All of the equipment efficiency requirements are mandatory measures.

The mandatory requirements for mechanical equipment must be included in the system design, whether the overall building compliance is the prescriptive or performance approach. These features are cost effective over a wide range of building types and mechanical systems.

Most mandatory features for equipment efficiency are requirements for the manufacturer. It is the responsibility of the designer to specify products in the building design that meet these requirements. Manufacturers of central air conditioners and heat pumps, room air conditioners, package terminal air conditioners, package terminal heat pumps, spot air conditioners, computer room air conditioners, central fan-type furnaces, gas space heaters, boilers, pool heaters and water heaters are regulated through the Title 20 Appliance Efficiency Regulations. Manufacturers must certify to the Energy Commission that their equipment meets or exceeds minimum standards. The Commission maintains a database which lists the certified equipment found at: www.energy.ca.gov/appliances/database

Additionally, manufacturers of low leakage air-handling units must certify to the Energy Commission that the air-handler unit meets the specifications in Reference Appendices JA9.

Mechanical equipment must be certified by the manufacturer as complying with the mandatory requirements in the following sections:

1. §110.0 - Mandatory Requirements for Systems and Equipment Certification

2. §110.1 - Mandatory Requirements for Appliances.

3. §110.2 - Mandatory Requirements for Space-Conditioning Equipment

a. Efficiency

b. Gas- and Oil-Fired Furnace Standby Loss Controls

c. Low Leakage Air-Handling Units

4. §110.3 - Mandatory Requirements for Service Water Heating Systems and Equipment

a. Certification by Manufactures

b. Efficiency

5. §110.4 - Mandatory Requirements for Pool and Spa Systems and Equipment

a. Certification by Manufactures

6. §110.5 - Natural Gas Central Furnaces, Cooking Equipment, and Pool and Spa Heaters: Pilot Lights Prohibited

Mechanical equipment must be specified and installed in accordance with sections:

1. §110.2 - Mandatory Requirements for Space Conditioning Equipment

a. Controls for Heat Pumps with Supplementary Electric Resistance Heaters

b. Thermostats

c. Open and Closed Circuit Cooling Towers (blowdown control)

2. §110.3 - Mandatory Requirements for Service Water Heating Systems and Equipment

3. §110.12 – Mandatory Requirements for Demand Management

4. §120.1 - Requirements for Ventilation and Indoor Air Quality

5. §120.2 - Required Controls for Space Conditioning Systems (see Section 4.5)

a. Occupant Controlled Smart Thermostats (OCST)

b. Direct Digital Controls (DDC)

c. Optimum Start/Stop Controls

d. Economizer Fault Detection and Diagnostics

6. §120.3 - Requirements for Pipe Insulation

7. §120.4 - Requirements for Air Distribution Ducts and Plenums

8. §120.5 - Required Nonresidential Mechanical System Acceptance

All space conditioning equipment installed in a nonresidential building, subject to these regulations, must be certified as meeting certain minimum efficiency and control requirements. These requirements are contained in §110.2 and vary based on the type and capacity of the equipment. Tables 110.2-A through 110.2-K list the minimum equipment efficiency requirements for the 2019 Energy Standards.

For equipment <65,000 Btu/hr see Nonresidential Appendix B

|

Equipment Type |

Size Category |

Efficiency a,b |

Test Procedurec | |

|

Air conditioners, air cooled both split and single packaged |

≥65,000 Btu/h and < 135,000 Btu/h |

11.2 EER |

||

|

≥135,000 Btu/h and < 240,000 Btu/h |

11.0 EER | |||

|

≥240,000 Btu/h and < 760,000 Btu/h |

10.0

EER | |||

|

≥760,000 Btu/h |

9.7 EER | |||

|

Air conditioners, water cooled |

≥65,000 Btu/h and < 135,000 Btu/h |

12.1 EER |

ANSI/AHRI 340/360 | |

|

≥135,000 Btu/h and < 240,000 Btu/h |

12.5 EER |

ANSI/AHRI 340/360 | ||

|

≥240,000 Btu/h and < 760,000 Btu/h |

12.4 EER |

ANSI/AHRI 340/360 | ||

|

≥760,000 Btu/h |

12.2 EER |

ANSI/AHRI 340/360 | ||

|

Air conditioners, evaporatively cooled |

≥65,000 Btu/h and < 135,000 Btu/h |

12.1

EERb |

ANSI/AHRI 340/360 | |

|

≥135,000 Btu/h and < 240,000 Btu/h |

12.0

EERb |

ANSI/AHRI 340/360 | ||

|

≥240,000 Btu/h and < 760,000 Btu/h |

11.9 EERb 12.1 IEERb |

ANSI/AHRI 340/360 | ||

|

≥760,000 Btu/h |

11.7

EERb |

ANSI/AHRI 340/360 | ||

|

Condensing units, air cooled |

≥ 135,000 Btu/h |

10.5 EER |

ASNI/AHRI 365 | |

|

Condensing units, water cooled |

≥ 135,000 Btu/h |

13.5 EER |

ASNI/AHRI 365 | |

|

Condensing units, evaporatively cooled |

≥ 135,000 Btu/h |

13.5 EER |

|

|

|

a IEERs are only applicable to equipment with capacity control as specified by ANSI/AHRI 340/360 test procedures b Deduct

