cooling

Source |

|

Applicability |

All systems |

|

Definition |

The source of cooling for the system; either chilled water, direct

expansion (DX), or other |

|

Units |

List (see above) |

|

Input Restrictions |

As designed (determined

automatically from system type) |

|

Standard Design |

The standard design cooling source is:

For built-up VAV (system 6) and CRAH (system 10):

chilled water,

For heating and ventilation (system 9), none, and

For all other systems, direct expansion (DX)

shown in Table 33 |

|

Standard Design:

Existing Buildings |

Same as proposed for

unaltered |

|

Gross Total Cooling

Capacity |

|

Applicability |

All cooling systems |

|

Definition |

The total gross cooling capacity (both sensible and

latent) of a cooling coil or packaged DX system at AHRI conditions. The building descriptors

defined in this chapter assume that the fan is modeled separately,

including any heat it adds to the air stream. The cooling capacity

specified by this building descriptor should not consider the heat of the

fan. |

|

Units |

Btu/h

|

|

Input Restrictions |

NOT A USER INPUT

For packaged equipment that has the fan motor in the air

stream such that it adds heat to the cooled air, the software shall

calculate the net total cooling capacity as follows:

Q(t,net,rated)=Q(t,gross,rated)-Q(fan,rated)

Where:

|

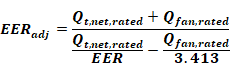

Q(t,net,rated) |

The net total cooling

capacity of a packaged unit as rated by AHRI (Btu/h) |

|

Q(t,gross,rated) |

The AHRI rated total

cooling capacity of a packaged unit (Btu/h) Qfan,rated;

the heat generated by the fan and fan motor (if fan motor is in

airstream) at AHRI rated conditions |

If the gross and net total

cooling capacities at AHRI conditions are known, the fan heat at rated

conditions is the difference between the two values. If the either the

gross or net total cooling capacity is unknown, the fan heat at rated

conditions shall be accounted for by using Equation 4:

Q(fan,rated) =

Q(t,gross,rated) X 0.0415

Equation 4 is based on an

AHRI rated fan power of 0.365 W/cfm, and a cooling airflow of 400

cfm/ton.

If the number of UMLH in

the proposed design exceeds 150, the software shall warn the user to

resize the equipment. |

|

Standard Design |

The gross total cooling capacity of the systems in the

standard design is determined from the standard design net cooling

capacity, and from applying the fan power rules above for adjusting for

fan heat. |

|

Standard Design:

Existing Buildings |

|

|

Gross Sensible Cooling

Capacity |

|

Applicability |

All cooling systems |

|

Definition |

The gross sensible cooling capacity of the coil or

packaged equipment at AHRI conditions. The building descriptors defined in

this chapter assume that the fan is modeled separately, including any heat

it adds to the air stream. The cooling capacity specified by this building

descriptor should be adjusted to calculate the net sensible cooling

capacity, which includes the effect of fan motor heat.

The sensible heat ratio (SHR) used by some energy

simulation tools can be calculated from the sensible cooling capacity and

total cooling capacity:

SHR = sensible cooling capacity/total cooling

capacity |

|

Units |

Btu/h |

|

Input Restrictions |

As designed.

For packaged equipment, the

compliance software adjusts the user

input of gross sensible cooling capacity to account for the effect of fan

motor heat as follows:

Q(s,net,rated) =

Q(s,gross,rated)-Q(fan,rated)

Where:

|

Q(s,net,rated) |

The AHRI rated (from

manufacturers’ literature) or net sensible cooling capacity of a

packaged unit (Btu/h) |

|

Q(fan,rated) |

The AHRI rated (from

manufacturers’ literature) or gross sensible cooling capacity of a

packaged unit (Btu/h) |

|

Q(fan,rated) |

The heat generated by

the fan and fan motor (if fan motor is in air stream) at AHRI rated

or hourly conditions (Btu/h). See gross total cooling capacity

building descriptor. |

If the number of UMLH in

the proposed design exceeds 150, the software shall warn the user to

resize the equipment. |

|

Standard Design |

The gross total cooling capacity of the systems serving

the standard design is autosized by the compliance software, and then

oversized by 15 percent. Sizing calculations shall be based on 0.5 percent

design dry-bulb and mean coincident wet-bulb. |

|

Standard Design:

Existing Buildings |

|

|

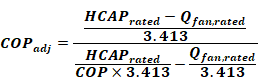

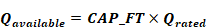

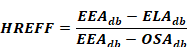

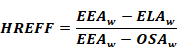

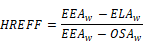

Gross Total Cooling

Capacity Curve |

|

Applicability |

All cooling systems |

|

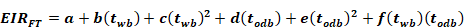

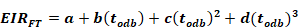

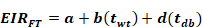

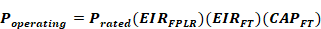

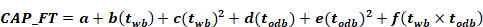

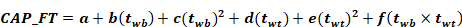

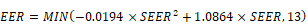

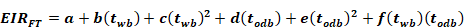

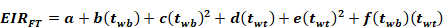

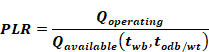

Definition |

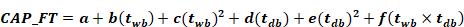

A curve that represents the available total cooling

capacity as a function of cooling coil and/or condenser conditions. The common form of

these curves is given as follows:

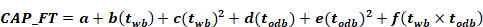

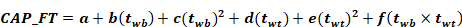

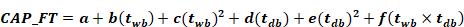

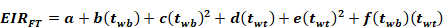

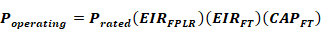

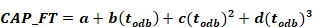

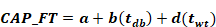

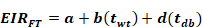

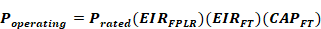

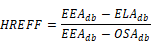

For air-cooled direct expansion:

For water-cooled direct expansion:

For chilled water coils:

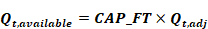

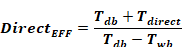

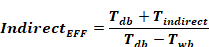

Where:

|

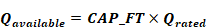

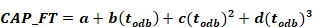

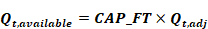

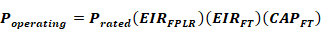

Qt, available |

Available cooling capacity at specified

evaporator and/or condenser conditions (MBH) |

|

Qt, adjust |

Adjusted capacity at AHRI conditions

(Btu/h) |

|

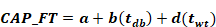

CAP_FT |

A multiplier to adjust Qt,

adjust |

|

twb |

The entering coil wet-bulb temperature

(°F) |

|

tdb |

The entering coil dry-bulb temperature

(°F) |

|

twt |

The water supply temperature (°F) |

|

todb |

The outside air

dry-bulb temperature (°F) |

Note: If an air-cooled unit employs an evaporative

condenser, todb is the effective dry-bulb temperature of the

air leaving the evaporative cooling unit.

Software may represent the relationship between cooling

capacity and temperature in ways other than the equations given above.

|

|

Units |

Data structure |

|

Input Restrictions |

As designed

The equations and

coefficients given above are the default. |

|

Standard Design |

Use the default curves or equivalent data for other

models |

|

Standard Design:

Existing Buildings |

|

|

Coil Latent Modeling

Method |

|

Applicability |

All DX cooling systems |

|

Definition |

The method of modeling coil latent performance at

part-load conditions |

|

Units |

List |

|

Input Restrictions |

One of the following

values:

Bypass factor – used by

DOE-2 based programs

NTU-effectiveness – used by

EnergyPlus |

|

Standard Design |

Same as proposed |

|

Standard Design:

Existing Buildings |

|

|

Coil Bypass

Factor |

|

Applicability |

All DX cooling systems using the bypass factor coil

latent modeling method |

|

Definition |

The ratio of air that bypasses the cooling coil at design conditions to the total system

airflow |

|

Units |

Ratio |

|

Input Restrictions |

Prescribed values defined

in Appendix 5.7 |

|

Standard Design |

Defaults |

|

Standard Design:

Existing Buildings |

|

|

Coil Bypass Factor

Adjustment Curve |

|

Applicability |

All DX cooling systems using the bypass factor coil

latent modeling method |

|

Definition |

Adjustments for the amount of coil bypass due to the

following factors:

•

Coil airflow rate as a percentage of rated system airflow

•

Entering air wet-bulb temperature

•

Entering air dry-bulb temperature

•

Part load ratio |

|

Units |

Data structure |

|

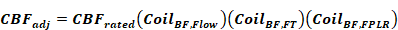

Input Restrictions |

Where applicable,

prescribed (fixed) simulation engine

defaults based on HVAC system type. The

following default values shall be used for the adjustment curves:

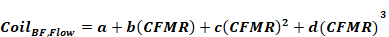

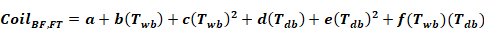

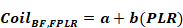

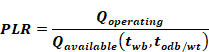

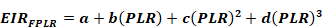

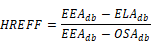

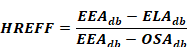

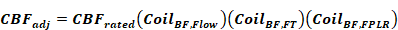

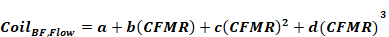

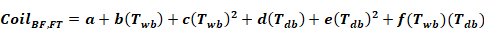

Where:

|

CBFRATED |

The coil bypass

factor at AHRI rating conditions |

|

CBFADJ |

The coil bypass

factor adjusted for airflow and coil conditions |

|

CFMR |

The ratio of airflow

to design airflow |

|

Coilbf, Flow |

A multiplier on the

rated coil bypass factor to account for variation in air flow across

the coil (take coefficients from Table 34) |

|

Coilf, FT |

A multiplier on the

rated coil bypass factor to account for a variation in coil entering

conditions (take coefficients from Table 35) |

|

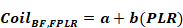

Coilbf, FPLR |

A multiplier on the

rated coil bypass factor to account for the part load ratio (take

coefficients from Table 36) |

|

Twb |

The entering coil

wet-bulb temperature (F) |

|

Tdb |

The entering coil

dry-bulb temperature (F) |

|

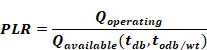

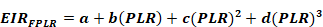

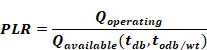

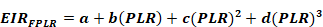

PLR |

Part load

ratio |

|

|

Standard Design |

Defaults |

|

Standard Design:

Existing Buildings |

|

|

|

|

|

Cooling Capacity Airflow Adjustment

Curve |

|

Applicability |

All DX cooling systems using the NTU effectiveness coil

latent modeling method |

|

Definition |

Normalized curve that varies cooling capacity as a

function of airflow, which affects system latent capacity |

|

Units |

Data structure |

|

Input Restrictions |

Where applicable, prescribed (fixed) simulation engine

defaults based on HVAC system type. The following default values shall be

used for the adjustment curves:

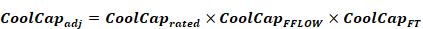

Where:

|

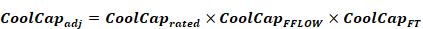

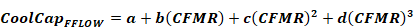

cmfr |

The ratio of airflow to design airflow |

|

CoolCapfflow |

A multiplier on the rated coil capacity to

account for variation in air flow across the coil (take coefficients

from Table 33) |

|

CoolCapft |

A multiplier on the rated coil bypass factor to

account for a variation in coil entering conditions (take

coefficients from Table 34) |

The curve takes the form:

With the coefficients defined in Appendix 5.7.

|

|

Standard Design |

Use defaults as described above |

|

Standard Design:

Existing Buildings |

|

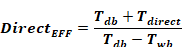

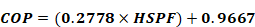

5.7.5.2 Direct Expansion

|

Direct Expansion Cooling Efficiency |

|

Applicability |

Packaged DX equipment |

|

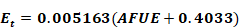

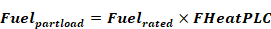

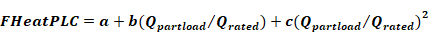

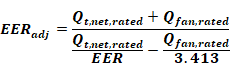

Definition |

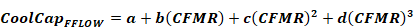

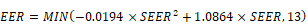

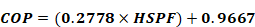

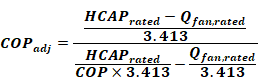

The cooling efficiency of a direct expansion (DX)