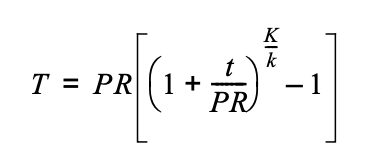

WHERE:

T = insulation thickness for material with conductivity K, inches.

PR = actual outside radius, inches.

t = Insulation thickness from Table 120.3-A-1 or Table 120.3-A-2, inches.

K = Conductivity of alternate material at the mean rating temperature indicated in Table 120.3-A for the applicable fluid temperature range, in Btu-inch per hour per square foot per °F.

k = The lower value of the conductivity range listed in Table 120.3-A for the applicable fluid temperature range, Btu-inch per hour per square foot per °F.

| Fluid Operating Temperature Range (°F) | Insulation Conductivity (in Btu·in./ft²·h·°F) | Insulation Mean Rating Temperature (°F) | Nominal Pipe Diameter < 1 inch | Nominal Pipe Diameter 1 to < 1.5 inches | Nominal Pipe Diameter 1.5 to < 4 inches | Nominal Pipe Diameter 4 to < 8 inches | Nominal Pipe Diameter 8 inches and larger |

| Above 350 | 0.32-0.34 | 250 | 4.5 inches | 5.0 inches | 5.0 inches | 5.0 inches | 5.0 inches |

| Above 350 | 0.32-0.34 | 250 | R 37 | R 41 | R 37 | R 27 | R 23 |

| 251-350 | 0.29-0.32 | 200 | 3.0 inches | 4.0 inches | 4.5 inches | 4.5 inches | 4.5 inches |

| 251-350 | 0.29-0.32 | 200 | R 24 | R 34 | R 35 | R 26 | R 22 |

| 201-250 | 0.27-0.30 | 150 | 2.5 inches | 2.5 inches | 2.5 inches | 3.0 inches | 3.0 inches |

| 201-250 | 0.27-0.30 | 150 | R 21 | R 20 | R 17.5 | R 17 | R 14.5 |

| 141-200 | 0.25-0.29 | 125 | 1.5 inches | 1.5 inches | 2.0 inches | 2.0 inches | 2.0 inches |

| 141-200 | 0.25-0.29 | 125 | R 11.5 | R 11 | R 14 | R 11 | R 10 |

| 105-140 | 0.22-0.28 | 100 | 1.0 inch | 1.5 inches | 1.5 inches | 1.5 inches | 1.5 inches |

| 105-140 | 0.22-0.28 | 100 | R 7.7 | R 12.5 | R 11 | R 9 | R 8 |

Fluid Operating Temperature Range (°F) | Insulation Conductivity | Insulation Mean Rating Temperature (°F) | Nominal Pipe Diameter < 1 inch | Nominal Pipe Diameter 1 to < 1.5 inches | Nominal Pipe Diameter 1.5 to < 4 inches | Nominal Pipe Diameter 4 to < 8 inches | Nominal Pipe Diameter 8 inches and larger |

Residential 40-60 | 0.21-0.27 | 75 | 0.75 inch | 0.75 inch | 1.0 inch | 1.0 inch | 1.0 inch |

Residential 40-60 | 0.21-0.27 | 75 | R-6 | R-5 | R-7 | R-6 | R-5 |

Nonresidential 40-60 | 0.21-0.27 | 75 | 0.5 inch | 0.5 inch | 1.0 inch | 1.0 inch | 1.0 inch |

Nonresidential 40-60 | 0.21-0.27 | 75 | R-3 | R-3 | R-7 | R-6 | R-5 |

Below 40 | 0.20-0.26 | 50 | 1.0 inch | 1.5 inches | 1.5 inches | 1.5 inches | 1.5 inches |

Below 40 | 0.20-0.26 | 50 | R-8.5 | R-14 | R-12 | R-10 | R-9 |

Footnote to Table 120.3-A-1 and Table 120.3-A-2:

These thicknesses are based on energy efficiency considerations only. Issues such as water vapor permeability or surface condensation sometimes require vapor retarders or additional insulation.