0.2 from the required EERs and IEERs for units with a heating section

other than electric resistance heat |

| |||

Source: California Energy Commission, 2019 Building Energy Efficiency Standards, Table 110.2-A

|

Equipment Type |

Size Category |

Efficiencya,b |

Test Procedurec | ||

|

Air cooled (cooling mode), both split system and single package |

≥65,000 Btu/h and < 135,000 Btu/h |

11.0 EER 12.2 IEER |

|||

|

≥135,000 Btu/h and < 240,000 Btu/h |

10.6 EER 11.6 IEER | ||||

|

≥240,000 Btu/h |

9.5 EER 10.6 IEER | ||||

|

Water source (cooling mode) |

≥65,000 Btu/h and < 135,000 Btu/h |

860F entering water |

13.0 EER |

ISO-13256-1 | |

|

Groundwater source (cooling mode) |

< 135,000 Btu/h |

590F entering water |

18.0 EER |

ISO-13256-1 | |

|

Ground source (cooling mode) |

< 135,000 Btu/h |

770F entering water |

14.1 EER |

ISO-13256-1 | |

|

Water source water-to-water (cooling) |

< 135,000 Btu/h |

860F entering water |

10.6 EER |

ISO-13256-2 | |

|

Groundwater source water-to-water |

< 135,000 Btu/h |

590F entering water |

16.3 EER |

ISO-13256-1 | |

|

Ground source brine-to-water (cooling mode) |

< 135,000 Btu/h |

770F entering water |

12.1 EER |

ISO-13256-2 | |

|

Air cooled (heating mode), split system and single package |

≥65,000 Btu/h and < 135,000 Btu/h (cooling capacity) |

470F db/430F wb outdoor air |

3.3 COP |

ANSI/AHRI 340/360 | |

|

170F db/150F wb outdoor air |

2.25 COP | ||||

|

≥135,000 Btu/h (cooling capacity) |

470F db/430F wb outdoor air |

3.2 COP | |||

|

170F db/150F wb outdoor air |

2.05 COP | ||||

|

Equipment Type |

Size Category |

Subcategory or Rating Condition |

Efficiencya |

Test Procedurec | |

|

Water source (heating mode) |

< 135,000 Btu/h (cooling capacity) |

680F entering water |

4.3 COP |

ISO-13256-1 | |

|

≥135,000 Btu/h and < 240,000 Btu/h (cooling capacity) |

680F entering water |

2.9 COP | |||

|

Groundwater source (heating mode) |

< 135,000 Btu/h (cooling capacity) |

500F entering water |

3.7 COP |

ISO-13256-1 | |

|

Ground source (heating mode) |

< 135,000 Btu/h (cooling capacity) |

320F entering water |

3.2 COP |

ISO-13256-1 | |

|

Water source water-to-water (heating mode) |

< 135,000 Btu/h (cooling capacity) |

680F entering water |

3.7 COP |

ISO-13256-2 | |

|

Groundwater source water-to-water (heating mode) |

< 135,000 Btu/h (cooling capacity) |

500F entering water |

3.1 COP |

ISO-13256-2 | |

|

Ground source brine-to-water (heating mode) |

< 135,000 Btu/h (cooling capacity) |

320F entering water |

2.5 COP |

ISO-13256-2 | |

|

a IEERs are applicable to equipment with capacity control as specified by ANSI/AHRI 340/360 test procedures. b Deduct 0.2 from the required EERs and IEERs for units with a heating section other than electric resistance heat c Applicable test procedure and reference year are provided under the definitions | |||||

Source: California Energy Commission, 2019 Building Energy Efficiency Standards, Table 110.2-B

|

Equipment Type |

Size Category |

Subcategory or Rating Condition |

Efficiency |

Test Procedurea |

|

Air-cooled gas-engine heat pump (cooling mode) |

All Capacities |

95° F db Outdoor air |

0.60 COP |

ANSI Z21.40.4A |

|

Air-cooled gas-engine heat pump (heating mode) |

All Capacities |

47° F db/43° F wb Outdoor air |

0.72 COP |

ANSI Z21.40.4A |

|

a Applicable test procedure and reference year are provided under the definitions | ||||

Source: California Energy Commission, 2019 Building Energy Efficiency Standards Table 110.2-C

|

Equipment Type |

Size Category |

Path A |

Path B |

Test Procedure | |

|

Air cooled, with condenser electrically operated |

< 150 tons |

≥ 10.1 EER ≥ 13.7 IPLV |

≥ 9.7 EER ≥ 15.8 IPLV |

| |

|

≥ 150 tons |

≥ 10.1 EER ≥ 14.0 IPLV |

≥ 9.7 EER ≥ 16.1 IPLV | |||

|

Air cooled, without condenser electrically operated |

All capacities |

Air-cooled chillers without condensers must be rated with matching condensers and comply with the air-cooled chiller efficiency requirements. | |||

|

Water cooled, electrically operated, (reciprocating) |

All capacities |

Reciprocating units must comply with the water-cooled positive displacement efficiency requirements. |

AHRI 550/590 | ||

|

Water cooled, electrically operated positive displacement |

< 75 tons |

≤ 0.750 kW/ton ≤ 0.600 IPLV |

≤ 0.780 kW/ton ≤ 0.500 IPLV |

AHRI 550/590 | |

|

≥ 75 tons and < 150 tons |

≤ 0.720 ≤ 0.560 IPLV |

≤ 0.750 kW/ton ≤ 0.490 IPLV | |||

|

≥ 150 tons and < 300 tons |

≤ 0.660 kW/ton ≤ 0.540 IPLV |

≤ 0.680 kW/ton ≤ 0.440 IPLV | |||

|

≥ 300 tons and < 600 tons |

≤ 0.610 kW/ton ≤ 0.520 IPLV |

≤ 0.625 kW/ton ≤ 0.410 IPLV | |||

|

> 600 tons |

≤ 0.560 kW/ton ≤ 0.500 IPLV |

≤ 0.585 kW/ton ≤ 0.380 IPLV | |||

|

Water cooled, electrically operated, centrifugal |

< 150 tons |

≤ 0.610 kW/ton ≤ 0.550 IPLV |

≤ 0.695 kW/ton ≤ 0.440 IPLV | ||

|

≥ 150 tons and < 300 tons |

≤ 0.610 kW/ton ≤ 0.550 IPLV |

≤ 0.635 kW/ton ≤ 0.400 IPLV | |||

|

≥ 300 tons and < 400 tons |

≤ 0.560 kW/ton ≤ 0.520 IPLV |

≤ 0.595 kW/ton ≤ 0.390 IPLV | |||

|

≥ 400 tons and < 600 tons |

≤ 0.560 kW/ton ≤ 0.500 IPLV |

≤ 0.585 kW/ton ≤ 0.380 IPLV | |||

|

≥ 600 tons |

≤ 0.560 kW/ton ≤ 0.500 IPLV |

≤ 0.380 IPLV | |||

|

Air cooled absorption, single effect |

All capacities |

≥ 0.600 COP |

NAd |

||

|

Water cooled absorption, single effect |

All capacities |

≥ 0.700 COP |

NAd | ||

|

Absorption double effect, indirect-fired |

All capacities |

≥ 1.000 COP ≥ 1.050 IPLV |

NAd | ||

|

Absorption double effect, direct-fired |

All capacities |

≥ 1.000 COP ≥ 1.000 IPLV |

NAd | ||

|

Water cooled gas engine driven chiller |

All capacities |

≥ 1.2 COP ≥ 2.0 IPLV |

NAd |

ANSI Z21.40.4A | |

|

a No requirement for: •Centrifugal chillers with design leaving evaporator temperature less than 36 degrees F; or •Positive displacement chillers with design leaving fluid temperatures less than or equal to 32 degrees F •Absorption chillers with design leaving fluid temperature less than 40 degrees F b Must meet the minimum requirements of Path A or Path B. However, both the full load (COP) and IPLV must be met to fulfill the requirements of the applicable Path. c See §100.1 for definitions d NA means not applicable | |||||

Source; California Energy Commission, Building Energy Efficiency Standards, Table 110.2-D

|

Equipment Type |

Size Category (Input) |

Subcategory or Rating Condition |

Efficiency |

Test Procedurec |

|

PTAC (cooling mode) newly constructed or newly conditioned or additions |

All capacities |

950F db Outdoor air |

14.0-(0.300 x Cap/1000) a EER |

|

|

PTAC (cooling mode) replacementsb |

All capacities |

950F db Outdoor air |

10.9-(0.213 x Cap/1000) a EER | |

|

PTHP (cooling mode) newly constructed or newly conditioned or additions |

All capacities |

950F db Outdoor air |

14.0-(0.300 x Cap/1000) a EER | |

|

PTHP (Cooling mode) replacementsb |

All capacities |

950F db Outdoor air |

10.8-(0.213 x Cap/1000) a EER | |

|

PTHP (Heating mode) newly constructed or newly conditioned or additions |

All capacities |

|

3.7-(0.052 x Cap/1000) a COP |

|

|

PTHP (Heating mode) replacementsb |

All capacities |

|

2.9-(0.026 x Cap/1000) a COP | |

|

SPVAC (cooling mode) |

< 65,000 Btu/h |

950F db/750F wb Outdoor air |

11.0 EER |

ANSI/ AHRI 390

|

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

950F db/750F wb Outdoor air |

10.0 EER | ||

|

≥ 135,000 Btu/h and < 240,000 Btu/h |

950F db/750F wb Outdoor air |

10.0 EER | ||

|

SPVAC (cooling mode) nonweatherized space constrained |

≤ 30,000 Btu/h |

950F db/750F wb Outdoor air |

9.20 EER | |

|

> 30,000 Btu/h and ≤36,000 Btu/h |

950F db/750F wb Outdoor air |

9.00 EER | ||

|

SPVHP (cooling mode) |

< 65,000 Btu/h |

950F db/750F wb Outdoor air |

11.0 EER | |

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

950F db/750F wb Outdoor air |

10.0EER | ||

|

≥ 135,000 Btu/h and < 240,000 Btu/h |

950F db/750F wb Outdoor air |

10.0 EER | ||

|

SPVHP (cooling mode) nonweatherized space constrained |

≤ 30,000 Btu/h |

950F db/750F wb Outdoor air |

9.20 EER | |

|

> 30,000 Btu/h and ≤36,000 Btu/h |

950F db/750F wb Outdoor air |

9.00 EER | ||

|

SPVHP (heating mode) |

< 65,000 Btu/h |

470F db/430F wb Outdoor air |

3.3 COP | |

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

470F db/430F wb Outdoor air |

3.0 COP | ||

|

≥ 135,000 Btu/h and < 240,000 Btu/h |

470F db/430F wb Outdoor air |

3.0 COP | ||

|

SPVHP (heating mode) nonweatherized space constrained |

≤ 30,000 Btu/h |

470F db/430F wb Outdoor air |

3.00 COP |

|

|

> 30,000 Btu/h and ≤36,000 Btu/h |

470F db/430F wb Outdoor air |

3.00 COP |

| |

|

a Cap means the rated cooling capacity of the product in Btu/h. If the unit’s capacity is less than 7000 Btu/h, use 7000 Btu/h in the calculation. If the unit’s capacity is greater than 15,000 Btu/h, use 15,000 Btu/h in the calculation. b Replacement units must be factory labeled as follows: “MANUFACTURED FOR REPLACEMENT APPLICATIONS ONLY; NOT TO BE INSTALLED IN NEWLY CONSTRUCTED BUILDINGS.” Replacement efficiencies apply only to units with existing sleeves less than 16 inches high or less than 42 inch wide and having a cross-sectional area less than 670 sq inches. c Applicable test procedure and reference year are provided under the definitions | ||||

Source: California Energy Commission, Building Energy Efficiency Standards Table 110.2-E

|

Equipment Type |

Subcategory |

Minimum Efficiency a |

Test Procedure b |

|

Liquid-to-liquid heat exchangers |

Plate type |

NR |

|

|

a NR: No requirement b Applicable test procedure and reference year are provided under the definitions | |||

Source: California Energy Commission, Building Energy Efficiency Standards Table 110.2-F

|

Equipment Type |

Total System Heat Rejection Capacity at Rated Conditions |

Subcategory or Rating Condition |

Performance Required, a, b, c, d |

Test Proceduree |

|

|

Propeller or axial fan open-circuit cooling towers |

All |

950F entering water 850F leaving water 750F entering air wb |

≥ 42.1 gpm/hp |

RS

|

|

|

Centrifugal fan open-circuit cooling towers |

All |

950F entering water 850F leaving water 750F entering air wb |

≥ 20.0 gpm/hp |

| |

|

Propeller or axial fan closed-circuit cooling towers |

All |

1020F entering water 900F leaving water 750F entering air wb |

≥ 16.1 gpm/hp |

| |

|

Centrifugal fan closed-circuit cooling towers |

All |

1020F entering water 900F leaving water 750F entering air wb |

≥ 7.0 gpm/hp |

| |

|

Propeller or axial fan evaporative condensers |

All |

R-507A test fluid 1650F entering gas temp 1050F condensing temp 750F entering air wb |

≥ 157,000 Btu/h x hp |

| |

|

All |

Ammonia test fluid 1400F entering gas temp 96.30F condensing temp 750F entering air wb |

≥ 134,000 Btu/h x hp |

| ||

|

Centrifugal fan evaporative condensers |

All |

R-507A test fluid 1650F entering gas temp 1050F condensing temp 750F entering air wb |

≥ 135,000 Btu/h x hp |

| |

|

All |

Ammonia test fluid 1400F entering gas temp 96.30F condensing temp 750F entering air wb |

≥ 110,000 Btu/h x hp |

| ||

|

Air cooled condensers |

All |

1250F condensing temperature R22 test fluid 1900F entering gas temperature 150F subcooling 950F entering db |

≥ 176,000 Btu/h x hp |

| |

|

a Open-circuit cooling tower performance is defined as the water flow rating of the tower at the given rated conditions divided by the fan motor nameplate power. b Closed-circuit cooling tower performance is defined as the process water flow rating of the tower at the given rated conditions divided by the sum of the fan motor nameplate rated power and the integral spray pump motor nameplate power. c Air-cooled condenser performance is defined as the heat rejected from the refrigerant divided by the fan motor nameplate power. d Open cooling towers shall be tested using the test procedures in CTI ATC-105. Performance of factory assembled open cooling towers shall be either certified as base models as specified in CTI STD-201 or verified by testing in the field by a CTI approved testing agency. Open factory assembled cooling towers with custom options added to a CTI certified base model for the purpose of safe maintenance or to reduce environmental or noise impact shall be rated at 90 percent of the CTI certified performance of the associated base model or at the manufacturer’s stated performance, whichever is less. Base models of open factory assembled cooling towers are open cooling towers configured in exact accordance with the Data of Record submitted to CTI as specified by CTI STD-201. There are no certification requirements for field erected cooling towers. e Applicable test procedure and reference year are provided under the definitions. For refrigerated warehouses or commercial refrigeration applications, condensers shall comply with requirements specified by §120.6(a). or §120.6(b) | |||||

Source: California Energy Commission, Building Energy Efficiency Standards, Table 110.2-G

|

Equipment Type |

Size Category |

Heating Section Type |

Sub-Category or Rating Condition |

Minimum Efficiency |

Test Procedurea |

|

Variable refrigerant flow (VRF) air conditioners, air cooled |

< 65,000 Btu/h |

All |

VRF Multi-Split System |

13.0 SEER |

|

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

Electric resistance (or none) |

VRF Multi-Split System |

11.2 EER

15.5 IEERb | ||

|

≥ 135,000 Btu/h and < 240,000 Btu/h |

Electric Resistance (or none) |

VRF Multi-Split System |

11.0 EER

14.9 IEERb | ||

|

≥ 240,000 Btu/h |

Electric Resistance (or none) |

VRF Multi-Split System |

10.0 EER

13.9 IEERb | ||

|

a Applicable test procedure and reference year are provided under the definitions. b IEERs are only applicable to equipment with capacity control as specified by ASNI/AHRI 1230 test procedures. | |||||

Source: California Energy Commission, Building Energy Efficiency Standards Table 110.2-H

|

Equipment Type |

Size Category |

Heating Section Type |

Sub-Category or Rating Condition |

Minimum Efficiency |

Test Procedureb |

|

VRF air cooled, (cooling mode) |

< 65,000 Btu/h |

All |

VRF multi-split systema |

13 SEER |

|

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

Electric resistance (or none) |

VRF multi-split systema |

11.0 EER 14.6 IEERc | ||

|

≥ 135,000 Btu/h and < 240,000 Btu/h |

Electric resistance (or none) |

VRF multi-split systema |

10.6 EER 13.9 IEERc | ||

|

≥ 240,000 Btu/h |

Electric resistance (or none) |

VRF multi-split Systema |

9.5 EER 12.7 IEERc | ||

|

VRF water source (cooling mode) |

< 65,000 Btu/h |

All |

VRF multi-split systema 860F entering water |

12.0 EER 15.8 IEER | |

|

≥ 65,000 Btu/h and < 135,000 Btu/h |

All |

VRF multi-split systema 860F entering water |

12.0 EER 15.8 IEER | ||

|

≥ 135,000 Btu/h and < 240,000 BTU/h |

All |

VRF multi-split systema 860F entering water |

10.0 EER 13.8 IEER | ||

|

≥ 240,000 Btu/h |

All |

VRF multi-split systema 590F entering water |

10.0 EER 12.0 IEER | ||

|

VRF groundwater source (cooling mode) |

< 135,000 Btu/h |

All |

VRF multi-split systema 590F entering water |

16.2 EER |

AHRI 1230 |

|

≥ 135,000 Btu/h |

All |

VRF multi-split systema 590F entering water |

13.8 EER | ||

|

VRF ground source (cooling mode) |

< 135,000 Btu/h |

All |

VRF multi-split systema 770F entering water |

13.4 EER | |

|

≥ 135,000 Btu/h |

All |

VRF multi-split systema 770F entering water |

11.0 EER | ||

|

VRF air cooled (heating mode) |

<65,000 Btu/h |

-- |

VRF multi-split system |

7.7 HSPF | |

|

≥65,000 Btu/h and <135,000 Btu/h (cooling capacity) |

-- |

VRF multi-split system 47ºF db/ 43ºF wb outdoor air |

3.3 COP | ||

|

VRF Multi-split system 17ºF db/15ºF wb outdoor air |

2.25 COP | ||||

|

≥ 135,000 Btu/h (cooling capacity) |

-- |

VRF multi-split system 470F db/ 430F wb outdoor air |

3.2 COP | ||

|

VRF multi-split system 170F db/ 150F wb outdoor air |

2.05 COP | ||||

|

VRF water source (heating mode) |

< 65,000 Btu/h (cooling capacity) |

-- |

VRF multi-split system 68 0F entering water |

4.3 COP | |

|

≥ 65,000 Btu/h and <135,000 Btu/h (cooling capacity |

-- |

VRF multi-split system 68 0F entering water |

4.3 COP | ||

|

≥135,000 Btu/h and <240,000 Btu/h (cooling capacity) |

-- |

VRF multi-split system 68 0F entering water |

4.0 COP | ||

|

≥ 240,000 Btu/h (cooling capacity) |

-- |

VRF multi-split System 68 0F entering water |

3.9 COP | ||

|

VRF groundwater source (heating mode)

|

<135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-Split System 50ºF entering water |

3.6 COP | |

|

≥135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-Split System 50ºF entering water |

3.3 COP | ||

|

VRF ground source |

<135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-Split System 32ºF entering water |

3.1 COP | |

|

≥135,000 Btu/h (cooling capacity) |

--- |

VRF Multi-Split System 32ºF entering water |

2.8 COP |

AHRI 1230 | |

|

a Deduct 0.2 from the required EERs and IEERs for VRF multi-split system units with a heating recovery section. b Applicable test procedure and reference year are provided under the definitions. c IEERs are only applicable to equipment with capacity control as specified by ANSI/AHRI 1230 test procedures. | |||||

Source: California Energy Commission, Building Energy Efficiency Standards, Table 110.2-I

|

Equipment Type |

Size Category (Input) |

Subcategory or Rating Conditionb |

Minimum Efficiency |

Test Procedurea |

|

Warm-air furnace, gas-fired |

≥ 225,000 Btu/h |

Maximum capacityb |

80% Et |

Section 2.39, thermal efficiency, ANSI Z21.47 |

|

Warm-air furnace, oil-fired |

≥ 225,000 Btu/h |

Maximum Capacityb |

81% Et |

Section 42, combustion, UL 727 |

|

All capacities |

Maximum capacityb |

80% Ec |

Section 2.10, efficiency, ANSI Z83.8 | |

|

Warm-air duct furnaces, gas-fired |

All capacities |

Maximum capacityb |

80% Ec |

Section 2.10, efficiency, ANSI Z83.8 |

|

Warm-air unit heaters, gas-fired |

All capacities |

Maximum capacityb |

81% Ec |

Section 40, combustion, UL 731 |

|

Warm-air unit heaters, oil-fired |

All capacities |

Maximum capacityb |

81% Ec |

Section 40, combustion, UL 731 |

Source: California Energy Commission, Building Energy Efficiency Standards, Table 110.2-J

|

Equipment Type |

Sub Category |

Size Category (Input) |

Minimum Efficiencyb,c |

Test Procedurea | |

|

Before 3/2/2020 |

After 3/2/2020 | ||||

|

Boiler, hot water |

Gas fired |

< 300,000 Btu/h |

82% AFUE |

82% AFUE |

DOE 10 CFR Part 430 |

|

≥ 300,000 Btu/h and ≤ 2,500,000 Btu/hd |

80% Et |

80% Et |

DOE 10 CFR Part 431 | ||

|

˃ 2,500,000 Btu/he |

82% Ec |

82% Ec | |||

|

Oil fired |

< 300,000 Btu/h |

84% AFUE |

84% AFUE |

DOE 10 CFR Part 430 | |

|

≥ 300,000 Btu/h and ≤ 2,500,000 Btu/hd |

82% Et |

82% Et |

DOE 10 CFR Part 431 | ||

|

˃ 2,500,000 Btu/he |

84% Ec |

84% Ec | |||

|

Boiler, steam |

Gas fired |

< 300,000 Btu/h |

80% AFUE |

80% AFUE |

DOE 10 CFR Part 430 |

|

Gas fired – all, except natural draft |

≥ 300,000 Btu/h and ≤ 2,500,000 Btu/hd |

79% Et |

79% Et |

DOE 10 CFR Part 431 | |

|

˃ 2,500,000 Btu/he |

79% Et |

79% Et |

DOE 10 CFR Part 431 | ||

|

Gas fired, natural draft |

≥ 300,000 Btu/h and ≤ 2,500,000 Btu/hd |

77% Et |

79% Et |

DOE 10 CFR Part 431 | |

|

˃ 2,500,000 Btu/he |

77% Et |

79% Et |

DOE 10 CFR Part 431 | ||

|

Oil fired |

< 300,000 Btu/h |

82% AFUE |

82% AFUE |

DOE 10 CFR Part 430 | |

|

≥ 300,000 Btu/h and ≤ 2,500,000 Btu/hd |

81% Et |

81% Et |

DOE 10 CFR Part 431 | ||

|

˃ 2,500,000 Btu/he |

81% Et |

81% Et |

DOE 10 CFR Part 431 | ||

|

a Applicable test procedure and reference year are provided under the definitions. b Ec = combustion efficiency (100% less flue losses). See reference document for detail information c Et = thermal efficiency. See test procedure for detailed information. d Maximum capacity – minimum and maximum ratings as provided for and allowed by the unit’s controls. e Included oil-fired (residual). | |||||

Source: California Energy Commission, Building Energy Efficiency Standards , Table 110.2-K

In the above tables, where more than one efficiency standard or test method is listed, the requirements of both shall apply. For example, air-cooled air conditioners have an EER requirement for full-load operation and an IEER for part-load operation. The air conditioner must have both a rated EER and IEER equal to or higher than that specified in the Energy Standards at the specified Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standard rating conditions. Where equipment serves more than one function, it must comply with the efficiency standards applicable to each function.

When there is a requirement for equipment rated at its “maximum rated capacity” or “minimum rated capacity,” the proper capacity shall be maintained by the controls during steady state operation. For example, a boiler with high/low firing must meet the efficiency requirements when operating at both its maximum capacity and minimum capacity.

Exceptions exist to the listed minimum efficiency for specific equipment. The first exception applies to water-cooled centrifugal water-chilling packages not designed for operation at ANSI/AHRI Standard 550/590 test conditions, which are:

a. 44 degrees Fahrenheit (F) leaving chilled water temperature

b. 85 degrees F entering condenser water temperature

c. Three gallons per minute per ton condenser water flow

Packages not designed to operate at these conditions must have maximum adjusted full load and NPLV ratings, which can be calculated in kW/ton, using Equation 4-1 and Equation 4-2.

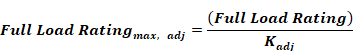

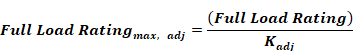

Equation 4-1

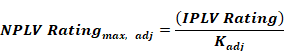

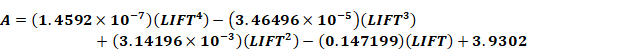

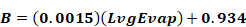

The values for the Full Load and IPLV ratings are found in Table 4-4. K_adj is the product of A and B as in Equation 4-3. A is calculated by entering the value for LIFT determined by Equation 4-5 into the fourth level polynomial in Equation 4-4 B is found using Equation 4-6.

Equation 4-3

LIFT=LvgCond-LvgEvap

Where:

LvgCond = Full-load leaving condenser fluid temperature (°F)

LvgEvap = Full-load leaving evaporator fluid temperature (°F)

Where:

LvgEvap = Full-load leaving evaporator fluid temperature (°F)

The maximum adjusted full load and NPLV rating values are only applicable for centrifugal chillers meeting all of the following full-load design ranges:

1. Minimum leaving evaporator fluid temperature: 36 degrees F

2. Maximum leaving condenser fluid temperature: 115 degrees F

3. LIFT greater than or equal to 20 degrees F and less than or equal to 80 degrees F

Centrifugal chillers designed to operate outside of these ranges are not covered by this exception and therefore have no minimum efficiency requirements.

Exception 2 are for positive displacement (air-cooled and water-cooled) chillers with a leaving evaporator fluid temperature higher than 32 degrees F. These equipment shall comply instead with Table 4-4 ( Table 110.2-D in the Energy Standard) when tested or certified with water at standard rating conditions, per the referenced test procedure.

Exception 3 is for equipment primarily serving refrigerated warehouses or commercial refrigeration systems. These systems must comply with the efficiency requirements of Energy Standards §120.6(a). or 120.6(b). For more information, see Chapter 10.

Manufacturers of any appliance or equipment regulated by Section 1601 of the Appliance Efficiency Regulations are required to comply with the certification and testing requirements of Section 1608(a) of those regulations. This includes being listed in the Modernized Appliance Efficiency Database System.

Equipment not covered by the Appliance Efficiency Regulations, for which there is a minimum efficiency requirement in the Energy Standards, cannot be installed unless the required efficiency data is listed and verifiable in one of the following:

1. The Energy Commission's database of certified appliances available at: www.energy.ca.gov/appliances/.

2. An equivalent directory published by a federal agency.

3. An approved trade association directory as defined in Title 20 California Code of Regulations, Section 1606(h) such as the Air Conditioning, Heating and Refrigeration Institute (AHRI) Directory of Certified Products. This information is available at www.ahridirectory.org.

4. The Home Ventilating Institute (HVI) certified products directory available at www.hvi.org.

The Energy Standards discourage use of electric resistance heating when an alternative method of heating is available. Heat pumps may contain electric resistance heat strips which act as a supplemental heating source. If this type of system is used, then controls must be put in place to prevent the use of the electric resistance supplementary heating when the heating load can be satisfied with the heat pump alone. tThe controls must set a cut-on temperature for compressor heating higher than the cut-on temperature for electric resistance heating. The cut-off temperature for compression heating must also be set higher than the cut-off temperature for electric resistance heating.

Exceptions exist for these control requirements if one of the following applies:

1. The electric resistance heating is for defrost and during transient periods such as start-ups and following room thermostat set points (or another control mechanism designed to preclude the unnecessary operation).

2. The heat pump is a room air-conditioner heat pump.

All heating or cooling systems are required to have a thermostat with setback capability and is capable of at least four set points in a 24-hour period. In the case of a heat pump, the control requirements of Section 4.2.4 must also be met.

In addition, per §120.2(b)4, the thermostats on all single zone air conditioners and heat pumps must comply with the demand responsive control requirements of Section 110.12(a), also known as the Occupant controlled Smart Thermostat (OCST). See Appendix D of this compliance manual for guidance on compliance with demand responsive control requirements.

Exceptions to §120.2(b)4, setback thermostat and OCST requirements:

1. Systems serving zones that must have constant temperatures to protect a process or product (e.g. a laboratory or a museum).

The following HVAC systems are exempt:

a. Gravity gas wall heaters

b. Gravity floor heaters

c. Gravity room heaters

d. Non-central electric heaters

e. Fireplaces or decorative gas appliance

f. Wood stoves

g. Room air conditioners

h. Room heat pumps

i. Packaged terminal air conditioners

j. Packaged terminal heat pumps

In most cases setup and setback are based on time of day only. However, see Section 4.5.1.4, Shut-off and Temperature Setup/Setback which describes those applications where occupancy sensing is also required to trigger setup and setback periods and shutting off ventilation air.

Forced air gas- and oil-fired furnaces with input ratings greater than or equal to 225,000 Btu/h are required to have controls and designs that limit their standby losses:

1. Either an intermittent ignition or interrupted device (IID) is required. Standing pilot lights are not allowed.

2. Either a power venting or a flue damper is required. A vent damper is an acceptable alternative to a flue damper for furnaces where combustion air is drawn from the conditioned space.

Any furnace with an input rating greater than or equal to 225,000 Btu/h that is not located within the conditioned space must have jacket losses not exceeding 0.75 percent of the input rating. This includes electric furnaces and fuel-fired units.

All open and closed circuit cooling towers with rated capacity of 150 tons or greater must have a control system that maximizes the cycles of concentration based on the water quality conditions. If the controls system is conductivity based, then the system must automate bleed and chemical feed based on conductivity. The installation criteria for the conductivity controllers must be in accordance with the manufacturer’s specifications to maximize accuracy. If the control system is flow based, then the system must be automated in proportion to metered makeup volume, metered bleed volume, and recirculating pump run time (or bleed time).

The makeup water line must be equipped with an analog flow meter and an alarm to prevent overflow of the sump in the event of water valve failure. The alarm system may send an audible signal or an alert through an energy management control system (EMCS).

Drift eliminators are louvered or comb-like devices that are installed at the top of the cooling tower to capture air stream water particles. These drift eliminators are now required to achieve drift reduction to 0.002 percent of the circulated water volume for counter-flow towers and 0.005 percent for cross-flow towers.

Additionally, maximum achievable cycles of concentration must be calculated with an Energy Commission approved calculator based on local water quality conditions (which is reported annually by the local utility) and a Langelier Saturation Index (LSI) of 2.5 or less. The maximum cycles of concentration must be catloged in the mechanical compliance documentation and reviewed and approved by the Professional Engineer (P.E.) of record. Energy Commission compliance document NRCC-MCH-E has a built in calculator. An approved excel file LSIcalculator is located on the Energy Commission’s website.

The website address for the excel calculator is: http://www.energy.ca.gov/title24/2013standards/documents/maximum_cycles_calculator.xls

The website address for the NRCC-MCH-06 is:

http://www.energy.ca.gov/2015publications/CEC-400-2015-033/appendices/forms/NRCC/

Pilot lights are prohibited in the following circumstances:

1. Fan type central furnaces. This includes all space-conditioning equipment that distributes gas-heated air through duct work §110.5(a). This prohibition does not apply to radiant heaters, unit heaters, boilers or other equipment that does not use a fan to distribute heated air.

Household cooking appliances, unless the appliance does not have an electrical connection, and the pilot consumes less than 150 Btu/h §110.5(b).

Pool and spa heaters §110.5(c) and §110.5(d) respectively.

Indoor and outdoor fireplaces §110.5(e).

Example 4-1

Question

If a 15 ton (180,000 Btu/h) air-cooled packaged AC unit with a gas furnace rated at 260,000 Btu/h maximum heating capacity has an EER of 10.9, an IEER of 12.3, and a heating thermal efficiency of 78 percent, does it comply?

Answer

No. While the cooling side appears to not comply because both the EER and IEER are less than the values listed in Table 4-1, the EER and IEER values in the table are for units with electric heat. Footnote b reduces the required EER and IEER by 0.2 for units with heating sections other than electric resistance heat. Since this unit has gas heat, the EER requirement is actually 10.8 and the IEER requirement is 12.2, this unit complies with the cooling requirements. The 0.2 deduction provided in Table 4-1 and Table 4-2 compensates for the higher fan power required to move air through the heat exchanger.

From Table 4-10, the heating efficiency must be at least 80 percent thermal efficiency. This unit has a 78 percent thermal efficiency and does not comply with the heating requirements, therefore, the entire unit does not comply since it’s a packaged unit.

Example 4-2

Question

A 500,000 Btu/h gas-fired hot water boiler with high/low firing has a full load combustion efficiency of 82 percent, 78 percent thermal efficiency and a low-fire combustion efficiency of 80 percent. Does the unit comply?

Answer

No. Per Table 4-11, the thermal efficiency must be greater than 80 percent. This boiler’s thermal efficiency is 78 percent (less than 80 percent) so it doesn’t comply.

Example 4-3

Question

A 300 ton water-cooled centrifugal chiller is designed to operate at 44 degrees F chilled water supply, 90 degrees F condenser water return and 3 gpm/ton condenser water flow. What is the maximum allowable full load kW/ton and NPLV?

Answer

As the chiller is centrifugal and is designed to operate at a condition different from AHRI Standard 550/590 standard rating conditions (44 degrees F chilled water supply, 85 degrees F condenser water return, 3 gpm/ton condenser water flow), the appropriate efficiencies can be calculated using the Kadj equations.

From Table 4-4 (Equipment Type: water cooled, electrically operated, centrifugal; Size Category: ≥ 300 tons and < 600 tons), this chiller at AHRI rating conditions is required to have a maximum full load efficiency of 0.560 kW/ton and a maximum IPLV of 0.520 kW/ton for Path A and a maximum full load efficiency of 0.595 kW/ton and a maximum IPLV of 0.390 kW/ton for Path B.

The Kadj is calculated as follows:

LIFT = LvgCond – LvgEvap = 90F-44F = 46F

A = (0.00000014592 x (46)4) – (0.0000346496 x (46)3 )+ (0.00314196 x (46)2) – (0.147199 x (46)) + 3.9302=1.08813

B = (0.0015 x 44) + 0.934 = 1.000

Kadj=A x B=1.08813

For compliance with Path A, the maximum Full load kW/ton = 0.560 / 1.08813 = 0.515 kW/ton and the maximum NPLV= 0.520 / 1.08813 = 0.478 kW/ton

For compliance with Path B the maximum Full load kW/ton = 0.595 / 1.08813 = 0.547 kW/ton and the maximum NPLV= 0.390 / 1.08813 = 0.358 kW/ton

To meet the mandatory measures of 4.2.2 (Energy Standards §110.2) the chiller can comply with either the Path A or Path B requirement (footnote b in Table 4-4 ). To meet the prescriptive requirement of 4.6.2.8 (Energy Standards §140.4(i) (Energy Standards §140.4(i)) the chiller would have to meet or exceed the Path B requirement.

Example 4-4

Question

A 300 ton water-cooled chiller with a screw compressor that serves a thermal energy storage system is designed to operate at 34 degrees F chilled water supply, 82 degrees F condenser water supply and 94 degrees F condenser water return, does it have a minimum efficiency requirement and if so, what is the maximum full load kW/ton and NPLV?

Answer

As the chiller is positive displacement (screw and scroll compressors are positive displacement) and is designed to operate at a chilled water temperature above 32 degrees F it does have a minimum efficiency requirement per 4.2.2 (Exception 2 to §110.2(a)). From Table 4-4 (Equipment Type: water cooled, electrically operated, positive displacement; Size Category: ≥ 300 tons) this chiller at AHRI rating conditions is required to have a maximum full load efficiency of 0.610 kW/ton and a maximum IPLV of 0.520 kW/ton for Path A and a maximum full load efficiency of 0.625 kW/ton and a maximum IPLV of 0.410 kW/ton for Path B.

The Kadj is calculated as follows:

LIFT

= LvgCond – LvgEvap = 94F-34F = 60F

A = (0.00000014592 x (60)4) –

(0.0000346496 x (60)3 )+ (0.00314196 x (60)2) – (0.147199 x *(60)) +

3.9302=0.81613

B = (0.0015 x 34) + 0.934 = 0.98500

Kadj=A x

B=0.80388

For compliance with Path A, the maximum Full load kW/ton = 0.610 / 0.80388 = 0.759 kW/ton and the maximum NPLV= 0.520 / 0.80388 = 0.647 kW/ton. For compliance with Path B the maximum Full load kW/ton = 0.625 / 0.80388 = 0.777 kW/ton and the maximum NPLV= 0.410 / 0.80388 = 0.510 kW/ton. To meet the mandatory measures of 4.2.2 (Energy Standards §110.2) the chiller can comply with either the Path A or Path B requirement (footnote b in Table 4-4 ). To meet the prescriptive requirement of 4.6.2.8 (Energy Standards §140.4(i)) the chiller would have to meet or exceed the Path B requirement.

Example 4-5

Question

Are all cooling towers required to be certified by CTI?

Answer

No. Per footnote d in Table 4-7, field-erected cooling towers are not required to be certified. Factory-assembled towers must either be CTI-certified or have their performance verified in a field test (using ATC 105) by a CTI-approved testing agency. Furthermore, only base models need to be tested; options in the air-stream, like access platforms or sound traps, will derate the tower capacity by 90 percent of the capacity of the base model or the manufacturer’s stated performance, whichever is less.

Example 4-6

Question

Are there any mandatory requirements for a water-to-water plate-and-frame heat exchanger?

Answer

Yes, Table 4-6 requires that it be rated per ANSI/AHRI 400. This standard ensures the accuracy of the ratings provided by the manufacturer.

A commercial boiler is a type of boiler with a capacity (rated maximum input) of 300,000 Btu/h or more and serving a space heating or water heating load in a commercial building.

A. Combustion air positive shut off shall be provided on all newly installed commercial boilers as follows:

1. All boilers with an input capacity of 2.5 MMBtu/h (2,500,000 Btu/h) and above, in which the boiler is designed to operate with a non-positive vent static pressure. This is sometimes referred to as natural draft or atmospheric boilers. Forced draft boilers, which rely on a fan to provide the appropriate amount of air into the combustion chamber, are exempt from this requirement.

2. All boilers where one stack serves two or more boilers with a total combined input capacity per stack of 2.5 MMBtu/h (2,500,000 Btu/h). This requirement applies to natural draft and forced draft boilers.

Combustion air positive shut off is a means of restricting air flow through a boiler combustion chamber during standby periods, and is used to reduce standby heat loss. A flue damper and a vent damper are two examples of combustion air positive shut-off devices.

Installed dampers can be interlocked with the gas valve so that the damper closes and inhibits air flow through the heat transfer surfaces when the burner has cycled off, thus reducing standby losses. Natural draft boilers receive the most benefit from draft dampers because they have less resistance to airflow than forced draft boilers. Forced draft boilers rely on the driving force of the fan to push the combustion gases through an air path that has relatively higher resistance to flow than in a natural draft boiler. Positive shut off on a forced draft boiler is most important on systems with a tall stack height or multiple boiler systems sharing a common stack.

B. Boiler combustion air fans with motors 10 horsepower or larger shall meet one of the following for newly installed boilers:

1. The fan motor shall be driven by a variable speed drive

2. The fan motor shall include controls that limit the fan motor demand to no more than 30 percent of the total design wattage at 50 percent of design air volume

Electricity savings result from run time at part-load conditions. As the boiler firing rate decreases, the combustion air fan speed can be decreased.

C. Newly installed boilers with an input capacity of 5 MMBtu/h (5,000,000 Btu/h) and greater shall maintain excess (stack-gas) oxygen concentrations at less than or equal to 5 percent by volume on a dry basis over firing rates of 20 percent to 100 percent. Combustion air volume shall be controlled with respect to firing rate or measured flue gas oxygen concentration. Use of a common gas and combustion air control linkage or jack shaft is prohibited.

Boilers with steady state full-load thermal efficiency of 85 percent or higher are exempt from this requirement.

One way to meet this requirement is with parallel position control. Boilers mix air with fuel (usually natural gas although sometimes diesel or oil) to supply oxygen during combustion. Stoichiometric combustion is the ideal air/fuel ratio where the mixing proportion is correct, the fuel is completely burned, and the oxygen is entirely consumed. Boilers operate most efficiently when the combustion air flow rate is slightly higher than the stoichiometric air-fuel ratio. However, common practice almost always relies on excess air to ensure complete combustion, avoid unburned fuel and potential explosion, and prevent soot and smoke in the exhaust. The drawbacks of excess air are increased stack heat loss and reduced combustion efficiency.

Parallel positioning controls optimize the combustion excess air based on the firing rate of the boiler to improve the combustion efficiency of the boiler. It includes individual servo motors allowing the fuel supply valve and the combustion air damper to operate independently of each other. This system relies on preset fuel mapping (i.e., a pre-programmed combustion curve) to establish proper air damper positions (as a function of the fuel valve position) throughout the full range of burner fire rate. Developing the combustion curve is a manual process. It is performed in the field with a flue-gas analyzer in the exhaust stack, determining the air damper positions as a function of the firing rate/fuel valve position. Depending on the type of burner, a more consistent level of excess oxygen can be achieved with parallel position compared to single-point positioning control with parallel positioning, the combustion curve is developed at multiple points (firing rates), typically 10 to 25 points. Parallel positioning controls allow excess air to remain relatively low throughout a burner’s firing range. Maintaining low excess air levels at all firing rates provides significant fuel and cost savings while still maintaining a safe margin of excess air to insure complete combustion.

The other method of control of combustion air volume is by measuring the flue gas oxygen concentration to optimize combustion efficiency. This method of control commonly called is oxygen trim control and can provide higher levels of efficiency than parallel positioning controls as it can also account for relative humidity of the combustion air. This control strategy relies on parallel positioning hardware and software as the basis but takes it a step further to allow operation closer to stoichiometric conditions. Oxygen trim control converts parallel positioning to a closed-loop control configuration with the addition of an exhaust gas analyzer and proportional-integral-derivative (PID) controller. This strategy continuously measures the oxygen content in the flue gas and adjusts the combustion air flow, thus continually tuning the air-fuel mixture.